Escolar Documentos

Profissional Documentos

Cultura Documentos

Kim 2003

Enviado por

naranjo-01Descrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Kim 2003

Enviado por

naranjo-01Direitos autorais:

Formatos disponíveis

Waste Management & Research

http://wmr.sagepub.com/ The optimisation of food waste addition as a co-substrate in anaerobic digestion of sewage sludge

Hyun-Woo Kim, Sun-Kee Han and Hang-Sik Shin Waste Manag Res 2003 21: 515 DOI: 10.1177/0734242X0302100604 The online version of this article can be found at: http://wmr.sagepub.com/content/21/6/515

Published by:

http://www.sagepublications.com

On behalf of:

International Solid Waste Association

Additional services and information for Waste Management & Research can be found at: Email Alerts: http://wmr.sagepub.com/cgi/alerts Subscriptions: http://wmr.sagepub.com/subscriptions Reprints: http://www.sagepub.com/journalsReprints.nav Permissions: http://www.sagepub.com/journalsPermissions.nav Citations: http://wmr.sagepub.com/content/21/6/515.refs.html

Downloaded from wmr.sagepub.com at University of Leeds on September 7, 2011

Waste Manage Res 2003: 21: 515x?x 515526 Printed in UK all rights reserved

Copyright ISWA 2002 2003

Waste Management & Research

ISSN 0734242X

The optimisation of food waste addition as a cosubstrate in anaerobic digestion of sewage sludge

Food waste has been regarded as the main source of various environmental pollution in Korea due to the high volatile solids (VS) and moisture content caused by the features of dietary habits. The feasibility of food waste as a co-substrate in anaerobic digestion of sewage sludge was investigated in mesophilic and thermophilic conditions using batch tests. Cumulative methane production, dissolved organic carbon (DOC) and volatile fatty acids (VFA) were monitored to find the optimal mixing ratios of food waste and sewage sludge for the enhanced performance of co-digestion. It was observed that adequately mixed food waste led to the enhanced methane production both at mesophilic and thermophilic conditions. However, a conventional linear regression conducted for the optimisation of co-substrate mixing ratios was not accurate in describing exact methane production trends of co-digestion because of the different biodegradability of substrates. Therefore, a remodified Gompertz equation showing nonlinear relationship between variables was developed to find exact information with the same experimental data obtained at 2g VS/l generally used in biochemical methane potential (BMP) tests. Based on an influential parameter, methane production rate (MPR), the optimal mixing ratios of food waste were 39.3% and 50.1% in mesophilic and thermophilic conditions, respectively. To confirm the application of the remodified Gompertz equation, secondary batch tests were conducted with the substrate concentrations of 1-4g VS/l. In overall range tested, the confident mixing ratios of food waste was adjusted to 30-40% and 40% in mesophilic and thermophilic conditions, respectively. The most significant factor for enhanced performance was the improved organic carbon content provided by additional food waste.

Hyun-Woo Kim Sun-Kee Han Hang-Sik Shin

Department of Civil and Environmental Engineering, Korea Advanced Institute of Science and Technology 373-1, Guseongdong, Yuseong-gu, Daejeon 305-701, Korea. Keywords: Anaerobic, co-digestion, food waste, sewage sludge, methane production rate (MPR), optimal mixing ratio, mesophilic and thermophilic conditions, wmr 6948.

Corresponding author: Hang-Sik Shin, Department of Civil and Environmental Engineering, Korea Advanced Institute of Science and Technology 373-1, Guseong-dong, Yuseong-gu, Daejeon 305701, Korea. Tel: +82-42-869-3613 Fax: +82-42-869-8460 Email: hangshin@kaist.ac.kr Received 23 July 2003, accepted in revised form 03 October 2003.

Waste Management & Research

Downloaded from wmr.sagepub.com at University of Leeds on September 7, 2011

515

Hyun-Woo Kim, Sun-Kee Han, Hang-Sik Shin

Introduction

Anaerobic digestion is one of the common and costeffective technologies for the stabilisation of organic fraction of municipal solid waste (OFMSW) because of its high energy recovery and limited environmental impact (Mata-Alvarez et al. 2000). However, conventional completely-mixed anaerobic sludge digestion processes in most wastewater treatment plants in Korea still suffer from unreliable performance, even though various researches have been made for higher treatment efficiency. Among various OFMSW produced, the generation of food waste reaches 11,000 tons per day in Korea, accounting for 23.2% of MSW (Korea Ministry of Environment, 2002). Food waste is the major source of decay, odour, and leachate in collection and transportation due to the high VS/TS (0.8-0.9) and moisture content (75-85%). Food waste, consolidated in landfills with other wastes, has resulted in serious environmental problems such as odour emanation, vermin attraction, toxic gas emission and groundwater contamination. However, if food waste is used as a co-substrate in anaerobic digestion of sewage sludge, there is much room for improvement in the digestion performance. The concept of co-digestion has been tested several times as an alternative because feed characteristics might be one of the major governing factors to sound performance. Addition of co-substrate to sewage sludge leads to enhanced biogas production and VS reduction due to deficient nutrient supply, toxic materials dilution, biodegradability improvement, and microbial activity stimulation (Cecchi et al. 1989, Kiely et al. 1997, Converti et al. 1997, Gallert & Winter 1997, Del Borghi et al. 1999, Stroot et al. 2001). However, the food waste fraction and characteristics vary with geographical location. It is necessary to suggest the adequate mixing ratio of Korean food waste for adjusting excess amount of inhibitory materials in co-digestion, such as volatile fatty acids (VFA), ammonia, sodium ions, etc (Mata-Alvarez et al. 2000). Biochemical methane potential (BMP) tests have been conducted because it is essential to identify the methanogenic activity of biomass and the influence of environmental conditions on methane conversion. Much useful information on kinetic parameters and process characteristics could be obtained by applying regression techniques. Until now, a conventional linear regression has been popular in the experiments using specific substrates and microorganisms. However, in co-digestion of sewage sludge and OFMSW, different biodegradability between two major substrates makes it more difficult to fit the cumulative tendency of experimental methane production data correctly. Therefore, to overcome the limitations of the simple linear regression, non-linear approach to co-digestion is needed

to estimate more accurate parameter values in methanogenesis of complex substrates. The reliability of process mainly depends on the characteristics of substrate especially in co-digestion. If a closely influential parameter is found in batch tests for mixing ratios of different substrates, it could be useful information and also save effort to evaluate the best performance of co-digestion more reasonably. This research was, therefore, performed to find the optimal mixing ratio of food waste and sewage sludge in co-digestion using the re-modified Gompertz equation. Also, the effect of food waste addition on anaerobic digestion of sewage sludge was investigated in mesophilic and thermophilic conditions on the basis of feed characteristics.

