Escolar Documentos

Profissional Documentos

Cultura Documentos

Agupta

Enviado por

budhladaDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Agupta

Enviado por

budhladaDireitos autorais:

Formatos disponíveis

Digest Journal of Nanomaterials and Biostructures Vol. 1, No. 1, March 2006, p.

1 -9

NANO AND BULK CRYSTALS OF ZnO: SYNTHESIS AND CHARACTERIZATION

Atul Gupta, H. S. Bhatti, D. Kumar, N. K. Vermaa, R. P. Tandonb Department of Physics, Punjabi University, Patiala-147 002, Punjab, India. SPMS, Thapar Institute of Engineering and Technology, Patiala-147 004, Punjab, India. Department of Physics, University of Delhi, Delhi, India.

Different sized (micro to nano) crystals of zinc oxide were obtained using different techniques of synthesis. Micro sized crystals were obtained by sintering zinc oxide with Di2O3, B2O3 and V2O5 fluxes. For preparing nanocrystals, precursor was prepared from zinc acetate and absolute ethanol. X-ray diffraction patterns of the crystals were obtained which confirm the wurtzite crystal structure of the ZnO phosphors. Scanning electron microscopic and transmission electron microscopic images of the prepared samples were recorded from where the particle sizes of the various samples of ZnO were calculated to be varying from 7.8 nm to 3 mm. Synthesized single, micro- and nano-crystals of ZnO were excited by nitrogen laser. Time resolved hyperbolic decay curves were observed from where various optical parameters such as excited state life-times ranging from 190 ns to 25.30 s, trapdepths varying from 0.14 eV to 0.27 eV and decay constant lying in between 0.56 to 0.72 were obtained. Keywords: Single crystal, bulk crystal, nano crystal, ZnO, XRD, TEM, SEM.

1. Introduction Zinc oxide is a very fast and efficient phosphor because of its wide band gap, large exciton binding energy and low threshold power for optical pumping [1-4]. PbO and PbF2 fluxes were used to prepare single crystals of pure and doped zinc oxide by various workers who studied their optical and electrical properties [5-7]. Various chemical synthesis methods have been employed by several workers to synthesize nano / micro crystals such as solvothermal, hydrothermal, self assembly and sol-gel, etc [8-12]. Various workers have been working on synthesis and characterization of different nanostructures of pure and doped zinc oxide phosphors. Spanhel and Anderson have explained the synthesis of nano crystals of zinc oxide using distillation set-up starting with products of zinc acetate and ethanol [13]. Using this technique they have obtained highly concentrated colloidal nanocrystals of ZnO of size varying from 3.5 nm - 5.5 nm with ageing and shown that these crystals remain in a dispersed state for weeks. Hossain et al have further modified this technique successfully to obtain nanobelts of ZnO of length 700 m using refluxing technique [14]. However our group has produced ZnO nanobelt of length 2.8 mm with increasing reaction time using the refluxing technique starting with zinc acetate and absolute ethanol [15]. Several workers have used capping agents such as poly vinyl pyridine (PVP), poly ethylene glycol (PEG) etc to stop particle agglomeration and obtained nanoparticles of size less than 5 nm [16-17]. These polymers produce spherical nanoparticles in shape because of the property of surface tension. Sol-gel and thin film deposition techniques are other best alternates to obtain particle size less than 5 nm [18-19]. Chakrabarti et al have obtained ZnO nanoparticles of size varying from 2.84 2.94 nm using tetraethylorthosilicate (TEOS) gel [19]. Figure 1 represents the brief review of various synthesis routes for preparing nanostructures of ZnO. This paper contributes for the synthesis and characterization of bulk- and nano-crystals of zinc oxide using various preparation routs. B2O3, V2O5 and Di2O3 fluxes have been tried to improve the crystallinty of ZnO. Nanocrystals of ZnO have been prepared using Spanhel and Anderson method [13].

Fig. 1. Various Synthesis Routes for preparing Nanostructures of ZnO

2. Synthesis and characterization 2.1 Synthesis of micro- and nano- crystals of ZnO Various routes were tried for synthesis of single, micro and nano crystals of zinc oxide which are discussed in detail as follows: 2.1.1 Synthesis of single crystal using B2O3 and V2O5 fluxes Single crystals of zinc oxide have been synthesized using flux method. B2O3 and V2O5 have been used as fluxes to improve the crystallinity. The mixture of ZnO, B2O3 and V2O5 was kept in a furnace for twenty days at 900 0C in a platinum crucible. After which the crystals were washed with distilled water and dried in an oven for half an hour. This method will be named as synthesis method 1. 0

1) Heating 900 C, 20 days

ZnO (Powder Form) + Fluxes

2) Washing, Drying

2.1.2 Synthesis of bulk crystals ZnO was sintered in air for two hours in a muffle furnace at 900 oC. The sample was then crushed to fine powder form and washed with distilled water to remove the residual impurities and dried in an oven at a temperature 100 oC for half an hour. This method will be named as synthesis method 2. ZnO

1) Heating, 9000C, 2 hrs

2) Washing, Drying

2.1.3 Synthesis of micro-sized crystals using absolute ethanol Colloidal solution was prepared from zinc acetate and absolute ethanol. 0.1M Zn2+ prepared from zinc acetate in absolute ethanol was refluxed under distillation and stirred for 3 hours at 80 oC. This is initially based on the method given by Spanhel et al, 1991. Condensate was separated out. The remaining hygroscopic product was mixed with 0.1M LiOH prepared in 100ml deionized water in which precipitates started forming after then precipitates were separated out using centrifugal

machine at 2500 rpm. Sample was then dried in the oven in oxygen atmosphere at 150 oC. This method will be named as synthesis method 3.

