Escolar Documentos

Profissional Documentos

Cultura Documentos

57150art 10 40-45

Enviado por

chidambaramrTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

57150art 10 40-45

Enviado por

chidambaramrDireitos autorais:

Formatos disponíveis

Chemical Bulletin of Politehnica University of Timisoara, ROMANIA Series of Chemistry and Environmental Engineering Chem. Bull. "POLITEHNICA" Univ.

(Timisoara)

Volume 55(69), 1, 2010

Structural Characterization of Some Mg/Zn-Al Type Hydrotalcites Prepared for Chromate Sorption from Wastewater

L. Cocheci*, P. Barvinschi**, R. Pode*, E. Popovici*** and E.M. Seftel***

*

Politehnica University of Timisoara, Faculty of Industrial Chemistry and Environmental Engineering, 2 Victoriei Sq., 300006 Timisoara, Romania laura.cocheci@chim.upt.ro

**

West University of Timisoara, Faculty of Physics, 4 Parvan Blvd., 300223 Timisoara, Romania Al. I. Cuza University of Iasi, Faculty of Chemistry, 11 Carol I Blvd., 700506 Iasi, Romania

***

Abstract: Five hydrotalcite-like compounds with different Mg/Zn ratio were prepared and characterized from a structural point of view, in order to be used for chromate uptake from wastewater. The chemical composition of the materials was determined using EPMA (electron probe microanalysis). The thermal behavior was investigated by DTG method. The structure of as-synthesized hydrotalcite-like samples was confirmed by X-Ray Diffraction and FTIR Spectroscopy methods. A part of the samples were activated in an oven, at temperatures of 500C in air, with a rate of 5C/min for 4 hours and the specific surface area of calcined compounds was measured. Keywords: hydrotalcite-type compound, structural characterization, thermal behavior, specific surface area, morphology

1. Introduction

Hydrotalcite, first discovered in Sweden around 1842, is a hydroxycarbonate of magnesium and aluminum and it occurs in nature in forms of foliated and contorted plates and/or fibrous masses [1]. The chemical formula of hydrotalcite is Mg6Al2(OH)16CO3 . 4H2O. Its structure can be explained by analogy with the crystal structure of brucite, Mg(OH)2. Brucite consists of a hexagonal close packing of hydroxyl ions with alternate octahedral sites occupied by Mg2+ ions. The metal hydroxide sheets in brucite crystal are neutral in charge and they overlap one another by Van der Waals interactions. In hydrotalcite, some of the Mg2+ cations of these brucite-like sheets are isomorphously substituted by Al3+ cations and thus formed mixed metal hydroxide layers, [Mg6Al2(OH)16]2+, acquire a net positive charge. This excess charge on the metal hydroxide layers is neutralized by CO32- anions accumulated in the interlayer region. The interlayer region also contains some water molecules for the stabilization of the crystal structure. The hydrotalcite-like compounds, also called anionic clays or layered double hydroxides, have similar structure as hydrotalcite and the general formula is [MII1-x MIIIx (OH)2]x+ [An-x/n . mH2O]x-, where MII is a divalent cation (Mg2+, Mn2+, Zn2+, Ni2+, Fe2+, Co2+, Cd2+, Cu2+ etc.), MIII a trivalent cation (Al3+, Fe3+, Ga3+, In3+, Cr3+ etc.) and Ancharge compensating anions (NO3-, Cl-, SO42-, ClO4- etc.). Interest in hydrotalcite-like compounds has grown due to their role in controlling the mobility of aqueous metals in the environment [2-6] as well as their use as catalysts [1,79] and catalysts precursors [10-12]. The decomposition of hydrotalcite-like compounds when heated at around 500 C leads to mixed metal oxides,

which are characterized by a high specific surface area and homogeneous dispersion of the metal cations. The mixed metal oxides can take up anions from aqueous solution, resulting in a concomitant reconstruction of the original layered structure, the so-called memory effect, as expressed by the following equations [13]: Mg1-xAlx(OH)2(CO3)x/2.mH2O x/2CO2 + (m+1) H2O

500C Mg1-xAlxO1+x/2 +

(1)

Mg1-xAlxO1+x/2 + (x/n)An- + (m+1+(x/2)+y)H2O Mg1-xAlx(OH)2(An-)x/2.mH2O+xOH(2) Therefore, the calcined hydrotalcite-like compounds can be used as potential ion exchangers/adsorbents for the removal of toxic anions from wastewaters. In this work, five hydrotalcite-like compounds containing Mg2+ and Zn2+ in different proportions as divalent cations were synthesized and characterized from a structural, textural and morphologic point of view, in order to be used as adsorbents for chromate anion removal.