Materials and methods

Seed

Seed micro-organisms were taken from lab-scale mesophilic and thermophilic anaerobic chemostats. The total suspended solids (TSS) and volatile suspended solids (VSS) concentrations of the thermophilic seed sludge were 21.8 and 8.0g/l, respectively, and those of the mesophlic seed sludge were 34.9 and 13.6g/l, respectively.

Substrate

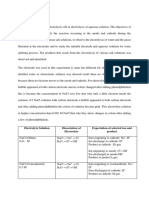

The feed was a mixture of food waste and sewage sludge, representing typical Korean food waste and sewage sludge. Food waste, sampled from a dining hall, was crushed by an electrical blender and diluted to 20% (v/v) with liquid from food waste. Sewage sludge was sampled from a local wastewater treatment plant. All the substrates were filtered through a stainless steel sieve (U.S. Mesh No. 10 with corresponding sieve openings of 2.00 mm). The characteristics of substrate were summarised in Table 1.

Operating procedure

The BMP tests were conducted using 160 ml serum bottles with a working volume of 100 ml. The bottles were operated at mesophilic (35C) and thermophilic (55C) temperatures, as shown in Tables 2 and 3. The various mixtures of food waste and sewage sludge were added to each serum bottle. Their initial concentrations were all set to 2g VS/l in Experiment I (Cho et al. 1995, Converti et al. 1997). Consulting the obtained mixing ratios results of Experiment I, substrate concentrations were controlled to 1-4g VS/l in Experiment II for verifying effects of substrate on MPR. After filling all the bottles to 80 ml with anaerobic medium solution, 20 ml of seed sludge was added to individual serum bottles. Each litre of anaerobic medium solu-

516

Waste Management & Research

Downloaded from wmr.sagepub.com at University of Leeds on September 7, 2011

The optimisation of food waste addition as a co-substrate in anaerobic digestion of sewage sludge

Table 1: Characteristics of substrates. Item Physical characteristics TS VS VS/TS % % 4.24 4.10 0.97 3.04 1.49 0.49 Unit Food waste Sewage sludge

Chemical Characteristics Carbon (C) Nitrogen (N) Hydrogen (H) Sulfur (S) C/N % % % % 45.7 2.2 6.7 20.8 24.4 3.4 3.9 0.7 7.2

tion contained 0.53g of NH4Cl, 0.27g of KH2PO4, 0.35 g of K2HPO4, 1.20 g of NaHCO3, 0.075 g of CaCl22H2O, 0.10 g of MgCl26H2O, 0.02 g of FeCl24H2O, 0.05 g of MnCl24H2O, 0.05 g of H3BO3, 0.05 g of ZnCl2, 0.03 g of CuCl2, 0.01 g of Na2MoO42H2O, 0.50 g of CoCl26H2O, 0.05 g of NiCl26H2O and 0.05 g of Na2SeO3. All the bottles were purged with N2 gas before sealing. The bottles were incubated in a rotary shaker to provide better contact of substrates, nutrients and microorganisms. The volume of biogas was determined using glass syringes of 5-50ml according to Owen et al. (1979).

Analytical methods

The contents of methane and carbon dioxide in the biogas were analysed by a gas chromatograph (GC, Gow Mac series 580) equipped with a thermal conductivity detector (TCD) and a 2 m x 2 mm stainless-steel column packed

Table 2: Batch reactor operating conditions of Experiment I.

with Porapak Q (80/100 mesh). During the experiments, 1 ml of sample was collected at a proper time with a syringe. The samples were immediately filtered through 0.45 m cellulose nitrate membrane filters (Whatman) and then stored at 4C for analysis. For the analyses of individual volatile fatty acid (VFA) concentrations, HPLC (Spectra Physics P2000) was used with an Aminex HPX-87H (300 x 7.8mm) column and a UV (210 nm) detector. Dorhmann DC-180 TOC analyser was used for total organic carbon (TOC) and the concentrations of dissolved organic carbon (DOC) were converted to chemical oxygen demand (COD) by assuming the average oxidation number of carbon as zero. Chemical composition of substrates was analysed by Elemental Analyser (Fisons, EA-1110) equipped with a dynamic flash combustion-oxidation chamber and TCD. The total solids (TS), VS, TSS, VSS were determined according to Standard Methods (APHA, 1998).

Preparation of substrate Temperature Batch reactor No. Design substrate (g VS/l) Sewage sludge (% of VS) Food waste (% of VS)

1 Thermophilic (55C) and Mesophilic (35C) sets 2 3 4

2 2 2 2

100 80 50 20

0 20 50 80

Waste Management & Research

Downloaded from wmr.sagepub.com at University of Leeds on September 7, 2011

517

Hyun-Woo Kim, Sun-Kee Han, Hang-Sik Shin

Table 3: Batch reactor operating conditions of Experiment II. Thermophilic reactor No. Mesophilic reactor No. Design substrate (g VS/l) 1 1 1 1 2 2 2 2 3 3 3 3 4 4 4 4 Sewage sludge (% of VS) 100 80 60 40 100 80 60 40 100 80 60 40 100 80 60 40 Food waste (% of VS) 0 20 40 60 0 20 40 60 0 20 40 60 0 20 40 60

9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

Regression analysis

Linear regression

In the batch tests, anaerobic degradation after initial lag time is limited by the terms associated with substrate and kinetics, which generally could be represented by a first order kinetic law with some assumptions. Thus, first order kinetic constants on the methane production in the serum bottles were evaluated according to the approach reported by Llabres-Luengo and Mata-Alvarez (1987) (P M) = e kt P (1)

fractions. In this study, equation (3) was developed to overcome the limitation of equation (2) by adding a secondary term. The first term represents the methane production from readily degradable materials in an early stage and the second term expresses the subsequent methane production from slowly degradable materials.

R2 e R1 e 1t)+1 +P2 exp ( (2t)+1 M=P1 exp ( P1 P2

(3)

Where, M = cumulative methane production (ml) at incubation time (d), P = methane production potential (ml).

Non-linear regression

Lay et al. (1997) reported that the cumulative methane production data in BMP tests were well fitted to a modified Gompertz equation (Zwietering et al. 1990, Zwietering et al. 1992, Cho et al. 1996) as shown in equation (2). R e ( t) +1 M=P exp P

Where, M = cumulative methane production (ml) at incubation time, t (d), 1 = initial lag-phase time (d), P1 = initial methane production potential (ml), R1 = initial methane production rate (ml/d), 2 = secondary lag-phase time (d), P2 = secondary methane production potential (ml), R2 = secondary methane production rate (ml/d). Accordingly, the equation (3) was fitted as a suitable model to describe the progress of cumulative methane production in batch co-digestion of food waste and sewage sludge.