Zn (Ac)2 + EtOH

1) Distillation under stirring 3 hr, 80 0C 2) 0.1M LiOH, Centrifugation, Drying

2.1.4 Synthesis of nanocrystals using absolute ethanol The precursor was prepared from zinc acetate and absolute ethanol in distillation set-up. 0.1M Zn2+ prepared from zinc acetate in absolute ethanol was refluxed under distillation and magnetic stirring for 3 hr at 80 oC. Condensate was separated out. The remaining hygroscopic product was mixed with 0.14M LiOH prepared in 100ml deionized water. Precipitates were separated out using centrifugal machine at 3500 rpm. Sample was then dried in the vacuum oven at 80 oC for 4 hours. The difference between this method and method mentioned in 2.1.3 is that the growth of nanocrystals is controlled with increasing molar concentration of LiOH from 0.1M to 0.14 M. By doing so the near neutral clusters are formed and pH values comes to be 8. Another change is in increased angular velocity of precipitates in centrifugal machine. This method will be named as synthesis method 4. Zn (Ac)2 + EtOH

1) Distillation under stirring 3 hr, 80 0C 2) 0.14M LiOH, Centrifugation, Vacuum Drying

2.2 Characterization of micro- and nano- crystals of ZnO 2.2.1 Optical characterization Nitrogen laser was employed for excitation of micro- and nano-crystals of zinc oxide. Nitrogen laser operates at wavelength of 337.1 nm (ultraviolet region) with high peak power 10 kW, pulsed in operation (7 ns). Synthesized crystals of ZnO were pasted on Pyrex glass plate using xylene. Emission was observed at an angle of 90 to the laser beam and the emission wavelength was selected by a monochromator. After selection of the emission wavelength, signal was sent to a photo-multiplier tube from where multiexponential decay curves were observed and finally sent to computer for simulation purposes. Absorption spectra of the micro- and nano-crystals of ZnO were obtained using Perkin Elmer spectrophotometer. 2.2.2 Morphological characterization Micro sized crystals of zinc oxide have been studied using X-ray diffraction (XRD) pattern and scanning electron microscopy (SEM). Nanocrystals of ZnO are characterized using transmission electron microscopy (TEM) and XRD. X-ray Diffraction (XRD) data for structural characterization of the various prepared samples of ZnO were collected on an X-ray diffractometer (PW1710) using Cu-K radiation. Scanning electron microscope (SEM) images of the samples were obtained from JSM-6100 type microscope. Transmission electron microscope (TEM) images of the samples were obtained using JEOL JEM 2000 Ex type microscope.

Fig. 2. Experimental Set-up using nitrogen laser as an excitation source. Emission wavelength is selected by monochromator. The decay curve is obtained by digital storage oscilloscope and simulated using computer assembly.

3. Theoretical 3.1 Theory of Luminescence When samples are exposed to the laser radiation, the electrons are raised from valence band to excited states. These electrons may return to the valence band with the emission of characteristic luminescent radiation. Intensity of phosphorescence radiation I at time t given by

I = I o e pt

straight line in case of single lifetime. However, in most of the cases, when one comes across the interaction of radiation with solids, there are trapping levels at different depths leading to multiple lifetime components yielding multiexponential decay curves. Transitions from the various radiative traps (trap-depths) corresponding to transition probability values are obtained from the following relation:

p = S e E / k T

where E is the energy of the level in the forbidden gap of the semiconductor (trap-depth), S is

9 1 the escape frequency factor ~ 10 s , k is the Boltzmanns constant and T is the absolute temperature .

In most of the cases, when one come across the interaction of radiation with solids, there are trapping levels at different depths. In an ideal case of uniform distribution, one can assume an equal number of traps at all depths. However in most of the cases, the distribution of traps, at different depths, is not uniform and is given by equation:

I = I 0 t b

where b is called the decay constant, a deciding factor for the distribution of trap states. 3.2 Particle size measurements Particle size D was calculated using Scherer formula D = 0.9 / cos where is the wavelength of Cu-K radiations (1.54), full width at half maximum of the peak corresponding to plane <101> and is the angle obtained from 2 value corresponding to maximum intensity peak in XRD pattern. Energy band gap was calculated from the effective mass model, which is given as below