2. Experimental

The hydrotalcite-like compounds were prepared by using a classic procedure: the co-precipitation method [1]. All used nitrates originated from Sigma. A solution of NaOH was slowly added to a 1 mol/L solution of zinc nitrate (Zn(NO3)2.6H2O), magnesium nitrate . (Mg(NO3)2 6H2O) and aluminum nitrate (Al(NO3)3.9H2O) in distilled water, under magnetic stirring, so that the pH was kept at a constant value under the command of a

40

Chem. Bull. "POLITEHNICA" Univ. (Timisoara)

Volume 55(69), 1, 2010

Hanna HI 991003 pH-meter. The mixing step was carried out for 1 h, at room temperature, under stirring, and then for 18 h on an oil bath at 80C, under magnetic stirring and reflux. The hydrotalcite powders were recuperated by centrifugation and washed several times with demineralized water until pH = 7. This step was followed by drying at 80C overnight. Then, the dried samples were crushed and sieved. The as-synthesized samples were denoted HTa (with the a values from 1 to 5). A part of the samples were activated in an oven, at temperatures of 500C in air, with a rate of 5C/min for 4 hours, in order to be transformed into the mixed oxide type (denoted hereafter as CHTa, with a = 1 - 5). The chemical composition of the as-synthesized products was determined using a JEOL JCXA 733 superprobe EPMA (electron probe micro analysis). The thermal analysis was performed under an inert atmosphere (nitrogen), from 20 to 500 C, with a heating rate of 5 C/min by using a TG 209 Netzsch analyzer. Powder X-ray diffraction patterns were recorded on a Bruker D8 Advance diffractometer using MoK radiation (0.70930 nm).

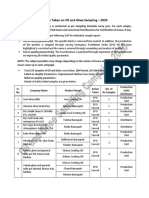

TABLE 1. Results of EPMA analysis

Sample HT1 HT2 HT3 HT4 HT5 Initial Mg/Zn/Al ratio (nitrate solutions) 2/0/1 2/1/1 1.5 / 2 / 1 1 / 2.5 / 1 0/4/1

Fourier transform infrared (FTIR) spectra were performed within the range of wavenumbers from 4000 to 400 cm-1 on a Shimadzu IRPrestige-21 FTIR spectrophotometer, with a nominal resolution of a 4 cm-1. The samples were prepared by mixing the powdered solids with KBr. Morphology was observed with a Philips XL20 scanning electron microscope. Surface areas, pore volumes and the adsorptiondesorption isotherms of the calcined samples were determined by N2 adsorption-desorption at 77 K, using the BET analysis method, with a Micromeritics ASAP 2020 instrument.

3. Results and Discussion

The cationic ratio in the as-synthesized hydrotalcite-like samples was in good agreement with the initial one, as the EPMA results showed no major changing in the final composition (Table 1).

% wt Mg 35.8 19.5 12.4 8.6 -

Elemental analysis % wt Zn 35.4 48.8 54.8 68.7

% wt Al 20.0 12.3 9.5 9.0 6.5

Final Mg/Zn/Al ratio (assynthesized samples) 1.98 / 0 / 1 1.76 / 1.19 / 1 1.45 / 2.12 / 1 1.06 / 2.52 / 1 0 / 4.37 / 1

According to TG analysis in Table 2, the samples showed the presence of the first weight loss step around 100 C corresponding to the loss of physically adsorbed water. Mass loss values corresponding to this process range from 3 to 7 %. Heating the samples at temperatures around 160 C leads to loss of interlayer water molecules, with a weight loss from 5 7 %. The weight loss at low temperatures for HT1 sample occur in a single step (92.5 C physically adsorbed water and 144.8 C interlayer water). Substitution of Mg2+ with Zn2+ cations leads to a loss of physically adsorbed and interlayer water molecules in several stages. The structure of hydrotalcites is based on substitution of divalent cations (Mg2+) with trivalent cations (Al3+), so that Mg(OH)2 . xH2O becomes Mg6Al3(OH)16CO3 . mH2O. The latter becomes MgxZnyAlz(OH)16CO3 . mH2O by Mg2+ with Zn2+ substitution. The several weight loss stages suggests that water molecules are different adsorbed on Mg-OH, Al-OH, and Zn-OH units. The main mass loss process occurs in the range of 180 380 C, when the weight losses are important, between 20 and 24 %. This weight losses are due to dehydroxylation and partial decarbonatation of the compounds. By heating the hydrotalcite-like compounds at temperatures above 380 C, the mass losses values are between 3 7 % and is due to total decarbonatation of the samples [14].

