Escolar Documentos

Profissional Documentos

Cultura Documentos

Selecting Target ISO Cleanliness Codes

Enviado por

luaguDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Selecting Target ISO Cleanliness Codes

Enviado por

luaguDireitos autorais:

Formatos disponíveis

Selecting Target ISO Cleanliness Codes

When setting target ISO fluid cleanliness codes for hydraulic and lubrication systems it is important keep in mind the objectives to be achieved. Maximizing equipment reliability and safety, minimizing repair and replacement costs, extending useful fluid life, satisfying warranty requirements, and minimizing production down-time are attainable goals. Once a target ISO cleanliness code is set following a progression of steps to achieve that target, monitor it, and maintain it justifiable rewards will be yours. Set the Target. The first step in identifying a target ISO code for a system is to identify the most sensitive on an individual system, or the most sensitive component supplied by a central reservoir. If a central reservoir supplies several systems the overall cleanliness must be maintained, or the most sensitive component must be protected by filtration that cleans the fluid to the target before reaching that component.

Recommended* Target ISO Cleanliness Codes and media selection for systems using petroleum based fluids per ISO4406:1999 for particle sizes 4[c] / 6[c] / 14[c]

Pressure < 140 bar < 2000 psi 20/18/15 19/17/14 20/18/15 18/16/13 18/16/13 Media x[c] = 1000 (x = 200) 22[c] (25) 12[c] (12) 22[c] (25) 7[c] (6) 7[c] (6) Pressure Media Pressure Media 212 bar x[c] = 1000 > 212 bar x[c] = 1000 3000 psi (x = 200) > 3000 psi (x = 200) 19/17/15 12[c] (12) 18/16/13 12[c] (12) 17/15/12 7[c] (6) 19/17/14 12[c] (12) 18/16/13 12[c] (12) 17/15/13 16/14/12 5[c] (3) 7[c] (6) 17/15/12 5[c] (3)

Pumps

Fixed Gear Fixed Piston Fixed Vane Variable Piston Variable Vane Valves Cartridge Check Valve Directional (solenoid) Flow Control Pressure Control (modulating) Proportional Cartridge Valve Proportional Directional Proportional Flow Control Proportional Pressure Control Servo Valve Bearings Ball Bearing Gearbox (industrial) Journal Bearing (high speed) Journal Bearing (low speed) Roller Bearing Actuators Cylinders Vane Motors Axial Piston Motors Gear Motors Radial Piston Motors Test Stands, Hydrostatic Test Stands Hydrostatic Transmissions

18/16/13 20/18/15 20/18/15 19/17/14 19/17/14 17/15/12 17/15/12 17/15/12 17/15/12 16/14/11

12[c] (12) 22[c] (25) 22[c] (25) 12[c] (12) 12[c] (12) 7[c] (6) 7[c] (6) 7[c] (6) 7[c] (6) 7[c] (6)

17/15/12 20/18/15 19/17/14 18/16/13 18/16/13 17/15/12 17/15/12 17/15/12 17/15/12 16/14/11

7[c] (6) 22[c] (25) 12[c] (12) 12[c] (12) 12[c] (12) 7[c] (6) 7[c] (6) 7[c] (6) 7[c] (6) 5[c] (3)

17/15/12 19/17/14 18/16/13 18/16/13 17/15/12 16/14/11 16/14/11 16/14/11 16/14/11 15/13/10

7[c] (6) 12[c] (12) 12[c] (12) 12[c] (12) 7[c] (6) 5[c] (3) 5[c] (3) 5[c] (3) 5[c] (3) 5[c] (3)

Other Considerations Table 1 recommends conservative target ISO cleanliness codes based on a several component manufacturers guidelines and extensive field studies for standard industrial operating conditions in systems using petroleum based fluids. If a nonpetroleum based fluid is used (i.e. water glycol) the target ISO code should be set one value lower for each size (4[c]/6[c]/14[c]). If a combination of the following conditions exists in the system the target ISO code should also be set one value lower: Component is critical to

safety or overall system reliability. Frequent cold start. Excessive shock or vibration. Other Severe operation conditions.