E = Eg +

2 h2

2mo R

2

1.8e2 4 r R

First term in the relation corresponds to band gap (Eg = 3.37 eV) of bulk crystals, second term is due to quantum confinement effects and third term is related with Coulomb interaction. R is the radius of the nanoparticles obtained from the XRD (average particle size = 7.8 nm). Equations (4) and (5) have been used to simulate particle size and band gap energy respectively of the ZnO nanocrystals using synthesis method 4. 4. Results and discussion Different sized (micron to nanometer) crystals of zinc oxide phosphors have been synthesized using four different methods and their optical and morphological characterizations have been done using Time Resolved Laser Induced Photoluminescence (TRPL), X-ray Diffraction (XRD) analysis, Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM) and UV absorption spectroscopy. Figure 2 represents the experimental set-up for photoluminescence multiexponenetial decay measurement using N2 laser as the excitation source. Figure 3 (a) represents the photograph of 3 millimeter sized crystal of zinc oxide using photogenic camera and (b) represents the XRD pattern of the crystal synthesized by method 1. Figure 4 (a) represents scanning electron microscopic image and (b) represents X-ray Diffraction pattern of the zinc oxide crystals synthesized by method 2. Figure 4 (a) reveals the crystal size varying from 1 - 4 m of ZnO and figure 4 (b) of XRD pattern of ZnO confirms wurtzite crystal structure of the ZnO. Lattice constants (a = b = 0.32 nm and c = 0.52 nm) and diffraction peaks corresponding to the planes <100>, <002> and <101> obtained from X-ray diffraction data are consistent with the JCPDS data of ZnO. Figure 5 represents the scanning electron microscopic image of the zinc oxide crystals obtained using synthesis method 3 and shows the crystal size less than 1 m. Figure 6 represents the intensity vs. time graph for the crystals synthesized by method 1, 2 and 3 by curves a, b and c respectively. Figure 7 (a) represents the transmission electron microscopic image of the nanocrystals of ZnO and figure 7 (b) represents XRD pattern with broadened peaks of ZnO nanocrystals synthesized using method 4. TEM images reveals size of nanocrystals less than 10 nm and was confirmed using Scherer formula (= 7.801 nm) as obtained from XRD data. It is clear from the figure 8 that the life-time values of zinc oxide nanocrystals are in nano-second time domain. Figure 9 represents the absorption wavelength graph for micro- and nano-crystals of ZnO synthesized by method 3 and 4 respectively. Spectrum 1 in figure 9 shows the absorption peak at 364 nm for nanocrystals of ZnO as synthesized using method 4, whereas curve 2 indicate the absorption peak at 368 nm for microcrystals synthesized using method 3. It is clear from absorption spectroscopy that band gap increases on decreasing particle size. The band gap energy have also been confirmed using the effective mass (using equation 5) model with particle size 7.8 nm (using equation 4) as obtained from XRD data. Table 1 indicates the data of life-time, trap-depth and decay constant values of the micro- and nano-crystals. It is observed from the data that life-time and trap-depth values are decreasing as the particle size is decreasing. However decay constant values are increasing with decrease in particle size indicating the traps to be more uniform at nanolevel.

Fig. 3 (a) Photographs using photogenic camera and (b) X-Ray Diffraction (XRD) of Single Crystals of Zinc Oxide Synthesized by Method 1.

Fig. 4 (a) Scanning Electron Micrographs (SEM) and (b) X-ray Diffraction (XRD) Zinc Oxide Crystals Synthesized by Method 2.

Fig. 5 (a) Scanning Electron Micrographs (SEM) and (b) X-ray Diffraction (XRD) of Zinc Oxide Crystals Synthesized by Method 3.

Fig. 6 Intensity vs. Time graph for the micro-crystal of ZnO synthesized by methods 1 (curve a), 2 (curve b) and 3 (curve c).

Fig. 7 (a) Transmission Electron Microscope (TEM) Image (b) X-ray Diffraction (XRD) for nanocrystals of Zinc Oxide synthesized by Method 4.

Fig. 8 Intensity vs. Time graph for nano-crystal of ZnO synthesized by method 4.

Fig. 9 Absorption Intensity vs. wavelength graph for ZnO nano-crystals (curve 1) and microcrystals (curve 2) synthesized by method 4 and 3 respectively.

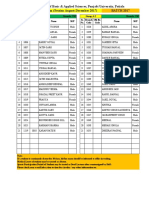

8 Table 1 Life-Time, Trap-Depth and Decay Constant Values for Micro- and Nano-Crystals of ZnO.

Sample synthesized by

Life-time values (in s)

Trap-depth values (in eV) E1 0.24 0.23 0.23 0.14 E2 0.25 0.24 0.24 0.24 E3 0.27 0.26 0.27 0.26

Decay constant b 0.56 0.58 0.62 0.72

2 3 1 Method 1 8.04 13.56 25.30 Method 2 6.52 10.02 18.68 Method 3 6.24 10.38 22.36 Method 4 190* 8.72 15.74 *life-time values are in nanoseconds time domain 5. Conclusion

