Escolar Documentos

Profissional Documentos

Cultura Documentos

R.d.electrical Schedule, 2009

Enviado por

henchudiTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

R.d.electrical Schedule, 2009

Enviado por

henchudiDireitos autorais:

Formatos disponíveis

To The Chief Engineer, R.D. Department, Govt. Of Tripura. Gurkhabasti, Agartala, West Tripura.

(Through Proper Channel) Subject: Submission of Provisional specimen of Schedule of Rates, Part-III: Internal Electrifications, 2009,R.D. Department, Govt. of Tripura.(Hard and soft copy) Respected Sir, Kindly refer to the subject cited above, I would like to inform you that as per direction conveyed in the meeting on 25/08/2009 in the office of the chief engineer, R.D. Department, Gurkhabasti ,Agartala, I have prepared the specimen of Schedule of Rates, Part-III: Internal Electrifications,2009 for R.D. Department, Govt. Of Tripura.. In this regards, the following consideration of facts has been followed with care during preparation of the enclosed specimen of schedule: i)The reference text book of Electrical Installation, Estimating & Costing by J.B. Gupta. ii)The reference text book of Electrical Wiring, Estimating & Costing by S.R. Chakraborty. iii)The Schedule Of Rates, Electrical, Internal, C.P.W.D.1972 & P.W.D.2002, Tripura. iv)Various catalogues of renown brands. v) Various renown web sites of Internet. vi)The Basic rates of items of External Electrification, Tripura State Electricity Corporation Ltd. vi)The basic approved rates of SPV materials and specifications of Tripura Renewable Energy Development Agency and Ministry of New and Renewable Energy (Remote village Electrification Programme), New Delhi. vi) Some important nomenclatures are incorporated in this schedule on work experience basis. In this connection, I would like to request you to take up the necessary arrangement to re-assess and re-check the basic rates quoted of various items specially of Air conditioners accessories and Xerox machine accessories etc. and also bodies of various nomenclatures etc. please. This is for favour of your kind information and doing the next course of action please. Yours faithfully Enclo: As stated Amarpur R.D. Block, South Tripura. Dated, 07/09/2009 (Er. Sujit Datta) Junior Engineer, Gr-I Amarpur R.D. Block. South Tripura.

Copy to 1)The Executive Engineer, R.D. Southern Division-I, Udaipur for kind information and necessary action please. 2)The B.D.O., Amarpur R.D. Block, South Tripura for kind information please.

(Er. Sujit Datta) Junior Engineer, Gr-I Amarpur R.D. Block.

GOVERNMENT OF TRIPURA RURAL DEVELOPMENT DEPARTMENT SCHEDLE OF RATES PART-III: INTERNAL ELECTRIFICATIONS 2009 PUBLISHED UNDER THE AUTHORITY OF THE CHIEF ENGINEER, R.D. DEPARTMENT AGARTALA

(This specimen of schedule of rates is provisionally prepared by Er.Sujit Datta, B.Tech(Electrical), J.E. Gr-I, Amarpur R.D, Block, South Tripura)

FOREWARD

It give me immense pleasure in bringing out the Schedule of Rates, Part-III :Internal Electrifications,2009,R.D. Department, Govt. Of Tripura. Since inception ,R.D. Department has been executing all types of Internal Electrification works by on follow of the schedule of Rates of CPWD 1972 and PWD 2002, Tripura. The engineers of R.D. Department has been facing problem a lot to prepare the estimate specially on Internal Electrification works as all those mentioned schedule are not owing to analysis based in respect to labour and materials component separately. As being all categorical Engineers of this Department are empowered to execute the internal electrification works and the working load has been increasing day by day of this Department, so far the present form of Schedule will meet up the demand from all corner. I would like to acknowledge my sincere appreciation and thanks to the team of Engineers and officials of this Department who have put in all the hard works and taken the pains to publish a Schedule of Rates, Part-III: Internal Electrifications in state to fulfill a long standing demand on score. Errors and omissions and suggestions for improvement of this schedule of Rates may kindly be brought to the notice of The Committee of Schedule of Rates, Part III: Internal Electrifications, R.D. Planning & Monitoring Cell, O/O The Chief Engineer, Rural Development Department, Govt. of Tripura, Gurkhabasti, Agartala, West Tripura.

I am indeed assured that this schedule of rates will display very much helpful and useful in handling to all concerned.

PREFACE

(In this page, the Secretary Cum Commissioner , R.D. Department, Govt. Of Tripura will give the approval of Schedule of rates)

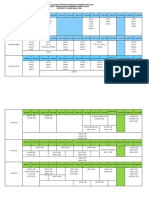

INDEX

SL NO 1. 2. ACTIVITY Salient Features of Schedule of Rates , Part-III: Internal Electrifications, 2009, R.D. Department, Govt. of Tripura Some Important Abbreviation 4 5 PAGES NO

3.

Rules of Internal Wiring, Consumption of Materials and Labourers

5-8

4.

Basic Rates of Labours and Materials

9-23

5 6 7. 8. 9. 10. 11. 12. 13. 14. 15. 16.

Approved Brands/ Manufacturers of materials PVC/Wooden/Conduit Wiring Cable and Wires Fittings and Accessories Lighting Accessories and Fittings Fans and its commissioning Switchgears and Change-Over-Switch Distribution Boards and Circuit breakers Metal Boxes and Bus bar Chambers Earthing and Loop Earthing Lightning Conductors & Arrester Underground Electrifications

24 25-27 27-30 30-31 32-34 34 35-36 36-38 39 40 41 42

17.

Remote Village Electrifications(Solar Photo Voltaic System)

43

18. 19.

Dismantling and Repairing Miscellaneous

43-50 51-53

1: SALIENT FEATURES OF SCHEDULE OF RATES PART-III: INTERNAL ELECTRIFICATIONS, 2009 R.D. DEPARTMENT, GOVT. OF TRIPURA. a) The basic rates of materials component relating to the internal electrification works as considered in this schedule of rates are by and large based on the prevalent market prices in the Tripura State during the first quarter of the year 2009-10. b) c) d) e) All the related item of works are involvement to labours and materials separately, the working out of labours as well as materials component is on experience basis. Providing means supplying. No provisions for Circuit/ Submain/Points wiring separately in this schedule of rates as all related components are varied in case to case practically, so in this regards, these are segregated part by part in respect to labours and materials components. No provisions in this schedule for estimating of labour wages by calculating Short Points, Medium Points and Long Points which is usual, as R.D. Department has been executing the Internal Electrifications works on engaging labours on daily basis departmentally, henceforth no contractor will be engaged in this regards , thereby no needing to labour wages for points calculation. Providing /supplying means related materials are to be supplied departmentally on follow of all codals formalities. 230-250 Volts & 415 Volts is related to single phase & three phase connection respectively. Present form of this schedule of rates is an out come to immense follow of Schedule of rates, Electrical (Part-I Internal), C.P.W.D. 1972 and P.W.D. 2002, Govt. of Tripura. Some important nomenclature of works has been incorporated on considering to face day to day works in this department. The special care has been taken up to analyze the labour components in this schedule so as not to hamper the interest of labour wages as recommended by The Indian Standards Institution, on follow of the mode of measurements of all wiring items on point basis i.e. Short, Medium and Long points. Surface wiring means wiring through PVC/Steel conduit on surface of wall, ceiling etc.

f) g) h) i) j) k)

l) m) n) o)

Recess wiring means concealed wiring which is buried in bricks or c.c. wall etc. Hiring cost of testing equipment like Megger, Multimeter, Tools, Insulation Resistance Tester, Earth Tester, Clamp Meter etc. is extra. The basic guidelines & specification of Ministry of New and Renewable Energy, Govt. of India for Remote Village Electrifications has been followed and dignified. Though this schedule is framed for Internal Electrification works, but some external electrification works like Service connection, Underground Electrification, Remote Village Electrification(SPV) etc. has been incorporated.

2.SOME IMPORTANT ABBREVIATION. A.C.= Alternating Current OR Air Conditioner. C.F.L.=Compact Fluorescent Lamp C.C.= Cement Concrete. D.C.= Direct Current D.P. = Double Pole. D.B. = Distribution Box. F.T.L.= Fluorescent Tube Light. F.P. = Four Pole. G.I. Pipe= Galvanized Iron Pipe. GLS= General Lighting Service H.P.S.V.= High Pressure Sodium Vapour. H.P.M.V.= High Pressure Mercury Vapour. 3:RULES OF INTERNAL WIRING, CONSUMPTION OF MATERIALS AND LABOURS: a) H.R.C= High Rupturing Capacity. M.C.B. = Miniature Circuit Breaker. P.V.C. = Polyvinyl Chloride. P.F. = Power Factor. P.C.C. Pole = Plain Cement Concrete Pole. R.C.C.B.=Residential Current Circuit Breaker. R.P.M.= Revolution Per Minute. S.P. & N. =Single Pole & Neutral. S.P.N.= Single Pole & Neutral. S.P.V.=Solar Photo Voltaic T.P. = Three Pole. T.P.N. = Three Pole & Neutral.

Concepts of Circuit and Sub-circuit: An electrical circuit is a network that has a closed loop, giving a return path for the current. Electrical apparatus is connected by cables to the supply main and to the associated protective and controlling devices usually fuses/MCBS and switches. This arrangement is known as Circuit. A circuit that feeds apparatus directly is known as Sub-circuit or Sub-main. A sub-circuit is a portion of a larger circuit.

b) i) ii) iii)

Some important rules of wiring: Every installation is to be properly protected near the point of entry of supply cables by a two-pole linked main switch and a fuse/MCB unit. A 3pole switch and fuse unit is to be used in 3-phase supply. Every sub-main is to be connected to a distribution board with fuse/MCB unit. Lights and fans may be wired on a common circuit. Each sub-main is not to have more than a total of 10(ten) points of lights, fans and socketoutlets. The load on each sub-main is to be restricted to 800 Watts . If a separate circuit is installed for fans only, the number of fans in that case is not to exceed 10(ten).

iv) v) vi)

The load on each power sub-main is to be normally restricted to 3000watts. In no case more than two socket- outlets are to be in a power submain. No additional load is to be connected to an existing wiring installation unless it has confirmed that wiring installation can safely carry the additional load and that the earthing arrangements are sufficient. After completion of the work the wiring installations are to be tested before going to utilization.

c)Findings of total loads: For determination of load of an installation the following ratings may be assumed unless the values are known or specified. i) Fluorescent Lamps-40 watts. ii)Ordinary Lamps, fans and sockets-outlets-60 watts. iii)Power sockets-outlets-1000 watts. iv)Exhaust fans as per of its capacity. d)Findings of numbers of Sub-main: The number of Sub-main are decided as per of points to be wired and total load to be connected to the supply systems. In one light and fan sub-main the maximum load that can be connected is 800 watts and the maximum numbers of points may be provided is 10.

But in one power Sub-main the maximum load that may be normally connected is 3000 watts and the number of socket-outlets may provided is 2. e)Findings of the rating of Main Switch and DB board: The current rating of main switch is decided as per total current of the circuit to be controlled by it. The number of ways and current rating of the DB board is decided as per number of Sub-mains to be connected to it and current of the Sub-main having highest current rating. f) Findings of size of Conductor: During determination of the sizes of conductor for internal wiring, the following three points are required to be considered: i)Minimum sizes of Cables: the conductor used in house wiring (except flexible and fittings wires)must not be of size less than 1/1.12mm in case of copper wire or 1/1.4mm or 1.5 Sq mm in case of aluminium wire. For flexible cords and fitting wire, a smaller lowest size is permissible i.e. 14/0.193 mm may be used. ii)Current Carrying Capacity: The wire or Cable should be of size sufficient to carry the maximum circuit current continuously without overheating. iii)Voltage Drop: Maximum voltage drop from supply terminals to any point on the wiring installation is not to exceed the prescribed limit of 2% of the supply voltage + 1 volt for light load wiring and 5% of declared supply voltage for power load wiring. Total line current in circuit= (Loads in all sub-mains X Power factor)/Declared Voltage in case of Single phase supply and in case of three phase supply, the line current = (Loads in all sub-mains X Power factor)/(Sqr-root of 3X Declared Voltage). For pure light load the power factor is taken to 1, in other cases it is taken as 0.85-0.95. g) The following TABLE-I shows the maximum current carrying capacity of Copper and Equivalent Aluminium Conductor: No and dia of wire in mm COPPER CONDUCTOR Nominal Current Current area in Sq rating in rating in mm Amps in 2Amps in 3 core cable or 4 core cable. 2 0.96 1.29 1.93 2.90 3 5 10 15 20 4 5 10 13 15 Approximate amperemetres per volt drop No and dia of wire in mm ALUMINIUM CONDUCTOR Nominal Current Current area in Sq rating in rating in mm Amps in 2Amps in 3 core cable or 4 core cable. 7 1.5 1.5 2.5 4.0 8 10 10 15 20 9 9 9 11 15 Approximate ampere-metres per volt drop

