Escolar Documentos

Profissional Documentos

Cultura Documentos

Dust Suppression Sys - Coal Wagon Unloading

Enviado por

Akshay KadbeTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Dust Suppression Sys - Coal Wagon Unloading

Enviado por

Akshay KadbeDireitos autorais:

Formatos disponíveis

PROJECT: xxxxx ltd. Doc.No.

Dt:

Ultratech Cement, MTPA Cement Plant Penta Project Coal Handling System (Specification for Dust Suppression system at Coal unloading hopper) Description Bidder's information Company name Contact person Telephone number Fax number Email Proposal number Revision General Plant Conditions Temperature Maximum Minimum Altitude Units

Revision 0 Date Approved by

Required

Vendor's Proposal

Text Text Text Text Text Text Text

C C m above MSL mm % Zone-II (as per IS :1893 part 1 2002) m/s As per IS:875 (part III) 1987

Rainfall (Annual) Relative humidity Seismic Zone Wind (at ground level) Bidder's scope of Supply Water tank Pump Electric motor Pipes incl. fittings

yes/no yes/no yes/no yes/no

Operating Conditions Wagon Capacity Type of Wagon Wagon overall Dimension in

Tons Text LxWxH

~60 BOX-NEW 3.273 x 3.25 x 10.6

1 of 4

PROJECT: xxxxx ltd. Doc.No. Dt:

meters Size of Tippler hopper Discharge time for Tippler Railway gauge Angle of tip/rotation Tipping Capacity Operating Material Flow rate Material Properties Material Size Bulk Density Volume Power Moisture Angle of repose Abrasiveness Dust suppression system consist of Water Tank Type Capacity / Volume Ball valve Size Solenoid valve size Float valve size Pumps Incl. mounting skid, inlet and outlet fittings, NRV Discharge @ 9 kg pressure Delivery Head Electric motor kW / rpm (Incl. control panel + on / off start / provision for earth leakage + dry run protection + overload relay. Pressure gauge for online sit pressure calibration > 10 bar Safety relief valve With 1 end connection @ 15 bar pressure Y strainer end connection MOC-MS with SS 250 mesh cleanable filter insert

LxWxH Seconds MM DEG tips/Hr TPH Text mm T/m3 T/m3 % deg Text

14 x 6 X 4.3 44 1676 (Broad Gauge) 150 ~24 1500 Coal

0.75 0.85 10-12 38 Moderate

SINTEX / RCC m3 mm mm mm

Vendor to specify Vendor to specify Vendor to specify Vendor to specify Vendor to specify

LPM LPM m

Vendor to specify Vendor to specify Vendor to specify Vendor to specify

Vendor to specify Vendor to specify Vendor to specify Vendor to specify mm Vendor to specify Vendor to specify

2 of 4

PROJECT: xxxxx ltd. Doc.No. Dt:

Sprinkler Incl. pipe , fitting , valve & supports Guards Provided by Vendor Code used for design (e.g., OSHA, MSHA) Removal method (e.g., bolted) Locations Other Pipes included Fittings included Supports included Recommended spare parts Special tools Vendor to test operation of installed equipment INSTRUMENTATION AND CONTROLS General Information Power supply Voltage / Frequency / Phases Load Control Voltage Voltage / Frequency / Phases

Vendor to specify yes/no Text Text Text yes

yes/no yes/no yes/no yes/no yes/no yes/no

yes yes yes yes yes yes

volts/Hz/P h KVA volts/Hz/P h yes/no

415 VAC 10% 50 Hz 2% / 3

240; 50 Hz; 1 phase VAC for MCC and 24 VDC for PLC control yes

All control voltages internally derived with suitable isolated 100% redundant control transformers Signal types Discrete Type Rating Analog CONTROL SYSTEM - PLC Provided by Vendor Software Provided by Vendor Weights

Type mA yes/no yes/no

Dry contact 240 VAC / 5 Amps. 4-20 Yes Yes

3 of 4

PROJECT: xxxxx ltd. Doc.No. Dt:

Water tank Pump (including electric motor) Miscellaneous Total weight of System

ton ton ton Ton

4 of 4

Você também pode gostar

- Maintenance in Cement PlantsDocumento11 páginasMaintenance in Cement PlantsAkshay Kadbe100% (1)