Micro- and nano-crystals of ZnO have been synthesized using different techniques and were characterized using XRD, SEM, TEM and TRPL. XRD pattern indicate the crystalline nature of the ZnO. Scanning electron microscopic and transmission electron microscopic images of the zinc oxide obtained indicate the size of the various crystals. It is concluded from time resolved laser induced photoluminescence spectra that the life-time values are varying from micro to nanoseconds and there is a considerable decrease in life-time values of the excited states. It is observed that with decreasing particle size of ZnO, life-time values are also decreasing and are in the order of nanosecond time domain for nanocrystals. Decay constant value for ZnO nanocrystals is highest among all the synthesized crystals. This indicates that the energy levels are more uniform within the energy band gap of the semiconductor material. Life-time shortening and increase in decay constant value of ZnO nanocrystals reveal that the synthesized nanophosphors are very efficient and fast. These synthesized crystals have various industrial applications such as active medium for laser oscillations, luminescent material for fluorescent tubes, bio-sensors etc. Acknowledgements This work has been supported by University Grants Commission, New Delhi Project No: 31-19/2005 (SR). The authors are also acknowledged to RSIC (XRD and SEM wing) Punjab University, Chandigarh for providing XRD pattern and SEM images. References [1] Z. K. Yang, P. Yu, G. K. L. Wong, M. Kawasaki, A. Ohtomo, H. Koinuma and Y. Segawa, Solid State Comm., 103, 459, 1997. [2] D. M. Bagnall, Y. F. Chen, Z. Zhu, T. Yao, S. Koyama, M. Y. Shen and T. Goto, Appl. Phys. Lett., 70, 2230, 1997. [3] M. Kawasaki, A. Ohtomo, I. Ohkubo, H. Koinuma, Z. K. Tang, P. Yu, G. K. L. Wong, B. P. Zhang and Y. Segawa, Sci. Engg., B 56, 239, 1998. [4] A. Ohtomo, M. Kawasaki, I. Ohkubo, H. Koinuma, T. Yasuda and Y. Segawa, Appl. Phys. Lett., 75, 980, 1999. [5] N. Ohashi, T. Sekiguchi, K. Aoyama, T. Ohgaki, Y. Terada, I. Sakaguchi, T. Tsurumi and H. Haneda, J. Appl. Phys., 91, 3658, 2002. [6] N. Ohashi, J. Tanaka, T. Ohgaki, H. Haneda, M. Ozawa and T. Tsurumi, J. Mat. Res., 17, 1529, 2002. [7] N. Ohashi, T. Ohgaki, T. Nakata, T. Tsurumi, T. Sekiguchi, H. Haneda, J. Tanaka, J. Korean Phys. Soc. 35, 287, 1999. [8] B. B. Lakshmi, C. J. Patrissi and C. R. Martin, Chem. Mater., 9, 2544, 1997. [9] L. Vayssieres, K. Keis, A. Hagfeldt and S. E. Lindquist, Chem. Mater., 13, 4395, 2001. [10] C. Pacholski, A. Kornowski, H. Weller, Angew. Chem. Int. Edn. Engl., 41, 1188, 2002. [11] L. Vayssieres, Adv. Mater., 15, 464, 2003. [12] B. Liu and H. C. Zeng, J. Am. Chem. Soc., 125, 4430, 2003. [13] L. Spanhel and M. R. Anderson, J. Am. Chem. Soc., 113, 2826, 1991.

[14] M. K. Hossain, S. C. Ghosh, Y. Boontongkong, C. Thanachayanont and J. Dutta, J. Meta. Nanocrys. Mat., 23, 27, 2005. [15] H. S. Bhatti, A. Gupta, N. K. Verma and S. Kumar, J. Mat. Sci: Mater Electron, 17, 281, 2006. [16] T. Hirano, H. Kozuka, J. Mat. Sci., 38, 4203, 2003. [17] A. Vladimir, Fonoberov and A. A. Balandina, Appl. Phys. Lett., 85, 24, 2004. [18] H. J. Lee1, B. S. Kim, C. R. Cho and S. Y. Jeong, Phys. Stat. Sol. (b) 241, 1533, 2004. [19] S. Chakrabarti, D. Ganguli and S. Chaudhuri, J. Phys. D: Appl. Phys. 36, 146, 2003. [20] H. S. Bhatti, R. Sharma, N. K. Verma and S. Kumar, Ind. J. Engg. Mat. Sc., 11, 121, 2004. [21] H. S. Bhatti, A. Gupta, N. K. Verma and S. Kumar, J. Phys. Chem. Solid, 67, 868, 2006.

Você também pode gostar

- Synthesis, Characterization and Optical Properties of Zinc Oxide NanoparticlesDocumento6 páginasSynthesis, Characterization and Optical Properties of Zinc Oxide NanoparticlesSyahmi NordinAinda não há avaliações

- Synthesis of Zinc Oxide Nanoparticles VIDocumento10 páginasSynthesis of Zinc Oxide Nanoparticles VIHarden PatilAinda não há avaliações

- Synthesis of ZnO Nanoparticles by Hydrothermal MethodDocumento9 páginasSynthesis of ZnO Nanoparticles by Hydrothermal MethodMariana BulileteAinda não há avaliações

- Visible Emission From Zno Nanorods Synthesized by A Simple Wet Chemical MethodDocumento10 páginasVisible Emission From Zno Nanorods Synthesized by A Simple Wet Chemical MethodKenn SenadosAinda não há avaliações

