Escolar Documentos

Profissional Documentos

Cultura Documentos

Attachment 1 - SOW For Port-O-Cabins

Enviado por

Zafar BakhshTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Attachment 1 - SOW For Port-O-Cabins

Enviado por

Zafar BakhshDireitos autorais:

Formatos disponíveis

SITE OFFICE

ALGHABBAN GROUP Page 1 of 8

STANDARD SPECIFICATIONS

PORTABLE BUILDINGS

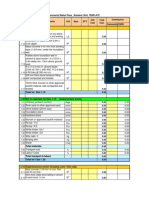

1. SCOPE Supply all supervision, labor, materials, tools, transportation, and incidentals necessary to fabricate, transport, off-load, position, and make fully operational modular porta cabin for office use as shown on the plans and according to the following requirements. The portacabin will 12 meter long by 3.75m wide and transportable over road. A oneyear warranty on all materials and workmanship will be furnished.

2. GENERAL REQUIREMENTS a. b. The portacabins will be designed to provide instant accommodation, suitable for local climatic conditions, and allow for minimum time for installation and use. All construction methods will be in conformance with accepted engineering practices to insure durable,( useable, and safe ) and will demonstrate acceptable workmanship reflecting journeyman quality of work of the various trades. The strength and rigidity of the component parts and/or the integrated structure will be determined by engineering analysis or by suitable load tests to simulate the actual loads and conditions of application that occur. The design stresses of all materials will conform to accepted engineering standards and practices. The use of materials not certified as to strength or stress grade will be limited to the minimum allowable stresses under accepted engineering standards and practices. All external portacabin utility connection features will be factory installed for connection to existing utilities at project site. All materials, devices, fixtures, fittings, equipment, appliances, appurtenances and accessories will be free from defects and will be warranted for a period of one (1) year from date of final acceptance. Prior to the use of any materials, devices, fixtures, fittings equipment, appliances, appurtenances and accessories, not meeting the following applicable requirements listed in this statement of work, being used in the fabrication, construction and installation of these portacabins, we will submit any necessary information and samples of substituted materials and workmanship.

c.

d.

e. f.

g.

GENERAL REQUIREMENTS (CONTD)

SITE OFFICE

ALGHABBAN GROUP Page 2 of 8

h.

All factory installed materials, devices, fixtures, fittings, equipment, appliances, appurtenances and accessories will be commercially and immediately available. All materials, devices, fixtures, fittings, equipment, appliances, appurtenances and accessories will be installed according to the manufacturers recommendations. We will submit a parts assembly list indicating all, devices, fixtures, fittings, equipment, appliances, appurtenances and accessories, make, model, dimensions and quantities used in the buildings. The portacabin unit will have a minimum of 4-foot wide removable metal steps with steel handrails. All steps will have a rise/run ratio of no more than 8:12. All treads will be a minimum of 12 inches. Handrails will be coated with red-oxide primer and finished with two (2) coats of oil-based light-colored enamel gloss paint to blend with portacabin exterior colors. Step assemblies will be made so that they are removable bolt on type. Treads will be fabricated of non-skid diamond studded plate metal.

i.

3. CHASSIS REQUIREMENTS All portacabin chassis and their individual chassis components will be fabricated of steel I-beams size 64x 120 mm. and will be designed using accepted engineering standards and practices. Portacabins will be crane liftable and transportable on a tractor-trailer flatbed vehicle. All steel portacabin chassis components will be coated with red-oxide primer. All assemblies will be in accordance with acceptable engineering standards. 4. FLOORING REQUIREMENTS a. b. Portacabin flooring will be a minimum of 18mm. thick plywood fixed on 40x 80 mm steel tube joists spaced at 40 cm center to center. Flooring will be fabricated of resilient vinyl tiles or sheet flooring with an overall minimum thickness of 1.6mm. All vinyl flooring will be installed as recommended by the vinyl-flooring manufacturer. All adhesives and primers will be waterresistant type and consistency recommended by the manufacturer of vinyl flooring. All vinyl flooring seams will be located at doorways perpendicular to door or at pivot points, or located along wall lines. All vinyl flooring edges at walls will be trimmed with edge molding to match color of wall finish. All vinyl flooring edges terminating at exterior doors will be trimmed with doorsill. All vinyl seams will be prepared in compliance with manufacturers recommendations and instructions. All vinyl will be matched for color and pattern along seams to provide for a seamless appearance. Exterior wall panels will be a minimum of 80mm thick, insulated with 75 mm thick rock wool and pre-painted corrugated sheet fixed over 12 mm thick plywood backing externally fixed on a 50 x 50 mm steel tube framing and 3.2 mm thick decorative wood-grain style plywood on the internal side. Interior backing will be 9 mm thick plywood over tube framing.

c.

