Escolar Documentos

Profissional Documentos

Cultura Documentos

1040 Method Development and Evaluation

Enviado por

Raposo IreneDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

1040 Method Development and Evaluation

Enviado por

Raposo IreneDireitos autorais:

Formatos disponíveis

1-22

INTRODUCTION (1000)

A more complete exposition3 of the above quality-control checks has been published.

7. References

1. ROSSUM, J.R. 1975. Checking the accuracy of water analyses through the use of conductivity. J. Amer. Water Works Assoc. 67:204.

2. FRIEDMAN, L.C. & D.E. ERDMANN. 1982. Quality Assurance Practices for Analyses of Water and Fluvial Sediments. Tech. Water Resources Inc., Book 5, Chapter A6. U.S. Government Printing Off., Washington, D.C. 3. OPPENHEIMER, J. & A.D. EATON. 1986. Quality control and mineral analysis. In Proc. Water Quality Technology Conference (Houston, Texas, December 8-11, 1985). American Water Works Assoc., Denver, Colo.

1040 METHOD DEVELOPMENT AND EVALUATION

1040 A. Introduction

Although standard methods are available from many nationally recognized sources, there may be occasions when they cannot be used or when no standard method exists for a particular constituent or characteristic. Therefore, method development may be required. Method development is the set of experimental procedures devised for measuring a known amount of a constituent in various matrices, in the case of chemical analyses; or a known characteristic (e.g., biological or toxicological) of various matrices.

1040 B. Method Validation

Whether an entirely new method is developed by accepted research procedures or an existing method is modied to meet special requirements, validation by a three-step process is required: determination of single-operator precision and bias, analysis of independently prepared unknown samples, and determination of method ruggedness.

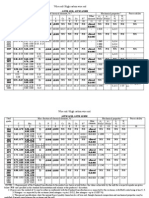

TABLE 1040:I. PRECISION AND BIAS FOR A SINGLE CONCENTRATION IN A SINGLE MATRIX Result mg/L 1.23 1.21 1.30 1.59 1.57 1.21 1.53 1.25 Sum Difference (1.30) 0.07 0.09 0.0 0.29 0.27 0.09 0.23 0.05 0.49 Squared Difference 0.0049 0.0081 0.0 0.0841 0.0729 0.0081 0.0529 0.0025 0.2335

1. Single-Operator Characteristics

This part of the validation procedure requires determining the method detection level (MDL) as in Section 1030; the bias of the method, i.e., the systematic error of the method; and the precision obtainable by a single operator, i.e., the random error introduced in using the method. To make these determinations, analyze at least 7 but preferably 10 or more portions of a standard at each of several concentrations in each matrix that may be used. Use one concentration at, or slightly above, the MDL and one relatively high so that the range of concentrations for which the method is applicable can be specied. The use of several concentrations to determine bias and precision will reveal the form of the relationship between these method characteristics and the concentration of the substance, the characteristic toxicity of the substance, or the biological factor of interest. This relationship may be constant, linear, or curvilinear and is a signicant characteristic of the method that should be explained clearly. Table 1040:I shows calculation of precision and bias for a single concentration in a single matrix from eight replicate analyses of a standard with a known concentration of 1.30 mg/L.

The bias is 0.49/8 0.06 mg/L and the precision is the square root of 0.2335/(81) 0.03336, or 0.18 mg/L (note that this is similar to the calculation for standard deviation).

2. Analysis of Unknown Samples

This step in the method validation procedure requires analysis of independently prepared standards where the value is unknown to the analyst. Analyze each unknown in replicate by following the standard operating procedure for the method. The mean amount recovered should be within three standard deviations (s) of the mean value of the standard but preferably within 2 s. Obtain the unknowns from other personnel in the analysts laboratory using either purchased analytical-grade reagents or

METHOD DEVELOPMENT AND EVALUATION (1040)/Method Validation

1-23

standards available from National Institute of Standards and Technology (NIST). If available for the particular constituent, performance evaluation samples from EPA-Cincinnati are particularly useful.

