Escolar Documentos

Profissional Documentos

Cultura Documentos

Best Practice Manual-Transformers 39

Enviado por

sunny_nsecTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Best Practice Manual-Transformers 39

Enviado por

sunny_nsecDireitos autorais:

Formatos disponíveis

ANNEXURE-1: GUIDELINES FOR INSTALLING TRANSFORMERS

When your transformer arrives on site, various procedures should be carried out to assure successful operation. The successful operation of a transformer is dependent on proper installation as well as on good design and manufacture. The instructions mentioned in the manufacturer manual or in Standards shall be followed to ensure adequate safety to personnel and equipment. This section will provide general guidelines for installing and testing both dry-type and liquid-filled transformers for placement into service.

Standard transformer tests performed for each unit include the following:

Ratio, for voltage relationship; Polarity for single- and 3-phase units (because single-phase transformers are sometimes connected in parallel and sometimes in a 3-phase bank); Phase relationship for 3-phase units (important when two or more transformers are operated in parallel); Excitation current, which relates to efficiency and verifies that core design is correct; No-load core loss, which also relates to efficiency and correct core design; Resistance, for calculating winding temperature Impedance (via short circuit testing), which provides information needed for breaker and/or fuse sizing and interrupting rating and for coordinating relaying schemes; Load loss, which again directly relates to the transformer's efficiency; Regulation, which determines voltage drop when load is applied; and Applied and induced potentials, which verify dielectric strength.

There are additional tests that may be applicable, depending upon how and where the transformer will be used. The additional tests that can be conducted include the following:

Impulse (where lightning and switching surges are prevalent); Sound (important for applications in residential and office areas and that can be used as comparison with future sound tests to reveal any core problems); Temperature rise of the coils, which helps ensure that design limits will not be exceeded; Corona for medium voltage (MV) and high-voltage (HV) units, which helps determine if the insulation system is functioning properly; Insulation resistance (meg-ohmmeter testing), which determines dryness of insulation and is often done after delivery to serve as a benchmark for comparison against future readings; and Insulation power factor, which is done at initial installation and every few years thereafter to help determine the aging process of the insulation.

39

Você também pode gostar

- LED Lighting at Truck Rest Area: Case StudyDocumento4 páginasLED Lighting at Truck Rest Area: Case Studysunny_nsecAinda não há avaliações

- TGD 031 Amendments To The M E D 005 For Post Primary Schools 8Documento1 páginaTGD 031 Amendments To The M E D 005 For Post Primary Schools 8sunny_nsecAinda não há avaliações

- Industrial and Logistics Light GuideDocumento14 páginasIndustrial and Logistics Light Guidesunny_nsecAinda não há avaliações

- Ene BG 4Documento14 páginasEne BG 4sunny_nsecAinda não há avaliações

- TGD 031 Amendments To The M E D 005 For Post Primary Schools 10Documento1 páginaTGD 031 Amendments To The M E D 005 For Post Primary Schools 10sunny_nsecAinda não há avaliações

- TGD 031 Amendments To The M E D 005 For Post Primary Schools 6Documento1 páginaTGD 031 Amendments To The M E D 005 For Post Primary Schools 6sunny_nsecAinda não há avaliações

- TGD 031 Amendments To The M E D 005 For Post Primary Schools 9Documento1 páginaTGD 031 Amendments To The M E D 005 For Post Primary Schools 9sunny_nsecAinda não há avaliações

- TGD 031 Amendments To The M E D 005 For Post Primary Schools 7Documento1 páginaTGD 031 Amendments To The M E D 005 For Post Primary Schools 7sunny_nsecAinda não há avaliações

- Approved Plan 406173Documento1 páginaApproved Plan 406173sunny_nsecAinda não há avaliações

- TGD 031 Amendments To The M E D 005 For Post Primary Schools 4Documento1 páginaTGD 031 Amendments To The M E D 005 For Post Primary Schools 4sunny_nsecAinda não há avaliações