Results and discussion

Effect of food waste addition on co-digestion performance and its regression (Experiment I)

(2)

Where, M = cumulative methane production (ml) at incubation time, t (d), = lag-phase time (d), P = methane production potential (ml), R = methane production rate (ml/d), e = 2.718. However, the equation was not accurate in describing exact cumulative methane production of codigestion due to different biodegradability between organic

Based on 2 g VS/l generally used in BMP , five serum bottles were operated at 55C with different mixtures of food waste and sewage sludge using thermophilic seed sludge. Another five bottles were operated at 35C with the same substrates and media using mesophilic seed sludge.

518

Waste Management & Research

Downloaded from wmr.sagepub.com at University of Leeds on September 7, 2011

The optimisation of food waste addition as a co-substrate in anaerobic digestion of sewage sludge

ecules, which cannot be easily transported into the bacterial cells, a further step of hydrolysis by exoenzymes should be considered (Del Borghi et al. 1999). Fig. 3 shows that, as the mixing ratios of food waste increased up to 50%, cumulative methane production in both conditions increased. Similar observation was reported by Cecchi et al. (1989) for the digestion of separatelycollected (SC) OFMSW and sewage sludge. Therefore, it indicated that the application of co-substrate significantly improved feed characteristics, resulting in higher methane potential. Higher ultimate methane yield of food waste can be found in Table 4, which shows reported data from various OFMSW. Also, it was confirmed that co-substrate, food waste, gave higher methane yields than previously reported BMP values (Table 4). The methane yields of all the batch reactors are shown in Table 5. The methane yields of the thermophilic digestion were higher by 19.2-29.3% than those of the mesophilic one. These trends of methane yields could be explained by the trends of VFA and DOC shown in Figs. 1 and 2. Ahn & Forster (2000) reported that thermophilic digestion, intrinsically, would have higher degrading capability and methanogenic activity. Moreover, most of the thermophilic co-digestion studies agreed that thermophilic condiTime (days) tion was a more balanced fermentation system in biogas production (Griffin et al. 1997, Gallert & Winter 1997, Del Borghi et al. 1999). In order to evaluate and optimise the previously discussed effects of food waste, a conventional linear regression was conducted by taking all the cumulative methane production data into consideration. Because it takes too much time to reach an ultimate value of BMP in case of a real substrate, the consideration of time becomes influential in optimising the use of food waste. Therefore, methane production rate (MPR) was regarded as the most important parameter. Time (days) Table 6 shows the first-order rate constants by using equation (1). In all the cases, higher values were obtained Fig. 1: DOC variations during co-digestion at different mixing ratios of food waste and sewage sludge. in thermophilic conditions. Fig. 3

As shown in Figs. 1 and 2, accelerated hydrolysis was observed by the addition of the proper amount of food waste in both temperature conditions. Thermophilic digestion showed a higher conversion rate in hydrolysis as well as acidogenesis. In thermophilic conditions, the major portion of DOC was identified as VFA. The levels of DOC and VFA sharply decreased after four days by fast acidogenesis and methanogenesis. However, in mesophilic conditions, DOC concentrations were kept high because the hydrolysates were not easily converted to VFA, indicating that the acidogenesis was a rate-limiting step. In anaerobic digestion of organic materials including large molecules or sterically incompatible molecules or highly crystalline mol-

DOC (mg COD/I)

DOC (mg COD/I)

Waste Management & Research

Downloaded from wmr.sagepub.com at University of Leeds on September 7, 2011

519

Hyun-Woo Kim, Sun-Kee Han, Hang-Sik Shin

due to the different biodegradability among organic fractions such as carbohydrates, proteins and lipids. Those obtained rate constants had very low confidence. Therefore, to describe more exact trends of methane production from complex substrate mixtures, the remodified Gompertz equation was tried as an alternative. Table 7 shows the estimated values by using equation (3), and Fig. 4 illustrates the exact description of regression results. The methane production potential (P1) and the lag phase time (1) increased as food waste addiTime (days) tion increased. However, in contrast with methane yields, MPR (R1) did not linearly depend on the increase of food waste addition. It decreased when the mixing ratios of food waste were higher than 50% of total VS. This phenomenon could be explained by the variations of VFA concentration. Since the high soluble organics contained in food waste were rapidly converted to VFA as shown in Fig. 2, a drastic pH drop must have inhibited the activity of methanogens as pointed out by Cho et al. (1995). Also, as the loading rate increased, VFA accumulation led methanogenesis to a rate-limiting step instead of hydrolysis (Shin et al. 2000). Time (days) Those MPR trends implied that there existed adequate food waste fraction showing the highest MPR. Fig. 2: Total VFA variations during co-digestion at different mixing ratios of food waste and Regression models based on food waste sewage sludge. fraction and MPR were developed to clarify the influence of food waste addialso illustrates the addition of food waste rapidly acti- tion on methane production rates as illustrated in Fig. 5. In vated methanogens to produce more methane gas when the results, 50% addition of food waste on VS basis showed substrates were properly mixed. When the food waste the highest MPR in thermophilic reactor set and 20% addifraction was 50%, the rate constant k50 was superior to tion of food waste gave the best result in mesophilic reacthat of the control in thermophilic conditions. Also, in tor set. The suggested quadratic equations presumed the mesophilic conditions, k50 was the highest value. Other estimated values with high correlation. Accordingly, prevalues of rate constants were similar to or a little higher dicted maximum MPR based on food waste fraction in VS than the control. However, equation (1) could not reflect could be calculated by the simple mathematics. Predicted the gradual methane production from slowly degradable optimal fractions of food waste at 2 g VS/l were 39.3% in materials. The fluctuation between regression lines and mesophilic and 50.1% in thermophilic conditions, respecthe value of ln((P-M)/P) significantly increased after tively. Those values meant allowable maximum mixing 4 days. Also, the linear regression could not reflect the ratios which could prevent VFA from accumulating during lag-phase time of batch reactors properly. It is largely the co-digestion of food waste and sewage sludge.