15/13/10 17/16/13 17/15/12 17/15/12 16/14/11

5[c] (3) 12[c] (12) 7[c] (6) 7[c] (6) 7[c] (6)

17/15/12 20/18/15 19/17/14 20/18/14 20/18/15

7[c] (6) 22[c] (25) 12[c] (12) 22[c] (25) 22[c] (25)

16/14/11 19/17/14 18/16/13 19/17/13 19/17/14

5[c] (3) 12[c] (12) 12[c] (12) 12[c] (12) 12[c] (12)

15/13/10 18/16/13 17/15/12 18/16/13 18/16/13

5[c] (3) 12[c] (12) 7[c] (6) 12[c] (12) 12[c] (12)

15/13/10 17/15/13

5[c] (3) 7[c] (6)

15/13/10 16/14/11

5[c] (3) 5[c] (3)

15/13/10 16/14/11

5[c] (3) 5[c] (3)

*Depending upon system volume and severity of operating conditions a combination of filters with varying degrees of filtration efficiency might be required (I.e. pressure, return, and off-line filters) to achieve and maintain the desired fluid cleanliness.

Example

Operating Pressure Most Sensitive Component Fluid Type Operating Conditions 156 bar, 2200 psi Directional Solenoid Water Glycol Remote location, repair difficult High ingression rate

ISO Code

19/17/14 18/16/13 17/15/12

Comments

recommended baseline ISO Code Adjust down one class Adjust down one class, combination of critical nature, severe conditions

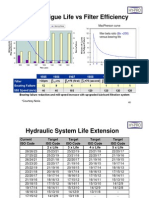

Extending Roller Bearing Life. Improving fluid cleanliness in lubrication systems for roller bearings can exponentially increase component life. Figure B describes attainable increases in life expectancy of roller bearings as improvements in ISO fluid cleanliness codes are made. Life extension for hydraulic components can be achieved by improving fluid cleanliness.

Current ISO Code 28/26/23 27/25/22 26/24/21 25/23/20 25/22/19 23/21/18

Target ISO Code 2 x Life 25/22/19 23/21/18 22/20/17 21/19/16 20/18/15 19/17/14

Target ISO Code 3 x Life 22/20/17 21/19/16 20/18/15 19/17/14 18/16/13 17/15/12

Target ISO Code 4 x Life 20/18/15 19/17/14 19/17/14 17/15/12 16/14/11 15/13/10

Target ISO Code 5 x Life 19/17/14 18/16/13 17/15/12 16/14/11 15/13/10 14/12/9

Accurate oil analysis - Once the target ISO fluid cleanliness code is established it is critical to properly measure the actual cleanliness of the system. A well designed plan to achieve cleanliness can be undermined if steps are not taken to ensure accurate and repeatable oil analysis. When sampling the oil a wide range of variables can affect the outcome yielding inaccurate results. For more information see Accurate oil sampling and analysis article. Oil sampling methods and practices - Bottle samples analyzed by independent laboratories is common and widely accepted as a method of quantifying fluid cleanliness. However, there are many variables associated with bottle sampling that can cause inaccurate readings. Background contamination in clean sample bottles or vacuum tubes can increase ISO codes by 1~4 classes per size measured, 4[c]/6[c]/14[c]. Inconsistent in-plant sampling practices (i.e. sample port flush time, bottle rinsed or not). Exposure of sample to airborne contaminate during sampling and analysis Analysis lab procedure repeatability by operator (i.e. agitation~count interval affect on suspension). Analysis lab calibration drift. Variability between oil analysis lab particle

On-line particle counting - Connecting an on-line particle counter directly to the hydraulic or lube system through sampling ports provides the most accurate snapshot of fluid cleanliness and eliminates many of the inherent variables associated with bottle sampling. Some particle counters can function with system pressure as low as 20 psi (1.42 bar) at certain viscosities for sampling pressure line, return line, or lubrication system. There are also particle counter options available to draw (Sip) the fluid from a reservoir, tote, or other container directly into the particle counter when system pressure is not available. Monitor sample port cleanliness in real time to know when the sample is truly representative of the system and not tainted with sample port contaminate buildup. Maintaining control of the sampling and analysis procedures increases the accuracy of your results, eliminates the waiting game to get samples back from a lab, allows quicker response to contamination related issues, and even save money on oil sample kits. No one knows your system better than you and once armed with the right oil analysis approach and diagnostic equipment you can make improvements in reliability. Oil sampling port types and locations - Just as sampling technique and method can compromise results, sampling port and location can also be a challenge. Sampling ports are often contamination collection points and must be flushed for up to 6 minutes before a truly representative sample is captured. Without a proper port flush the results can be affected. Port location is also critical to obtaining a good sample. Locating a sampling where there is turbulent flow will provide more realistic results than a laminar area. For more information see Accurate oil sampling and analysis article. PTK-1 Oil analysis kit - Patch test kits are a good complement to on-line particle counters as they provide the capability to visually analyze contamination levels and types in the system. The kit includes a microscope, vacuum pump, test patches, and solvent dispenser integrated into a carrying case. The kit also features a reference manual to correlate visual patch appearance to approximate ISO code.