5. WALLS / PARTITIONS REQUIREMENTS a.

SITE OFFICE

ALGHABBAN GROUP Page 3 of 8

b. c. d. e.

Interior walls will be a 40x 40 mm tube-frame drywall construction, Cover gypsum panels with 3.2 mm. decorative wood-grain style plywood. Option for interior walls: finish will be smooth textured paint over plaster board panels. External wall finish option finish will be all-weather heavy-textured paint applied on undercoat primer, plus a protective waterproof oil-based topcoat. Color of exterior walls will be as required by the client. However we stock white and beige colors. We will submit a paint color sample for clients approval before work begins.

6. WINDOW REQUIREMENTS a. Windows will be made of aluminum profile and installed according to the attached drawings and will be a minimum of 120 cm wide x 100 cm. high. b. All window sashes will be horizontal sliding. c. Window assemblies will include a 6mm thick single -pane tinted glass and 25 mm aluminum mini blinds. d. The bottom of the window opening will be between 90-100 cm above the finished floor of the portacabin. e. All windows will be installed in a manner that allows for proper operation and provides maximum protection against the elements. f. Windows will be designed using accepted engineering standards and practices to withstand regional wind loads and to minimize heat transfer. 7. ROOF REQUIREMENTS a. b. The roof will be fabricated of 26-gauge corrugated mettallic sheeting, fixed to A frame type roof trusses with neoprene-washer roof nails or screws. Roof trusses will be pre-engineered, fabricated of 40 x 40 x 4 mm steel angles double pitched no more than a 1 to 12 slope to form an A type shape and properly spaced using accepted engineering standards and practices. Ceiling will be a minimum of 8 feet in height and will be fabricated of 12mm. thick ceiling board fixed, as to prevent sagging or detachment, to bottom of roof trusses and joints sealed with battens fabricated of same material as ceiling board. Ceiling board will be finished with white light-textured paint applied to primer undercoat. Other option is 60x 60 cm exposed grid acoustical false ceiling. Please specify. Option for Roof: Metallic roof slates, textured, 6 colors are available.

c.

d.

SITE OFFICE

ALGHABBAN GROUP Page 4 of 8

8. INSULATION REQUIREMENTS a. Insulation will be installed between exterior walls cavities and roof cavities to provide a minimum of an R19-value rating for walls, and ceiling.

9. DOOR REQUIREMENTS a. Portacabin doors will be aluminum doors with insulated core panels, completely water proof and pre-finished powder coated paint finish. b. All door jamb material will be weatherproof and will match door color. c. All doors will be a minimum of 90cm in width and 210 cm. in height. d. All doors will be fabricated without a vision panel. e. All doors will be installed in a manner, which allows proper operation and provides protection against the elements. Weather stripping will be provided on all exterior doors and doorjambs. f. Standard hardware for all exterior doors will be brass or aluminum keyed-knob or keyed-lever type lockset with brass or aluminum hinges. There will be three hinges installed per door and will be hinged for door to swing horizontally according to plans. All exterior doors will be installed with a hydraulic door closer. g. All exterior doors will be open outwards. 10. ELECTRICAL REQUIREMENTS a. All electrical materials, devices, appliances, fittings and other equipment will be listed or labeled and approved by a recognized testing agency and will be connected using accepted engineering standards and practices. As part of the contract proposal, and prior to award, we will provide the following: i. ii. The estimated electrical power requirement (in kilowatt and amps) per portacabin with all systems and components installed The rated capacity for the main breaker

b. Branch-circuit distribution equipment will be installed in portacabin assembly and will include over current protection rated at 125 percent of circuit load, consisting of circuit breakers, for each branch circuit. c. All distribution equipment in the portacabin assembly will be installed and have a rating suitable for the connected loads as determined by acceptable engineering standards and practices. All distribution panels will be located in an accessible location. A clear working space of at least 30 inches wide and 30 inches in front of the distribution panels will be provided, and distribution panel doors will have sufficient clearance to be extended to their full open position (at least 90 degrees). This space will extend from floor to the top of the distribution panel. Each circuit breaker within the distribution panel will be labeled for its particular load and function.