- Paper 21Documento6 páginasPaper 21Emon AzharAinda não há avaliações

- Sol-Gel Synthesis of Zinc Oxide Nanoparticles Using Citrus Aurantifolia ExtractsDocumento4 páginasSol-Gel Synthesis of Zinc Oxide Nanoparticles Using Citrus Aurantifolia ExtractsAnonymous ix7WERGAinda não há avaliações

- Synthesis and Characterization of Znonano-Rods at Different TemperatureDocumento6 páginasSynthesis and Characterization of Znonano-Rods at Different TemperatureInternational Journal of Application or Innovation in Engineering & ManagementAinda não há avaliações

- Phsv04i03p0119 PDFDocumento7 páginasPhsv04i03p0119 PDFphysicsjournalAinda não há avaliações

- Synthesis and Characterization of Zno Nanopowder by Non-Basic RouteDocumento9 páginasSynthesis and Characterization of Zno Nanopowder by Non-Basic RouteOvidiu CristiAinda não há avaliações

- Synthesis of Sno Nano Rods and Their Photocatalytic PropertiesDocumento5 páginasSynthesis of Sno Nano Rods and Their Photocatalytic PropertiesLai van CuongAinda não há avaliações

- Simple Hydrothermal ZnO, 2013Documento7 páginasSimple Hydrothermal ZnO, 2013hellna284Ainda não há avaliações

- Simple Hydrothermal Preparation of Zinc Oxide Powders Using Thai Autoclave UnitDocumento7 páginasSimple Hydrothermal Preparation of Zinc Oxide Powders Using Thai Autoclave UnitAlexander Fabián GAinda não há avaliações

- Sonochemical and Microwave-Assisted Synthesis of Linked Single-Crystalline Zno RodsDocumento6 páginasSonochemical and Microwave-Assisted Synthesis of Linked Single-Crystalline Zno RodssecateAinda não há avaliações

- Superlattices and Microstructures: V. Devabharathi, K.L. Palanisamy, N. Meenakshi SundaramDocumento6 páginasSuperlattices and Microstructures: V. Devabharathi, K.L. Palanisamy, N. Meenakshi SundaramKL PSAinda não há avaliações

- From Zinc Selenate To Zinc Selenide NanostructuresDocumento8 páginasFrom Zinc Selenate To Zinc Selenide Nanostructuresprakush_prakushAinda não há avaliações

- 2 Au NPs Electrochemically Deposited On Porous Si PL SEM EDXDocumento6 páginas2 Au NPs Electrochemically Deposited On Porous Si PL SEM EDXben0706Ainda não há avaliações

- Bhujel2019 PDFDocumento6 páginasBhujel2019 PDFbib123456789huAinda não há avaliações

- Structural, Magnetic and Electrochemical Properties of Coxzn1-X Fe2O4 Nanoparticles Synthesized by Co-Precipitat..Documento10 páginasStructural, Magnetic and Electrochemical Properties of Coxzn1-X Fe2O4 Nanoparticles Synthesized by Co-Precipitat..vijayamathubalan pandyAinda não há avaliações

- 123 PDFDocumento3 páginas123 PDFAurelia Anggit WMAinda não há avaliações

- Microwave-Assisted Hydrothermal Synthesis of ZnO Rod-Assembled Microspheres and Their Photocatalytic PerformancesDocumento5 páginasMicrowave-Assisted Hydrothermal Synthesis of ZnO Rod-Assembled Microspheres and Their Photocatalytic Performanceskarina CruzAinda não há avaliações

- Synthesis of ZnO Nanospheres With Uniform Nanopores by A Hydrothermal ProcessDocumento6 páginasSynthesis of ZnO Nanospheres With Uniform Nanopores by A Hydrothermal ProcessSekhar BabuAinda não há avaliações

- Structural Investigations and Magnetic Properties of Cobalt Ferrite Nanoparticles Prepared by SolDocumento5 páginasStructural Investigations and Magnetic Properties of Cobalt Ferrite Nanoparticles Prepared by SolAlin DrucAinda não há avaliações

- Hydrothermal PreparationDocumento6 páginasHydrothermal PreparationShubhankit KatiyarAinda não há avaliações

- Optik: Azeddine Chelouche, Tahar Touam, Djamel Djouadi, Ali AksasDocumento4 páginasOptik: Azeddine Chelouche, Tahar Touam, Djamel Djouadi, Ali AksasyuyunworoAinda não há avaliações

- Hydrothermal SynthesisDocumento4 páginasHydrothermal SynthesisSubhashini VedalaAinda não há avaliações

- 1.obsevrve The Optical Properties of Zno After Modification Through Laser AbliationDocumento14 páginas1.obsevrve The Optical Properties of Zno After Modification Through Laser Abliationsidra khalidAinda não há avaliações

- Zinc Oxide Nanostructured Material For Sensor Application: Corresponding AuthorDocumento5 páginasZinc Oxide Nanostructured Material For Sensor Application: Corresponding AuthorMahfuzur Rahman MafuzAinda não há avaliações