- Waste Heat RecoveryDocumento6 páginasWaste Heat RecoveryAkshay KadbeAinda não há avaliações

- Weld Setup July2012 HAZDocumento4 páginasWeld Setup July2012 HAZAkshay Kadbe100% (1)

- Is 808-1989 Steel TableDocumento24 páginasIs 808-1989 Steel TableAtul Kumar Engineer86% (28)

- Welding ElectrodeDocumento7 páginasWelding ElectrodeAkshay KadbeAinda não há avaliações

- Bag Filter Bag Matl For CoalDocumento10 páginasBag Filter Bag Matl For CoalAkshay KadbeAinda não há avaliações

- Tata Steel PipeDocumento36 páginasTata Steel PipeAkshay KadbeAinda não há avaliações

- Tax Saving On Medical ReibursementDocumento8 páginasTax Saving On Medical ReibursementAkshay KadbeAinda não há avaliações

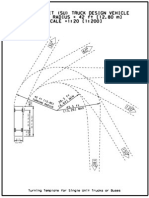

- Truck RadiusDocumento1 páginaTruck RadiusAkshay KadbeAinda não há avaliações

- TSR 117Documento16 páginasTSR 117Karthick VelayuthamAinda não há avaliações

- Kalina Cycle For WHRSDocumento7 páginasKalina Cycle For WHRSAkshay KadbeAinda não há avaliações

- Manually Operated Diversion Plough ADocumento1 páginaManually Operated Diversion Plough AAkshay KadbeAinda não há avaliações

- HardnessDocumento16 páginasHardnessAkshay Kadbe0% (1)

- Local Exhaust VentilationDocumento26 páginasLocal Exhaust Ventilationmirali74100% (1)

- Bag Filter Bag Matl For CoalDocumento10 páginasBag Filter Bag Matl For CoalAkshay KadbeAinda não há avaliações

- Design of Inert Gas SystemsDocumento6 páginasDesign of Inert Gas SystemsAkshay KadbeAinda não há avaliações

- Encyclopedia of Dust CollectorDocumento28 páginasEncyclopedia of Dust CollectorAkshay KadbeAinda não há avaliações

- Electrically Operated Diversion PloughDocumento1 páginaElectrically Operated Diversion PloughAkshay KadbeAinda não há avaliações

- Jet Pulse FilterDocumento12 páginasJet Pulse FilterAkshay KadbeAinda não há avaliações

- Loss in Weight FeederDocumento27 páginasLoss in Weight FeederAkshay KadbeAinda não há avaliações

- Tech Spec E6010Documento1 páginaTech Spec E6010Akshay KadbeAinda não há avaliações

- Kiln ErectionDocumento13 páginasKiln ErectionAkshay Kadbe67% (3)

- Loss in Weight FeederDocumento27 páginasLoss in Weight FeederAkshay KadbeAinda não há avaliações

- Dimensions of Anchor Bolts, U BoltsDocumento1 páginaDimensions of Anchor Bolts, U Boltsakhilr141Ainda não há avaliações

- Banking General AwarenessDocumento6 páginasBanking General AwarenessAkshay KadbeAinda não há avaliações

- Acad Mech UserguideDocumento426 páginasAcad Mech UserguideRajiv RamanathanAinda não há avaliações

- Book1 Chap1Documento45 páginasBook1 Chap1Akshay KadbeAinda não há avaliações

- SKS Engineers Delhi BrochureDocumento2 páginasSKS Engineers Delhi BrochureAkshay KadbeAinda não há avaliações

- Data Sheet Metal Detectors MS08-85 SQTADocumento2 páginasData Sheet Metal Detectors MS08-85 SQTAAkshay KadbeAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Light Duty Commercial Electric Water Heaters: Junior, Tall & Short Models - 6 To 120 GallonsDocumento2 páginasLight Duty Commercial Electric Water Heaters: Junior, Tall & Short Models - 6 To 120 GallonssasikalaAinda não há avaliações

- Frequently Asked Questions: Your Solar PV and Electronic MeterDocumento4 páginasFrequently Asked Questions: Your Solar PV and Electronic Metererkamlakar2234Ainda não há avaliações

- Conference ProceedingsDocumento176 páginasConference ProceedingsNanasaheb PatilAinda não há avaliações

- Earthing System - Wikipedia, The Free EncyclopediaDocumento7 páginasEarthing System - Wikipedia, The Free EncyclopediaSharaf Ali ZyoudAinda não há avaliações