SITE OFFICE

ALGHABBAN GROUP Page 5 of 8

d. A 3 phase 4 wire cable will be needed for each portacabin. Exact length of cable will be determined upon site visit. e. All exterior equipment, or the enclosures in which it is installed will be weatherproof. f. A red Warning label will be mounted on or adjacent to all service equipment. g. Portacabin units will be pre-wired as follows; Weatherproof main circuit panel box installed on outside of portacabin with a minimum 60 amp main breaker with 8 each, 20-amp sub breakers. Main circuit panel will be rated 120/240 volt, 3-phase All lighting fixtures, switches, receptacle outlets, and any fans will be wired for 120 volts. All receptacle will be 20 amp, 125 VAC European standard. Please see the layout for location of outlets. Weatherproof A/C service disconnect installed on outside of portacabin, rated at 30 amp, 1 phase, 220- volt, 60 HZ All light fixtures in rooms will be 60x 60 cm recessed type, 110- volt, 60 Hz. While main entrance light will be 60 watt. incandescent light fixture weather proof type. Toilet lights will be special lights suitable for wet areas. h. Grounding of both electrical and non-electrical metal parts in the portacabin assembly will be through connection to a grounding bus in each portacabin assembly distribution panel. The grounding bus will be grounded through the greencolored insulated conductor in the supply cord or the feeder wiring to the service ground in the service-entrance equipment located adjacent to each portacabin assembly location. Neither the frame of the portacabin assembly nor the frame of any appliance will be connected to the neutral conductor in the portacabin assembly. i. Any metallic roof and exterior covering will be considered bonded if the metal panels overlap one another and are securely attached to the wood or metal frame parts by metallic fasteners, and if the lower panel of the metallic exterior covering is secured by metallic fasteners at a cross member of the chassis by two (2) metal straps per portacabin unit or section at opposite ends. The bonding strap material will be a minimum of 4 inches in width of material equivalent to the skin or a material of equal or better electrical conductivity. The straps will be fastened with paint-penetrating fittings (such as screws and star washers or equivalent). j. During painting or staining of the portacabins, it will be permitted to paint metal raceways (except where grounding continuity would be reduced) or the sheath of the nonmetallic cable. Some arrangement, however, will be made so that no paint will be applied to the individual wires, as the color-coding may be obliterated by the paint. k. Metal-clad and nonmetallic cables will be protected where they pass through 50 x 50 mm studs or at other studs or frames where the cable or armor would be less than

SITE OFFICE

ALGHABBAN GROUP Page 6 of 8

40 mm. from the inside or outside surface of the studs when the wall covering materials are in contact with the studs. Steel plates on each side of the cable, or a tube, with not less than No. 16 MSG wall thickness will be required to protect the cable. These plates or tubes will be securely held in place. l. Where metallic junction box or receptacle faceplates are used they will be effectively grounded. m. At least 10cm of free conductor will be left at each outlet box except where conductors are intended to loop without joints. n. When outdoors or under-chassis line-voltage wiring is exposed to moisture or physical damage, it will be protected by rigid metal conduit. The conductors will be suitable for wet locations. Electrical metallic tubing may be used when closely routed against frames, and equipment enclosures. o. All boxes, fittings, and cabinets will be securely fastened in place, and will be supported from a structural member of the portacabin, either directly or by using a substantial brace. Snap-in type boxes provided with special wall or ceiling brackets that securely fasten boxes in walls or ceilings will be permitted. p. All outlet boxes will fit closely to openings in combustible walls and ceilings, and be flush with such surfaces. q. All wall receptacles, except receptacles for air conditioners, will be 110 volt, single phase, 20 ampere with ground, 125-vac rated and have a minimum of one (1) outlets per receptacle. r. All wall receptacles and light fixtures, which are installed outdoors, in compartments accessible from the outdoors, and all outlets located in latrines, will have ground-fault circuit protection for personnel. s. One duplex outlet will be located on each wall a a minimum and at 3 meter spacing on longer walls. Location of receptacles will be submitted for your approval. t. All interior lighting fixtures will be fluorescent tube type lights and light output will be as designed using accepted engineering standards and practices for office lighting systems. u. All exterior lighting will be provided at each exterior doorway landing and will be weatherproofed. Light output will be as designed using accepted engineering standards and practices for exterior lighting systems. v. All lighting fixtures will be covered with translucent-type covers. Every electrical fixture or appliance will be accessible for inspection, service, repair, or replacement without removal of permanent construction. w. Air conditioner wall receptacles or other approved electrical power supply device will be installed within reach of each A/C unit power cord and will be energized to accommodate a 2-ton, 24,000 BTU air conditioning unit,240 volt. All air conditioner wall receptacles will accommodate the air conditioner power cord plug. Breakers for A/C units will be rated in accordance with A/C unit manufacturers specifications.