520

Total VFA (mg COD/L)

Total VFA (mg COD/I)

Waste Management & Research

Downloaded from wmr.sagepub.com at University of Leeds on September 7, 2011

The optimisation of food waste addition as a co-substrate in anaerobic digestion of sewage sludge

Table 4: Comparisons of methane yields during co-digestion of various OFMSW and sewage sludge in mesophilic and thermophilic conditions. Reference This study

a

OFMSW

CH4 yield (l CH4/g VS)

Temperature conditions

SS only

0.116 & 0.163 0.215 & 0.280

35C & 55C 35C & 55C

Food waste (50%) + SS (50%) Previous BMP tests Owens & Chynoweth (1993) Grass Office paper waste Cho et al. (1995) Converti et al. (1997) Misi & Foster (2001) Food waste Wood & corn starch (50%)+ SS(50%)

bWAS

0.209 0.369 0.472 0.103 0.130 0.180

35C 35C 37C 35C 35C 35C

Chicken manure (50%) + WAS (50%) Previous continuous experiment Cecchi et al. (1989) Griffin et al. (1997) Del Borghi et al. (1999) Stroot et al. (2001)

a c

SC-OFMSW (50%) + SS (50%)

0.364 0.157 & 0.254 0.180 0.259

35C 35C & 55C 55C 37C

Paper & food waste (80%) + SS (20%) House-hold waste (50%) + SS (50%) Paper & food waste (80%) + SS (20%)

sewage sludge,

wasted activated sludge, c separately-collected

Table 5: Biochemical methane potentials (BMP) during co-digestion at different mixing ratios of food waste and sewage sludge in mesophilic and thermophilic conditions. Mixing ratio of food waste (% of VS) 0 20 50 80 Thermophilic conditions (l CH4/g VS) 0.163 0.222 0.280 0.344 Mesophilic conditions (l CH4/g VS) 0.116 0.157 0.215 0.257 Mesophilic/Thermophilic (%) 71.2 70.7 76.8 74.7

Table 6: First-order regression coefficients during co-digestion at different mixing ratios of food waste and sewage sludge in mesophilic and thermophilic conditions. First-order regression coefficient at different mixing ratios of food waste addition (% of VS) Unit 0 0.21 0.86 d-1 0.15 0.88 20 0.22 0.92 0.18 0.94 50 0.35 0.93 0.22 0.94 80 0.20 0.97 0.18 0.82

Thermophilic kinetic constant Correlation factor (R2) Mesophilic kinetic constant Correlation factor (R2)

d-1

Waste Management & Research

Downloaded from wmr.sagepub.com at University of Leeds on September 7, 2011

521

Hyun-Woo Kim, Sun-Kee Han, Hang-Sik Shin

regression for each set of reactors. In thermophilic conditions, maximum MPR was consistently maintained at about 40% of food waste addition as the substrate concentration increased from 1 to 4 g VS/l. In mesophilic conditions, the maximum MPR values (22.527.5 ml CH4/g VS/d) were much lower than those (70-80 ml CH4/g VS/l) of thermophilic conditions. Similarly, as the substrate concentration increased, the mixing ratios of food waste for the optimal MPR were almost stable at 40%. Therefore, it was possible to suggest the optimal range of food waste Time (days) fraction. When the food waste fraction was 40% in thermophilic conditions, the maximum MPR values were 80.045.0 ml CH4/g VS/d. On the other hand, in case of mesophilic conditions, 40% of food waste addition resulted in the highest MPR values of 27.5-17.5 ml CH4/g VS/d, respectively. If the food waste addition is controlled depending on these ranges, the MPR would be maintained to the desirable levels. Such a high value could give enough efficiency of methane recovery and VS destruction to anaerobic co-digestion processes. The results obtained in this study suggested that co-digestion of food waste and sewage sludge could be a Time (days) good alternative for improving low performance of conventional anaerobic Fig. 3: Cumulative methane production and first order rate constants during co-digestion at digestion of sewage sludge. Previous different mixing ratios of food waste and sewage sludge. studies reported that it was feasible to digest nutrient-rich MSW with other coConfirmation test of the remodified Gompertz equation substrate containing a high amount of readily biodegradon co-digestion performance for various substrate conable substances (Stroot et al. 2001). One of the important centrations (Experiment II) factors for the enhanced performance of co-digestion was To confirm the effectiveness of the remodified Gompertz high biodegradability of food waste, which compensated equation, the influence of substrate concentrations (1-4 g for the lack of readily-biodegradable substances in sewVS/l) were tested. The mixing ratios of food waste and sew- age sludge. It could be monitored by nutrient balance age sludge were reset to 0:100, 20:80, 40:60 and 60:40 on expressed as a carbon to nitrogen (C/N) ratio. Hawkes VS basis for each set of reactors, of which the correspond- (1980) suggested that the optimal C/N ratio for anaeroing C/N ratios were 7.2, 9.9, 12.7 and 15.4, respectively. bic digestion was in the range of 20-30. Hasimoto (1983) The specific MPR values, MPR divided by the amount of reported that carbon addition stimulated the CH4 yield at VS added, were calculated for comparisons. low C/N ratio. The average C/N ratio of typical Korean Fig. 6 illustrates the contours of estimated MPR values sewage sludge was just around seven due to the old comin mesophilic and thermophilic conditions by non-linear bined sewer system. Thus, if food waste is added as a

522

-In((P-M)/P

-In((P-M)/P

Waste Management & Research

Downloaded from wmr.sagepub.com at University of Leeds on September 7, 2011

The optimisation of food waste addition as a co-substrate in anaerobic digestion of sewage sludge

Cummulative CH4 production (ml)

tion of extracellular polysaccharides, common tools for micro-organisms to communicate with outer environment, resulting in improved bacterial attachment to solid surface and the high rate biodegradation.

Conclusions

It was demonstrated that the codigestion of sewage sludge mixed with food waste had a distinct positive effect on MPR and methane yields by keeping the adequate fraction of food Time (days) waste. In order to overcome the incorrect estimation of linear regression, the complex remodified Gompertz equation was tested to fit the cumulative methane production curve of codigestion. With the same experimental data obtained at 2 g VS/l generally used in BMP tests, the remodified Gompertz equation gave more exact results with high correlation than the conventional linear regression. The predicted optimal fractions of food waste based on MPR were found to be 39.3% in mesophilic and 50.1% in thermophilic conditions, respectively. To confirm the application of the remodified Gompertz equation, secondary experiments were conducted Time (days) based on different substrate concentrations (1-4 g VS/l). In all the cases, the Fig. 4: Regression results of the remodified Gompertz equation during co-digestion at different complex remodified Gompertz equamixing ratios of food waste and sewage sludge. tion described the cumulative methane production with high correlation. co-substrate, the C/N ratio becomes 12.7 which is more From contours, the confidence fractions of food waste appropriate for anaerobic digestion. It indicates that the guaranteeing the highest MPR was 30-40% in mesophilic addition of food waste plays an important role in providing and 40% in thermophilic conditions, respectively. Also, it essential organic carbon to sewage sludge. Moreover, food revealed that MPR values were more sensitive to the food waste has substantially a high hydrolytic kinetic constant waste fraction of VS than the mixed substrate concentra(Vavilin et al. 1999). Although the elemental substances of tion regardless of temperature conditions. The important food waste such as carbohydrates, proteins and lipids have factors for the enhanced performance of co-digestion were different hydrolytic kinetic constants (Christ et al. 1999), enhanced biodegradability caused by additional organic fast acidogenesis and methanogenesis can be possible by carbon, nutrient balance and adequate mixing ratio. the enhancement of rate-limiting hydrolysis. Thus, the bal- Additional carbon source supplied by food waste provided anced anaerobic environment led to the increased MPR preferable environment for the growth and activity of and methane yield of anaerobic biomass. Another specific anaerobes. These optimal mixing strategies could give opinion was reported by Schmidt and Ahring (1994) that the guideline for the practical operation of anaerobic cothe increase of organic carbon could stimulate the produc- digestion processes.