TABLE 2. TG and DTG results for the hydrotalcite-like compounds

Sample Heat flow step(C) 20 126 126 181 181 368 368 500 20 103 HT2 103 180 180 373 373 500 20 77 77 160 HT3 160 380 380 500 20 86 86 158 158 366 366 500 20 136 HT5 136 236 236 321 321 - 500 Temperature (C) 92.5 144.8 315.8 438.6 55.2 73.7 96.1 129.2 175.9 211.8 256.2 463.5 55.6 131.9 249.4 286.9 424.5 57.7 131.1 234.7 449.8 76.4 129.1 188.2 284.1 421.6 Weight loss (%) 6.75 5.41 24.11 6.88 5.69 7.20 22.34 4.00 2.82 7.31 20.66 2.93 3.31 6.51 21.88 2.71 6.55 16.21 5.14 5.43

HT1

HT4

41

Chem. Bull. "POLITEHNICA" Univ. (Timisoara)

Volume 55(69), 1, 2010

(003)

Intensity (a.u.)

(006)

(009) (102) (015) (110)(113) (116)

HT1 HT2 HT3 HT4 HT5

(018)

10

20

2 ( )

30

40

50

Figure 1. The XRD patterns of the samples

Figure 1 show the XRD patterns of the prepared hydrotalcites. The XRD patterns show that all the compounds have layered structure [7]. The peaks which correspond to basal planes (003) and (006) are present at low 2 angles. Also, the reflections (110) and (113) observed at 2 angles between 25 and 30 , are characteristic for hydrotalcite-like compounds. The difference in the intensities of the reflections from one sample to another indicates different degrees of crystallinity when the cationic composition varies. The calculation of unit cell parameters was done by the peaks indexing in the hexagonal crystal system (Table 3).

TABLE 3. The unit cell parameters for the as-synthesized samples

Sample HT1 HT2 HT3 HT4 HT5 Unit cell parameters a () c () c' () 3.04 23.64 7.88 3.02 22.83 7.61 3.02 22.95 7.65 3.02 22.65 7.55 3.08 23.68 7.79 Polytype 3R 3R 3R 3R 3R

The parameter a represents the distance between two adjacent cations (bi- or trivalent) in the layer, the parameter c is related to the total thickness of the brucite-like layer and the interlayer distance, whereas c = 3c = 3d003. The values obtained here are close to previously reported data for similar materials [15,16]. It can be noticed that the unit cell parameter a value is not influenced by the nature of divalent cations incorporated in the brucite-like layers because they do not have too different ionic radii (rMg2+ = 0.65 and rZn2+ = 0.74 ) and do not lead to distortions in

the octahedral planes. The decrease of the parameter c, therefore, the decrease of the interlayer spacing c, can be attributed to a distortion of the hydrotalcite network induced in the substitution process of magnesium by zinc [17]. The FTIR spectra of all the resultant hydrotalcite-type compounds are characteristic for this type of materials, as it shows in Figure 2. The broad and strong absorption band in the range of 3600-3200 cm-1 is due to the O-H stretching vibration of the surface and interlayer water molecules. The broad shoulder close to 3000 cm-1 has been attributed to hydrogen bounding between water and carbonate anions in the interlayer galleries. The adsorption band in the range 1650 1620 cm-1 is due to the bending vibration of the interlayer water molecules ((HOH)) [1]. The absorption bands located around 1500 cm-1, identified in the spectra of HT2, HT3, HT4 and HT5 samples, are due to the stretching vibrations (3) of carbonate anions [18]. The presence of a multiple band between 1200-1600 cm-1 and not a single intense band at 1383 cm-1 indicates that the symmetry of the carbonate anions is lowered from the planar D3h to the C2 symmetry. The lowering of the symmetry also causes the activation of the 1 mode at 1050 cm-1. Weakly resolved shoulders present between 850 820 cm-1 are attributed to bending vibrations (2) of carbonates. The band located around 783 cm-1, identified in the FTIR spectra of HT2, HT3 and HT4 samples, are due to the Al O or Zn Al O bond vibrations in the brucite-like layer [19].