3. Method Ruggedness

A or a B or b C or c D or d E or e F or f G or g Result

TABLE 1040:III. FACTOR MATRIX FOR METHOD RUGGEDNESS DETERMINATION Combinations Factor value 1 A B C D E F G s 2 A B c D e f g t 3 A b C d E f g u 4 A b c d e F G v 5 a B C d e F g w 6 a B c d E f G x 7 a b C D e f G y 8 a b c D E F g z

A test of the ruggedness, i.e., stability of the result produced when steps in the method are varied, is the nal validation step. It is especially important to determine this characteristic of a method if it is to be proposed as a standard or reference method. A properly conducted ruggedness test will point out those procedural steps in which rigor is critical and those in which some leeway is permissible. The Association of Ofcial Analytical Chemists1 has suggested a method for this test in which eight separate analyses can be used to determine the effect of varying seven different steps in an analytical procedure. To illustrate, suppose the effect of changing the factors in Table 1040:II is to be determined. To make the determination, denote the nominal factors by capital letters A through G and the variations by the corresponding lower-case letters. Then set up a table of the factors as in Table 1040:III. If combination 1 is analyzed, the result will be s. If combination 2 is analyzed, the result will be t, and so on until all eight combinations have been analyzed. To determine the effect of varying a factor, nd the four results where the factor was nominal (all caps) and the four where it was varied (all lower case) and compare the averages of the two groups. For example, to compare the effect of changing C to c, use results (s u w y)/4 and (t v x z)/4. Calculate all seven pairs to get seven differences, which can then be ranked to reveal those with a signicant effect on the results. If there is no outstanding difference, calculate the average and standard deviation of the eight results s through z. The standard deviation is a realistic estimate of the precision of the method. This design tests main effects, not interactions.

4. Equivalency Testing

Source: YOUDEN, W. J. & E. H. STEINER. 1975. Statistical Manual of AOAC. Assoc. Ofcial Analytical Chemists, Washington, D.C.

a minimum of three concentrations by the alternate and by the standard method. If the range of concentration is very broad, test more concentrations. Once an initial set of analyses (ve or more) has been made at each chosen concentration, apply the following statistical steps:2 1. Test the distribution of data for normality and transform the data if necessary (Section 1010B). 2. Select an appropriate sample size based on an estimate of the standard deviation.3 3. Test the variances of the two methods using the F-ratio statistic. 4. Test the average values of the two methods using a Student-t statistic. An explanation of each of these steps with additional techniques and examples has been published.4 Because the number of analyses can be very large, the calculations become complex and familiarity with basic statistics is necessary. A listing of standard, reference, and equivalent methods for water analysis is available.5

5. References

1. YOUDEN, W.J. & E.H. STEINER. 1975. Statistical Manual of AOAC. Assoc. Ofcial Analytical Chemists, Washington, D.C. 2. WILLIAMS, L.R. 1985. Harmonization of Biological Testing Methodology: A Performance Based Approach in Aquatic Toxicology and Hazard Assessment. 8th Symp. ASTM STP 891, R.C. Bahner & D.J. Hansen, eds. American Soc. Testing & Materials, Philadelphia, Pa. 3. NATRELLA, M.G. 1963. Experimental Statistics. National Bureau of Standards Handbook 91, Washington, D.C. 4. U.S. ENVIRONMENTAL PROTECTION AGENCY. 1983. Guidelines for Establishing Method Equivalency to Standard Methods. Rep. 600/X83-037, Environmental Monitoring Systems Lab., Las Vegas, Nev. 5. U.S. ENVIRONMENTAL PROTECTION AGENCY. 1994. Guidelines establishing test procedures for the analysis of pollutants under the Clean Water Act. Final rule. 40 CFR Part 136; Federal Register 59:20: 4504.

After a new method has been validated by the procedures listed above, it may be prudent to test the method for equivalency to standard methods, unless none exist. This requires analysis of

TABLE 1040:II. VARIATIONS IN FACTORS FOR METHOD RUGGEDNESS DETERMINATION Factor Mixing time Portion size Acid concentration Heat to Hold heat for Stirring pH adjust Nominal 10 min 5g 1M 100C 5 min yes 6.0 Variation 12 min 10 g 1.1M 95C 10 min no 6.5

1-24

INTRODUCTION (1000)

1040 C. Collaborative Testing

Once a new or modied method has been developed and validated it is appropriate to determine whether the method should be made a standard method. The procedure to convert a method to standard status is the collaborative test.1 In this test, different laboratories use the standard operating procedure to analyze a select number of samples to determine the methods bias and precision as would occur in normal practice. In planning for a collaborative test, consider the following factors: a precisely written standard operating procedure, the number of variables to be tested, the number of levels to be tested, and the number of replicates required. Because method precision is estimated by the standard deviation, which itself is the result of many sources of variation, the variables that affect it must be tested. These may include the laboratory, operator, apparatus, and concentration range.