Cummulative CH4 production (ml)

Waste Management & Research

Downloaded from wmr.sagepub.com at University of Leeds on September 7, 2011

523

Hyun-Woo Kim, Sun-Kee Han, Hang-Sik Shin

Methane production rate (R1, ml/d)

Mixing ratios of food waste (% at 2 g VS/I)

Methane production rate (R1, ml/d)

Mixing ratios of food waste (% at 2 g VS/I)

Fig. 5: Regression models of methane production rates estimated by the remodified Gompertz equation during co-digestion at different mixing ratios of food waste and sewage sludge. Table 7: Non-linearly estimated regression parameters from the remodified Gompertz equation during co-digestion at different mixing ratios of food waste and sewage sludge in mesophilic and thermophilic conditions. Non-linearly estimated parameter value at different mixing ratio of food waste(% of VS) 0 Methane production potential (P1) Thermophilic conditions Methane production rate (R1) Lag-phase time (1) Correlation factors (R2) Methane production potential (P1) Mesophilic conditions Methane production rate (R1) Lag-phase time (1) Correlation factors (R2) ml ml/d d ml ml/d d 14.0 9.9 0.1 0.996 13.7 2.5 0.0 0.993 20 25.4 13.6 0.1 0.996 22.2 4.7 0.3 0.997 50 40.0 18.731 0.3 0.997 43.8 4.6 1.3 0.998 80 45.2 14.8 1.0 0.997 26.2 2.7 1.4 0.998

Temperature

Item

Unit

524

Waste Management & Research

Downloaded from wmr.sagepub.com at University of Leeds on September 7, 2011

The optimisation of food waste addition as a co-substrate in anaerobic digestion of sewage sludge

Mixing ratios of food waste (% of mixed substrate VS)

Mixed substrate concentration (g VS/I)

Mixing ratios of food waste (% of mixed substrate VS)

Mixed substrate concentration (g VS/I)

Fig. 6: Variations of estimated methane production rates (MPR, l CH4/gVS/d) during co-digestion at different mixing ratios of food waste and sewage sludge depending on various mixed substrate concentrations.

C/N ratio of mixed substrate (mg/mg)

C/N ratio of mixed substrate (mg/mg)

Waste Management & Research

Downloaded from wmr.sagepub.com at University of Leeds on September 7, 2011

525

Hyun-Woo Kim, Sun-Kee Han, Hang-Sik Shin

Acknowledgements

This research was supported by a grant (No.M1-0203-000063) from the National Research Laboratory Program of Korea Ministry of Science and Technology.

References

Ahn, J.H. & Forster C.F. (2000) A comparison of mesophilic and thermophilic anaerobic upflow filters. Bioresource Technol. 73, pp. 201205. APHA, WPCF, AWWA (1998) Standard Methods for the examination of Water and Wastewater, 20th Ed. APHA, Washington, D. C. Cecchi, F., Pavan, P ., Mata-Alvarez, J. & Vallini, G. (1989) Co-composting research in Italy. Biocycle 30(7), pp. 6871. Cecchi, F., Pavan, P . & Mata-Alvarez, J. (1996) Anaerobic co-digestion of sewage sludge: application to the macroalgae from the Venice lagoon. Resource, Conservation and Recycling. 17, pp. 5766, Cho, J.K., Park, S.C. & Chang, H.N. (1995) Biochemical methane potential and solid state anaerobic digestion of Korean food wastes. Bioresource Technol. 52, pp. 245253. Cho, H.Y., Yousef, A.E. & Sastry, S.K. (1996) Growth Kinetics of Lactobacillus acidophilus under ohmic heating. Biotechnol. Bioeng. 49, pp. 334-340. Christ, O., Faulstich, M. & Wilderer, P . (1999) Mathematical modelling of the hydrolysis of anaerobic processes. In the Second International Symposium on Anaerobic Digestion of Solid Wastes, Barcelona, Vol. 2, pp. 58. Converti, A., Drago, F., Ghiazza, G. & Del Borghi, M. (1997) Co-digestion of municipal sewage sludges and pre-hydrolysed woody agricultural wastes. J. Chem. Tech. Biotechnol. 69, pp. 231239. Del Borghi, A., Converti, A., Palazzi, E. & Del Borghi, M. (1999) Hydrolysis and thermophilic anaerobic digestion of sewage sludge and organic fraction of municipal solid waste. Bioprocess Eng. 20, pp. 553560. Gallert, C. & Winter, J. (1997) Mesophilic and thermophilic anaerobic digestion of source-sorted organic wastes: effect of ammonia on glucose degradation and methane production. Appl. Microbiol. Biotechnol. 48, pp. 405410. Griffin, M.E., McMahon, K.D., Mackie, R.I. & Raskin, L. (1998) Methanogeic population dynamics during start-up of anaerobic digesters treating municipal solid waste and sewage sludge. Biotechnol. Bioeng. 57(3), pp. 342355. Hamzawi, N., Kennedy, K.J. & Mclean, D.D. (1998) Anaerobic digestion of co-mingled municipal solid-waste and sewage-sludge. Wat. Sci. Technol. 38(2), pp. 127132. Hasimoto, A.G. (1983) Conversion of straw-manure mixtures to methane at mesophilic and thermophilic temperatures. Biotechnol. Bioeng. 25, pp. 185200. Kiely, G., Tayfur, G., Dolan, C. & Tanji, K. (1997) Physical and mathematical modelling of anaerobic digestion of organic wastes. Wat. Res. 31(3), pp. 534540. Korea ministry of environment (2002) Status of waste generation and management. The statistics yearbook of environment. pp. 496498. Lay, J.J., Li, Y.Y. & Noike, T. (1998) The influence of pH and ammonia concentration on the methane production in high-solid digestion processes. Water Environ. Res. 70(5), pp. 10751082. Llabres-Luengo, P . & Mata-Alvarez, J. (1987) Kinetic study of the anaerobic digestion of straw-pig manure mixture. Biomass 14, pp. 129142. Mata-Alvarez, J., Mac, S. & Llabrs, P . (2000) Anaerobic digestion of organic solid waste. An overview of research achievements and perspectives, Bioresource Technol. 74, pp. 316. Misi, S. N. & Foster, C. F. (2001) Batch co-digestion of multi-component agro-wastes. Bioresource Technol. 80, pp. 1928. Owen, J.M. & Chynoweth, D.P . (1993) Biochemical methane potential of municipal solid waste (MSW) components. Wat. Sci. Technol. 27(2), pp. 114. Owen, W.F., Stuckey D.C., Healy, J.B., Jr., Young, L.Y. & McCarty, P .L. (1979) Bioassay for monitoring biochemical methane potential and anaerobic toxicity. Wat. Res. 13, pp. 485493. Parkin, G.F. & Owen, W.F. (1986) Fundamentals of anaerobic digestion of wastewater sludges. J. Environ. Eng. 112(5), pp. 867920. Rivard, C.J., Himmel, M.E., Vinzant, T.B., Adney, W.S., Wyman, C.E., & Grohmann, K. (1990) Anaerobic digestion of processed municipal solid waste using a novel high solids reactor: maximum solids levels and mixing requirements. Biotechnol. Lett. 12, pp. 235240. Schmidt, J.E. & Ahring, B.K. (1994) Extracellular polymers in granular sludge from different upflow anaerobic sludge blanket (UASB) conditions. Appl. Microbiol. Biotechnol. 42, pp. 457462. Shin, H.S., Kim, S.H., Han, S.K. & Lee, C.Y. (2002) Degradation and inhibitory effects of LCFA in anaerobic digestion. In World Water Congress, IWA, Melbourne. Shin, H.S. & Song, Y.C. (1995) A model for evaluation of anaerobic degradation characteristics of organic waste : focusing on kinetics, rate-limiting step. Environ. Technol. 16, pp. 775784. Shin, H.S., Han, S.K., Song, Y.C. & Hwang, E.J. (2000) Biogasification of food residuals. Biocycle 41(8), pp. 8286. Stroot, P .G., Mcmahon, K.D., Mackie, R.I. & Raskin L. (2001) Anaerobic codigestion of municipal solid waste and sewage sludge under various mixing conditions. Wat. Res. 35(7), pp. 18041816. Vavilin, V.A., Rytov, S.V., Lokshina, L.Y. & Rintala, J.A. (1999) Description of hydrolysis and acetoclastic methanogenesis as the rate-limiting steps during anaerobic conversion of solid waste into methane. In the Second International Symposium on Anaerobic Digestion of Solid Wastes, Barcelona, Vol. 2, pp. 1518. Zwietering, M.H, Jongenburger, I., Rimbouts, F.M. & vant Riet, K. (1990) Modelling of the bacterial growth curve. Appl. Environ. Microbiol. 56, pp. 1857. Zwietering, M.H., Rimbouts, F.M. & vant Riet, K. (1992) Comparison of definitions of lag phase and the exponential phase in bacterial growth. J. Appl. Bacteriol. 72, pp. 139.