- How To Rebuild Your Small-Block Ford - 0912656891Documento163 páginasHow To Rebuild Your Small-Block Ford - 0912656891Linda Porter100% (4)

- First Private Sector High Voltage DC Transmission Line Matyari - LahoreDocumento2 páginasFirst Private Sector High Voltage DC Transmission Line Matyari - LahoreAdeelAinda não há avaliações

- YC4F Euro II - EnglishDocumento71 páginasYC4F Euro II - EnglishJavier Amorin100% (4)

- Technology Roadmap Delivering Sustainable BioenergyDocumento94 páginasTechnology Roadmap Delivering Sustainable BioenergyAndres Felipe TorresAinda não há avaliações

- The Global Solar Radiation Estimation and Analysis of Solar Energy Case Study For Osmaniye TurkeyDocumento10 páginasThe Global Solar Radiation Estimation and Analysis of Solar Energy Case Study For Osmaniye TurkeyAnonymous PufNjgAinda não há avaliações

- Double Break Centre Rotating Isolator, Mumbai, IndiaDocumento3 páginasDouble Break Centre Rotating Isolator, Mumbai, IndiajigyeshAinda não há avaliações

- Mass BalanceDocumento5 páginasMass BalanceSidharth RazdanAinda não há avaliações

- D C Motors: Irect UrrentDocumento32 páginasD C Motors: Irect UrrentNeelam Prabhu-GaunkarAinda não há avaliações

- 3-Phase Transformer Report 2Documento17 páginas3-Phase Transformer Report 2nguyentai325100% (1)

- Energy Resources MCQs GuideDocumento11 páginasEnergy Resources MCQs GuideSyed Mueed AliAinda não há avaliações

- Fuel CellsDocumento16 páginasFuel Cellspramod gaikwadAinda não há avaliações

- 03 HAL-2011 Steering Tools FDocumento10 páginas03 HAL-2011 Steering Tools FMiftahul Riski NasutionAinda não há avaliações

- Levelized Cost of HydrogenDocumento14 páginasLevelized Cost of Hydrogennourhen rjabAinda não há avaliações

- Rajasthan SKAY Guidelines for Land Leasing Under PM-KUSUM CDocumento11 páginasRajasthan SKAY Guidelines for Land Leasing Under PM-KUSUM CAbhimanyaAinda não há avaliações

- Daikinskyairgar 22Documento2 páginasDaikinskyairgar 22adehakAinda não há avaliações

- Apv - Evaporator HandbookDocumento68 páginasApv - Evaporator HandbookJosiane CostaAinda não há avaliações

- Hydra FuelDocumento2 páginasHydra FuelRazvan PredaAinda não há avaliações

- Manejadora Ducto YMSFDocumento4 páginasManejadora Ducto YMSFjuanAinda não há avaliações

- Helping You To Understand Your British Gas StatementDocumento2 páginasHelping You To Understand Your British Gas StatementMujtaba AliAinda não há avaliações

- A New Generalized Discontinuous PWM For Current Source Space Vector InverterDocumento11 páginasA New Generalized Discontinuous PWM For Current Source Space Vector InverterAnonymous WDbkjMOuAinda não há avaliações

- Systems: Lubrication & Filtration, Turbine FoundationsDocumento52 páginasSystems: Lubrication & Filtration, Turbine FoundationsSuriya KJAinda não há avaliações

- Briggs 15,5hp - Motor 31A600 PDFDocumento10 páginasBriggs 15,5hp - Motor 31A600 PDFnarciso84traninAinda não há avaliações

- Test Yourself C - BT MLH 12 - KeyDocumento4 páginasTest Yourself C - BT MLH 12 - KeyThao NguyenAinda não há avaliações

- Conservation of Energy Without Friction MC Questions PDFDocumento6 páginasConservation of Energy Without Friction MC Questions PDFLynn Hollenbeck BreindelAinda não há avaliações

- 0-28V 6-8A Power Supply (LM317, 2N3055)Documento4 páginas0-28V 6-8A Power Supply (LM317, 2N3055)Curta AlinAinda não há avaliações

- Waste Management: Hamid R. Amini, Debra R. ReinhartDocumento7 páginasWaste Management: Hamid R. Amini, Debra R. ReinhartUnknownAinda não há avaliações