1 1/1.12 3/0.736 3/0.915 7/0.736

5 55 72 110 165

6 1/1.40 1/1.40 1/1.80 1/2.24

10 22.5 22.5 37.4 61.5

7/0.915 7/1.12 7/1.32 7/1.626 19/1.12 19/1.32 19/1.626

4.52 6.45 9.35 14.50 19.35 25.80 38.70

28 36 43 53 62 74 97

22 29 34 42 50 59 78

260 380 545 820 1050 1475 2200

1/2.80 1/3.55 7/1.70 7/2.24 7/2.50 7/3.00 --------

6.0 10.0 16.0 25.0 35.0 50.0 --------

27 34 43 59 60 91 --------

21 27 35 48 55 69 --------

90.3 145.8 238.0 408.0 495.0 690.0 ------

For Example1: Please find herewith an example to determine the size of the conductor for two-core cable required to carry the maximum current of 25 amperes in a consumer circuit. The length of cable is measured between from existing P.C.C. Pole to consumer energy meter point is 60 metres and declared supply voltage is 230 volts. In this case, Total amperemetres in the circuit = Maximum current in the circuit X length of the circuit cable( lead and return) =25x2X60 =3000 ampere-metres. So far, the permissible voltage drop= (2%X230+1)=5.6 Volts. Ampere-metres per volt of permissible drop=(Total ampere- metres in the circuit)/ Permissible voltage drop =3000/5.6=535.71

From TABLE-I the cable having voltage drop of figure next to the figure of ampere-metres per volt drop, determined above, is 7/1.32 mm having current carrying capacity of 43 Amps and giving 1 volt drop per 545 ampere-metres. So, the size of copper cable i.e. 7/1.32 (9.35 Sq mm) may be selected for this circuit or the size of aluminium cable i.e.7/1.7 (16.0 Sq-mm) may be selected for this circuit and this sizes of cable will be fitted between support of supply main and consumer meter point. h) The following TABLE-II shows the maximum current carrying capacity of Copper Conductor Flexible Cords and Cables: Current rating in amperes for twin,3coreOr 4-core flexible cords subject to voltage drop Circular Type Twin Twisted Type 2 2 4 3 7 5 13 10 18 15 23 20 Approximate voltage drop per 10 metre run with current in previous column. 2.00 1.84 1.76 2.0 1.93 1.75 Permissible weight in kg supported by twin flexible cords. 1.36 2.268 4.536 4.536 4.536 4.536

Sl.No. 1 2 3 4 5 6

No.& Diameter in mm 14/0.193 23/0.193 40/0.193 70/0.193 110/0.193 162/0.193

Nominal Area in Sq- mm 0.387 0.645 1.097 1.936 3.097 4.516

i)The following TABLE-III shows current rating of Aluminium Conductor P.V.C. Insulated /P.V.C. Sheathed Armoured OR unmoored: Conductor Sizes Sq-mm 1.50 2.50 4.0 6.0 10.0 16.0 25.0 35.0 50.0 Single core(3 Nos) Amp 17 24 31 39 51 66 86 100 120 Laid in Ground Twin Single 3,3.5 Or 4 core Single Amp 18 25 32 40 55 70 90 110 135 Amp 16 21 18 35 46 60 76 92 110 Single core(3 Nos) Amp 17 24 30 37 51 65 84 100 115 In Single way Duct Twin Single 3,3.5 Or 4 core Single Amp 16 21 27 34 45 58 76 92 115 Amp 14 18 23 30 39 50 63 77 95 Single core(3 Nos) Amp 15 21 27 35 47 64 84 105 130 In Air Twin Single Amp 16 21 27 35 47 59 78 99 125 3,3.5 Or 4 core Single Amp 13 18 23 30 40 51 70 86 105

j)The following TABLE-III shows various Motor current rating: Approximate amperes per phase taken by modern induction motor allowing reasonable efficiencies and p.f. Single Phase 415 Volts 1.20 Amp 1.70 Amp 2.0 Amp 2.80 Amp 3.50Amp 5.0 Amp 6.50Amp 8.00 Amp 15.0Amp 22.00 Amp 29.00 Amp 42.00 Amp Three Phase 415 Volts 1.0 Amp 1.40 amp 1.70Amp 2.50 Amp 3.20 Amp 4.50 Amp 6.00Amp 7.50Amp 14.0 Amp 21.0Amp 28.00 Amp 39.00 Amp

H.P. rating of Motor

0.5 H.P. 0.75 H.P. 1.0 H.P. 1.50 H.P. 2.0 H.P. 3.0 H.P. 4.0 H.P. 5.0 H.P. 10.0 H.P. 15.0 H.P. 20.0 H.P. 30.0 H.P.

230 Volts 3.50 Amp 4.80 Amp 6.20Amp 8.70 Amp 11.0 Amp 17.50 Amp 20.00 Amp 24.00 Amp 47.00 Amp 70.00Amp 91.00 Amp 135.00 Amp

k)Maximum number of PVC insulated conductor cable that can be drawn in one PVC casing capping /conduits: Size of PVC casing SL NO 1 2 3 4 5 6 Sizes of conductor 1.5 Sqmm 2.5Sqmm 4.0 Sq-mm 6.0Sqmm 10.0 Sqmm 16.0 Sqmm 10nos 10 nos 4 nos ------------------25X10 mm 16 Nos 16 nos 12 nos 8 nos 6 Nos 4 Nos 40 X10 mm 19mm 5 nos 5 Nos 3 nos 2 Nos 2nos ------10 nos 8 Nos 6 nos 5 Nos 4 nos 2 Nos Size of PVC Conduit. 25mm 32mm 18 nos 12nos 10 nos 8 Nos 6Nos 3nos 40mm ------------------------6 Nos 5Nos

l)Recommended Air Changes for Ventilation per Hour: Lavatories Assembly Halls Banks Boiler Houses Canteen/Restaurants Cinema/Theaters Factories/Workshop Foundries Hospitals Kitchen laboratories 8----12 4-----8 40---60 12----20 20----30 12----20 40----60 8-----12 20----30 8-----12 Twice the number of air changes must be allowed where smoke occurs. No. of Exhaust fans= (Volume of Space X Air Changes per hour) Air delivery of fan per hours. For better air movement, distribute fans uniformly. Photographic darkrooms 10----15 20---30

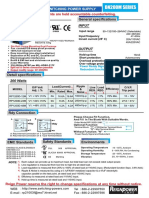

m)Method of measurement of Point Wiring: In case of light/fan/exhaust fan/call bell/plug point wiring, the length per point will be treated as follows: a) Short point: From 0.00m t0 3.00m b) Medium Point: Above 3.00m t0 6.00m c) Above 6.00m to 10.oo m. In case of above 10.00m, the extra length will be considered as sub main. n) Circuit/Submain wiring: Sub-main/circuit wiring shall mean the length of wiring from one main of distribution switch gear/D.B./S.B. to another main or distribution switch gear//D.B./S.B. In exceptional cases, R.D. Department may follow the measurement of point wiring/ submain wiring as recommended by the Indian Standards Institution and also in Tripura State, Schedule of Rates, Internal Electrification, P.W.D. and the payment of labour wages is also made on that measurement basis . But in this case all the payment will be made excluding the cost of materials supply departmentally, contractor profits and other charges if any. 4:BASIC RATES OF LABOURS AND MATERIALS BASIC RATE OF LABOUR WAGES: Labour Department , Govt. of Tripura has revised the rate of labour wages per day working of 8(eight) hours for constructional works undertaken by various departments as follows: i)Un-skilled Labour= Rs.100/-per day. ii)Semi-skilled Labour=Rs.102/- per day. iii)Skilled Labour= Rs.120/- per day. iv) Highlly Skilled Labour=Rs.136/- per day. This revised rate of labour wages has been accepted for execution of Internal Electrification Works under R.D. Department subject to revision of wages by Government from time to time. BASIC RATES OF MATERIALS: Air Conditioners: Name of Products a)DC Inverter type AC b)Floor Standing AC c)Hot and cold AC d)Window AC e)Art Cool AC f)Multi Split AC g)Split AC i) Cassette/Ducted Type AC Capacity in Ton 1.0 Ton 1.5 Ton 1.5 Ton 2.0 Ton 3.0Ton 4.0 Ton 1.0 Ton 2.0 Ton 1.0 Ton 1.5 Ton 2.5 ton 1.0 Ton 2.0 Ton 3.0 Ton 1.0 Ton 2.0 Ton 2.0Ton 3.0 Ton 4.0 Ton Units 1 No 1 No 1 No 1 No 1 No 1 No 1 No 1 No 1 No 1 No 1 No 1 No 1 No 1 No 1 No 1 No 1 No 1 No 1 No ix)Capacitor 3:AC Box for Air Conditioners: Sl No 1 2 3 4 Product Flush Mounting 25 Amp(Heavy duty Socket & MCB mounted on plate with frame attached with Metal Box) Flush Mounting with Unbreakable Box Surface Mounting S.P. MCB With 2010Amp Socket & Metal Box Surface Mounting S.P.N. MCB With 20-10Amp Socket & Metal Box Piece, Rs. Rs.498/Rs.479/Rs.379/Rs.519/Price, Rs. Rs.24,400/Rs.30,100/Rs.32,000/Rs.34,000/Rs.64,000/Rs.88,500/Rs.12,400/Rs.15,100/Rs.14,400/Rs.18,100/Rs.21,500/Rs.22,990/Rs.43,390/Rs.53,390/Rs.24,240/Rs.38,390/Rs.63,000/Rs.94,000/Rs.1,18,000/1 No 650/-

2. Air Conditioner AccessoriesName of Products i)Knob Control ii)Power Switch iii)Thermostat iv)Wheel Blower v)Fan blade vi)A/C condenser vii)Assy Front viii)Universal filter x)Compressor Units 1 No 1 No 1 No 1 No 1 No 1 No 1 No 1 No 1 No Price, 55/355/450/1855/650/4500/2500/150/3680/-

4.Bus bar Chamber ( with cooper strip): RATING 32 Amp 63 Amp 63 Amp 100 Amp 100Amp VOLTS 415 415 415 415 415 SIZE OF BOX 300X240X80 330X280X100 455X330X120 455X330X120 610X410X150 NO. Of STRIPS 4 4 6 4 6 PRICE, RS. 1,040/1,740/2,700/3,000/4,200/-

200 Amp 200Amp 300 Amp 300 Amp 400 Amp 500 Amp 630 Amp

415 415 415 415 415 415 415

455X330X120 610X410X150 455X410X120 610X410X150 610X410X150 610X410X150 610X410X150

4 6 4 6 4 4 4

3,960/5,400/7,080/9,250/9.500/9.890/11,100/-

5. Bakelite Sheet (3mm thick)

1 Sqm

Rs.470/-

6. Bulk Head fittingsSl No 1 Diecasted Bulk Head with 100 w GLS 2 3 4 5 ABS Bulk Head with 100 w GLS Industrial Bulk Head with 10 W CFL Pixel Bulk Head with 1X9 W CFL Decorative Elliptical Bulkhead with 2X9 W CFL

Product Rs.350/Rs.298/Rs.450/Rs.550/Rs.990/-

Rate per piece

7.Cable and Wires(rate per coil, 1 coil=90 mtr.) PVC insulated Aluminium Conductor Cable 3 --------------------------------------------------------------------------------Rs.200/Rs.350/Rs.550/Rs.650/Rs.950/Rs.1650/Rs.2200/PVC insulated Copper Conductor Cable 4 --------------------------------------------------------------Rs.450/Rs.650/Rs.950/Rs.1550/Rs.2100/Rs.2800/Rs.4200/Rs.8,400/Rs.12400/PVC sheathed /insulated aluminium Conductor Cable 5 --------------------------------------------------------------------------------Rs.250/Rs.400/Rs.600/Rs.700/Rs.1050/Rs.1820/Rs.2450/PVC sheathed /insulated Copper Conductor Cable 6 ---------------------------------------------------------------Rs.500/Rs.675/Rs1000/Rs.1550/Rs.2250/Rs.2900/Rs.4300/Rs.8900/Rs.13700/Weather proof Twin copper conductor 7 ---------------------------------------------------------------Rs.800/Rs.1,200/Rs.1,800/Rs.2500/Rs.3300/Rs.4500/Rs.8500/Rs.12,500/Rs.13,900/-

SL No

Nominal area/sizes of conductor

Flexible Cord 8 Rs.180/Rs.200/Rs.400/Rs.500/Rs.550/Rs.650/------------------------------------------------------------------------------

1 2 1 14/0.193mm 2 23/0.193mm 3 40/0.193mm 4 70/0.193mm 5 110/0.193mm 6 162/0.193mm 7 0.75 Sq-mm 8 1.0 Sq-mm 9 1.50 Sq-mm 10 2.50Sq-mm 11 4.0Sq-mm 12 6.0 Sq-mm 13 10.0 Sq-mm 14 16.0 Sq-mm 15 25.0 Sq-mm 8. Call Bell(AC) SL NO 1 2 3 Product Bazzer Type Ding Dong Type Electronic Musical