42

Chem. Bull. "POLITEHNICA" Univ. (Timisoara)

Volume 55(69), 1, 2010

HT1

3093 1645 1066

HT2

3554 3512 3093 3462 3442 1363 1093 1641 1624 1516 1359 1095 3469 3078 1633 1514 1354

Transmitance (a.u.)

817 659 422 653 559 835 783

HT3

434

HT4

3522

840

783

648 468

HT5

3020 1622 3454 3385 3066 3454 1620 1502 1355 1516 1361 1431

1086

837 783

561 634

433

1065 833 669 599 426

4000

3600

3200

2800

2400

2000

-1

1600

1200

800

400

Wavenumber (cm )

Figure 2. The FTIR spectra of the hydrotalcite-like compounds

In addition, the spectra contains absorption bands at 670-620 cm-1 (4 bending vibrations of carbonate bonds), 590-560 cm-1 (may be due to stretching and bending vibrations of M O, M O M and O M O bonds) and 460 420 cm-1 (vibrations of Mg OH, Al OH and Zn OH bonds from hydrotalcite octahedral networks). The last two absorption bands are typical for brucite-like layer. The analysis of SEM micrographs (Figure 3) reveals that the prepared hydrotalcites-like compounds have good crystallinity, however the crystals are in great cohesion and have variable dimensions. Agglomerated and irregular sheets, lying on top of one another can be observed. These aspects are typical for hydrotalcites obtained by coprecipitation method at low supersaturation [20]. Figure 4 shows the N2 adsorption-desorption plots at 77 K for the calcined samples CHT1, CHT4 and CHT5. In all cases, the patterns correspond to the IV type but the hysteresis loops are different. The sample CHT1 shows the H2 type hysteresis loop while the presence of the H1 type in the Zn-containing samples is observed. Therefore, the pore shapes are different when the Zn2+ cations are introduced. In the first case, the H2 hysteresis loop is broad, the desorption branch being much steeper than the adsorption branch, associated with the interconnected pores and evidencing the mesoporous materials with a more complex morphology. In the former case the H1 hysteresis loop is relatively narrow with the adsorption and desorption branches nearly parallel, associated to compact packings of homogeneus spheres and narrow pore size distributions. The specific surface area values range is between 244 32m2/g. The values decrease systematically upon increasing the Zn2+ content in the samples.

Figure 3. The SEM images of as-synthesized samples

The hydrotalcite-like compounds with two divalent metals in the brucite-like layer have similar values for their specific surface area but substantially lower than CHT1 sample.

43

Chem. Bull. "POLITEHNICA" Univ. (Timisoara)

Volume 55(69), 1, 2010

350

CHT1

300

Adsorbed volume (cm3/g STP)

CHT4

250

200

150

100

CHT5

50

0 0 0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9 1

Relative pressure (p/p0)

Figure 4. N2 adsorption-desorption isotherms of calcined samples CHT1, CHT4 and CHT5

4. Conclusions

Five hydrotalcite-like compounds with different Mg : Zn : Al molar ratio were synthesized based on aqueous solutions of corresponding nitrates. EPMA analysis showed that, after synthesis, the molar ratio between the cations remained unchanged. According to thermal analysis, the samples showed the presence of four weight loss steps corresponding to: the loss of physically adsorbed water, the loss of interlayer water molecules, dehydroxylation and decarbonatation of compounds. The XRD analysis allowed the calculation of unit cell parameters a, c and c, respectively. With the introduction of the second divalent cation in the brucite-like network, the parameter a value has not changed significantly, however, also for the other parameters values have changed due to the deformation of the hydrotalcite network. FTIR analysis showed that in the interlayer region only carbonate is present as charge compensating anion. The vibration domains of interlayer anion, physically adsorbed water and vibrations of the specific bonds from hydrotalcite octahedral network were identified. Morphological analysis, by SEM method, revealed the formation of layered double hydroxides crystals, but also their cohesion, resulting in different particle sizes. Textural analysis was performed for the five hydrotalcite-like compounds thermaly treated at 500 C for 4 hours. The specific surface area values decreased systematically upon increasing the Zn2+ content in the samples. The hydrotalcite-like compounds with two