- Study of Structural and Optical Properties of Zinc Oxide Rods Grown On Glasses by Chemical Spray PyrolysisDocumento8 páginasStudy of Structural and Optical Properties of Zinc Oxide Rods Grown On Glasses by Chemical Spray PyrolysismanisjcAinda não há avaliações

- 18 - Shen2008, Photocatalytic Degradation For Methylene Blue Using Zinc Oxide PreparedDocumento4 páginas18 - Shen2008, Photocatalytic Degradation For Methylene Blue Using Zinc Oxide Preparedhellna284Ainda não há avaliações

- Sol Gel Method Zinc OxideDocumento10 páginasSol Gel Method Zinc OxideAdzan RamadhanAinda não há avaliações

- ZnO SynthesisDocumento4 páginasZnO Synthesissoumendra ghoraiAinda não há avaliações

- Structural, Optical, Morphological and Dielectric Properties of Cerium Oxide NanoparticlesDocumento5 páginasStructural, Optical, Morphological and Dielectric Properties of Cerium Oxide NanoparticlesSuhaib ImtiyazAinda não há avaliações

- 1 PDFDocumento4 páginas1 PDFRobby KephiAinda não há avaliações

- Characterization of A Clay-Polymer Composite Using The Infrared SpectrosDocumento3 páginasCharacterization of A Clay-Polymer Composite Using The Infrared SpectrosAnonymous 9XI54PvKPAinda não há avaliações

- Solvothermal Synthesis and Characterization of ZnSe Nanoplates PDFDocumento4 páginasSolvothermal Synthesis and Characterization of ZnSe Nanoplates PDFghoraisoumendra9252Ainda não há avaliações

- Al ZnO Khan14Documento7 páginasAl ZnO Khan14krlnmAinda não há avaliações

- Investigation of Sol-Gel Synthesized CdO-ZnO PDFDocumento11 páginasInvestigation of Sol-Gel Synthesized CdO-ZnO PDFNicolas Carvajal HerreraAinda não há avaliações

- Shi 1999Documento6 páginasShi 1999Tatiane NascimentoAinda não há avaliações

- Journal of Alloys and CompoundsDocumento5 páginasJournal of Alloys and CompoundsCarlos LopezAinda não há avaliações

- Nagara Ju 2017Documento6 páginasNagara Ju 2017AliAinda não há avaliações

- 10 1016@j Ijleo 2017 04 013Documento20 páginas10 1016@j Ijleo 2017 04 013Shifa ChaudhariAinda não há avaliações

- SYNTHESIS OF NANOSIZED CuO PARTICLES A SIMPLEDocumento7 páginasSYNTHESIS OF NANOSIZED CuO PARTICLES A SIMPLEPrakash KhudeAinda não há avaliações

- Synthesis, Structural and Morphological Characterization of Ceo - Zno Nanosized Powder Systems From Pechini S MethodDocumento6 páginasSynthesis, Structural and Morphological Characterization of Ceo - Zno Nanosized Powder Systems From Pechini S MethodKAREN MILAGROS MARTINEZ FLORESAinda não há avaliações

- C H Gas Sensor Based On Ni-Doped Zno Electrospun Nanofibers: CeramicsDocumento5 páginasC H Gas Sensor Based On Ni-Doped Zno Electrospun Nanofibers: CeramicsUmairaAinda não há avaliações

- Characterization of CuODocumento5 páginasCharacterization of CuOBilal JuttAinda não há avaliações

- 847 AugustineCDocumento10 páginas847 AugustineCRenato EvangelistaAinda não há avaliações

- Synthesis of Zinc Oxide Nanocrystalline Powders For Cosmetic ApplicationsDocumento6 páginasSynthesis of Zinc Oxide Nanocrystalline Powders For Cosmetic ApplicationsMaritnela Gomez JimenezAinda não há avaliações

- Synthesis and Characterization of Zinc Oxide Nanoparticles With Small Particle Size DistributionDocumento8 páginasSynthesis and Characterization of Zinc Oxide Nanoparticles With Small Particle Size DistributionMónica Tatiana HerreraAinda não há avaliações

- 2012201Documento8 páginas2012201YocobSamandrewsAinda não há avaliações

- Tin OxidationDocumento7 páginasTin Oxidationsunny kumarAinda não há avaliações

- Nanorods 2Documento5 páginasNanorods 2Yash SharanAinda não há avaliações

- Synthesis of Yttria-Stabilized Zirconia Film by Aerosol Flame Pyrolysis DepositionDocumento6 páginasSynthesis of Yttria-Stabilized Zirconia Film by Aerosol Flame Pyrolysis Depositionamirlove206Ainda não há avaliações

- NO O S Z O N: Ptical Ensing in N AnostructuresDocumento4 páginasNO O S Z O N: Ptical Ensing in N AnostructuresSadaf ZiaAinda não há avaliações

- Research Article Synthesis and Characterization of Zno-Zro Nanocomposites For Photocatalytic Degradation and Mineralization of PhenolDocumento13 páginasResearch Article Synthesis and Characterization of Zno-Zro Nanocomposites For Photocatalytic Degradation and Mineralization of PhenolBagya RajAinda não há avaliações