1. Variables

and the number of replicates is

r 1 (30/18) 2.7 or r 3.

3. Illustrative Collaborative Test

Test at least the following variables: LaboratoryInvolve at least three different laboratories, although more are desirable to provide a better estimate of the standard deviation; ApparatusBecause model and manufacturer differences can be sources of error, analyze at least two replicates of each concentration per laboratory; OperatorsTo determine overall precision, involve at least six analysts with not more than two from each laboratory; LevelsIf the method development has indicated that the relative standard deviation is constant, test three levels covering the range of the method. If it is not constant, use more levels spread uniformly over the operating range. If matrix effects are suspected, conduct the test in each medium for which the method was developed. If this is not feasible, use appropriate grades of reagent water as long as this is stipulated in the resulting statement of method characteristics.

2. Number of Replicates

Send each of ve laboratories four concentrations of a compound (4.3, 11.6, 23.4, and 32.7 mg/L) with instructions to analyze in triplicate using the procedure provided. Tabulate results as shown in Table 1040:IV below (the results for only one concentration are shown). Because there are no obviously aberrant values (use the method in Section 1010B to reject outliers), use all the data. Calculate the average and standard deviation for each laboratory; use all 15 results to calculate a grand average and standard deviation. The difference between the average of each laboratory and the grand average reveals any signicant bias, such as that shown for Laboratories 1 and 3. The difference between the grand average and the known value is the method bias, e.g., 33.0 32.7 0.3 mg/L or 0.9%. The relative standard deviation of the grand average (1.5 mg/L) is 4.5%, which is the method precision, and the s for each laboratory is the single-operator precision. As noted in Table 1040:IV, the sum of the deviations from the known value for the laboratories was 1.3, so the average deviation (bias) was 1.3/5 0.26, rounded to 0.3, which is the same as the difference between the grand average and the known value. For all four unknowns in this test, the percentage results indicated increasing bias and decreasing precision as the concentration decreased. Therefore, to describe the method in a formal statement, the precision would be given by a straight line with the formula y mx b; where y is the relative standard deviation, m is the slope of the line, x is the concentration, and b is the relative standard deviation

TABLE 1040:IV. SAMPLE COLLABORATIVE TEST RESULTS Deviation Laboratory 1 Result mg/L 32.7 35.2 36.3 32.6 33.7 33.6 30.6 30.6 32.4 32.6 32.5 33.9 32.4 33.4 32.9 (x)/n 33 s 1.5 Experimental xs 34.71.8 33.30.6 31.21.0 33.00.8 32.60.8 From Known 2.0 From Grand Average 1.7

Calculate the number of replicates after the number of variables to be tested has been determined by using the formula:

r 1 (30/P )

0.6 1.5 0.3 0.1 1.3

0.3 1.8 0 0.4 0.2

where:

r number of replicates and P the product of several variables. 4

The minimum number of replicates is two. As an example, if three levels of a substance are to be analyzed by single operators in six laboratories on a single apparatus, then P is calculated as follows:

P 3 1 6 1 18

EXPRESSION OF RESULTS (1050)/Units

1-25

AND

TABLE 1040:V. METHOD PRECISION Known Amount mg/L 4.3 11.6 23.4 32.7 Amount Found mg/L 4.8 12.2 23.8 33

BIAS Bias % 11.5 5.6 1.9 0.9

CV (% Standard Deviation) 12.5 10.2 5.4 4.5

at concentration 0. The values found from the collaborative test are shown in Table 1040:V. These results indicate that the method is acceptable. However, concentrations of less than about 10 mg/L require greater care in analysis.

4. Reference

1. YOUDEN, W.J. & E.H. STEINER. 1975. Statistical Manual of the AOAC. Assoc. Ofcial Analytical Chemists, Washington, D.C.