SITE OFFICE

ALGHABBAN GROUP Page 7 of 8

11. MECHANICAL REQUIREMENTS a. Air conditioning Two wall mounted split air conditioning units will be provided installed. (Max. 18000 BTU). Each air conditioning unit will be connected to air conditioner wall receptacles or other approved power-supply device.

b. Toilet Toilet will consist of following fixtures 1 each. Water closet western ( toilet seat ) 1 each . Wash Basin 1 each. Perennial Hose. 1 each. Water heater 1 set. Mirror and bathroom accessories. 1 each. Exhaust fan 1- All pressure pipes will be PVC, Class-4. 2- All drain pipes will be PVC Class 3 3- Water heaters will be 50 liters electric type. 4- Wall and floor finish will be ceramic tiles. c. Kitchen Kitchen will consist of following fixtures 1 each. Stainless steel sink, single bowl with rack ) 1 each . water mixer Grohe or equal. 1 set . Kitchen cabinets floor mounted 1 each. Kitchen cabinets wall mounted 1 set. Exhaust filter. 1 each. Exhaust fan 1234567All pressure pipes will be PVC, Class-4. All drain pipes will be PVC Class 3 Hot Waterlines will be connected to Toilets heater. Kitchen cabinets will be made of Aluminum and HD Laminate. Work top will be made of 2 cm thick natural marble. Wall finish will be water proof decorative ply wood. Floor finish will be 1.7mm tick seamless linoleum.

SITE OFFICE

ALGHABBAN GROUP Page 8 of 8

13. SPECIAL REQUIREMENTS ( optional) a. Metal sheet skirting or painted block skirting will be installed after placing the portacabin on site at the final destination and all of the electrical systems are connected. The skirting will be installed around the perimeter of the assembled portacabin units. Skirting will be coated with all-weather heavy-textured paint applied on undercoat primer, plus a protective waterproof oil-based topcoat. A 45 cm x 90 cm access door will be provided and fabricated of same material as skirting and will be placed around perimeter such that an access door is provided on each side of assembled portacabin unit in the center of each side. Access door will be hinged and a security latch assembly attached to door. Access door hardware will be fabricated of brass or aluminum.. Color of skirting walls and access doors will match exterior colors and textures of portacabin at project site. b. Mobility 14 diameter double wheel single axle for movements within the site will be provided as option. The trailer can be towed using a 4WD vehicle. Tow bar will be as per customers requirements.

14. PLANS AND MATERIAL SUBMITTAL REQUIREMENTS c. Prior to the use of any material, devices, fixtures, fittings, equipment, appliances, wiring and accessories used in the fabrication, construction and installation of these portacabin we will submit information and or samples for approval. This will include: o o o o o o Windows ..Paragraph 6 (a through f) Doors ...Paragraph 9 (a through d) Door Hardware .. ..Paragraph 9 (e and f) Air Conditioners .Paragraph 11 (section-a) Floor material . . . . . ..Paragraph 4 (section-d) Wall siding and panels .. Paragraph 11 (section-b&c)

Você também pode gostar

- Technical Submittal BunaDocumento17 páginasTechnical Submittal Bunazaid khanAinda não há avaliações

- Site Mobilization Plan Riyadh (SEVEN) Rev 01Documento26 páginasSite Mobilization Plan Riyadh (SEVEN) Rev 01RABIE EL MAGHWRY ABDELKHALEK ELGHAMRYAinda não há avaliações