526

Waste Management & Research

Downloaded from wmr.sagepub.com at University of Leeds on September 7, 2011

Você também pode gostar

- Modeling of Anaerobic Digestion of Canary GrassDocumento8 páginasModeling of Anaerobic Digestion of Canary GrassProAkademiaAinda não há avaliações

- Anaerobic DigestionDocumento12 páginasAnaerobic Digestionhiteshn008Ainda não há avaliações

- Effect of leachate recirculation on anaerobic food waste digestionDocumento4 páginasEffect of leachate recirculation on anaerobic food waste digestionRianAwanggaAinda não há avaliações

- Sustainability 12 05222 v2Documento11 páginasSustainability 12 05222 v2Nur AthirahAinda não há avaliações

- Journal of Environmental Management: Research ArticleDocumento8 páginasJournal of Environmental Management: Research ArticleThobiasAinda não há avaliações

- Accepted Manuscript: Bioresource TechnologyDocumento34 páginasAccepted Manuscript: Bioresource TechnologyMiguel Angel Ramos RuizAinda não há avaliações

- J Renene 2005 09 029Documento8 páginasJ Renene 2005 09 029সাইদুর রহমানAinda não há avaliações

- Anaerobic Co-Digestion of Algal Sludge and Waste Paper To Produce MethaneDocumento5 páginasAnaerobic Co-Digestion of Algal Sludge and Waste Paper To Produce MethaneIka SulistyaningtiyasAinda não há avaliações

- Effect of feed to inoculum ratios on biogas yields of food and green wastesDocumento6 páginasEffect of feed to inoculum ratios on biogas yields of food and green wastesArif HidayatAinda não há avaliações

- Two-Stage Anaerobic Digestion of Food Waste and Horticultural Waste in High-Solid System PDFDocumento9 páginasTwo-Stage Anaerobic Digestion of Food Waste and Horticultural Waste in High-Solid System PDFfiana31Ainda não há avaliações

- Renewable Energy: Xingbao Gao, Xiao Liu, Wei WangDocumento7 páginasRenewable Energy: Xingbao Gao, Xiao Liu, Wei WangErikaAinda não há avaliações

- Projeto Experimental Fatorial para Aumentar A Produção de Metano Na Digestão de Resíduos LácteosDocumento7 páginasProjeto Experimental Fatorial para Aumentar A Produção de Metano Na Digestão de Resíduos LácteosLuís Paulo CardosoAinda não há avaliações

- Bioreactor For Vegetable WastesDocumento16 páginasBioreactor For Vegetable Wastesichiwaaa sanAinda não há avaliações

- Anaerobic Co Digestion of Food Waste and Dairy Manure Effects of Food Waste Particle Size and Organic Loading RateDocumento7 páginasAnaerobic Co Digestion of Food Waste and Dairy Manure Effects of Food Waste Particle Size and Organic Loading RateAnonymous MVHQ97KEoPAinda não há avaliações

- Waste Management: Mathava Kumar, Yan-Liang Ou, Jih-Gaw LinDocumento8 páginasWaste Management: Mathava Kumar, Yan-Liang Ou, Jih-Gaw LinTihah SakuraAinda não há avaliações

- Anaerobic Co Digestion of Organic WastesDocumento17 páginasAnaerobic Co Digestion of Organic WastesAnonymous MVHQ97KEoPAinda não há avaliações