1050 EXPRESSION OF RESULTS

1050 A. Units

This text uses the International System of Units (SI) and chemical and physical results are expressed in milligrams per liter (mg/L). See Section 7020D for expression of radioactivity results. Record only the signicant gures. If concentrations generally are less than 1 mg/L, it may be more convenient to express results in micrograms per liter (g/L). Use g/L when concentrations are less than 0.1 mg/L. Express concentrations greater than 10 000 mg/L in percent, 1% being equal to 10 000 mg/L when the specic gravity is 1.00. In solid samples and liquid wastes of high specic gravity, make a correction if the results are expressed as parts per million (ppm) or percent by weight:

ppm by weight mg/L sp gr

% by weight

mg/L 10 000 sp gr

In such cases, if the result is given as milligrams per liter, state specic gravity. The unit equivalents per million (epm), or the identical and less ambiguous term milligram-equivalents per liter, or milliequivalents per liter (me/L), can be valuable for making water

TABLE 1050:I. CONVERSION FACTORS* (Milligrams per LiterMilliequivalents per Liter) Ion (Cation) Al B3 Ba2 Ca2 Cr3 Cu2 Fe2 Fe3 H K Li Mg2 Mn2 Mn4 Na NH4 Pb2 Sr2 Zn2

3

me/L mg/L 0.111 0.277 0.014 0.049 0.057 0.031 0.035 0.053 0.992 0.025 0.144 0.082 0.036 0.072 0.043 0.055 0.009 0.022 0.030 2 5 56 90 70 47 81 72 1 58 1 29 40 81 50 44 653 83 59

mg/L me/L 8.994 3.604 68.66 20.04 17.33 31.77 27.92 18.62 1.008 39.10 6.941 12.15 27.47 13.73 22.99 18.04 103.6 43.81 32.70

Ion (Anion) BO2 Br Cl CO32 CrO42 F HCO3 HPO42 H2PO4 HS HSO3 HSO4 I NO2 NO3 OH PO43 S2 SiO32 SO32 SO42

me/L mg/L 0.023 0.012 0.028 0.033 0.017 0.052 0.016 0.020 0.010 0.030 0.012 0.010 0.007 0.021 0.016 0.058 0.031 0.062 0.026 0.024 0.020 36 52 21 33 24 64 39 84 31 24 33 30 880 74 13 80 59 37 29 98 82

mg/L me/L 42.81 79.90 35.45 30.00 58.00 19.00 61.02 47.99 96.99 33.07 81.07 97.07 126.9 46.01 62.00 17.01 31.66 16.03 38.04 40.03 48.03

* Factors are based on ion charge and not on redox reactions that may be possible for certain of these ions. Cations and anions are listed separately in alphabetical order.

Você também pode gostar

- Method Validation NotesDocumento15 páginasMethod Validation NotesRamling PatrakarAinda não há avaliações

- Metrology and Calibration in GLPDocumento30 páginasMetrology and Calibration in GLPNicolas Quero Carvajal100% (1)

- Sop For Biorad PCRDocumento3 páginasSop For Biorad PCRMichael OkekeAinda não há avaliações

- Nci PBCF HTB22 - MCF7 - Sop 508 PDFDocumento26 páginasNci PBCF HTB22 - MCF7 - Sop 508 PDFmumu4loveAinda não há avaliações

- Biosimilar Guidelines India 2016Documento53 páginasBiosimilar Guidelines India 2016Kush MukherjiAinda não há avaliações

- QM - FDA - Request For Quality MetricsDocumento31 páginasQM - FDA - Request For Quality Metricspchakravarty_2Ainda não há avaliações

- HPLC SOP Guide for Garner LabDocumento5 páginasHPLC SOP Guide for Garner LabQuoc BinhAinda não há avaliações

- Buffy Coat & Plasma Collection. Serum CollectionDocumento8 páginasBuffy Coat & Plasma Collection. Serum Collectionduhita_aninditaAinda não há avaliações

- Agilent 1100 Capillary LC System ManualDocumento196 páginasAgilent 1100 Capillary LC System ManualstflockAinda não há avaliações

- Biological Assay in Quality ControlDocumento34 páginasBiological Assay in Quality ControlDilawar KhanAinda não há avaliações

- The Role of Microbiology in The Design and Development of Pharmaceutical Manufacturing ProcessesDocumento4 páginasThe Role of Microbiology in The Design and Development of Pharmaceutical Manufacturing ProcessesHari RamAinda não há avaliações

- Nabl 102 PDFDocumento74 páginasNabl 102 PDFRajat JainAinda não há avaliações

- QBD Approach To Analytical Method PDFDocumento21 páginasQBD Approach To Analytical Method PDFAsti Destilia SafrudinAinda não há avaliações

- SOP Pipettes AESOP13640-08 052013 en Online PDFDocumento0 páginaSOP Pipettes AESOP13640-08 052013 en Online PDFPutriErvinaAinda não há avaliações