Rate per piece Rs.59/Rs.88/Rs.214/-

9.Ceiling Flush(with GLS lamp): 10.Change- Over- Switch. a) Porcelain Type Price Rs. DP 550/1107/1944/690/840/2140/Price Rs. TP 990/1240/2560/Price Rs. FP 1120/1370/2900/Name of Products 32 Amp 415 a)200mm(nominal size) b)250 size) 63mm(nominal Amp 415 c)305mm(nominal size) 100 Amp 415 200 Amp 300 Amp 400 Amp 415 415 415 Units 1.0 No1.0 No 3900/1.0 No 5100/7600/10,200/14,400/Price, Rs. 1862/Rs.250/Rs.300/4300/Rs.350/5700/8,400/11,600/16,300/-

Rating 16 Amp 32 Amp 63 Amp 16 Amp 32 Amp 63 Amp

Volts 240 240 240 415 415 415

11.(b) Change- Over- Switch. b) Heavy Duty Knife Type Rating 16 Amp 415 Volts Price Rs. TP Price Rs. FP 1548/-

12.Copier Machine/Xerox Machine 1 No 13. Copier Machine/Xerox Machine Accessories: ` Name of accessories Price in Rs. 1 Set 1 Set 1 Set 1 Set 1 Set 1 Set 1 Set 1 Set 1 Set 1 Set 1 Set 1 No 1 No 1 No

Rs. 1,20,000/= Price in Rs. 800/500/3000/400/1000/500/300/600/200/300/250/1500/700/200/Price, Rs. 25mm dia 45/40/120/55/43/93/11/15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 Corona wire Fuser Sleeves Teflon film Fuser film Lamps Upper Fuse Rollers Lens/CCD Board Platen Cover Scan Drive Motor Paper tray Cooling fan Toner Motor Main Motor Thermistor Thermal fuse. 1 No 1 Set 1 Set 1 Set 1 No 1 No 1 Set 1 no 1 No 1 no 1 No 1 No 1 No 1 No 1 No 400/-

1 OPC drums 2 Laser drums 3 Toner Parts 4 Rubber Parts 5 Gears 6 Belts 7 Rollers 8 Copier parts 9 Magnetic rolls 10 Electronic Parts 11 Lower rollers 12 Housing Wire termination 13 Scanner wire 14 Paper feed tire 14.Conduit and conduit accessories. Name of Products i)P.V.C. Conduit Pipe ii)P.V.C. flexible conduit Pipe iii)H.G./L.G. M.S. Conduit Pipe (16G) iv)Inspection Bends v)Conduit Couplers vi)Junction Box vii)Saddles 15. Computer Units Metre Metre Metre Nos Nos Nos Nos

Price, Rs. 19mm dia 32/28/83/45/37/88/9/-

Price, Rs. 32mm dia 55/48/155/65/52/100/15/-

Price, Rs. 40mm dia 70/62/176/83/60/110/22/-

Price, Rs. 50mm dia 96/88/239/90/65/130/33/-

Name of Products a)Desktop(C2D,320GB HDD,LCD Monitor,3GB RAM) b)Lap-Top(C2D,250 GB HDD,3GB RAM) 16.Detofix 1 Kg Rs.80/-

Units 1 Unit 1 Unit

Price, Rs. Rs.29,190/Rs.40,990/-

17.a) Distribution Board(rewireable):

Name of Products 2 Way DB 3Way DB 4 Way DB 6 Way DB 8 Way DB 10Way DB 12 Way DB 18. Fuse Units(Kit-kat) RATING 16 Amp 32 Amp 16 Amp 32 Amp 63 Amp 100 Amp 200 Amp 300 Amp (Porcelain Rewirable Type)

Units 1.0 No 1.0 No 1.0 No 1.0 No 1.0 No 1.0 No 1.0 No

Prices, Rs. Rs.70/Rs.140/Rs.200/Rs.300/Rs.350/Rs.450/Rs.650/-

VOLTS 240 240 415 415 415 415 415 415

PRICE, RS. 55/108/108/135/410/425/740/1,550/-

19.Distribution Fuse Boards:

Amps 16 32 16

Volts 240 240 415

Type SPN SPN TPN

2 Ways 270/465/1620/-

3 Ways 335/585/2060/-

4 Ways 405/805/2210/-

6 ways 585/1045/2280/-

8 ways 740/1320/3705/-

10 Ways 920/1730/4390/-

32 63 20. Earthing Materials:

415 415

TPN TPN

2070/4110/-

2700/5050/-

3220/6040/-

4025/8020/-

4945/10465/-

6140/12420/-

Name of Products a) 40 mm G.I. pipe(M.G.) with all accessories b)20 mm dia G.I.pipe (M.G.) c)Charcoal d)Salte)Copper plate(600mmX600mmX 3mm) with all accessories f) G.I.Earth Plate (600mmX600mmX6mm) with all accessories g) G.I. Wire (6SWG/8SWG) h)Copper Wire (8SWG) i)Funnel with wire mesh j)G.I. reducer 40mmX20mm 21.Fans with all accessories.

Units 1.0 Mtr 1.0 Mtr 1.0 Kg 1.0 Kg 1.0 Set/Kg 1.0 Set/Kg 1.0 Kg 1.0 Kg 1.0 Set 1.0 No

Prices, Rs. Rs.176/Rs.83/Rs.10/Rs.9/Rs.7,150/-/Rs.550/Rs.3,200/-/Rs.160/Rs.39/Rs.550/Rs.150/Rs.45/-

Types Of Fan Non-Decorative Types Premium Types Decorative Types Under-light Types with Remote Special Finish Fans with Remote Super High Speed (600 or 750mm) a) Ceiling fan(1400/1200 mm sweep) : Types Of Fan 300 mm Sweep 400 mm Sweep b)Table fan: Types Of Fan 400mm Sweep 450mm Sweep 500 mm Sweep

Units 1 No 1 No 1 No 1 No 1 No 1 No

Price, Rs. Rs.1450/Rs.1650/Rs.2200/Rs.2900/Rs.2300/Rs.1900/-

Units 1 No 1 No

Price, Rs. Rs.1,410/Rs.1,980/-

Units 1 No 1 No 1 No

Price, Rs. Rs.2,400/Rs.3,110/Rs.1,980/-

d)Pedestal/Stand Fan : Types Of Fan 230 mm Sweep 300 mm Sweep 400 mm Sweep 450 mm Sweep e)Wall mounting Fan Types Of Fan 230 mm sweep 300 mm sweep 400 mm sweep 450 mm sweep 230 mm shutter300 mm shutter400 mm shutter450 mm shutterUnits 1 No 1 No 1 No 1 No 1 No 1 No 1 No 1 No Price, Rs. Rs.930/Rs.1080/Rs.1,200/Rs.1,400/Rs.300/Rs.400/Rs.430/Rs.550/Units 1 No 1 No 1 No 1 No Price, Rs. Rs.1,560/Rs.1,630/Rs1,900/Rs.2,690/-

Products Fan regulator(resistance type)Fan regulator(Electronic Type)Fan capacitor (2.5 mfd)Fan down rodCAPCON Capacitor type Regulator

Units 1No 1 No 1 No 1 Metre 1 No

Price, Rs. Rs.65/Rs.100/Rs.30/Rs.150/Rs.180/-

22.Fan Items 23. Formica Sheet. 24. Fax Machine. Sqm No Rs.270/Rs.14,500/-

25:HPSV/HPMV- Spares: Name of Products HPSV Lamps HPMV Lamps Electronic Ignitor for HPSV Ballast for HPSV Ballast for HPMV M.S. Control Gear Box for HPSV M.S. Control Gear Box for HPMV Cast Aluminium Control Gear Box for HPSV

Price, Rs. 70/80 W 450/220/190/580/510/1550/1275/2200/-

Price, Rs. 150/125 W 650/250/190/880/590/2190/1350/2685/-

Price, Rs. 250 W 725/485/190/1360/875/2550/1775/3120/-

Price, Rs. 400 W 850/625/190/1650/1270/2975/2150/3425/-

26.Lamps & Accessories: a) GLS Lamp and other accessories: Products Units GLS Lamp 1 No Decoration and Night Lamp 1 No Neon Lamp 1 No Colour Cap 1 No Indicator Light 1 No 300 W Halogen Lamps 1 No 500 W Halogen Lamps 1 No 1000 W Halogen Lamps 1 No c)CFL Lamp Catagory ELD SPIRAL GLOBE LOTUS CIRCLED e)Minilites Set: TYPES CFL Mini -Recess Mini-Surface Mini-Oval Mini-Round Price ,Rs. 5W 120/155/240/190/----------Price ,Rs. 15 W 140/220/315/215/----------Price ,Rs. 20 W 200/230/--------------------140/Price ,Rs. 30 W 300/500/----------340/350/Price ,Rs. 45 W 525/600/------------------------------Price ,Rs. 65 W 675/800/------------------------------Price,Rs. 13/12.50 10/10/125/130/150/180/b)FTL and accessories: Products 20/18 watt Fluorescent Lamps 40/36 watt Fluorescent Lamps 20/18/40/36 watt FTL ballast(Copper/Aluminium) 40/36 watt electronic ballast(Stella/Santro) 20/18 watt electronic ballast(Stella/Santro) Starter with Capacitor Rotar Holder R-2 per pair Rotar Holder Brass Part per Pair Units 1 No 1 No 1 No 1 No 1 No 1 No 1 No 1 No Price, Rs. 45/50/Rs.195/Rs.335/Rs.315/Rs.9/Rs.22/Rs.25/-

Price , Rs 9W 925/900/700/700/-

Price , Rs 11 W 1100/950/750/750/-

Price , Rs 18 W 1200/1050/860/860/-

f)Down-Lighter Set: TYPES CFL Lamps Mounting Vertical Position Lamps Mounting Horizontal Position

Price , Rs 9W 550/690/-

Price , Rs 11 W 670/730/-

Price Rs 18 W 750/790/-

27. Lightning Conductor & Arrester Materials: Name of Products with Sizes a) Lightning conductor finial made of 25mm dia 300 mm long copper having single prong at top with 85 mm dia, 3mm thick copper base plate b) Lightning conductor finial made of 25mm dia 300 mm long G.I. tube having single prong at top with 85 mm dia, 3mm thick G.I. base plate c) Copper tape 20 mmX3 mm thick tape(0.533 Kg/metre) d) Copper tape32 mmX6 mm thick tape(1.705 Kg/metre) e)G.I. tape 20 mmX3 mm thick tape(0.461 Kg/metre) f) G.I. tape 32 mmX6 mm thick tape(1.475 Kg/metre) g)Lightning Arrester(Rod gap/Horn gap arrester, Generally alloy of Zinc) 28.Lamp Shades Name of Products with Sizes a)250X90mm vitreous E.I. conical shade. b)280mm vitreous E.I. coolican shade c)100 mm dia 125 mm long Frosted glass shade d)90 mm dia 150 mm long heat resistant glass shade with anodized aluminium back plate e)150 mm dia glass with Aluminium anodized gallery f)180 mm dia glass with Aluminium anodized gallery

Units 1.0Set 1.0Set 1.0 Kg 1.0 Kg 1.0 Kg 1.0 Kg. 1.0 Kg.

Price, Rs. Rs.1100/Rs.300/Rs.550/Rs.550/Rs.160/Rs.160/Rs.160/-

Units 1.0 No 1.0 No 1.0 No 1.0 No 1.0 No 1.0 No

Price, Rs. Rs.35/Rs.40/Rs.45/Rs.40/Rs.25/Rs.30/-

10

29. Fancy Bracket FittingsName of Products with Sizes a)L-type cast aluminium anodized wall bracket 150 mm projection length with 3 mm dia back plate and brass bracket holderb) Fancy wall bracketof anodized aluminium 12 mm dia rod fixed on 3 mm thick 170 mmX40 mm painted M.S. Plate & brass bracket holder c)Watertight bracket made of 19 mm dia H.G. coduit,250 mm long with brass holder, 250mm vitreous E.I. shade,125 mm long 100mm dia glass globe complete with watertight gasket30. M.S. Metal Boards: Sizes of Boards a)75mmX75mmX60mm. b)150mmX150mmX60mm. c)180mmX100mmX60mm. d)200mmX125mmX60mm e)200mm X150mmX60mm f)200mmX250mmX100mm. g)200mmX300mmX100mm. h)250mmX380mmX100mm. i)300mmX380mmX100mm. j)300mmX450mmX100mm 31. M.S. Metal Boxes(Pre-fabricated, godrej type ): Sizes of Metal Boxes a)762mmX900 mmX450 mm b)1000mm X1200mmX450mm. c)900mm X1200mm. X450mm. 32. Main Switch: a) Switch Fuse Units: RATING Units 1 No 1 No 1 No 1 No 1 No 1 No 1 No 1 No 1 No 1 No