divalent metals in the brucite-like layer have similar values for their specific surface area but substantially lower than CHT1 sample (244 m2/g). The patterns of N2 adsorption-desorption plot correspond to the IV type but the hysteresis loops are different. The sample CHT1 shows a H2 type hysteresis loop while the presence of a H1 type in the Zn-containing samples is observed. Therefore, the pore shapes are different when Zn2+ cations are introduced. ACKNOWLEDGEMENTS Thanks are due to Conf. Geza Bandur (Politehnica University of Timisoara) for his help with DTG measurements, Prof. Ioan Lazau and Dr. Zoltan Ecsedi (Politehnica University of Timisoara) for their help with textural analyses of samples and Conf. Florica Manea (Politehnica University of Timisoara) and Dr. Aniela Pop (AQUATIM SA) for their help with SEM images.

REFERENCES

1. Cavani, F., Trifiro, F., and Vaccari, A., Catal. Today, 11, 1991, 173301. 2. Houri, B., Legrouri, A., Barroug, A., Forano, C., and Besse, J.P., Collect. Czech. Commun., 63, 1998, 732-740. 3. Lazaridis, N.K., Pandi, T.A., and Matis, K.A., Ind. Eng. Chem. Res., 43, 2004, 2209-2215. 4. Cocheci, L., Pode, R., Popovici, E., Dvininov, E., and Iovi, A., Environmental Engineering and Management Journal, 8, 2009, 865-870. 5. Delorme, F., Seron, A., Gautier, A., and Crouzet, C., J. Mater. Sci., 42, 2007, 5799-5804.

44

Chem. Bull. "POLITEHNICA" Univ. (Timisoara) 6. Yang, L., Shahrivari, Z., Liu, P.K.T., Sahimi, M., and Tsotsis, T.T., Ind. Eng. Chem. Res., 44, 2005, 6408-6815. 7. Seftel, E.M., Popovici, E., Mertens, M., De Witte, K., Van Tendeloo, G., Cool, P., and Vansant, E.F., Microporous Mesoporous Mater., 113, 2008, 296-304. 8. Pode, R., Cocheci, L, Popovici, E., Seftel, E.M., and Pode, V., Rev. Chim., 59, 2008, 898-901. 9. Shumaker, J.L., Crofcheck, C., Tackett, S.A., Santillan-Jimenez, E., and Crocker, M., Catal. Lett., 115, 2007, 56-61. 10. He, F.A., and Zhang, L.M., J. Colloid Interface Sci., 315, 2007, 439444. 11. He, F.A., and Zhang, L.M., Composites Science and Technology, 67, 2007, 3226-3232. 12. Kantam, M.L., Roy, S., Roy, M., Sreedhar, B., Choudary, B.M., and De, R.L., J. Mol. Catal. A: Chem., 273, 2007, 26-31. 13. Lv, L., He, J., Wei, M., Evans, D.G., and Duan, X., Water Res., 40, 2006, 735-743.

Volume 55(69), 1, 2010 14. Vagvolgyi, V., Palmer, S.J., Kristof, J., Frost, R.L., and Horvath, E., J. Colloid Interface Sci., 318, 2008, 302-308. 15. Vaccari, A., Catal. Today, 41, 1998, 53-71. 16. Seftel, E.M., Dvininov, E., Lutic, D., Popovici, E., and Ciocoiu, C., J. Optoelectron. Adv. M., 7, 2005, 2869-2874. 17. Carja, C., Nakamura, R., Aida, T., and Niiyama, H., Microporous Mesoporous Mater., 47, 2001, 275-284. 18. Davila, V., Lima, E., Bulbulian, S., and Bosch, P., Microporous Mesoporous Mater., 107, 2008, 240-246. 19. Prikhodko, R.V., Sychev, M.V., Astrelin, I.M., Erdmann, K., Mangel, A., and van Santen, R.A., Russ. J. Appl. Chem., 74, 2001, 1573-1577. 20. Forano, C., in: Wypych, F., and Satyanarayana, K.G. (Eds.), Clay Surfaces. Fundamentals and Applications, Elsevier Academic Press, Amsterdam, 2004, 425-458. Received: 17 March 2010 Accepted: 28 May 2010