- JFD 100Documento1 páginaJFD 100ecsuperalAinda não há avaliações

- Cabinet Features and Specs for Fire Hose Reel and Layflat ModelsDocumento4 páginasCabinet Features and Specs for Fire Hose Reel and Layflat Modelsmain mydriveAinda não há avaliações

- MS HoneycombDocumento3 páginasMS Honeycombmoytabura96Ainda não há avaliações

- Shoring ProcedureDocumento7 páginasShoring Procedurechebok manAinda não há avaliações

- 33 PACS Quick Build PanelsDocumento44 páginas33 PACS Quick Build PanelsOrianAinda não há avaliações

- Pulley Manufacturing ProceduresDocumento4 páginasPulley Manufacturing ProceduresVijayakumar SamyAinda não há avaliações

- Fit Up ReportDocumento41 páginasFit Up ReportFendik NewbieAinda não há avaliações

- Method Statement For Prefabrication and Erection PipingDocumento10 páginasMethod Statement For Prefabrication and Erection PipingMidhun K ChandraboseAinda não há avaliações

- Multiplex Vertical Structures Method StatementDocumento7 páginasMultiplex Vertical Structures Method StatementAdel SaqqaAinda não há avaliações

- 7T04-CS-00-PC-011 R13 Consruction Procedure For Alloy Steel PipingDocumento9 páginas7T04-CS-00-PC-011 R13 Consruction Procedure For Alloy Steel PipingMoustafa FaresAinda não há avaliações

- Afco - CV01 Series - Swing Check ValveDocumento4 páginasAfco - CV01 Series - Swing Check Valveafie pio pioAinda não há avaliações

- ITP Fencing Rev - 00 PDFDocumento3 páginasITP Fencing Rev - 00 PDFanon_987276020Ainda não há avaliações

- Work Procedure For Installation of Wall Exhaust Fan & Louver VentilationDocumento15 páginasWork Procedure For Installation of Wall Exhaust Fan & Louver VentilationJoyce Gordonio100% (1)

- Pipeline StandardDocumento50 páginasPipeline Standardsofianina05Ainda não há avaliações

- TIMAS-PR-PI-002 - Installation Procedure For Pipe SupportDocumento14 páginasTIMAS-PR-PI-002 - Installation Procedure For Pipe SupportMechanical Static WRKAinda não há avaliações

- Itp Ralgo HssDocumento5 páginasItp Ralgo Hssmark quijlvoAinda não há avaliações

- ENV-SPV-DR-B-011 Dimensional Inspection Procedure-Rev - ADocumento9 páginasENV-SPV-DR-B-011 Dimensional Inspection Procedure-Rev - AyoeyAinda não há avaliações

- Amfah Infrastructures Pvt. Ltd. ProfileDocumento18 páginasAmfah Infrastructures Pvt. Ltd. ProfileAjay Singh LucknowAinda não há avaliações

- Plumbing Method of StatementDocumento2 páginasPlumbing Method of Statementgvs rao100% (1)

- Structural Steel ErectionDocumento7 páginasStructural Steel Erectionzaki fadlAinda não há avaliações

- General Civil Work Method Statement For RoadsDocumento3 páginasGeneral Civil Work Method Statement For RoadsKaram MoatasemAinda não há avaliações

- Fire & Safety Lab and Generator Building Testing Laboratory On Modon-3-Dammam, KSADocumento7 páginasFire & Safety Lab and Generator Building Testing Laboratory On Modon-3-Dammam, KSAMiqdadAinda não há avaliações

- Raychem WPCT Heat Shrink SleevesDocumento4 páginasRaychem WPCT Heat Shrink SleevesmngAinda não há avaliações

- Method Statement For External Painting Work With Using Suspended PlatformDocumento22 páginasMethod Statement For External Painting Work With Using Suspended PlatformĐặng Quang HuyAinda não há avaliações

- Genset Concrete Pad Detail-SignedDocumento1 páginaGenset Concrete Pad Detail-SignedJOSEPH ANTHONY VINCE MOICOAinda não há avaliações

- Procedure For Installation of Steel Stair StructureDocumento6 páginasProcedure For Installation of Steel Stair StructureImamah AliAinda não há avaliações

- How To Write A Welding Procedure Specification (WPS)Documento5 páginasHow To Write A Welding Procedure Specification (WPS)Mohamed Atef100% (1)