Units 1 Set 1 Set 1 Set

Price, Rs. Rs.250/Rs.300/Rs.350/-

Price, Rs. Rs.35/Rs.70/Rs.60/Rs.80/Rs.90/Rs.130/Rs.200/Rs.240/Rs.270/Rs.300/-

Units 1 No 1 No 1 No

Price, Rs. Rs.1800/Rs.2500/Rs2450/-

VOLTS

Price Rs. SPN 306/801/2052/-

Price Rs. DP

Price Rs. TP

Price Rs. TPN

Price Rs. TPN With HRC 930/1250/2750/5450/8,500/9,950/18,500/27,936/-

16 Amp 32 Amp 16 Amp 32 Amp 63 Amp 63 Amp 100 Amp 200 Amp 320 Amp 400 Amp 500Amp

240 240 415 415 415 415 415 415 415 415 415 b)Isolator Switches(Porcelain Type):

374/882/1098/2286/-

785/1030/2340/4400/6,540/8,800/14,500/24,066/-

900/1060/2390/4670/6,920/9,110/15,700/25,956/-

RATING 16 Amp 32 Amp 63 Amp 100 Amp c)Main Switch(Cubicle): Rating

VOLTS 415 415 415 415

Price Rs. TP 666/925/1950/3,250/-

Price Rs. TPN 700/960/2010/3,310/-

Price Rs. Fp 805/1150/2315/3970/-

Price,Rs. Open Execution 4 Pole(O/E) 32 Amp 63 amp 125 Amp 250 Amp 320 Amp 400 Amp 33. MCB Enclosure(DB) a) MCB Enclosure fitted with DIN Rail NO of Ways Price Rs. Plastic Enclosure 1 Way 2 Way 3 Way 72/72/117/12 Ways 16 Ways Steel 1030/1405/2970/6025/7425/8475/-

Price,Rs. With Steel Sheet Encl. 4 Pole(W/E) 1780/2220/4060/7565/8995/10,285/-

Price Rs. Sheet Enclosure 135/135/171/-

570/670/-

860/980/-

b)MCB Enclosure (Sheet Steel), SP&N Type Price Rs. SP&N Single Door 4 Ways 320/6 Ways 390/8 Ways 450/10 Ways 510/-

Price Rs. Double Door 500/590/670/770/-

11

c)MCB Enclosure (Sheet Steel), SP&N,(Consumer Units) Ways Price Rs. 2+2 Ways 2+4 Ways 2+6 Ways 2+8 Ways 2+10 Ways 2+12 Ways 2+14 Ways 2+16 Ways Rs.500/Rs.590/Rs.670/Rs.770/Rs.860/Rs.1098/Rs.1150/Rs.1,035/d)MCB Enclosure (Sheet Steel), TP&N,(Consumer Units) Type Price Rs. TP&N Single Door 3X4 Ways 3X6 Ways 3X8 Ways 3X12Ways 1089/1341/1584/2061/-

Price Rs. Double Door 1460/1770/2010/2750/-

e)MCB Horizontal DB (TPN) No. of Ways 4 Ways 6 Ways 4 Ways 6 Ways 8 Ways 12 Ways

Incoming Outgoing 4+12 4+18 8+12 8+18 8+24 8+36

Price Rs. 1445/1715/1460/1745/2025/2815/f)MCB Vertical DB (TPN) No. of Ways 4 8 12

Incoming Outgoing 8+12 8+24 8+36

Price Rs. 3,180/4,395/5,670/-

g)Cable End Box: (For mounting on top or bottom of Distribution Box for extra wire & Cables) Item SPN SPN SPN SPN TPN- Horizontal TPN- Horizontal TPN- Horizontal TPN- Horizontal TPN- Vertical i)Plug & Socket only: Rating Product

No. of Way 4 8 12 16 4 6 8 12 4/8/12

Price Rs. 210/280/340/405/445/515/625/840/665/-

h)Plug & Socket Board with Enclosure: RATING PRODUCT 10 Amp 20 Amp 20Amp 30 Amp SP&N,2 Pole, SP/DP MCB SP&N,2 Pole, SP/DP MCB TP&N,3 Pole, TP MCB TP&N,3 Pole, TP MCB

PRICE,R S. 590/605/1200/1680/-

Price, Rs. Only Plug 115/115/155/285/-

Price,Rs. Only Socket 115/115/155/285/-

10Amp 20Amp 20Amp 30 Amp

SP SP TP TP 34: MCB(240/415 V,50 Hz, Breaking Capacity 10 KA) Price Rs. Price Rs. SP SPN 115/351/234/477/270/513/-

Rating B Series 6-32 Amp 40 Amp 50-63Amp

Price Rs. DP 396/513/576/-

Price Rs. TP 458/610/936/-

Price Rs. TPN 620/790/1035/-

Price Rs. FP 680/840/1125/-

Rating C Series 0.5-5 Amp 6-32 Amp 40 Amp 50-63 Amp 35: MCB- Isolator: (240/415 V,50 Hz) RATING 40 Amp 63 Amp 100Amp

Price Rs. SP 100/120/234/270/-

Price Rs. SPN 350/360/477/513/-

Price Rs. DP 396/400/523/576/-

Price Rs. TP 584/594/620/790/-

Price Rs. TPN 756/630/990/1080/-

Price Rs. FP 836/850/1052/1160/-

Price Rs. SP 120/135/205/-

Price Rs. DP 260/285/380/-

Price Rs. TP 365/420/585/-

Price Rs. FP 520/585/690/-

36.Mono Bloc Electrical Motor Capacity of Motor a)0.5 HP b)1.0 HP c)1.5 HP d)2.0 HP e)3.0 HP (Single phase, 250 Volts,50Hz): 37. Mono-Block Electrical Motor (Three Phase, 415 Volts) Units 1 No 1 No 1 No 1 No 1 No Price, Rs. Rs.3,300/Rs.4,500/Rs.8,500/Rs.10,300/Rs.17,500/-

12

Capacity of Motor a)0.5 HP b)1.0 HP c)1.5/2.0 HP d)3.0 HP e)5.0 HP e)10.0 HP f)15.0 HP g)20.0 HP

Units 1 No 1 No 1 No 1 No 1 No 1 No 1 No 1 No

Price, Rs. Rs.3,500/Rs.5,300/Rs.14,550/Rs.25,500/Rs.27,300/Rs.30,300/Rs.35,200/Rs.42,700/-

38. Submersible Pump Set)Capacity of Motor a)0.5 HP b)1.0 HP c)1.5 HP d) 2.0 HP

Units 1 No 1 No 1 No 1 No

Price, Rs. 9,980/13,535/14,585/22,382/1 No Each Price, Rs. Rs.12/Rs.15/Rs.20/Rs.38/Rs.48/Rs.15,350/Rs.4/-

39. Mono Bloc Submersible Pump motor (single phase,1.5/2.0 hp) 40. PVC casing and capping accessories 41.PVC casing and capping: Sizes of products a)15 mmX10 mm b)20mmX10 mm c)25 mmX10 mm d)40 mmX20mm e)50mmX20mm Units 1 Metre 1 Metre 1 Metre 1 Metre 1 Metre

42. PVC Flush Board : Front cover sizes of Board a)76mmx76 mm b)102mm x 102 mm c)102 mmx178mm d)152mmX203mm e)203mmX300mm f)254mm X300mm g)300mm X 380mm

Units 1 No 1 No 1 No 1 No 1 No 1 No 1 No

Price, Rs. Rs.15/Rs.16/Rs.25/Rs.40/Rs.80/Rs.120/Rs.150/-

13

43.PVC Tape: SL NO 1 2 3 4 5 6 Width X Length 1.80 CmX9Mtr 1.80 CmX4Mtr 1.25 CmX9.14Mtr 1.25 CmX4.57Mtr 1.90 CmX25 Mtr 1.80 CmX25 Mtr(Super grip brand) Rate per Roll Rs.11.20 Rs.5.50 Rs.8/Rs.4/Rs.31.50 Rs.9/-

44.POST TOP LANTERNS/ BOLLARDS/FLOOD LIGHT/ PARKING LIGHT: Name of products Ratings with category i)200 W GLS Standard Post Top Lanterns Flying Saucer Shape Post Top Spherical Shape Post Top Blow Molded Diamond Shape Post top Mushroom Shape Post Top Bollards for CFL Lamps Post Top Lantern for CFL Lamp Parking Lights for CFL Lamp Decorative (Lotus) Post Top Flood Light ii)125 W HPMV iii)70 W HPSV i)125 W HPMV ii)70 W HPSV i)125 W HPMV ii)70 W HPSV i)125 W HPMV ii)70 W HPSV 70 W HPSV i)1X9 W CFL ii)2X9 W CFL 1X11 W CFL i)2X18 W CFL ii)2X26 W CFL i)150 W HPSV ii)250 W HPSV i)250 W HPSV ii)400 W HPSV iii)70 W MH iv)150 MH v)400 W MH 45.RCCB(Residential Current Circuit Breakers) (240/415 V,50 Hz, Sensitivity 30/100/300 m Amp) Rating Price Rs. DP 25 Amp 1780/32/40 Amp 2079/63 Amp 2367/47. Refrigerator Name Products Deofresh/ Direct Cool/Forst Refrigerator of Capacity Products 180 LTR. 195 LTR. 220 LTR. 230 LTR. 250 LTR. 310 LTR. 350 LTR. of

Units 1 Set 1 Set 1 Set 1 Set 1 Set 1 Set 1 Set 1 Set 1 Set 1 Set 1 Set 1 Set 1 Set 1 Set 1 Set 1 Set 1 Set 1 Set 1 Set 1 Set 1 Set 1 Set

Price ,Rs. 1300/1750/1900/2300/2450/2500/2650/2500/2650/3050/1700/1800/1450/1750/1775/4500/5050/4,500/5,550/3700/4250/ 5550/-

Price,Rs. FP 2220/2367/2727/Price, Rs. Rs.9,490/Rs.9,600/Rs.11,500/Rs.12,000/Rs.14,500/Rs.21,800/Rs.29,200/-

46. Room heaterCategory of Heater a) Radiant Room Heater. b) Convection Room Heater. c) Oil filled room Heater. 48. Re-winding Materials Of Electrical Motor: Name of Materials a)Super enameled Copper Wire b)Insulation Paper c) Slipper d)Cotton Tape f)Varnish

Units 1 No 1 No 1 No

Price , Rs. Rs.799/Rs.3,349/Rs.5,690/-

Units 1 Kg 1 Sqm 1 No 1 Roll 1 Ltr

free

Price , Rs. 600/40/8/40/200/-

49. Street Light Luminaires: a) HPSV fittings: TYPES OF LIGHT HPSV b) HPMV fittings: TYPES OF LIGHT HPMV c) CFL fittings: TYPES OF LIGHT CFL

Price, Rs. 70W 2,650/-

Price, Rs. 150W 5,050/-

Price, Rs. 250W 5,450/-

Price, Rs. 400W 6,400/-

Price, Rs. 80W 2,690/-

Price, Rs. 125W 2,750/-

Price, Rs. 250W 3950/-

Price, Rs. 400W 4,990/-

Price, Rs. 1X9W 850/-

Price, Rs. 1X11W 850/-

Price, Rs. 1X13W 890/-

Price, Rs. 1X18W 890/-

50. Switch, Socket, Holder, Ceiling Rose etc.(ISI Marked) Sl No 1 2 3 4 5 Product 5/6 Amp. Flash switch (1 Way) 5/6 Amp. Flash switch (2 Way) 5/6 Amp Bell Push Switch 5/6 Amp Master Bell Push Switch with Neon 5/6 Amp 2 Pin Socket Rates per piece Rs.17/Rs.21/Rs.19.50 Rs.32/Rs.17/6 7 8 9 10 11 12 13 5/6 Amp 3 Pin Socket 5/6 Amp 2-In-1 Socket 5/6 Amp 3-In-1 Socket 5/6 Amp 2 in 1 Multi Socket 6/13 Amp Combi Socket 10 Amp Fuse Unit(Kit Kat) 16 Amp Deluxe Fuse(Kit Kat) 10/16 Amp Fuse Knob(Kit Kat) Rs.24/Rs.24/Rs.24/Rs.24/Rs.36/Rs.26/Rs.30/Rs.20/-

14

14

16/20 Amp Flash switch (1Way)

Rs.58/-

15

16/20 Amp Flash switch (2Way)

Rs.70/-

15

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33. 34 35

16 Amp 3 Pin Socket 16/20 Amp Universal Socket 10/20 Amp Combined Unit (Switch & Socket) 10/20 Amp Combined Unit (Switch ,Socket & Box) 10/20 Amp Combined Unit (Switch ,Socket, Neon & Box) 32 Amp Surface D.P. with Neon Indicator 32 Amp Concealed D.P. with Neon Indicator 32 Amp T.P. Switch with Fuse Neon Lamp Indicator(230 Volt) Angle holder Batten holder Pandent holder Single Adaptor Ceiling rose(2 plate) Ceiling rose(3 plate) 6 Amp 3 Pin Top 16 Amp 3 Pin Top Bed Switch(1-way) Bed Switch(2-Way) Hanging Bell Push Switch

Rs.58/Rs.58/Rs.97/Rs.107/Rs.112/Rs. 92/Rs.92/Rs.175/Rs.22/Rs.20/Rs.20/Rs.19/Rs.15/Rs.18/Rs.20/Rs.36/Rs.52/Rs.19/Rs.22/Rs.22/-