45

Você também pode gostar

- STRS 2013 06 12 Rose KetonesDocumento4 páginasSTRS 2013 06 12 Rose KetoneschidambaramrAinda não há avaliações

- Gallotanin 1Documento17 páginasGallotanin 1chidambaramrAinda não há avaliações

- GaloreTx-Peptide Chemistry Capabilities Feb 24 2019Documento13 páginasGaloreTx-Peptide Chemistry Capabilities Feb 24 2019chidambaramrAinda não há avaliações

- An Environmentally Benign Benzylic Oxidation Catalyzed by Hypervalent Iodine Intermediate in WaterDocumento4 páginasAn Environmentally Benign Benzylic Oxidation Catalyzed by Hypervalent Iodine Intermediate in WaterchidambaramrAinda não há avaliações

- The Preparation of Secondary Aliphatic Biazo-Compounds From HydrazonesDocumento3 páginasThe Preparation of Secondary Aliphatic Biazo-Compounds From HydrazoneschidambaramrAinda não há avaliações

- Macrocyclization by Ring-Closing Metathesis in The Total Synthesis of Natural Products: Reaction Conditions and LimitationsDocumento16 páginasMacrocyclization by Ring-Closing Metathesis in The Total Synthesis of Natural Products: Reaction Conditions and LimitationschidambaramrAinda não há avaliações

- Communications To The EditorDocumento3 páginasCommunications To The EditorchidambaramrAinda não há avaliações

- Organocatalytic Asymmetric Epoxidation and Aziridination of Olefins and Their Synthetic ApplicationsDocumento58 páginasOrganocatalytic Asymmetric Epoxidation and Aziridination of Olefins and Their Synthetic ApplicationschidambaramrAinda não há avaliações

- Kon 2011Documento1 páginaKon 2011chidambaramrAinda não há avaliações

- Chapter 24Documento41 páginasChapter 24chidambaramrAinda não há avaliações

- Case Study: Base Effects in A Challenging Suzuki ReactionDocumento1 páginaCase Study: Base Effects in A Challenging Suzuki ReactionchidambaramrAinda não há avaliações

- 10 1021@cr0200116Documento22 páginas10 1021@cr0200116chidambaramrAinda não há avaliações

- MCT Oil Rev2014 Ver2 2014-03-05Documento8 páginasMCT Oil Rev2014 Ver2 2014-03-05chidambaramrAinda não há avaliações

- Case Study 4Documento2 páginasCase Study 4chidambaramrAinda não há avaliações

- Working With Hazardous Chemicals: A Publication of Reliable Methods For The Preparation of Organic CompoundsDocumento5 páginasWorking With Hazardous Chemicals: A Publication of Reliable Methods For The Preparation of Organic CompoundschidambaramrAinda não há avaliações

- U585507Documento201 páginasU585507chidambaramrAinda não há avaliações

- Natural Biotech Solutions To Flavour & Fragrance IndustryDocumento18 páginasNatural Biotech Solutions To Flavour & Fragrance IndustrychidambaramrAinda não há avaliações

- Advances in The Krapcho DecarboxylationDocumento8 páginasAdvances in The Krapcho DecarboxylationchidambaramrAinda não há avaliações

- PerfumeryDocumento14 páginasPerfumerychidambaramr100% (2)

- Working With Hazardous Chemicals: A Publication of Reliable Methods For The Preparation of Organic CompoundsDocumento4 páginasWorking With Hazardous Chemicals: A Publication of Reliable Methods For The Preparation of Organic CompoundschidambaramrAinda não há avaliações

- TBHPDocumento12 páginasTBHPchidambaramrAinda não há avaliações

- Who Says Akbar Was GreatDocumento222 páginasWho Says Akbar Was GreatArya Veer0% (1)

- Binap Synthesis SchemeDocumento2 páginasBinap Synthesis SchemechidambaramrAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Aluminium - Hull Structure in Naval ApplicationsDocumento6 páginasAluminium - Hull Structure in Naval ApplicationsStefano CostaAinda não há avaliações

- Marketing Study of Mango JuiceDocumento18 páginasMarketing Study of Mango JuiceVijay ArapathAinda não há avaliações

- Wilo Water PumpDocumento16 páginasWilo Water PumpThit SarAinda não há avaliações

- Total Elbow Arthroplasty and RehabilitationDocumento5 páginasTotal Elbow Arthroplasty and RehabilitationMarina EAinda não há avaliações