- Standard BoQ TEMPLATE Market PlaceDocumento4 páginasStandard BoQ TEMPLATE Market PlaceAntoine YabichinoAinda não há avaliações

- Pipe Laying HDPEDocumento6 páginasPipe Laying HDPEFun TonAinda não há avaliações

- Appendix A Proforma of Method StatementDocumento6 páginasAppendix A Proforma of Method StatementSubramanian SaravananAinda não há avaliações

- 3009 - Method Statement For Administration Building Construction PDFDocumento38 páginas3009 - Method Statement For Administration Building Construction PDFNjilou LagaticAinda não há avaliações

- Clevis HangerDocumento60 páginasClevis HangerFernando RuizAinda não há avaliações

- Tac Company Profile 2012Documento33 páginasTac Company Profile 2012vista_serverAinda não há avaliações

- DSR 2013Documento472 páginasDSR 2013Anjaneyulu BodhanapuAinda não há avaliações

- Method Statement For Setting Up Anchor Bolts in Steel StructureDocumento3 páginasMethod Statement For Setting Up Anchor Bolts in Steel StructureIbrahim AlrabibAinda não há avaliações

- Chain Link Fences and Gates Part 1 - General 1.1 DescriptionDocumento5 páginasChain Link Fences and Gates Part 1 - General 1.1 Descriptionm_a_nada67% (3)

- Jacking Procedurefor Construction of Tanks NEWDocumento9 páginasJacking Procedurefor Construction of Tanks NEWVikram RangasamyAinda não há avaliações

- 17.25 Victaulic Style 489 Stainless Steel Rigid CouplingDocumento4 páginas17.25 Victaulic Style 489 Stainless Steel Rigid Couplingguita riefAinda não há avaliações

- Covering Letter-For Karanam Ind-PebDocumento13 páginasCovering Letter-For Karanam Ind-PebswapnilAinda não há avaliações

- Work Procedure Pipe SupportDocumento10 páginasWork Procedure Pipe Supportmc chesterAinda não há avaliações

- Method Statement For For Cable Tray and Conduit Installation With Risk AssesmentDocumento9 páginasMethod Statement For For Cable Tray and Conduit Installation With Risk Assesmentobasiigwe8499Ainda não há avaliações

- Method Statement For LV Cables & Wires InstallationDocumento6 páginasMethod Statement For LV Cables & Wires InstallationUmaira ZainalAinda não há avaliações

- Generator Transformer & Unit Auxiliary Transformer Installation 070903Documento18 páginasGenerator Transformer & Unit Auxiliary Transformer Installation 070903bewid100% (1)

- Calcualtion INERTIA BASESDocumento12 páginasCalcualtion INERTIA BASESJomyJose100% (1)

- 1.fabrication and Installation of Pipe SupportDocumento5 páginas1.fabrication and Installation of Pipe Supportsethu1091100% (3)

- Scope of Work for Pipeline InstallationDocumento10 páginasScope of Work for Pipeline InstallationAsongwe HansAinda não há avaliações

- Water Tightness Test Report For Water Retaining StructureDocumento2 páginasWater Tightness Test Report For Water Retaining StructureLakshithaGonapinuwalaWithanageAinda não há avaliações

- Method Statement For Carbon Steel U G Piping Fabrication ErectionDocumento28 páginasMethod Statement For Carbon Steel U G Piping Fabrication ErectionAriel Anasco100% (1)

- PIPE INSTALLATION MATERIALSDocumento29 páginasPIPE INSTALLATION MATERIALSjanithAinda não há avaliações

- Method Statement Striking FormworkDocumento3 páginasMethod Statement Striking FormworkSurya HeriwijayaAinda não há avaliações

- National Cyber Security Center Qatar Project DetailsDocumento1 páginaNational Cyber Security Center Qatar Project Detailsmohamed haniAinda não há avaliações

- C1729 Is A New ASTM Standard For Aluminum JacketingDocumento2 páginasC1729 Is A New ASTM Standard For Aluminum JacketingTushar Arekar100% (2)

- Raised Floor Works-SpecsDocumento5 páginasRaised Floor Works-SpecsdenisjayAinda não há avaliações

- Grid CeilingDocumento10 páginasGrid CeilingpurchasehydAinda não há avaliações

- Architectural SpecificationsDocumento5 páginasArchitectural SpecificationsRio Design GroupAinda não há avaliações