16

51.Solar Photo Voltaic System: SL No 1 2 3 4 5 Name of products Solar PV Lantern ,Module-IIA Home Lighting System Model-I, 18 W Module,1 light. Home Lighting System Model-II, 37 W Module, 2 lights. Street Lighting System,74 w Module,11 W lamp Power Plants with all accessories i/c civil works Units 1 Set 1 Set 1 Set 1 Set 1 KW Price in Rs. Rs.3,775/Rs.6,165/Rs.11,250/Rs.20,578/Rs.3,15,000/-

52.Tube Light fittingsc)DecorativeBoxTypeFittin a)Patti Fittings: Sl No 1 2 Product IX40/36 W Supreme Patti with Electronic Ballast IX20/18 W Supreme Patti with Electronic Ballast Rates per piece Rs.355/Rs.335/-

b)Box type fittings Sl Product No 1 1X40/36 W FTL Lamp 2 1X20/36 W FTL Lamp 3 2X40/36 W FTL Lamp 4 1X40/36 W FTL Lamp(VPIT) 5 2X40/36 W FTL Lamp(VPIT) Sl Product No 1 1X40/36 W FTL Lamp 2 1X20/18 W FTL Lamp 3 2X40/36 W FTL Lamp d)Decorative mirror Optics fittingsSl Product No 1 1X40/36 W FTL Lamp 2 2X40/36 W FTL Lamp c) Street light FittingsSl Product No 1 1X40/36 W FTL Lamp 2 2X40/36 W FTL Lamp

Rates per piece Rs.415/Rs.405/Rs.615/Rs.505/Rs.695/Rates per piece Rs.669/Rs.549/Rs.1229/Rates per piece Rs.990/Rs.1289/-

Rates per piece Rs.969/Rs.1319/-

17

53. Surface Mounting Box: a) Surface Mounting Box For Switches Sl Product No 1 1 GANG BOX 2 2 GANG BOX 3 3 GANG BOX 4 4 GANG BOX 5 5 GANG BOX 6 6 GANG BOX 7 7 GANG BOX b)Domestic Sl No 1 2 3 4 5 6 7 8 9 Surface Mounting Box Product 1 GANG BOX 2 GANG BOX 3 GANG BOX 4 GANG BOX 5 GANG BOX 6 GANG BOX 4 GANG DOUBLE DOMESTIC 5 GANG DOUBLE DOMESTIC 6 GANG DOUBLE DOMESTIC

Rates per piece Rs.7.50 R.10.50 Rs.16/Rs.19/Rs.22/Rs.27/Rs.30/-

Rates per piece Rs.9/R.12/Rs.17.50 Rs.21/Rs.23/Rs.29/Rs.26/Rs.30/Rs.33/-

54.Service Connection(Electrical): Sl Product No 1 8/7.5 mtr PCC Pole 2 ACSR 3 Stay Set(Complete) 4 L.T. Stay Insulator 5 L.T. Shakle Insulator 6 G.I. wire(8SWG) 7 Nuts & Bolts 8 Streps & Bolts 9. Single Phase Electronic Energy-meter 10. Three Phase Electronic Energy-meter 11 Reel Insulator(4-10 ) Sq-mm 12 Reel Insulator (16-25 ) Sq-mm

Units 1 No 1 Mtr 1 set 1 No 1 No 1 Kg 1 Kg 1 Kg 1 No 1 No 1 No 1 No

Rate Rs.3400/Rs.25/Rs.565/Rs.8/Rs.10.50 Rs.39/Rs.41/Rs.41/Rs.730/Rs.1950/Rs.0.50/Rs.95/-

55.Screws,pins,link clips and round cleats: Products Unit a) Iron Screws 20 mm 1 Pkt b)Iron screws 35mm 1 Pkt c)Iron Screws 45mm 1 Pkt d)Iron Pins 1Kg e)Link clips50mm/65 mm1 Pkt

Price ,Rs. Rs.35/Rs.35/Rs.50/Rs.80/Rs.10/-

18

56.Servicing materials for Electrical motor Name of materials a)Bearing b)Mechanical Seal c)Impeller d)Key e)O-seal f)Capacitor(25/30/36) g)Cooling fan h)Terminal Units 1 No 1 No 1 No 1 No 1 No 1 No 1 No 1 No Price ,Rs. 200/250/-/150/20/25/400/150/75/-

57. Wood batten: Sizes of batten a)15 mm b)19 mm c)25 mm d)32 mm e)40 mm f)50 mm Unit 1 Metre 1 Metre 1 Metre 1 Metre 1 Metre 1 Metres Price ,Rs. Rs.6.50 Rs.7.50 Rs.8.20 Rs.9.50 Rs.10.65 Rs.11.75

58. Water Heater :

19

Capacity of Products a) 10 Ltr Vertical b)15 Ltr Vertical c)25 Ltr Vertical d) 35 Ltr Vertical 59.Under Ground Electrification Materials: a)Armoured Aluminium Conductor, Price of 1 Metre in Rs. Size in Sq -mm 4.0 Sq-mm 6.0 Sq-mm 10.0Sq-mm 16.0sq-mm 1 Core ------------------------------------Rs.88/2 Core Rs.105/Rs.129/Rs.139/Rs.150/-

Units 1 No 1 No 1 No 1 No

Price ,Rs Rs.5,799/Rs.6,649/Rs.6,899/Rs.8,899/-

3Core Rs.115/Rs.148/Rs.162/Rs.150/Rs.222/3Core Rs.65/Rs.83/Rs.106/Rs.145/Rs.167/-

3.5Core --------------------------------Rs.262/3.5Core --------------------------------Rs.202/-

4 Core Rs.140/Rs.165/Rs.170/Rs.213/Rs.227/4 Core Rs.84/Rs.100/Rs.123/Rs.177/Rs.218/-

25.0sq-mm Rs.110/Rs.166/b) Un-Armoured Aluminium Conductor, Price of 1 Metre in Rs. Size in Sq -mm 1 Core 2 Core 4.0 Sq-mm 6.0 Sq-mm 10.0Sq-mm 16.0sq-mm 25.0sq-mm c)Other Associate materials: SL NO 1 2 3 4 5 6 7 ------------------------------------Rs.43/Rs.60/Rs.54/Rs.65/Rs.84/Rs.105/Rs.113/-

Name of Products 1 no 1 Metre 1 Metre 1 Metre 1 Kg 1 no 1 No

Units

Price, Rs. Rs.10,710/Rs.45/Rs.45/Rs.45/Rs.41/Rs.5,600/Rs.3,800/-

12 Mtr. Long Steel tubular pole MS Channel 100X50X50X6 mm MS Angle 50X50X6mm MS Flate 50X6mm Nuts& Bolts Assorted 7/8 Mtr long S.T. Pole Pole Mounting Box,1.0mX0.90mX0.50m

60: Danger Plates(HT/LT)

1 No

Rs.45

5: APPROVED BRANDS/ MANUFACTURERS OF MATERIALS Sl No Description of items Make

1.Air conditioner LOGICOOL/ LG/HUNDUI/VOLTAS/VIDEOCON/GODREJ/WHIRPOOL 2.Basbar Chamber 3.Bulk Head fittings4.Conduit Accessories 6. Change- Over- Switch 7. Ceiling Flush 8. Ceiling Rose 9. Ceiling/Exhaust/Table/Stand Fan 10. Copier Machine/Xerox Machine 11.Computer/Computer(Desktop/ Laptop) 12. Energy meter 13. Fax Machine 14. HPSV/HPMV/HPMH fittings i/c accessories 15. Fancy Bracket fittings16.Fluorescent TL fittings i/c accessories Main Switch/ Distribution Board/MCB a) Category A: b)Category B: c)Category C: 18. Piano Type switch: 19. Plug Socket 20.Pendent/Batten/Angle Holder 21. PVC sheathed & insulated aluninium/copper conductor cable: 22. PVC casing and capping i/c accessories 23.Room heater24..Refrigerator 25.Weather proof twin core aluminiumr /Copper conductor cabled. National/Fenolex/Havells/Nicco/Plaza/A.K.Lite Presto plast/Precision Bajaj/LG Samsung/L.G./Electrolux/Godrej/Videocon National/Fenolex/Havells/Nicco/Plaza/A.K.Lite L&T/English Electric Standard/Havells/HPL/SSK/Indo-Koap GECO/GETA/ASCO Anchor/Precision/Cona/Maru/SSK/JJ deluxe(Fancy) - Do- DoHavells/Geco/Ship Crompton/Phillips AKG/Plaza/Precision Havells/Geco Crompton/Phillips Anchor/Precision/Cona/Maru/SSK/JJ deluxe(Fancy) Crompton/Khaitan/Usha/Bajaj/Orient Cannon/Xerox/Ricoh HCL/HP/COMPAQ/LANAVO/DELL Anchor/ Havells/Geco Cannon/Xerox/Ricoh/Modi Philips/Crompton/Bajaj Crompton/Phillips Philips/Crompton/Bajaj

5. Call Bell(Buzzer/Ding Dong/Musical)Anchor/Precision/Cona/Maru/SSK/JJ deluxe(Fancy)

20

26.Water Heater 27.Armoured/unmoored Aluminium Cable (Rallision PVC/XPLE Insulated) 6: PVC /WOODEN/ CONDUIT WIRING : SL NO 1 1

Bajaj/Birla life Style/Crompton Greaves/Singer Ship switch gear/Havells

DESCRIPTION OF ACTIVY 2 Providing and fixing of P.V.C. casing and capping including all accessories (p.v.c. bend, corner, joint, elbow etc.) as required as per direction of EngIn- Charge. a)15 mmX10 mm

UNITS 3

MATERIALS REQUIREMENT 4

LABOUR REQUIREMENT 5

Metre

PVCcasing and caping (15mm) =1.0 Mtr PVC accessories=1.5 Nos Detifix=0.01 Kg G.I.Screw=0.08 PKt PVCcasing and caping (20mm)=1.0 Mtr PVC accessories=1.5 Nos Detifix=0.01 Kg G.I.Screw=0.08 PKt

S.SK=0.02 No S.K.=0.05 No H.SK=0.03 No S.SK=0.02 No S.K.=.0.05 No H.SK=0.03 No

b)20mmX10 mm

Metre c)25 mmX10 mm

PVCcasing and caping (25mm)=1.0 Mtr PVC accessories=1.5 Nos Detifix=0.01 Kg G.I.Screw=0.08 PKt Metre

S.SK=0.02 No SK.=.0.05 No H.SK=0.03 No

d)40 mmX20mm

PVCcasing and caping (40mm)=1.0 Mtr PVC accessories=1.5 Nos Detifix=0.017 Kg G.I.Screw=0.08 PKt

S.SK=0.027 No S.K.=.0.06 No H.SK=0.036 No

e)50mmX20mm Metre

PVCcasing and caping (50mm)=1.0 Mtr PVC accessories=1.5 Nos Detifix=0.017 Kg G.I.Screw=0.08 Pkt.

S.SK=0.027 No SK.=.0.06 No H.SK=0.036 No

Metre 2 Providing and fixing of P.V.C. Conduit/H.G.or L.G. Mild Steel Conduit in surface wiring including all accessories, painting etc as required as per direction of Eng- In- Charge. a)19 mm dia

19mm PVC conduit=1.0Mtr 19mmPVC conduit accessories =1.5 Nos Detofix=0.02 Kg G.I. Screw=0.04 Pkt Metre 25mm PVC conduit=1.0Mtr 25mm PVC conduit accessories =1.5 Nos Detofix=0.02 Kg Screw=0.04 Pkt 32mm PVC conduit=1.0Mtr 32mm PVC conduit accessories =1.5 Nos Detofix=0.02 Kg Screw=0.04 Pkt

U/SK=0.04 No S/SK=0.08 No H/SK=0.06 No

b)25 mm dia

U/SK=0.04 No S/SK=0.08 No H/SK=0.06 No

Metre c)32 mm dia

U/SK=0.04 No S/SK=0.08 No H/SK=0.06 No

Metre d)40 mm dia

40mm PVC conduit=1.0Mtr 40mm PVC conduit accessories=1.5 Nos Detofix=0.02 Kg Screw=0.04 Pkt 50mm PVC conduit=1.0Mtr 50mm PVC conduit accessories=1.5 Nos Detofix=0.02 Kg Screw=0.04 Pkt

U/SK=0.05 Nos S/SK=0.09 nos H/SK=0.065 Nos

e)50 mm dia Metre

U/SK=0.05 Nos S/SK=0.09 nos H/SK=0.065 Nos

Metre 3 Providing and fixing of P.V.C. Conduit/H.G. or L.G. M.S. Condit in conceal wiring including all accessories, cutting the wall and making good the same as required. a)19 mm dia