- American National Standard For Filters Used inDocumento14 páginasAmerican National Standard For Filters Used inBaskara PrabawaAinda não há avaliações

- Design Qualification Protocol FOR Static Passbox (MODEL NO.: AJE/SPB/2DS/01)Documento10 páginasDesign Qualification Protocol FOR Static Passbox (MODEL NO.: AJE/SPB/2DS/01)Druva MAinda não há avaliações

- Not For: Biosafety Cabinetry: Design, Construction, Performance, and Field CertificationDocumento47 páginasNot For: Biosafety Cabinetry: Design, Construction, Performance, and Field CertificationDinda Sukmaningrum MahardhikaAinda não há avaliações

- G OwningDocumento6 páginasG Owningk.p.100% (1)

- Difference Between Calibration, Testing and Validation: Accuracy, Precision, Resolution & SensitivityDocumento27 páginasDifference Between Calibration, Testing and Validation: Accuracy, Precision, Resolution & SensitivityAmit NainAinda não há avaliações

- Analytical Procedures and Methods Validation For Drugs and Biologics - US FDA Final GuidanceDocumento18 páginasAnalytical Procedures and Methods Validation For Drugs and Biologics - US FDA Final GuidanceDan StantonAinda não há avaliações

- 41 (1) In-Process Revision - 1790 - Visual Inspection of InjectionsDocumento10 páginas41 (1) In-Process Revision - 1790 - Visual Inspection of InjectionsBudy WijiyantoAinda não há avaliações

- Not For Sale: Biosafety Cabinetry: Design, Construction, Performance, and Field CertificationDocumento24 páginasNot For Sale: Biosafety Cabinetry: Design, Construction, Performance, and Field CertificationEmiAinda não há avaliações

- A History of The OOS ProblemDocumento5 páginasA History of The OOS ProblemmcyqcbsacAinda não há avaliações

- AGIT Guidelines Development Validation Spreadsheets EN PDFDocumento21 páginasAGIT Guidelines Development Validation Spreadsheets EN PDFASHOK KUMAR LENKAAinda não há avaliações

- Cost Saving Tips For The HPLC UserDocumento2 páginasCost Saving Tips For The HPLC UserKavisa GhoshAinda não há avaliações

- Unit 8 High Performance Liquid Chromatography HPLCDocumento57 páginasUnit 8 High Performance Liquid Chromatography HPLCNathanianAinda não há avaliações

- Statistical Techniques in BioassayDocumento249 páginasStatistical Techniques in BioassayMartha Ximena Ninco CastañedaAinda não há avaliações

- Quality Process and Control in Cell ProductionDocumento22 páginasQuality Process and Control in Cell ProductionCaths AprilliaAinda não há avaliações

- Prism 6 Curve Fitting GuideDocumento453 páginasPrism 6 Curve Fitting GuideoschlepAinda não há avaliações

- Bio-RadTechNote2861 Principles of Curve FittingDocumento4 páginasBio-RadTechNote2861 Principles of Curve Fittingyumyum9Ainda não há avaliações

- Standard Operating Protocol (HPLC)Documento7 páginasStandard Operating Protocol (HPLC)Sandhy TampubolonAinda não há avaliações

- Microbiology Audit Guidance EbookDocumento23 páginasMicrobiology Audit Guidance EbookArmando Saldaña100% (1)

- HPLC Column UsageDocumento11 páginasHPLC Column Usagenetelsrt1298Ainda não há avaliações

- HPLC Agilent 1100 PDFDocumento76 páginasHPLC Agilent 1100 PDFZaharia MariusAinda não há avaliações

- Biologic Therapies:: Clinical Implications For Rheumatologists, Gastroenterologists, Allied Health PractitionersDocumento14 páginasBiologic Therapies:: Clinical Implications For Rheumatologists, Gastroenterologists, Allied Health PractitionersSundar RamanathanAinda não há avaliações

- Analytical Method Validation - Pharmaceutical GuidelinesDocumento3 páginasAnalytical Method Validation - Pharmaceutical GuidelinesMSL IndiaAinda não há avaliações

- ICH Topic Q 6 BDocumento17 páginasICH Topic Q 6 BAprianaRohmanAinda não há avaliações

- Lectures On Biostatistics-Ocr4Documento446 páginasLectures On Biostatistics-Ocr4Kostas GemenisAinda não há avaliações