Machine Tool Contamination Field Study

Focus: Solving contamination issues resulting from insufficient filtration on power units and machine tools.

APPLICATIONS

Pressure filters are ideal for protecting control valves and other sensitive components from internally generated contaminate and ingression. Machine tools without a pressure filter protecting valve manifolds after the pump. Power units on CNC lathes and milling equipment, Plastics injection molding, mobile equipment, and other small industrial machines with sensitive control valves.

The Problem - Insufficient filtration

Machine tools and power units are frequently designed without the filtration necessary to maintain recommended fluid cleanliness levels for the system. A fluid cleanliness case study of three CNC lathes (A, B, C) raised some concern. The only filtration present was either a coarse suction strainer or coarse return-line screen. Baseline oil analysis (see fig 1) revealed that fig. 1 the fluid cleanliness levels of the Machine ISO code* hydraulic fluids (per ISO 4406 code chart) were higher than A 22 / 20 / 14 recommended levels for the B 23 / 20 / 14 system components (see fig 2).

C 23 / 21 / 16 fig 2. Pumps <2000 psi Fixed gear 20/18/15 Fixed vane 20/18/15 Fixed piston 19/17/14 Variable vane 18/16/13 Variable piston 18/16/13 Valves Directional (solenoid) Proportional Servo Valve

Contamination Basics & Sources

Particulate contamination is the number one cause of hydraulic component failure, and 70~75% of failures are related to surface degradation caused by mechanical wear. Sources of particulate contamination Built-In contamination (assembly environment, dirty new components and hoses, metal fabrication) Ingested contamination ( leaky reservoirs, no reservoir breather, worn rod wipers and bearing seals, dirty replacement components, system exposure during maintenance, new oilsee fig 3.) Internally generated contamination (abrasive wear, adhesive wear, stress related wear, corrosion, fluid breakdown)

Fig 3 (new oil typical ISO code 24/21/18).

2000~3000 19/17/15 19/17/14 18/16/13 17/15/12 17/15/13 2000~3000 20/18/15 17/15/12 16/14/11

>3000 psi 18/16/13 17/15/12 16/14/12 >3000 psi 19/17/14 16/14/11 15/13/10

Solution Part I - System Clean-up

The pressure filter assembly, including 12[c] = 1000 filter element and element condition indicator, was added to each of the three machines (see fig 4) after the pressure pump (piston type). After nine days of operation the indicators on machines A and C were signaling terminal pressure drop. At that time all three elements were serviced and the oil was analyzed (see fig 5). The ISO codes improved, but not to the level recommended for servo valves. The next step was to set target cleanliness codes and enhance the filtration efficiency to reach the target. The spent elements that were removed contained large particles including piping putty (from installation of new hoses) and other large debris fig. 5 that was not being Mach. ISO code before ISO code after 9 days removed by the Pressure filter (12[c] = 1000) suction strainer. A 22 / 20 / 14 19 / 18 / 12 B 23 / 20 / 14 21 /18 / 12 C 23 / 21 / 16 20 / 18 / 13

Fig 4.