21

b)25 mm dia Metre c)32 mm dia Metre d)40 mm dia Metre e)50 mm dia

19mm PVC conduit=1.0 Mtr 19mm PVC accessories=0.5 Mtr Cement mortar(1:3)=0.0016 cum 25mm PVC conduit=1.0 Mtr 25mm PVC accessories=0.5 Mtr Cement mortar(1:3)=0.0016 cum 32mm PVC conduit=1.0 Mtr 32mm PVC accessories=0.5 Mtr Cement mortar(1:3)=0.0016 cum 40mm PVC conduit=1.0 Mtr 40mm PVC accessories=0.5 Mtr Cement mortar(1:3)=0.0036 cum

U/SK=0.08 Nos S/SK=0.15 nos H/SK=0.12 Nos U/SK=0.08 Nos S/SK=0.15 nos H/SK=0.12 Nos U/SK=0.08 Nos S/SK=0.15 nos H/SK=0.12 Nos U/SK=0.09 Nos S/SK=0.17 nos H/SK=0.14 Nos U/SK=0.09 Nos S/SK=0.17 nos H/SK=0.14 Nos

Metre

50mm PVC conduit=1.0 Mtr 50mm PVC accessories=0.5 Mtr Cement mortar(1:3)=0.0036 .

cum

Metre 4 Providing and fixing of wood casing and capping including all accessories etc as required. a)15 mm Metre b)19 mm Metre

Wooden batten(15mm)=1.0 Mtr Link Clips & pins=0.03 Pkt Detofix= 0.01 Kg Wooden batten(19mm)=1.0 Mtr Link Clips & pins=0.375 Pkt Detofix= 0.01 Kg

U/SK=0.023 No S/SK=0.053 Nos H/SK=0.04 Nos U/SK=0.023 No S/SK=0.053 Nos H/SK=0.04 Nos

c)25 mm Metre

Wooden batten(25mm)=1.0 Mtr Link Clips & pins=0.375 Pkt Detofix= 0.01 Kg

U/SK=0.023 No S/SK=0.053 Nos H/SK=0.04 Nos

U/SK=0.023 No S/SK=0.053 Nos H/SK=0.04 Nos d)32 mm Wooden batten(32mm)=1.0 Mtr Link Clips & pins=0.375 Pkt Detofix= 0.01 Kg Wooden batten(40mm)=1.0 Mtr Link Clips & pins=0.3 75Pkt Detofix= 0.01 Kg U/SK=0.026 No S/SK=0.0673Nos H/SK=0.06 Nos U/SK=0.026 No S/SK=0.056Nos H/SK=0.06 Nos Wooden batten(50mm)=1.0 Mtr Link Clips & pins=0.375 Pkt Detofix= 0.01 Kg Metre

e)40 mm Metre f)50 mm

Metre

7:CABLES AND WIRES SL NO 1 1 DESCRIPTION OF ACTIVY 2 Supplying and laying of PVC insulated aluminium /copper conductor cable in existing PVC casing and capping including necessary connection etc as required. a)1.5 Sq mm PVC insulated aluminium conductor(1.5 Sqmm) =2.0 Mtr PVC Tape =.002 Pkt PVC insulated aluminium /copper conductor(2.5 Sqmm) =2.0 Mtr PVC tape=.002 Pkt PVC insulated aluminium /copper U/SK=0.01 Nos S/SK=0.02 Nos SK= 0.01 Nos H/Sk=0.01 No U/SK=0.01 Nos S/SK=0.02 Nos SK= 0.01 Nos H/Sk=0.01 No UNITS 3 MATERIALS REQUIREMENT 4 LABOUR REQUIREMENT 5

b)2.5 Sq mm

Metre

Metre c)4.0 Sq mm

22

d)6.0 Sq mm Metre

/copper conductor(4.0 Sqmm) =2.0 Mtr PVC tape=.002 Pkt PVC insulated aluminium/ copper conductor(6.0 Sqmm) =2.0 Mtr PVC tape=.002 Pkt

U/SK=0.01 Nos S/SK=0.02 Nos SK= 0.01 Nos H/Sk=0.01 No U/SK=0.012 Nos S/SK=0.022 Nos SK= 0.013 Nos H/Sk=0.015 No U/SK=0.012 Nos S/SK=0.022 Nos SK= 0.013 Nos H/Sk=0.015 No U/SK=0.012 Nos S/SK=0.022 Nos SK= 0.013 Nos H/Sk=0.015 No

e)10 Sq mm Metre PVC insulated aluminium/ copper conductor(10 Sqmm) =2.0 Mtr PVC tape=.002 Pkt PVC insulated aluminium/ copper conductor(16 Sqmm) =2.0 Mtr PVC tape=.002 Pkt

f)16 Sq-mm Metre

Metre 2 Supplying and laying of PVC insulated aluminium /copper conductor cable in existing PVC conduit of surface wiring including necessary connection etc as required. a)1.5 Sq mm b)2.5 Sq mm Metre Metre c)4.0 Sq mm PVC insulated aluminium/ copper conductor(2.5 Sqmm) =2.0 Mtr PVC tape=.002 Pkt PVC insulated aluminium/ copper conductor(4.0 Sqmm) =2.0 Mtr PVC tape=.002 Pkt PVC insulated aluminium/ copper conductor(6.0 Sqmm) =2.0 Mtr PVC tape=.002 Pkt Metre PVC insulated aluminium/ copper conductor(10 Sqmm) =2.0 Mtr PVC tape=.002 Pkt f)16 Sq mm Metre PVC insulated aluminium/ copper conductor(16 Sqmm) =2.0 Mtr PVC tape=.002 Pkt U/SK=0.013 Nos S/SK=0.022 Nos SK= 0.013 Nos H/Sk=0.02 No U/SK=0.013 Nos S/SK=0.022 Nos SK= 0.013 Nos H/Sk=0.02 No U/SK=0.011 Nos S/SK=0.021 Nos SK= 0.012 Nos H/Sk=0.01 No U/SK=0.011 Nos S/SK=0.021 Nos SK= 0.012 Nos H/Sk=0.01 No U/SK=0.013 Nos S/SK=0.022 Nos SK= 0.013 Nos H/Sk=0.02 No

PVC insulated aluminium/ copper conductor(1.5 Sqmm) =2.0 Mtr PVC tape=.002 Pkt

U/SK=0.011 Nos S/SK=0.021 Nos SK= 0.012 Nos H/Sk=0.01 No

d)6.0 Sq mm

Metre

e)10 Sq mm

Metre 3 Supplying and laying of PVC insulated aluminium /copper conductor cable in existing PVC conduit of concealed wiring including necessary connection etc as required. a)1.5 Sq mm PVC insulated aluminium conductor(1.5 Sqmm) =2.0 Mtr PVC tape=.002 Pkt PVC insulated aluminium conductor(2.5 Sqmm) =2.0 Mtr PVC tape=.002 Pkt PVC insulated aluminium conductor(4.0 Sqmm) =2.0 Mtr PVC tape=.002 Pkt Metre PVC insulated aluminium conductor(6.0 Sq-mm) =2.0 Mtr PVC tape=.002 Pkt Metre f)16 Sq-mm Metre PVC insulated aluminium conductor(10 Sqmm) =2.0 Mtr PVC tape=.002 Pkt PVC insulated aluminium /copper conductor(16 Sqmm) =2.0 Mtr PVC Tape=.002 Pkt /copper U/SK=0.022 Nos S/SK=0.032 Nos SK= 0.017 Nos H/Sk=0.055 No U/SK=0.022 Nos S/SK=0.032 Nos SK= 0.017 Nos H/Sk=0.055 No U/SK=0.022 Nos S/SK=0.032 Nos SK= 0.017 Nos H/Sk=0.055 No /copper

U/SK=0.02 Nos S/SK=0.031 Nos SK= 0.016 Nos H/Sk=0.05 No U/SK=0.02 Nos S/SK=0.031 Nos SK= 0.016 Nos H/Sk=0.05 No U/SK=0.02 Nos S/SK=0.031 Nos SK= 0.016 Nos H/Sk=0.05 No

b)2.5 Sq mm

Metre

/copper

c)4.0 Sq mm

Metre

/copper

d)6.0 Sq mm

e)10 Sq mm

/copper

23

Metre

Supplying and laying of PVC sheathed / insulated aluminium /copper conductor cable in existing wooden casing and capping including necessary connection etc as required. a)1.5 Sq mm PVC tape=.002 Pkt PVC Sheathed/ aluminium/copperconductor (1.5 Sqmm)=2.0 Mtr PVC tape=.002 Pkt PVC Sheathed/ aluminium/copper conductor (2.5 Sqmm)=2.0 Mtr PVC tape=.002 Pkt PVC Sheathed/ aluminium/copper conductor (4.0 Sqmm)=2.0 Mtr Metre PVC tape=.002 Pkt PVC Sheathed/ aluminium/copper conductor (6.0 Sqmm)=2.0 Mtr PVC tape=.002 Pkt PVC Sheathed/ aluminium/copper Conductor (10 Sqmm)=2.0 Mtr PVC tape=.002 Pkt PVC Sheathed/ aluminium/copper conductor (16 Sq-mm)=2.0 Mtr PVC tape=.002 Pkt U/SK=0.013 Nos S/SK=0.023 Nos SK= 0.014 Nos H/Sk=0.013 No U/SK=0.013 Nos S/SK=0.023 Nos SK= 0.014 Nos H/Sk=0.013 No U/SK=0.013 Nos S/SK=0.023 Nos SK= 0.014 Nos H/Sk=0.013 No U/SK=0.014 Nos S/SK=0.024 Nos SK= 0.014 Nos H/Sk=0.014 No U/SK=0.014 Nos S/SK=0.024 Nos SK= 0.014 Nos H/Sk=0.014 No U/SK=0.014 Nos S/SK=0.024 Nos SK= 0.014 Nos H/Sk=0.014 No

insulated

Metre b)2.5 Sq mm

insulated

Metre c)4.0 Sq mm

insulated

d)6.0 Sq mm

insulated

e)10 Sq mm Metre f)16 Sq mm

insulated

insulated

Metre

Metre

Providing and wiring with weather proof twin core copper conductor cable, grading of 250/415Volts or 650/1100 Volts for outdoor wiring , power supply, industrial works including necessary connection as required. a)1.5 Sq mm U/SK=0.011 Nos S/SK=0.021 Nos SK= 0.012 Nos H/Sk=0.01 No U/SK=0.011 Nos S/SK=0.021 Nos SK= 0.012 Nos H/Sk=0.01 No U/SK=0.011 Nos S/SK=0.021 Nos SK= 0.012 Nos H/Sk=0.01 No core copper U/SK=0.013 Nos S/SK=0.022 Nos SK= 0.013 Nos H/Sk=0.02 No

b)2.5 Sq mm Metre

Weather proof twin core copper conductor (1.5 Sqmm) =1.0 Mtr PVC tape=.002 Pkt Weather proof twin conductor(2.5 Sqmm) =1.0 Mtr PVC tape=.002 Pkt core copper

c)4.0 Sq mm

Metre

d)6.0 Sq mm

Metre

Weather proof twin core copper conductor(4.0 Sqmm) =1.0 Mtr PVC tape=.002 Pkt Weather proof twin conductor(6.0 Sqmm) =1.0 Mtr PVC tape=.002 Pkt

e)10.0 Sq mm

Metre Weather proof twin core copper conductor(10 Sqmm) =1.0 Mtr PVC tape=.002 Pkt U/SK=0.013 Nos S/SK=0.022 Nos SK= 0.013 Nos H/Sk=0.02 No

f)16.0 Sq mm Weather proof twin core copper conductor(16 Sqmm) =1.0 Mtr PVC tape=.002 Pkt U/SK=0.013 Nos S/SK=0.022 Nos SK= 0.013 Nos H/Sk=0.02 No

Metre

Metre

Providing and fixing 16/0.193 mm twin twisted flexible braided cable in

Twin twisted flexible braided cable(16/0.20

U/SK=0.005 Nos

24

polythine sieve or conduit of suitable size on the floor/wall or on side of the table/door etc as required. 7 Providing and fixing 14/0.193 mm twin core PVC sheathed flexible cable on floor /wall or on side of the table/door etc as required. Providing and fixing 23/0.193 mm twin flexible braided and compound cable on floor /wall or or on side of the table/door etc as required.