- Aer 534 QCDocumento48 páginasAer 534 QCsunny_nsecAinda não há avaliações

- TGD 031 Amendments To The M E D 005 For Post Primary Schools 6Documento1 páginaTGD 031 Amendments To The M E D 005 For Post Primary Schools 6sunny_nsecAinda não há avaliações

- Pbu TGD 026 Addendum 1 2Documento1 páginaPbu TGD 026 Addendum 1 2sunny_nsecAinda não há avaliações

- TGD 031 Amendments To The M E D 005 For Post Primary Schools 3Documento1 páginaTGD 031 Amendments To The M E D 005 For Post Primary Schools 3sunny_nsecAinda não há avaliações

- TGD 031 Amendments To The M E D 005 For Post Primary Schools 2Documento1 páginaTGD 031 Amendments To The M E D 005 For Post Primary Schools 2sunny_nsecAinda não há avaliações

- Special Education Class Design Guidance Addendum 1Documento1 páginaSpecial Education Class Design Guidance Addendum 1sunny_nsecAinda não há avaliações

- TGD 031 Amendments To The M E D 005 For Post Primary Schools 5Documento1 páginaTGD 031 Amendments To The M E D 005 For Post Primary Schools 5sunny_nsecAinda não há avaliações

- TGD 031 Amendments To The M E D 005 For Post Primary Schools 1Documento1 páginaTGD 031 Amendments To The M E D 005 For Post Primary Schools 1sunny_nsecAinda não há avaliações

- TGD 031 Amendments To The M E D 005 For Post Primary Schools 2Documento1 páginaTGD 031 Amendments To The M E D 005 For Post Primary Schools 2sunny_nsecAinda não há avaliações

- TGD 031 Amendments To The M E D 005 For Post Primary Schools 1Documento1 páginaTGD 031 Amendments To The M E D 005 For Post Primary Schools 1sunny_nsecAinda não há avaliações

- Pbu TGD 026 Addendum 1 10Documento1 páginaPbu TGD 026 Addendum 1 10sunny_nsecAinda não há avaliações

- Special Education Class Design Guidance Addendum 1Documento1 páginaSpecial Education Class Design Guidance Addendum 1sunny_nsecAinda não há avaliações

- Pbu TGD 026 Addendum 1 7Documento1 páginaPbu TGD 026 Addendum 1 7sunny_nsecAinda não há avaliações

- Pbu TGD 026 Addendum 1 10Documento1 páginaPbu TGD 026 Addendum 1 10sunny_nsecAinda não há avaliações

- Multi-sensory and Para-Ed RoomsDocumento1 páginaMulti-sensory and Para-Ed Roomssunny_nsecAinda não há avaliações

- Pbu TGD 026 Addendum 1 6Documento1 páginaPbu TGD 026 Addendum 1 6sunny_nsecAinda não há avaliações

- Pbu TGD 026 Addendum 1 2Documento1 páginaPbu TGD 026 Addendum 1 2sunny_nsecAinda não há avaliações

- Pbu TGD 026 Addendum 1 8Documento1 páginaPbu TGD 026 Addendum 1 8sunny_nsecAinda não há avaliações

- Pbu TGD 026 Addendum 1 4Documento1 páginaPbu TGD 026 Addendum 1 4sunny_nsecAinda não há avaliações

- Pbu TGD 026 Addendum 1 3Documento1 páginaPbu TGD 026 Addendum 1 3sunny_nsecAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Ion Plasma Generator-T&D98Documento64 páginasIon Plasma Generator-T&D98ULTG KOTABUMIAinda não há avaliações

- Unit 11 Boyle Charles GayLussac and Combined Gas Law Worksheet Gas WS 1 2010Documento2 páginasUnit 11 Boyle Charles GayLussac and Combined Gas Law Worksheet Gas WS 1 2010Pablo AlconzAinda não há avaliações

- Relief Design SizingDocumento9 páginasRelief Design SizingDark KnightAinda não há avaliações

- Mechanical Properties of FluidsDocumento27 páginasMechanical Properties of Fluidsanon_42348947Ainda não há avaliações