- Tips and Tricks HPLC Troubleshooting PDFDocumento30 páginasTips and Tricks HPLC Troubleshooting PDFjuakfuenmayorAinda não há avaliações

- 4 Bioassays PDFDocumento17 páginas4 Bioassays PDFDrAmit VermaAinda não há avaliações

- UV-Vis Based Determination of Protein ConcentrationDocumento7 páginasUV-Vis Based Determination of Protein ConcentrationeshihAinda não há avaliações

- Agilent 1220 Infinity LC User Manual PDFDocumento380 páginasAgilent 1220 Infinity LC User Manual PDFYaimé DelgadoAinda não há avaliações

- Lentiviral Vectors: Andrew M.L. LeverDocumento26 páginasLentiviral Vectors: Andrew M.L. LeverDa NyAinda não há avaliações

- PPTDocumento48 páginasPPTMukesh KumarAinda não há avaliações

- Sop For Using Micro-Pipet in Lab.Documento3 páginasSop For Using Micro-Pipet in Lab.Shafquat AasifiAinda não há avaliações

- HPLC Problems-1Documento15 páginasHPLC Problems-1sanihgholiyahAinda não há avaliações

- TOC and Conductivity Ch. P 2010Documento3 páginasTOC and Conductivity Ch. P 2010Hong HuangAinda não há avaliações

- LCMS Trouble ShootingDocumento68 páginasLCMS Trouble ShootingLuis VilchezAinda não há avaliações

- Bioanalytical Method ValidationDocumento44 páginasBioanalytical Method ValidationSvetlana Iuliana PolianciucAinda não há avaliações

- Steps For Analytical Method Development - Pharmaceutical GuidelinesDocumento1 páginaSteps For Analytical Method Development - Pharmaceutical GuidelinesAnju NarraAinda não há avaliações

- Protocol Agilent 1100 HPLC ChemstationDocumento9 páginasProtocol Agilent 1100 HPLC ChemstationNarongchai PongpanAinda não há avaliações

- No 1 Method ValidationDocumento2 páginasNo 1 Method ValidationdanaciortanAinda não há avaliações

- Erythropoietin Concentrated Solution (1316)Documento5 páginasErythropoietin Concentrated Solution (1316)Mulayam Singh YadavAinda não há avaliações

- Introduction To Flow Cytometry: Principles Data Analysis Protocols TroubleshootingDocumento35 páginasIntroduction To Flow Cytometry: Principles Data Analysis Protocols TroubleshootingMario LuigiAinda não há avaliações

- Cabina de Seguridad Biologica - Bioare - Nu 480-400e PDFDocumento107 páginasCabina de Seguridad Biologica - Bioare - Nu 480-400e PDFAdrian Gomez BaldeonAinda não há avaliações

- Nonclinical Safety Assessment: A Guide to International Pharmaceutical RegulationsNo EverandNonclinical Safety Assessment: A Guide to International Pharmaceutical RegulationsWilliam J. BrockAinda não há avaliações

- ICH Quality Guidelines: An Implementation GuideNo EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleAinda não há avaliações

- Cama de Gato8Documento10 páginasCama de Gato8Raposo IreneAinda não há avaliações

- Calculation: 2-44 Physical & Aggregate Properties (2000)Documento5 páginasCalculation: 2-44 Physical & Aggregate Properties (2000)Ronald Figo Torres EcheAinda não há avaliações

- Dureza HardnessDocumento3 páginasDureza HardnessivoneAinda não há avaliações

- 2170 Flavor Profile AnalysisDocumento6 páginas2170 Flavor Profile AnalysisRaposo IreneAinda não há avaliações

- 2350 Oxidant Demand RequirementDocumento5 páginas2350 Oxidant Demand RequirementRaposo IreneAinda não há avaliações

- Waste Treatment Disposal MethodsDocumento2 páginasWaste Treatment Disposal MethodsRaposo IreneAinda não há avaliações

- SM2310 AcidityDocumento3 páginasSM2310 AcidityShadiaMilenaOquendoMuñozAinda não há avaliações

- 2160 Taste e 2170 Flavor Profile AnalysisDocumento4 páginas2160 Taste e 2170 Flavor Profile AnalysisRaposo IreneAinda não há avaliações

- 1080 Reagent WaterDocumento3 páginas1080 Reagent WaterRaposo IreneAinda não há avaliações

- 1050 Expression of ResultsDocumento3 páginas1050 Expression of ResultsRaposo IreneAinda não há avaliações