- Synthesis and Studies of PANI/Cerium Dioxide Nanocomposites: E. Kumar, P. SelvarajanDocumento4 páginasSynthesis and Studies of PANI/Cerium Dioxide Nanocomposites: E. Kumar, P. SelvarajansobisobiAinda não há avaliações

- Physica E: A.F. Lotus, S.N. Tacastacas, M.J. Pinti, L.A. Britton, N. Stojilovic, R.D. Ramsier, G.G. ChaseDocumento5 páginasPhysica E: A.F. Lotus, S.N. Tacastacas, M.J. Pinti, L.A. Britton, N. Stojilovic, R.D. Ramsier, G.G. ChaseEstudiante2346Ainda não há avaliações

- Samad I Pak Chin 2017Documento37 páginasSamad I Pak Chin 2017banepostingAinda não há avaliações

- Heat, Mar 2011Documento5 páginasHeat, Mar 2011emediageAinda não há avaliações

- Microwave-Assisted Synthesis and Characterization of Cao NanoparticlesDocumento7 páginasMicrowave-Assisted Synthesis and Characterization of Cao NanoparticlesBeth JiménezAinda não há avaliações

- Journal of The Brazilian Chemical Society: Cover PictureDocumento6 páginasJournal of The Brazilian Chemical Society: Cover PicturebudhladaAinda não há avaliações

- B. Tech Part-I - Group List - 1st Sem - Batch 2017Documento12 páginasB. Tech Part-I - Group List - 1st Sem - Batch 2017budhladaAinda não há avaliações

- Isotherm and Kinetic Studies On Adsorption of Malachite Green Using Chemically Synthesized Silver NanoparticlesDocumento17 páginasIsotherm and Kinetic Studies On Adsorption of Malachite Green Using Chemically Synthesized Silver NanoparticlesbudhladaAinda não há avaliações

- Journal of The Brazilian Chemical Society: Cover PictureDocumento6 páginasJournal of The Brazilian Chemical Society: Cover PicturebudhladaAinda não há avaliações

- Inspiring Chemistry: Editor-in-Chief: Chair of The Editorial BoardDocumento2 páginasInspiring Chemistry: Editor-in-Chief: Chair of The Editorial BoardbudhladaAinda não há avaliações

- 2012 Analytical Chemistry Laboratory Manual (Aprasas Uzsienio Studentams)Documento57 páginas2012 Analytical Chemistry Laboratory Manual (Aprasas Uzsienio Studentams)budhladaAinda não há avaliações

- Sorption of Divalent Metal Ions From Aqueous Solution by Carbon Nanotubes: A ReviewDocumento8 páginasSorption of Divalent Metal Ions From Aqueous Solution by Carbon Nanotubes: A ReviewbudhladaAinda não há avaliações

- 651 IntroNotes3Documento54 páginas651 IntroNotes3budhladaAinda não há avaliações

- Ijbmbs 2470 4490 01 201Documento7 páginasIjbmbs 2470 4490 01 201budhladaAinda não há avaliações

- Metallic and Organic Nanomaterials and Their Use in Pollution Control: A ReviewDocumento11 páginasMetallic and Organic Nanomaterials and Their Use in Pollution Control: A ReviewbudhladaAinda não há avaliações

- Metallic and Organic Nanomaterials and Their Use in Pollution Control: A ReviewDocumento11 páginasMetallic and Organic Nanomaterials and Their Use in Pollution Control: A ReviewbudhladaAinda não há avaliações

- 2Documento16 páginas2budhladaAinda não há avaliações

- Nanotechnology, Water, & DevelopmentDocumento44 páginasNanotechnology, Water, & DevelopmentAlper Emin TürkoğluAinda não há avaliações

- NN 304735 RDocumento7 páginasNN 304735 RbudhladaAinda não há avaliações

- Q62 DZ MW 4 D3Documento26 páginasQ62 DZ MW 4 D3budhladaAinda não há avaliações

- Research Journal of Pharmaceutical, Biological and Chemical SciencesDocumento12 páginasResearch Journal of Pharmaceutical, Biological and Chemical SciencesbudhladaAinda não há avaliações

- 99 J 9 D 88 J TFDocumento16 páginas99 J 9 D 88 J TFbudhladaAinda não há avaliações

- DR MukeshDocumento5 páginasDR MukeshbudhladaAinda não há avaliações

- 8aaa8e0b-becc-4864-8a6c-fed3adf66a08Documento6 páginas8aaa8e0b-becc-4864-8a6c-fed3adf66a08budhladaAinda não há avaliações

- Sensors 13 06204Documento13 páginasSensors 13 06204budhladaAinda não há avaliações

- General Chemistry Lab Safety: Proper Handling of Chemicals and EquipmentDocumento2 páginasGeneral Chemistry Lab Safety: Proper Handling of Chemicals and EquipmentbudhladaAinda não há avaliações

- Sensors 13 06204Documento13 páginasSensors 13 06204budhladaAinda não há avaliações