- AcousticDocumento10 páginasAcousticKurnianda Dian WulandariAinda não há avaliações

- 7 GypsumboardDocumento8 páginas7 GypsumboardKurnianda Dian WulandariAinda não há avaliações

- Wood Door GuideDocumento8 páginasWood Door GuidewalidAinda não há avaliações

- Lumber PricelistDocumento3 páginasLumber PricelistZafar BakhshAinda não há avaliações

- Priced List Materail ListDocumento6 páginasPriced List Materail ListZafar BakhshAinda não há avaliações

- Installation of Steel Structure FoundationsDocumento21 páginasInstallation of Steel Structure FoundationsZafar BakhshAinda não há avaliações

- TDE Loss Previention and HIP 8MAYDocumento132 páginasTDE Loss Previention and HIP 8MAYZafar BakhshAinda não há avaliações

- Maintenance BuildingDocumento6 páginasMaintenance BuildingZafar BakhshAinda não há avaliações

- Commercial 95 Warranty Rev3!11!03Documento1 páginaCommercial 95 Warranty Rev3!11!03Zafar BakhshAinda não há avaliações

- With or Without Fuse (Please Specify)Documento1 páginaWith or Without Fuse (Please Specify)Zafar BakhshAinda não há avaliações

- OPM Technical Specification SectionsDocumento535 páginasOPM Technical Specification SectionsZafar BakhshAinda não há avaliações

- Tower DrawingsDocumento26 páginasTower DrawingsZafar BakhshAinda não há avaliações

- Phenolic Bath WallsDocumento1 páginaPhenolic Bath WallsZafar BakhshAinda não há avaliações

- Ce-4100 (3 of 5)Documento1 páginaCe-4100 (3 of 5)Zafar BakhshAinda não há avaliações

- Sta00005 001Documento1 páginaSta00005 001Zafar BakhshAinda não há avaliações

- Ce-4100 (2 of 5)Documento1 páginaCe-4100 (2 of 5)Zafar BakhshAinda não há avaliações

- Ce-4100 (2 of 5)Documento1 páginaCe-4100 (2 of 5)Zafar BakhshAinda não há avaliações

- Side View Precast MoldDocumento1 páginaSide View Precast MoldZafar BakhshAinda não há avaliações

- Concrete Slab & Footing Details - Sizes, Thickness & Post DimensionsDocumento1 páginaConcrete Slab & Footing Details - Sizes, Thickness & Post DimensionsZafar BakhshAinda não há avaliações

- Ce-4102 (1 of 1)Documento1 páginaCe-4102 (1 of 1)Zafar BakhshAinda não há avaliações

- Cable TablesDocumento13 páginasCable TablesBilal AhmadAinda não há avaliações

- Supplier Registration RequirmentsDocumento1 páginaSupplier Registration RequirmentsZafar BakhshAinda não há avaliações

- UC XLPE CatalogueDocumento63 páginasUC XLPE CatalogueZafar BakhshAinda não há avaliações

- 1 - Boq of Phase-Vii Dha LHR Exten Sec U & TDocumento8 páginas1 - Boq of Phase-Vii Dha LHR Exten Sec U & TZafar BakhshAinda não há avaliações

- Alpha 6Documento14 páginasAlpha 6Zafar BakhshAinda não há avaliações

- Higher Algebra - Hall & KnightDocumento593 páginasHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Lorentz - Pvdisconnect 440 20 Manual - en PDFDocumento8 páginasLorentz - Pvdisconnect 440 20 Manual - en PDFLuis RolaAinda não há avaliações

- XC3S400 XilinxDocumento204 páginasXC3S400 XilinxpeppaAinda não há avaliações

- Over Current Protection in PV Array InstallationsDocumento12 páginasOver Current Protection in PV Array InstallationsRocco LaricchiaAinda não há avaliações

- PLC Leaflet (2013.1)Documento24 páginasPLC Leaflet (2013.1)Donald Santana BautistaAinda não há avaliações

- Appendix I - Checklist - Internal Review of Drawings - ElectricalDocumento3 páginasAppendix I - Checklist - Internal Review of Drawings - ElectricalJuan AlayoAinda não há avaliações