Metre Metre

mm)=1.0 Mtr PVC tape=.002 Pkt Twin core PVC sheathed cable(14/0.193 mm)=1.0 Mtr PVC tape=.002 Pkt Twin flexible braided cable(23/0.193 mm) =1.0 Mtr PVC tape=.002 Pkt flexible

Metre

and compound

S/SK=0.001 Nos SK= 0.005 Nos H/Sk=0.005 No U/SK=0.005 Nos S/SK=0.001 Nos SK= 0.005 Nos H/Sk=0.005 No U/SK=0.005 Nos S/SK=0.001 Nos SK= 0.005 Nos H/Sk=0.005 No

8: FITTINGS AND ACCESSORIES SL DESCRIPTION OF ACTIVY NO 1 2 1 Supplying and fixing wooden sheet switch board with bakelite/formica cover flushed in wall /ceiling etc as required. a)76mmx76mm b)102mm x 102 mm c)102 mmx178mm d)152mmX203mm

UNITS 3

MATERIALS REQUIREMENT 4 Wooden Board= 1.0 No BakeliteSheet/Formica Sheet =0.01No Detofix=0.01 Kg G.I. Screw(35/8)=0.03Pkt G.I. Screw(13/12)=0.003 Pkt

LABOUR REQUIREMENT 5 U/SK=0.04 no S/SK=0.02 No SK=0.01 No H/SK=0.009 No

Each

----------------------------------------e)203mmX300mm f)254mm X300mm g)300mm X 380mm 2 Supplying and fixing wooden sheet switch board flushed in wall /ceiling etc as required. a)76mmx76 mm b)102mm x 102 mm c)102 mmx178mm d)152mmX203mm ----------------------------------------e)203mmX300mm f)254mm X300mm g)300mm X 380mm

Wooden Board=1.0 No Bakalite Sheet/Formica sheet =0.025 No Detofix= 0.02Kg G.I. Screw(35/8)=0.05 Pkt G.I. Screw(13/12)=0.005 Pkt Each Each Wooden Board= 1.0 No Detofix=0.01 Kg G.I. Screw(35/8)=0.03Pkt G.I. Screw(13/12)=0.003 Pkt

U/SK=0.06 no S/SK=0.03 No SK=0.015 No H/SK=0.011 No U/SK=0.03 no S/SK=0.015 No SK=0.015 No H/SK=0.008 No

Each 3 Supplying and fixing P.V.C. sheet switch board flushed in wall/ceiling etc as required. a)76mmx76 mm b)102mm x 102 mm c)102 mmx178mm d)152mmX203mm ----------------------------------------e)203mmX300mm f)254mm X300mm g)300mm X 380mm 4 Supplying and fixing of the items of accessories including necessary connection etc as required as per direction of Eng-In- Charge. a)Angle holder/batten holder/ Pandent holder/Ceiling rose/ Adaptor etc ----------------------------------------b)5/6 Amps Fuse unit/Flash switch/3/2 pin socket/Combi Socket/Multi Socket/Bell push Switch etc. ----------------------------------------c)15/16 Amp Flash switch/3/2 Socket/Combi Socket etc. ----------------------------------------d)10/20 Amp Combined Unit/32 Amp Surface or Concealed D.P. or T.P. with neon indicator. Pin 15/16 Amp socket/Universal Each

Wooden Board=1.0 No Detofix= 0.02Kg G.I. Screw(35/8)=0.05 Pkt G.I. Screw(13/12)=0.005 Pkt PVC Board= 1.0 No Detofix=0.01 Kg G.I. Screw(35/8)=0.03Pkt G.I. Screw(13/12)=0.003 Pkt

U/SK=0.05 no S/SK=0.02 No SK=0.012 No H/SK=0.009 No U/SK=0.03 no S/SK=0.015 No SK=0.015 No H/SK=0.008 No

Each

Each

------------------------------PVC Board=1.0 No Detofix= 0.02Kg G.I. Screw(35/8)=0.05 Pkt G.I. Screw(13/12)=0.005 Pkt

U/SK=0.05 no S/SK=0.02 No SK=0.012 No H/SK=0.009 No

Angle holder/batten holder/ Pandent holder/Ceiling rose etc=1.0 No --------------------------------b)5/6 Amps Fuse unit/Flash switch/3/2 pin socket/Combi Socket/Multi Socket/Bell push Switch etc.=1.0 no ----------------------------------c)15/16 Amp Flash switch/3/2 Pin 15/16 Amp socket/ Universal Socket/Combi Socket etc.=1.0 No ------------------------------d)10/20 Amp Combined Unit/32 Amp Surface or Concealed D.P. or T.P. with neon indicator.=1.0 No

U/SK=0.01 No S/SK=0.02No SK= 0.025 No H/SK=0.01No U/SK=0.015 No S/SK=0.03No SK= 0.03 No H/SK=0.03No

U/SK=0.025 No S/SK=0.034No SK= 0.035 No H/SK=0.04No U/SK=0.035 No S/SK=0.05No SK= 0.05 No H/SK=0.05No

Supplying and fixing call bell and push suitable for D.C./A.C. single phase 230 volts complete as required. a)Bazzer Type b)Ding Dong Type c)Electronic Musical Supplying and fixing of plug and Socket Board (10/20/30 Amp) i/c connection etc. as required. Supplying and fixing of A/C Box for air Conditioner /refrigerator etc (10/20/30 Amp) i/c connection etc. as required.

Call Bell (Bazzer/Ding Dong/Musical)= 1.0 No

U/SK=0.011 No S/SK=0.02 No SK= 0.025 No H/SK=0.011No U/SK=0.06 no S/SK=0.05 No SK=0.012 No H/SK=0.02 No U/SK=0.06 no S/SK=0.05 No

Each

Plug Socket=1.0 no (10/20/30 Amp) A/C Box=1.0 No (10/20/30 Amp

Each

25

Supplying and fixing of Surface mounting Box (1/2/3/4/5/6/7 Gang Box) for domestic/industrial purpose etc. i/c connection etc. as required. Supplying and fixing of Fuse Units (16/32/63/200 Amp ) i/c connection etc. as required.

Each

Gang Box=1.0 No (1/2/3/4/5/6/7) Fuse units (16/32/63/200 Amp ) =1.0 no

Each

SK=0.012 No H/SK=0.02 No U/SK=0.03 no S/SK=0.03 No SK=0.012 No H/SK=0.03 No U/SK=0.035 No S/SK=0.05No SK= 0.05 No H/SK=0.05No

9:LIGHTINGS ACCESSORIES & FITTINGS SL DESCRIPTION OF ACTIVY NO 1 2 1 Providing and fixing of GLS/ CFL/Indicator Lamps of capacity 250 Volts AC as required. a)10/40/60/100 watt GLS Lamps b)5 to 65 watt CFL Lamps c)5 to 125 watt Indicator Lamps 2 Supplying and fixing bulk head fittings complete with one no 60/100 watt GLS or required rating of C.F.L. bulb including connection etc as required. 3 Supplying and fixing Decorative circular ceiling flush fitting complete with holder, aluminium anodized back plate and glass globe including connection etc as required. a)200 mm dia(nominal size) b)250 mm dia (nominal size) c)305 mm dia (nominal size) 4 Supplying and fixing L type cast aluminium anodized wall bracket 150 mm (nominal size), projection length with 3mm thick,75mm dia back plate and brass bracket holder complete including conne- ctions etc. as required. 5 Supplying and fixing fancy wall bracket of anodized aluminium 12 mm dia rod ,fixedon 3 mm thick 170mm X 40mm painted m.s plate with brass bracket holder complete including conne -ctions etc. as required. 6 Supplying and fixing water tight bracket made of 19mm dia H.G. conduit,250 mm long with brass holder, 250 vitrous enameled iron shade 125mm long 100 mm dia glass Globe complete with water tight bracket including connections etc. as required. 7 Supplying and fixing 250mmX90 mm (nominal size) vitrous enameled iron conical shade as required. 8 9 10 Supplying and fixing 280 mm (nominal size) vitrous enameled iron cool can shade as required Supplying and fixing glass globe anodized aluminium gallery as required. a)150 mm dia b)180 mm dia Supplying and fixing of single Fluorescent Tube Light (FTL) fittings (indoor/out door type)complete with 1 no 40/36 watt FTL, 1 no 40/36 watt copper ballast, starter, holder, PF improving capacitor etc. i/c connection etc. as required. a)Patti fittings. b)Box Type fittings. c)Decorative Box type fittings. ---------------------------------d)Street Light fittings.

UNITS 3 Each

MATERIALS REQUIREMENT 4 GLS/CFL/Indicator Lamps= 1.0 Nos

LABOUR REQUIREMENT 5 S/SK=0.0147 nos

Each

Bulk head=1.0 No (with GLS/CFL lamp) Decorative Ceiling flush (200/250/305mm) = 1.0 no L Type wall Bracket =1.0 No Fancy Wall bracket = 1.0no

U/SK=0. 12 No H/SK=0.06No S/SK=0.09 Nos H/SK=0.05 Nos

Each

Each

U/SK=0. 12 No H/SK=0.06No U/SK=0. 12 No H/SK=0.06No

Each Each Each Water Tight Bracket =1.0 No Vitrous E.I. conical Shade (250mmX90mm) =1.0 No Vitrous E.I. coolcan shade =1.0 Nos Glass Globe(150/180mm)= 1.0 Nos U/SK=0. 12 No H/SK=0.06No S/SK=0.0147 nos S/SK=0.0147 nos U/SK=0. 12 No H/SK=0.06No

Single Flourescent Tube (Patti/Box /Decorative)= 1.0 No

Light

U/SK=0. 12 No H/SK=0.06No

-------------------------Single Street light fittings, FTL=1.0 Nos 25 mm G.I. Pipe=0.90 Mtr Cement Morter= FTL(40/36)= 1 No

U/SK=0. 24 No S/SK=0.095 Nos H/SK=0.12No

11

Supplying and fixing of double Fluorescent Tube Light (FTL) fittings (indoor/out door type)complete with 2 nos 40/36 watt FTL, 2 nos 40/36 watt copper ballast, starter, holder, PF improving capacitor i/c connection as required. a)Box Type fittings. b)Decorative Box type fittings. c)Decorative Mirror optics fittings d)Street Light fittings.

Double Fluorescent Tube Light= 1.0 No Each Double Street light fittings, FTL=1.0 No 25 mm G.I. Pipe=0.90 Mtr Cement Morter=L.S. FTL(40/36)= 1 No

U/SK=0. 13 No H/SK=0.062No

Each

U/SK=0.242 No S/Sk=0.096 Nos H/SK=0.13 No

12

13

Providing and fixing of Out door /Street light H.P.S.V. lamp fittings with necessary ballast, capacitor, ignitor, holder, lamp etc i/c connection as required. a)70 watt HPSV Lamps. b)150 watt HPSV Lamps. c)250 watt HPSV Lamps d)400 watt HPSV lamps. Providing and fixing of H.P.S.V./H.P.M.V./CFL Post Top Lanterns/Bollards/Flood light /Parking Light fittings (Diamond/ Mushroom/Spherical/Lotus Shaped ) complete with necessary ballast, capacitor, ignitor, holder, lamp etc i/c connection as required.

Each

40 mm G.I.Pipe=3.10 Mtr G.I. Bend= 1.0 No H.P.S.V. lamp=1.0 No

U/SK=0. 726 No S/SK=0.288 Nos H/SK=0.39 No

Each 14 15 16 17 18 Supplying and fixing of 20/18 watt FTL i/c necessary connection etc. as required. Supplying and fixing of 40/36 watt FTL i/c necessary connection etc. as required. Supplying and fixing of 20/18 watt FTL ballast i/c necessary connection etc. as required. Supplying and fixing of 40/36 watt FTL ballast i/c necessary connection etc. as required. Supplying and fixing of 40/36 watt Electronic FTL ballast i/c necessary connection etc. as required.

40mm G.I.Pipe =1.0mtr G.I. Bend= 1.0 No Post top/Bollard/Parking Light(H.P.S.V./H.P.M.V./CFL)=1.0 No Grouting Works= as required. FTL(20/18)=1.0 No FTL(40/36)=1.0 No Ballast(20/18)=1.0 No Ballast(40/36)=1.0 No Electronic ballast(40/36) =1.0 No

U/SK=0.484 No S/Sk=0.192 Nos H/SK=0.26 No

Each Each Each Each Each

S/SK=0.0157 nos S/SK=0.0157 nos S/SK=0.017 nos S/SK=0.017 nos S/SK=0.017 nos

26

19 20 21

Supplying and fixing of 2X 40/36 watt Electronic FTL ballast i/c necessary connection etc. as required. Supplying and fixing of 40/36 watt FTL starter i/c necessary connection etc. as required Supplying and fixing of double Fluorescent Tube Light (FTL) fittings with cutting of false ceiling, preparation etc for housing the same (indoor type)complete with 2 nos 40/36 watt FTL, 2 nos 40/36 watt copper ballast, starter, holder, PF improving capacitor etc. i/c connection etc. as required. a)Box Type fittings. b)Decorative Box type fittings. c)Decorative Mirror optics fittings.

Each Each

Electronic ballast(40/36) =1.0 No Starter= 1.0 No

S/SK=0.017 nos S/SK=0.0157 nos

Each

Double Fluorescent Tube Light= 1.0 No U/SK=0. 484 No S/SK=0.192 Nos H/SK=0.26 No

22

Supply and fixing of Mini-light Set/Down industrial/theatre/Hall etc i/c connection as required.

Lighter

Set

for Each

Mini-light Set/Down Lighter Set=1.0 no

U/SK=0.35 No S/Sk=0.112 Nos H/SK=0.22 No U/SK=0.02 no S/SK=0.02 No SK=0.012 No H/SK=0.01 No

23

Supply and fixing of M.S. Control Gear Box for H.P.S.V./H.P.M.V. fittings i/c connection etc. as required.