- What To Do Following A Workplace AccidentDocumento5 páginasWhat To Do Following A Workplace AccidentMona DeldarAinda não há avaliações

- Coarse DispersionsDocumento35 páginasCoarse Dispersionsraju narayana padala0% (1)

- Action Taken On Oil and Ghee Sampling - 2020Documento2 páginasAction Taken On Oil and Ghee Sampling - 2020Khalil BhattiAinda não há avaliações

- Hemostatic AgentsDocumento18 páginasHemostatic AgentshariAinda não há avaliações

- Free Higher Education Application Form 1st Semester, SY 2021-2022Documento1 páginaFree Higher Education Application Form 1st Semester, SY 2021-2022Wheng NaragAinda não há avaliações

- E-Kabin - O Series - Monoblock Enclosure - ENGDocumento12 páginasE-Kabin - O Series - Monoblock Enclosure - ENGCatalina CocoşAinda não há avaliações

- Team SportsDocumento143 páginasTeam SportsYashAinda não há avaliações

- Complement Fixation Test: Process Testing For Antigen Semi-Quantitative Testing References External LinksDocumento2 páginasComplement Fixation Test: Process Testing For Antigen Semi-Quantitative Testing References External LinksYASMINAAinda não há avaliações

- IB Final ShellDocumento25 páginasIB Final ShellsnehakopadeAinda não há avaliações

- Metallurgical Test Report: NAS Mexico SA de CV Privada Andres Guajardo No. 360 Apodaca, N.L., C.P. 66600 MexicoDocumento1 páginaMetallurgical Test Report: NAS Mexico SA de CV Privada Andres Guajardo No. 360 Apodaca, N.L., C.P. 66600 MexicoEmigdio MartinezAinda não há avaliações

- Beckhoff Service Tool - USB StickDocumento7 páginasBeckhoff Service Tool - USB StickGustavo VélizAinda não há avaliações

- RMP ContractDocumento181 páginasRMP ContractHillary AmistosoAinda não há avaliações

- Chi - Square Test: PG Students: DR Amit Gujarathi DR Naresh GillDocumento32 páginasChi - Square Test: PG Students: DR Amit Gujarathi DR Naresh GillNaresh GillAinda não há avaliações

- Intoduction To WeldingDocumento334 páginasIntoduction To WeldingAsad Bin Ala QatariAinda não há avaliações

- Resume Massage Therapist NtewDocumento2 páginasResume Massage Therapist NtewPartheebanAinda não há avaliações

- As Level Chemistry Practical Paper 3 - GCE GuideDocumento1 páginaAs Level Chemistry Practical Paper 3 - GCE GuideJamal AldaliAinda não há avaliações

- Borelog CP.101Documento1 páginaBorelog CP.101radixkusumaAinda não há avaliações

- Pressure Vessels SHO ProgrammeDocumento42 páginasPressure Vessels SHO Programmehew ka yeeAinda não há avaliações

- Payroll Solution in Single SheetDocumento818 páginasPayroll Solution in Single SheetTarique KhanAinda não há avaliações

- A Review On Bioactive Compounds of Beet Beta Vulgaris L Subsp Vulgaris With Special Emphasis On Their Beneficial Effects On Gut Microbiota and Gastrointestinal HealthDocumento13 páginasA Review On Bioactive Compounds of Beet Beta Vulgaris L Subsp Vulgaris With Special Emphasis On Their Beneficial Effects On Gut Microbiota and Gastrointestinal HealthWinda KhosasiAinda não há avaliações

- Flores V PinedaDocumento10 páginasFlores V Pinedacha chaAinda não há avaliações

- Anatomy of The SkinDocumento28 páginasAnatomy of The Skinay254Ainda não há avaliações

- Earth Loop ImpedanceDocumento5 páginasEarth Loop ImpedanceKaranjaAinda não há avaliações

- Grand Hyatt Manila In-Room Dining MenuDocumento14 páginasGrand Hyatt Manila In-Room Dining MenuMetroStaycation100% (1)

- Gay Costa Del Sol - 2010Documento2 páginasGay Costa Del Sol - 2010gayinfospainAinda não há avaliações

- Fundamental Molecular Biology: GenomesDocumento45 páginasFundamental Molecular Biology: GenomesMoonHoLeeAinda não há avaliações