- Quality Assurance and Quality Control For Project Effectiveness in Construction and Management IJERTV9IS020028 PDFDocumento5 páginasQuality Assurance and Quality Control For Project Effectiveness in Construction and Management IJERTV9IS020028 PDFjamal ChekoAinda não há avaliações

- Specification For Seamless Cold-Drawn Intermediate Alloy-Steel Heat-Exchanger and Condenser TubesDocumento5 páginasSpecification For Seamless Cold-Drawn Intermediate Alloy-Steel Heat-Exchanger and Condenser Tubesmr.aghelAinda não há avaliações

- Software Quality Assurance Basics and ObjectivesDocumento23 páginasSoftware Quality Assurance Basics and Objectiveslaiba noorAinda não há avaliações

- Exploration Project Management: About GeovaleDocumento2 páginasExploration Project Management: About GeovaleEll HaKim ERdhaAinda não há avaliações

- Call 800-DIESELS (343-7357) : Natural Gas EngineDocumento10 páginasCall 800-DIESELS (343-7357) : Natural Gas EnginereycoeleAinda não há avaliações

- Ochure - Pole Type Structure2Documento16 páginasOchure - Pole Type Structure2Jayita KarAinda não há avaliações

- Communication All Cables PLC Pinout (Pinagem de Todos Os Cabos de Comunicação PLC)Documento3 páginasCommunication All Cables PLC Pinout (Pinagem de Todos Os Cabos de Comunicação PLC)Jaziel CabralAinda não há avaliações

- VDA Field Failure Analysis - Joint Quality Management in The Supply Chain - Marketing and Service PDFDocumento60 páginasVDA Field Failure Analysis - Joint Quality Management in The Supply Chain - Marketing and Service PDFserchecko1Ainda não há avaliações

- Distinguish Between Link and Channel in MultiplexingDocumento7 páginasDistinguish Between Link and Channel in MultiplexingZAINALABDEN ALNAWAAinda não há avaliações

- HTML Basics II - 2QDocumento16 páginasHTML Basics II - 2Qperlishell74Ainda não há avaliações

- BS en 148 1 (1999) - Respiratory Protective Devices PDFDocumento12 páginasBS en 148 1 (1999) - Respiratory Protective Devices PDFck19654840Ainda não há avaliações

- Understanding NIST HL7 v2 Test Tools: Focus On ONC 2015 Health IT CertificationDocumento61 páginasUnderstanding NIST HL7 v2 Test Tools: Focus On ONC 2015 Health IT CertificationSpit FireAinda não há avaliações

- Config Guide For Sap SourcingDocumento36 páginasConfig Guide For Sap SourcingJawad Ahmed Hasan50% (2)

- Gowin IPUG948EDocumento36 páginasGowin IPUG948ELuiz OliveiraAinda não há avaliações

- CSerialPort v1Documento4 páginasCSerialPort v1gabionsAinda não há avaliações

- Maintenance of GateDocumento20 páginasMaintenance of GateMyles OliverAinda não há avaliações

- Loading Guidelines Volume2Documento243 páginasLoading Guidelines Volume2AndreiCabaAinda não há avaliações

- 1448 - P 31 - Smoke Point PDFDocumento9 páginas1448 - P 31 - Smoke Point PDFSameer MandalAinda não há avaliações

- Srs Diagnosis Epb m139 Oem v2.3Documento35 páginasSrs Diagnosis Epb m139 Oem v2.3thierry42Ainda não há avaliações

- GeForce7150/7100/7050 User ManualDocumento15 páginasGeForce7150/7100/7050 User Manualcr33pz1llaAinda não há avaliações

- About KotsonsDocumento31 páginasAbout KotsonsVinayak GargAinda não há avaliações

- ALV Programming GuideDocumento45 páginasALV Programming GuideBipin ShuklaAinda não há avaliações

- KPBR Regularization OrderDocumento46 páginasKPBR Regularization Ordersooji456Ainda não há avaliações

- Code of Conduct - Hellofresh: Core Values and Corporate CultureDocumento6 páginasCode of Conduct - Hellofresh: Core Values and Corporate CultureMadi100% (1)

- KP-00+++-CQ712-G0011 - Rev.A - ITP For For Cathodic Protection (CP)Documento7 páginasKP-00+++-CQ712-G0011 - Rev.A - ITP For For Cathodic Protection (CP)Utku Can Kılıç100% (2)