Each

M. S. Control Gear Box for H.P.S.V./H.P.M.V. fittings=1.0 No

10: FANS AND ITS COMMISSIONING. SL NO 1 1 DESCRIPTION OF ACTIVY 2 Providing ,installation, testing,, commissioning of ceiling fan of 1200/1400 mm sweep ,250 volts A.C.(Nondecorative/decorative/Super high speed) with regulator including carriage etc as per direction of Eng-In- Charge. Providing and installation of exhaust fan opening i/c making the hole to suit the size for the fan , making good the damages, testing, commissioning, carriage etc. as required. a)230 mm sweep. b)300 mm sweep. c)400 mm sweep d)450 mm sweep Supplying and fixing of necessary shutter for exhaust fan in the existing hole i/c necessary carriage & painting etc. as required. a)230 mm shutter. b)300 mm shutter. c)400 mm shutter. d)450 mm shutter. Supplying and fixing of 230/300/400/450 mm sweep wall mounting fan i/c necessary connection & carriage etc. as required. Supplying and fixing of 400/450/500 mm sweep, 250 volts, A.C. Table/Stand /pedestal fan i/c necessary connection & carriage etc. as required. UNITS 3 Each MATERIALS REQUIREMENT 4 Ceiling fan=1.0 no (1200/1400mm sweep) Electronic Regulator=1.0 no LABOUR REQUIREMENT 5 U/SK=0. 12 No H/SK=0.06No

Each

Exhaust fan=1.0 No (230/300/400/450)

U/SK=0. 484 No S/SK=0.196 Nos H/SK=0.26 No

Each

Shutter for exhaust fan=1.0 No (230/300/400/450) Wall Mounting Fan= 1.0 No (230/300/400/450) Table/Stand No(400/450/500) fan=1.0

S/SK=0.038 No U/SK=0. 13 No H/SK=0.062No H/SK=0.031No U/SK=0.065 No

4 5

Each Each

11:SWITCHGEAR & CHANGE OVER SWITCH SL NO 1 1 DESCRIPTION OF ACTIVY 2 Providing and fixing of SP&N Main switch(Switch Fuse Unit) (rewireable) 250 volts i/c drilling holes on Board/M.S. clamp connection etc. as required. a)15/16 Amps b)30/32 Amps. Providing and fixing of DP Main switch (rewireable) 250 volts i/c drilling holes on Board/M.S. clamp connection etc. as required. a)15/16 Amps b)30/32 Amps. Providing and fixing of 60/63 Amps DP Main switch (rewireable) 415 volts i/c drilling holes on Board/M.S. clamp connection etc. as required. Providing and fixing of TP Main switch (rewireable) 415 volts i/c drilling holes on Board/M.S. clamp connection etc. as required. a)15/16 Amps b)30/32 Amps. c)60/63 Amps. d)100 Amps. Providing and fixing of TPN Main switch (rewireable) 415 volts i/c drilling holes on Board/M.S. clamp connection etc. as required. a)15/16 Amps b)30/32 Amps. ---------------------------------------------c)60/63 Amps. d)100 Amps. UNITS 3 Each MATERIALS REQUIREMENT 4 Main Switch(SP&N)= 1.0 No (15 to 32 Amp) LABOUR REQUIREMENT 5 U/SK=0. 13 No H/SK=0.123No

Each Each

DP Main Switch= 1.0 No (15 to 32 Amp) DP Main switch (60/63)=1.0 No T.P. Main Switch (15 to 32)= 1.0 No

U/SK=0. 13 No H/SK=0.153No U/SK=0. 484 No S/Sk=0.192 Nos H/SK=0.26 No U/SK=0. 13 No H/SK=0.123No U/SK=0. 484 No S/SK=0.192 Nos H/SK=0.26 No U/SK=0. 13 No H/SK=0.123No

Each -------Each T.P. Main Switch(60 to 100)= 1.0 No TPN Main Switch(15 to 32)= 1.0 No ----------------------TPN Main Switch(60 to 100)= 1.0 No

Each -------Each

U/SK=0. 484 No S/SK=0.192 Nos H/SK=0.26 No U/SK=0. 13 No H/SK=0.123No

Providing and fixing of TPN Main switch (rewireable/HRC) 415 volts i/c drilling holes on Board/M.S. clamp connection etc. as required. a)15/16 Amps b)30/32 Amps. ---------------------------------------------c)60/63 Amps. d)100 Amps

Each

TPN Main Switch(15 to 32) ( rewireable/HRC) = 1.0 No ---------------- -----TPN Main Switch(60 to 100) ( rewireable/HRC) = 1.0 No

Each

U/SK=0. 484 No S/SK=0.192 Nos H/SK=0.26 No

27

Providing and fixing of TPN Main switch (cubicle) 415 volts(metal enclosed) i/c drilling holes on Board/M.S. clamp connection etc. as required. a)32 Amps. b)63 Amps. c)100 Amps. d)125 Amps. ---------------------------------------------e)160 Amps. e)200 Amps. g)250 Amps. h)315 Amps. i)400 Amps. Providing and fixing of Change-Over-Switch i/c drilling holes on Board/M.S. clamp connection etc. as required. a)32Amps. DP b)63 Amps. DP c)32 Amps. TP ---------------------------------------------d)63 Amps. TP e)100 Amps. TP e)32 Amps. FP g)63 Amps. FP h)100 Amps. FP

Each

TPN Main Switch(15 to 32) ( cubicle) = 1.0 No

U/SK=0. 13 No H/SK=0.123No

---------------- -----TPN Main Switch(60 to 400) (Cubicle) = 1.0 No Each

---------------------U/SK=0. 484 No S/SK=0.192 Nos H/SK=0.26 No U/SK=0. 242 No S/SK=0.096 Nos H/SK=0.13 No

Change-Over-Switch= 1.0

Each ----------------------------Change-Over-Switch= 1.0 Each U/SK=0. 484 No S/SK=0.192 Nos H/SK=0.26 No

12:DISTRIBUTION BOARD AND CIRCUIT BREAKER. SL NO 1 1 DESCRIPTION OF ACTIVY 2 Supplying and fixing of DB 250 Volts , 15/16 Amps per way (rewireable) i/c drilling holes on board/ M.S. Clamp connection etc. as required. a) 2 Way. b) 3Way. c) 4 Way. d) 6 Way. e) 8 Way. f) 10Way. g) 12 Way. Supplying and fixing of sheet metal MCB enclosure with DIN rail complete with necessary bas bar, earth bar, neutral links etc i/c connection as required. a)1 Way b)2 Way c)3 Way UNITS 3 MATERIALS REQUIREMENT 4 LABOUR REQUIREMENT 5

Each

DB(2/3/4/6/8/10/12 ways)= 1.0 No M.S. Clamp=L.S.

U/SK=0. 06 No S/SK= 0.07 No H/SK=0.123No

Each 3 Supplying and fixing of Sheet metal MCB Enclosure, SP&N, Single/Double Door with necessary bas bar, earth bar, neutral links, din rail etc i/c connection as required. a) 4 Way b) 6 Way c) 8 Way d) 10 way. e) 12 Way. f) 16 way. Supplying and fixing of Sheet Steel MCB Enclosure, SP&N, Consumer Units, Single/Double Door with necessary bas bar, earth bar, neutral links, din rail etc i/c connection as required. a) 2+2 Way b) 2+4 Way c)2+6 Way d) 2+10 way. e) 2+12 Way. f) 2+14 way g)2+16 Way Supplying and fixing of Single Pole,240 Volts B Or C series MCB in the existing MCB DB complete with connection etc. as regard. a)5 to 32 Amps. b)40 Amps. c)63 Amps. Supplying and fixing of SP & N ,240 Volts B Or C series MCB in the existing MCB DB complete with connection etc. as regard. a)5 to 32 Amps. b)40 Amps. c)63 Amps. Supplying and fixing of Double Pole ,240 Volts B Or C series MCB in the existing MCB DB complete with connection etc. as regard. a)5 to 32 Amps. b)40 Amps. c)63 Amps Supplying and fixing of Triple Pole ,240 Volts B Or C series MCB in the existing MCB DB complete with connection etc. as regard. a)5 to 32 Amps. b)40 Amps. c)63 Amps Supplying and fixing of TP & N , 415 Volts B Or C series MCB in the existing MCB DB complete with connection etc. as regard. a)5 to 32 Amps. b)40 Amps. c)63 Amps Supplying and fixing of Four pole , 415 Volts B Or. C series MCB in the existing MCB DB complete with connection etc. as regard. a)5 to 32 Amps.

MCB enclosure with DIN rail(1/2/3 way) =1.0 No

U/SK=0. 06 No S/SK= 0.07 No H/SK=0.123No

Each

MCB Enclosure, SP&N, Single/Double Door(4/6/8/10/12/16) ways =1.0 No

U/SK=0. 10 No S/SK= 0.08 No H/SK=0.15No

Each

MCB Enclosure, SP&N, (Consumer Unit)Single /Double Door((2+2)/(2+4)/ (2+6)/(2+8)/2+10)/ (2+12)/(2+14)/(2+16) ways =1.0 No

U/SK=0. 18 No S/SK= 0.18 No H/SK=0.18No

Each

MCB(SP)= 1.0 No (5 to 32 /40 /63 Amps.)

U/SK=0. 03 No H/SK=0.052No

Each

MCB(SP&N)= 1.0 No (5 to 32 /40 /63 Amps.)

U/SK=0. 031 No H/SK=0.053No

Each

MCB(DP)= 1.0 No (5 to 32 /40 /63 Amps.)

U/SK=0. 032 No H/SK=0.054No

Each

MCB(TP)= 1.0 No (5 to 32 /40 /63 Amps.)

U/SK=0. 033 No H/SK=0.055No

Each

MCB(TP&N)= 1.0 No(5 to 32 /40 /63 Amps.)

U/SK=0. 034 No H/SK=0.056No

10

U/SK=0. 035 No

28

b)40 Amps. c)63 Amps. 11 Supplying and fixing of Single Pole,240 Volts Isolator in the existing MCB DB complete with connection etc. as regard. a)40 Amps. b)63 Amps. c)100 Amps Supplying and fixing of Double Pole,240 Volts Isolator in the existing MCB DB complete with connection etc. as regard. a)40 Amps. b)63 Amps. c)100 Amps Supplying and fixing of Triple Pole, 415 Volts Isolator in the existing MCB DB complete with connection etc. as regard. a)40 Amps. b)63 Amps. c) 100 Amps Supplying and fixing of Four Pole, 415 Volts Isolator in the existing MCB DB complete with connection etc. as regard. a)40 Amps. b)63 Amps. c)100 Amps Supplying and fixing of RCCB, 240/415 Volts,50 Hz, Sensitivity 30/100/300 Mili-Amp i/c connection etc. as required. a)25 Amp. b)32/40 Amps. c)63 Amp Supplying and fixing of Sheet Steel MCB Enclosure, TP&N, Consumer Units, Single/Double Door with necessary bas bar, earth bar, neutral links, din rail etc i/c connection as required. a)3X4 Way b)3X6 Way c)3X8 Way d)3X12 Way Supplying and fixing of MCB Horizontal DB(TPN) i/c drilling holes on board/ M.S. Clamp, connection etc. as required. i)4 Way. (4 incoming+12 outgoing) ii)6Way. ( 4 incoming+18 outgoing) ii)4 Way. ( 8 incoming+12 outgoing) iii)6 Way. ( 8 incoming+18 outgoing) iv)8 Way .( 8 incoming+24 outgoing) v)12Way. ( 8 incoming+36 outgoing) 18 Supplying and fixing of MCB Vertical Each DB(TPN) i/c drilling holes on board/ M.S. Clamp, connection etc. as required. i)4 Way. ii)6Way. ii)4 Way. iii)6 Way. iv)8 Way. v)12Way. 19 (4 incoming+12 outgoing) (4 incoming+18 outgoing) (8 incoming+12 outgoing) ( 8 incoming+18 outgoing) ( 8 incoming+24 outgoing) ( 8 incoming+36 outgoing)

Each

MCB(FP)= 1.0 No (5 to 32 /40 /63 Amps.)

H/SK=0.057No

Each

MCB(SP)= 1.0 No (40 /63/100 Amps.)

U/SK=0. 06 No H/SK=0.104No

12

Each

MCB(DP)= 1.0 No (40 /63/100 Amps.)

U/SK=0. 061 No H/SK=0.105No

13

Each

MCB(FP)= 1.0 No (40 /63/100 Amps.)

U/SK=0. 062 No H/SK=0.106No

14

Each Each

MCB(FP)= 1.0 No (40 /63/100 Amps.) RCCB=1.0 No (25/32/40/63 Amp)

U/SK=0. 063 No H/SK=0.107No U/SK=0. 093 No H/SK=0.16No

15

16

MCB Enclosure, SP&N, (Consumer Unit)Single /Double Door(3X4/3X6/3X8 /3X12) =1.0 No

U/SK=0. 20 No S/SK= 0.25 No H/SK=0.20No

17

Each

U/SK=0. 40 No S/SK= 0.35 No H/SK=0.30No MCB Horizontal DB(TPN)=1.0 No

Each

U/SK=0. 40 No S/SK= 0.35 No H/SK=0.30No MCB Vertical DB(TPN)=1.0 No