- La Generación de Electricidad A Partir de Residuos de Alimentos y Las Características de La Materia Orgánica en La Celda de Combustible MicrobianaDocumento7 páginasLa Generación de Electricidad A Partir de Residuos de Alimentos y Las Características de La Materia Orgánica en La Celda de Combustible Microbianaソーダ エドゥアルドAinda não há avaliações

- Novel Bioreactor Configuration for Organic Waste DigestionDocumento270 páginasNovel Bioreactor Configuration for Organic Waste Digestionclaudio06111983Ainda não há avaliações

- New Insights Into Co-Digestion of Activated Sludge and Food Waste Biogas VersusDocumento25 páginasNew Insights Into Co-Digestion of Activated Sludge and Food Waste Biogas VersusWulandariAinda não há avaliações

- Liu 2019 IOP Conf. Ser. Earth Environ. Sci. 330 032041Documento5 páginasLiu 2019 IOP Conf. Ser. Earth Environ. Sci. 330 032041Nata ŠaAinda não há avaliações

- Accepted Manuscript: Process Safety and Environment ProtectionDocumento37 páginasAccepted Manuscript: Process Safety and Environment ProtectionNestor Garay CahuanaAinda não há avaliações

- Art 7Documento6 páginasArt 7Rodny NavarroAinda não há avaliações

- Preliminary Studies On The Performance of Vacuum Black WaterDocumento7 páginasPreliminary Studies On The Performance of Vacuum Black WaterNDUNGUTSE JEAN MAURICEAinda não há avaliações

- Biomass and Bioenergy: Research PaperDocumento9 páginasBiomass and Bioenergy: Research PaperajitsssAinda não há avaliações

- Departemen Pertanian, 2006Documento9 páginasDepartemen Pertanian, 2006Zainul Fikri TampengAinda não há avaliações

- Thermophilic Versus Mesophilic Anaerobic DigestionDocumento14 páginasThermophilic Versus Mesophilic Anaerobic DigestionatmanebensaidAinda não há avaliações

- Effect of Inoculum-to-Substrate Ratio on Sheep Paunch Manure BiogasDocumento7 páginasEffect of Inoculum-to-Substrate Ratio on Sheep Paunch Manure BiogasendeshawAinda não há avaliações

- Management of Kitchen WasteDocumento3 páginasManagement of Kitchen WasteDian SetyaAinda não há avaliações

- ANTONOPOULOU - 2015 - Modeling of Anaerobic Digestion of Food Industry WastesDocumento7 páginasANTONOPOULOU - 2015 - Modeling of Anaerobic Digestion of Food Industry WastesThobiasAinda não há avaliações

- Bio KineticsDocumento7 páginasBio KineticsSushil MeshramAinda não há avaliações

- Tongco2020 Article EnhancementOfHydrolysisAndBiogDocumento9 páginasTongco2020 Article EnhancementOfHydrolysisAndBiogJim TsikasAinda não há avaliações

- Impact of Seed Bioaugmentation on Thermophilic Anaerobic DigestersDocumento10 páginasImpact of Seed Bioaugmentation on Thermophilic Anaerobic DigestersMario WhoeverAinda não há avaliações

- Anaerobic Co-Digestion of Chicken Manure PDFDocumento6 páginasAnaerobic Co-Digestion of Chicken Manure PDFAgos RiosAinda não há avaliações

- Xing 2013Documento8 páginasXing 2013Vijaya GosuAinda não há avaliações

- Bioresource Technology: Su Yun Xu, Obuli P. Karthikeyan, Ammaiyappan Selvam, Jonathan W.C. WongDocumento6 páginasBioresource Technology: Su Yun Xu, Obuli P. Karthikeyan, Ammaiyappan Selvam, Jonathan W.C. WongAnonymous MVHQ97KEoPAinda não há avaliações

- Waste Management: Golnaz Arab, Daryl MccartneyDocumento11 páginasWaste Management: Golnaz Arab, Daryl Mccartneybelkira69Ainda não há avaliações

- Chemical Engineering Journal: Rocío Montañés, Montserrat Pérez, Rosario SoleraDocumento8 páginasChemical Engineering Journal: Rocío Montañés, Montserrat Pérez, Rosario SoleraMiguel Angel Ramos RuizAinda não há avaliações

- Improving Acidogenic Performance in Anaerobic Degradation of Solid Organic Waste Using A Rotational Drum Fermentation SystemDocumento7 páginasImproving Acidogenic Performance in Anaerobic Degradation of Solid Organic Waste Using A Rotational Drum Fermentation SystemGui Do EspAinda não há avaliações

- Evaluation of Biochemical Methane Potential and Kinetics On The Anaerobic Digestion of Vegetable Crop ResiduesDocumento14 páginasEvaluation of Biochemical Methane Potential and Kinetics On The Anaerobic Digestion of Vegetable Crop ResiduesKentner Chavez CorreaAinda não há avaliações

- Evaluation of The Biomethane Potential of Solid Fish Waste - 2012Documento6 páginasEvaluation of The Biomethane Potential of Solid Fish Waste - 2012Ivan Lobos PanguilefAinda não há avaliações

- 1 PBDocumento6 páginas1 PBvalentinaAinda não há avaliações

- Energy Conversion and ManagementDocumento9 páginasEnergy Conversion and ManagementNurkholis Bin AbdulAinda não há avaliações

- 2015-Zayneb Article MorphologicalPhysiologicalAndBDocumento7 páginas2015-Zayneb Article MorphologicalPhysiologicalAndBNathália Felix BomfimAinda não há avaliações

- Improvement of The Biochemical Methane Potential of Food Waste by Means of Anaerobic Co-Digestion With Swine ManureDocumento12 páginasImprovement of The Biochemical Methane Potential of Food Waste by Means of Anaerobic Co-Digestion With Swine ManureGuilhermeGomesAinda não há avaliações

- Hosseinikoupaie 2014Documento8 páginasHosseinikoupaie 2014Eduardo CMoralesAinda não há avaliações

- Transformer - Zaher Et Al WER2009Documento9 páginasTransformer - Zaher Et Al WER2009Escáner VendetaAinda não há avaliações

- Eq16022fu1 PDFDocumento9 páginasEq16022fu1 PDFMuhammad UmerAinda não há avaliações

- Biochemical Engineering Journal: Regular ArticleDocumento8 páginasBiochemical Engineering Journal: Regular ArticleShakila Aulia ZahraAinda não há avaliações

- Kelompok 5 Chemical and Spectroscopic Characterization of Water Extractavle Organic Matter During Vermicomposting of Cattle DungDocumento7 páginasKelompok 5 Chemical and Spectroscopic Characterization of Water Extractavle Organic Matter During Vermicomposting of Cattle DungSona RomadhonAinda não há avaliações