- Preparation of ReagentsDocumento3 páginasPreparation of ReagentsRaposo IreneAinda não há avaliações

- Inspect F50: Everything Needed For Conventional High Resolution Sample InvestigationDocumento4 páginasInspect F50: Everything Needed For Conventional High Resolution Sample InvestigationMiruna PetriaAinda não há avaliações

- Culverts DesignDocumento21 páginasCulverts DesignNani CherryAinda não há avaliações

- RaceDocumento3 páginasRaceapi-3769525100% (5)

- K3 Skema Cemerlang Set 1Documento4 páginasK3 Skema Cemerlang Set 1annurshah05Ainda não há avaliações

- The Effect of Open Area On Sieve Tray Performance: T. YanagiDocumento24 páginasThe Effect of Open Area On Sieve Tray Performance: T. Yanagifumanchu@fastmail.fmAinda não há avaliações

- UTM Arau Prepares 4-BromobenzophenoneDocumento7 páginasUTM Arau Prepares 4-BromobenzophenoneMay Lee100% (1)

- 3-11-8 - Pressure Vessel Cs - UopDocumento31 páginas3-11-8 - Pressure Vessel Cs - UopSean Davis100% (1)

- Renown Chemical BrochureDocumento44 páginasRenown Chemical BrochureSalih OzerAinda não há avaliações

- Everything About Alkynes - Q&ADocumento22 páginasEverything About Alkynes - Q&AJoostGoAinda não há avaliações

- Strain Gauges DatasheetDocumento100 páginasStrain Gauges DatasheetSantiago UrgilesAinda não há avaliações

- High Carbon Wire RodDocumento9 páginasHigh Carbon Wire Rodninganray6316100% (1)

- BN-DG-C01A Plant Layout - General RequirementsDocumento11 páginasBN-DG-C01A Plant Layout - General RequirementsatramanathanAinda não há avaliações

- ΔL, SIF, Hoop Stress, API StandardsDocumento3 páginasΔL, SIF, Hoop Stress, API StandardsVijay KumarAinda não há avaliações

- Antimicrobial Silver Nanoparticle Bacterial Cellulose Wound DressingDocumento9 páginasAntimicrobial Silver Nanoparticle Bacterial Cellulose Wound Dressingfranciscrick69Ainda não há avaliações

- MNL 67-2009 PDFDocumento128 páginasMNL 67-2009 PDFlolo100% (2)

- DNeasy® Mericon® Food HandbookDocumento32 páginasDNeasy® Mericon® Food HandbookmarianariasAinda não há avaliações

- Design of Fatigue StrengthDocumento21 páginasDesign of Fatigue StrengthRaviteja VgaAinda não há avaliações

- 442-032 PDF PDFDocumento12 páginas442-032 PDF PDFCalAinda não há avaliações

- Glassware Cleaning ProcedureDocumento3 páginasGlassware Cleaning ProcedureMukta TalukderAinda não há avaliações

- A Comparative Study of ZnO-PVP and ZnO-PEG Nanoparticles ActivityDocumento8 páginasA Comparative Study of ZnO-PVP and ZnO-PEG Nanoparticles ActivityVũ Hải NamAinda não há avaliações

- Recovery and Purification of Lactic Acid From Fermentation BrothDocumento185 páginasRecovery and Purification of Lactic Acid From Fermentation BrothBilli CostanAinda não há avaliações

- Precious Metal Recovery Part 1Documento3 páginasPrecious Metal Recovery Part 1mladen lakicAinda não há avaliações

- The Laws of Thermodynamics and Your Air Conditioner (less than 40 charsDocumento13 páginasThe Laws of Thermodynamics and Your Air Conditioner (less than 40 charsluizcristianofsAinda não há avaliações

- Inorganic NotesDocumento4 páginasInorganic NotesMr. XAinda não há avaliações

- Handout BottleneckDocumento7 páginasHandout BottleneckVenkatesh NenavathAinda não há avaliações

- Etch Rates For Micromachining Processing PDFDocumento2 páginasEtch Rates For Micromachining Processing PDFJohnathanAinda não há avaliações

- Sulfur and Nirogen IndustriesDocumento58 páginasSulfur and Nirogen IndustriesSarah SanchezAinda não há avaliações

- Cea 4022Documento25 páginasCea 4022mohammadAinda não há avaliações

- Production Technology Course OutDocumento5 páginasProduction Technology Course Outmurjass85Ainda não há avaliações