- Pre Commissioningchecklist 211027021204 - 2Documento150 páginasPre Commissioningchecklist 211027021204 - 2nassarkiAinda não há avaliações

- Cours Transfert Thermique 7Documento12 páginasCours Transfert Thermique 7ndn NgondzaAinda não há avaliações

- Iec60076 10 2016Documento128 páginasIec60076 10 2016chengkkAinda não há avaliações

- EURAMET Cg-19 V 2.0 Guidelines in Uncertainty Volume 01Documento20 páginasEURAMET Cg-19 V 2.0 Guidelines in Uncertainty Volume 01fabfalcioniAinda não há avaliações

- Woodward Generator Load SensorDocumento30 páginasWoodward Generator Load SensorRichard Lawrence100% (2)

- Energy Band Gap of A Solid SemiconductorDocumento6 páginasEnergy Band Gap of A Solid SemiconductorGayathripriya AseervadamAinda não há avaliações

- AnaChem ConceptsDocumento2 páginasAnaChem ConceptsEricka Mae CamaradorAinda não há avaliações

- Eddy Making ResistanceDocumento26 páginasEddy Making ResistanceNaval Siahaan100% (1)

- YU Classical Mechanics Course SyllabusDocumento6 páginasYU Classical Mechanics Course SyllabusMark KaplanAinda não há avaliações

- Astralpool Master Catalogue 2021Documento672 páginasAstralpool Master Catalogue 2021trangweicoAinda não há avaliações

- 04 Line Imp K-Factor Distance Transmission LineDocumento25 páginas04 Line Imp K-Factor Distance Transmission LineMosa Dalahma100% (1)

- DR NTTPSDocumento41 páginasDR NTTPSnagasuresh100% (1)

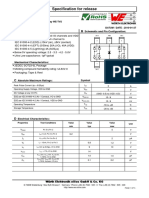

- TVS Diode Array WE-TVS Specification SheetDocumento5 páginasTVS Diode Array WE-TVS Specification SheetAlex LuzAinda não há avaliações

- Mi 3210 Teraohmxa 10Kv: Professional Insulation Testing With Powerful Diagnostic ToolsDocumento2 páginasMi 3210 Teraohmxa 10Kv: Professional Insulation Testing With Powerful Diagnostic ToolsTuan Anh Le CongAinda não há avaliações

- Pre-Test: Guidance MaterialDocumento29 páginasPre-Test: Guidance MaterialshambelAinda não há avaliações

- Chapter 8 - GravitationDocumento14 páginasChapter 8 - Gravitationspt007Ainda não há avaliações

- Introduction To Differential EquationsDocumento15 páginasIntroduction To Differential EquationsKAWA AMADAMINAinda não há avaliações

- Voltage Protection Relay 900VPR-2: FeaturesDocumento2 páginasVoltage Protection Relay 900VPR-2: FeaturesRahul PallipparaAinda não há avaliações

- Gen - Phy 2 12 Q4 SLM1Documento17 páginasGen - Phy 2 12 Q4 SLM1Kyla HernandezAinda não há avaliações

- Datasheet - Solargiga 560W JMPV-X1 72Documento2 páginasDatasheet - Solargiga 560W JMPV-X1 72tacianoAinda não há avaliações

- CollisionDocumento14 páginasCollisionAfia S HameedAinda não há avaliações

- Type K Thermocouple Reference TableDocumento2 páginasType K Thermocouple Reference TablemohamedelmansouriAinda não há avaliações

- Einstein Theory of RelativityDocumento26 páginasEinstein Theory of RelativityPrince JurynAinda não há avaliações

- Thermodynamic Properties and Phase ChangesDocumento22 páginasThermodynamic Properties and Phase ChangesHaikal HassanAinda não há avaliações

- Mixed CV Motion and UA Motion Review-1Documento4 páginasMixed CV Motion and UA Motion Review-1juliannlevine445Ainda não há avaliações

- WBJEE MQB Physical Inorg Chemistry-20210701173850152602Documento33 páginasWBJEE MQB Physical Inorg Chemistry-20210701173850152602Sanjana DuttaAinda não há avaliações