- Jabbar332013ACSj3675Documento18 páginasJabbar332013ACSj3675budhladaAinda não há avaliações

- Q62 DZ MW 4 D3Documento26 páginasQ62 DZ MW 4 D3budhladaAinda não há avaliações

- Determination of Phenols in Runoff: M. Grynkiewicz, Ż. Polkowska, A. Kot-Wasik, J. NamieśnikDocumento5 páginasDetermination of Phenols in Runoff: M. Grynkiewicz, Ż. Polkowska, A. Kot-Wasik, J. NamieśnikbudhladaAinda não há avaliações

- Determination of Phenols in Runoff: M. Grynkiewicz, Ż. Polkowska, A. Kot-Wasik, J. NamieśnikDocumento5 páginasDetermination of Phenols in Runoff: M. Grynkiewicz, Ż. Polkowska, A. Kot-Wasik, J. NamieśnikbudhladaAinda não há avaliações

- Mineral WaterDocumento2 páginasMineral WaterbudhladaAinda não há avaliações

- 1Documento1 página1budhladaAinda não há avaliações

- Full PaDocumento1 páginaFull PabudhladaAinda não há avaliações

- Discussion Exp 2Documento2 páginasDiscussion Exp 2Eqieyn Jerr50% (2)

- Vetiver Oil (Vetiveria Zizanioides)Documento7 páginasVetiver Oil (Vetiveria Zizanioides)Shafira NurfadhilaAinda não há avaliações

- NCERT Exemplar For Class 12 Chemistry Chapter 2Documento37 páginasNCERT Exemplar For Class 12 Chemistry Chapter 2Shinchan in HindiAinda não há avaliações

- Kaziqueks Guide To AlchemyDocumento34 páginasKaziqueks Guide To AlchemyDenkonoAinda não há avaliações

- IELTS Academic Reading Test 1-1Documento11 páginasIELTS Academic Reading Test 1-1Shinta80% (5)

- Sparkling Cocktails Martini Cocktails: With Lime and MintDocumento2 páginasSparkling Cocktails Martini Cocktails: With Lime and MintKnotsAinda não há avaliações

- ASTM For PetroDocumento6 páginasASTM For PetroPhu HaoAinda não há avaliações

- Chem 31.1 Formal Report 1Documento3 páginasChem 31.1 Formal Report 1chewazableAinda não há avaliações

- Maratek Product Line 8 PageDocumento8 páginasMaratek Product Line 8 Pagenps1966Ainda não há avaliações

- Synthesis of Alkyl HalideDocumento3 páginasSynthesis of Alkyl HalideKelvin LabarezAinda não há avaliações

- Azeotropic DistillationDocumento98 páginasAzeotropic Distillationmyself_riteshAinda não há avaliações

- All Kasganj 450 CsDocumento1 páginaAll Kasganj 450 Cskush mishraAinda não há avaliações

- 4th Opp Final ReportDocumento30 páginas4th Opp Final ReportLEBOGANG MASHABELAAinda não há avaliações

- Etylene Oxit ProductDocumento24 páginasEtylene Oxit ProductPhạm Văn CảnhAinda não há avaliações

- Simulation of McCabeDocumento10 páginasSimulation of McCabejohnAinda não há avaliações

- Astm UopDocumento5 páginasAstm UopSaro HAinda não há avaliações

- Bai Yun-2Documento8 páginasBai Yun-2Hamada Shoukry MohammedAinda não há avaliações

- Gasoline Hysys PDFDocumento60 páginasGasoline Hysys PDFalexia183100% (1)

- 126Documento18 páginas126bamban bamAinda não há avaliações

- L 1.4 - Mixture SeparationDocumento17 páginasL 1.4 - Mixture SeparationJhon Emmanuel E. LusicoAinda não há avaliações

- Che 3G04 Winter 2004 Mcmaster UniversityDocumento33 páginasChe 3G04 Winter 2004 Mcmaster UniversityAris Koreya100% (2)

- Densitati BauturiDocumento4 páginasDensitati BauturiCristi TomaAinda não há avaliações

- Material BalanceDocumento29 páginasMaterial Balancepeter-albert.danielAinda não há avaliações

- EnglishDocumento215 páginasEnglishBrian ChenAinda não há avaliações

- Lesson 2 - Fractional DistillationDocumento5 páginasLesson 2 - Fractional DistillationAditya ShyamsunderAinda não há avaliações

- Phenol ProductionDocumento9 páginasPhenol ProductionPlant Design100% (1)

- 03 - Crude - Destillation Units PDFDocumento35 páginas03 - Crude - Destillation Units PDFRodrigo Goyzueta FloresAinda não há avaliações

- Is1205-2022-Softening Point BitumenDocumento10 páginasIs1205-2022-Softening Point BitumenbaubleAinda não há avaliações

- A Seminar Report ON Solar Power Water Purification OpportunitiesDocumento28 páginasA Seminar Report ON Solar Power Water Purification OpportunitiesJay Tailor100% (1)

- Selection and Design of CondensersDocumento27 páginasSelection and Design of Condensersjdgh1986Ainda não há avaliações