- Evaluation of The Microbial Diversity in An UASB ReactorDocumento9 páginasEvaluation of The Microbial Diversity in An UASB ReactorStone BrickWallAinda não há avaliações

- Bioresource Technology: Sami Luste, Sari LuostarinenDocumento8 páginasBioresource Technology: Sami Luste, Sari LuostarinenJim TsikasAinda não há avaliações

- Microbial EEA Affects Performance in A Full-Scale Modified ASPDocumento8 páginasMicrobial EEA Affects Performance in A Full-Scale Modified ASPCelina SanchezAinda não há avaliações

- MORTAZAEI - 2017 - High-Rate Anaerobic Digestion of Yogurt WastewaterDocumento9 páginasMORTAZAEI - 2017 - High-Rate Anaerobic Digestion of Yogurt WastewaterThobiasAinda não há avaliações

- Master Thesis: Moving Biofiles in Sequential Discharge Reactor (SBR)Documento88 páginasMaster Thesis: Moving Biofiles in Sequential Discharge Reactor (SBR)DianerAinda não há avaliações

- Green Energy Through Synergistic IntegraDocumento8 páginasGreen Energy Through Synergistic IntegraOm PrakashAinda não há avaliações

- Influence of Total Solids and Inoculum on Food Waste Anaerobic DigestionDocumento26 páginasInfluence of Total Solids and Inoculum on Food Waste Anaerobic Digestionrafi mfAinda não há avaliações

- Anaerobic Co-Digestion of Swine Manure With Energy Crop ResiduesDocumento9 páginasAnaerobic Co-Digestion of Swine Manure With Energy Crop ResiduesDel Valle Montero MarcoAinda não há avaliações

- African Journal of Biotechnology Vol. 8 (2)Documento6 páginasAfrican Journal of Biotechnology Vol. 8 (2)Perpustakaan UPI FABIO UNSOEDAinda não há avaliações

- Physical-Chemical Properties of Foods: New Tools for PredictionNo EverandPhysical-Chemical Properties of Foods: New Tools for PredictionAinda não há avaliações

- Biophysico-Chemical Processes of Anthropogenic Organic Compounds in Environmental SystemsNo EverandBiophysico-Chemical Processes of Anthropogenic Organic Compounds in Environmental SystemsAinda não há avaliações

- Useful XFOIL Command ListDocumento6 páginasUseful XFOIL Command ListHariharan RamanathanAinda não há avaliações

- Quizlet-Philippine Electrical CodeDocumento2 páginasQuizlet-Philippine Electrical Codena zafira0% (1)

- MK-PPT Chapter 1Documento37 páginasMK-PPT Chapter 1Nicolás SánchezAinda não há avaliações

- Discussion Exp 2 Chm674Documento4 páginasDiscussion Exp 2 Chm674Eva Lizwina MatinAinda não há avaliações

- Fundamental of Database: Madda Walabu University College of Computing Department of Information TechnologyDocumento46 páginasFundamental of Database: Madda Walabu University College of Computing Department of Information TechnologychalaAinda não há avaliações

- Mobile GIS Platforms and Applications with ArcGISDocumento28 páginasMobile GIS Platforms and Applications with ArcGISZachary Perkins100% (1)

- MSC Syllabus PDFDocumento34 páginasMSC Syllabus PDFMayadarAinda não há avaliações

- The 2009 ACM ASIA Programming Contest Dhaka Site: Hosted by North South University Dhaka, BangladeshDocumento21 páginasThe 2009 ACM ASIA Programming Contest Dhaka Site: Hosted by North South University Dhaka, BangladeshPhạm Hữu Thạnh ĐạtAinda não há avaliações

- Flow MeterDocumento9 páginasFlow MeterShin BoAinda não há avaliações

- TONISITASDocumento17 páginasTONISITASDewi Ria OAinda não há avaliações

- Dokumen - Tips - Simple Stresses From MathalinoDocumento58 páginasDokumen - Tips - Simple Stresses From MathalinoMidas Troy VictorAinda não há avaliações

- EE6010-High Voltage Direct Current TransmissionDocumento12 páginasEE6010-High Voltage Direct Current Transmissionabish abish0% (1)

- The Tom Bearden Website-StupidityDocumento7 páginasThe Tom Bearden Website-StupiditybestiariosAinda não há avaliações

- 2023 Key Stage 2 Mathematics Braille Transcript Paper 1 ArithmeticDocumento8 páginas2023 Key Stage 2 Mathematics Braille Transcript Paper 1 ArithmeticMini WorldAinda não há avaliações

- Basic Concepts: ProbabilityDocumento32 páginasBasic Concepts: ProbabilityJhedzle Manuel BuenaluzAinda não há avaliações

- Focal Points: Basic Optics, Chapter 4Documento47 páginasFocal Points: Basic Optics, Chapter 4PAM ALVARADOAinda não há avaliações

- AlgebraI Part2Documento42 páginasAlgebraI Part2Marcial Jr. MilitanteAinda não há avaliações

- Hypothesis TestingDocumento2 páginasHypothesis TestingNerish PlazaAinda não há avaliações

- h2 PR Final Key SP 13Documento3 páginash2 PR Final Key SP 13George ConstantinouAinda não há avaliações

- Uptime Awards: Recognizing The Best of The Best!Documento40 páginasUptime Awards: Recognizing The Best of The Best!Eric Sonny García AngelesAinda não há avaliações

- Module 6 The HypothesisDocumento14 páginasModule 6 The HypothesisJester Guballa de LeonAinda não há avaliações

- CS250 LCD Keypad User Manual: GE InterlogixDocumento32 páginasCS250 LCD Keypad User Manual: GE InterlogixpttnpttnAinda não há avaliações

- Sybase Basic & Advanced T-SQL ProgrammingDocumento3 páginasSybase Basic & Advanced T-SQL Programmingmehukr0% (1)

- Science - Abm8566 SMDocumento51 páginasScience - Abm8566 SMBhabaniAinda não há avaliações

- Unit 2Documento76 páginasUnit 2Mithila100% (1)

- CO Limba Engleza, Anul 2Documento56 páginasCO Limba Engleza, Anul 2Bocaneala Gianina100% (1)

- Directions: Answer The Following Question(s) .: A. B. C. D. E. FDocumento6 páginasDirections: Answer The Following Question(s) .: A. B. C. D. E. FdiamondtressAinda não há avaliações

- Continuous DeploymentDocumento2 páginasContinuous DeploymentVenkat Reddy0% (1)

- Maquina de Anestesia - ADSIIDocumento2 páginasMaquina de Anestesia - ADSIIalexanderAinda não há avaliações

- MP Lab3Documento4 páginasMP Lab3kawish420Ainda não há avaliações