Solution Part II - Enhanced Filtration and Target Cleanliness Codes

A target ISO Cleanliness Code of 16 / 14 / 11 (measured at filter effluent) was established for all three machines to protect and maximize piston pump and solenoid valve life. New filter elements were installed with a more efficient rating of 5[c] = 1000 (3 = 200 according to old standards) to achieve fig. 7 the target. After 60 days of service the oil from all three Mach. ISO code ISO code after ISO code after machines was analyzed (see fig 7), even though none of the before filter 60 days 180 days assemblies were indicating terminal pressure drop. ( 5[c] = 1000) ( 5[c] = 1000) Machines B and C were able to attain the target while A did not, although adding of the pressure filter made considerable A 22 / 20 / 14 17 / 15 / 11 11 / 9 / 7 improvement in cleanliness. The oil was sampled after 180 days B 23 / 20 / 14 15 / 13 / 8 13 / 11 / 9 using an on-line particle counter connected to the drain plug of C 23 / 21 / 16 16 / 12 / 10 14 / 11 / 9 the filter bowl. This location represents one of the dirtiest points on the system since the oil has been through the system and in the reservoir. Sampling with an on-line particle Hydraulic Component fig. 8 counter and proper flushing techniques eliminates Current Target Target Target Target variables associated with bottle sampling. Figure 8 ISO Code ISO Code ISO Code ISO Code ISO Code illustrates increased life expectancy for hydraulic 2 x Life 3 x Life 4 x Life 5 x Life components that can be realized by reducing fluid cleanliness codes. The benefits of clean fluid justify 28/26/23 25/22/19 22/20/17 20/18/15 19/17/14 the cost of filtration. 27/25/22 23/21/18 21/19/16 19/17/14 18/16/13 26/24/21 22/20/17 20/18/15 19/17/14 17/15/12 Benefits of clean fluid 25/23/20 21/19/16 19/17/14 17/15/12 16/14/11 Minimize unplanned equipment downtime. 25/22/19 20/18/15 18/16/13 16/14/11 15/13/10 Reduce maintenance costs and labor. 23/21/18 19/17/14 17/15/12 15/13/10 14/12/9 Reduce expensive component repair or 22/20/17 18/16/13 16/14/11 15/13/10 13/11/8 replacement costs. 21/19/16 17/15/12 15/13/10 13/11/8 Improve operating efficiency of equipment 20/18/15 16/14/11 14/12/9 with sensitive components. 19/17/14 15/13/10 13/11/8 Extend service life of fluids. 18/16/13 14/12/9 17/15/12 13/11/8 Adding a desiccant breather to the reservoir assures that the air ingested is dry and clean. Reducing water content reduces chemical compound formation, biological growth, oxidation and extends fluid life. Desiccant breathers also control particulate contaminate ingression down to 4[c] or 2 with absolute efficiency. Filler-breather caps commonly found on reservoirs dont properly control particulate contamination. Specific desiccant breathers also adsorb water and oil mist as the reservoir exhales. A full range of adapters is commonly available to retro-fit any reservoir.

Você também pode gostar

- WE 201 - Bearing Maintenance and TechnologyDocumento2 páginasWE 201 - Bearing Maintenance and TechnologyBjorn FejerAinda não há avaliações

- Operation and Maintenance Manual FOR Winch TYPE: 07.02.08: (Acc. To MSC.1/Circ.1206)Documento12 páginasOperation and Maintenance Manual FOR Winch TYPE: 07.02.08: (Acc. To MSC.1/Circ.1206)GogaAinda não há avaliações

- Failure Analysis of A Diesel Engine Rocker ArmDocumento7 páginasFailure Analysis of A Diesel Engine Rocker Armabhijeet7362Ainda não há avaliações

- LT32599 10Documento38 páginasLT32599 10Angela BaileyAinda não há avaliações

- 16.wear Debris Analysis-A Meaningful Condition Monitoring Technique For Industrial Drives PDFDocumento6 páginas16.wear Debris Analysis-A Meaningful Condition Monitoring Technique For Industrial Drives PDFWesley DoorsamyAinda não há avaliações

- FS110 - What Causes Engine Oil ConsumptionDocumento4 páginasFS110 - What Causes Engine Oil ConsumptionPrabakar MahesanAinda não há avaliações

- Photography of Gear Failures: Robert ErricheuoDocumento4 páginasPhotography of Gear Failures: Robert Erricheuorashm006ranjan100% (1)

- Certified Maintenance & Reliability Technician CMRT Candidate Guide For Certification and Re-CertificationDocumento3 páginasCertified Maintenance & Reliability Technician CMRT Candidate Guide For Certification and Re-Certificationlinbaba123Ainda não há avaliações

- CM20190617 40dc1 03446Documento16 páginasCM20190617 40dc1 03446غسان عبد الناظرAinda não há avaliações

- Engine Oil MythsDocumento2 páginasEngine Oil Mythshpss77Ainda não há avaliações

- General Discussions On Lubricating OilsDocumento59 páginasGeneral Discussions On Lubricating OilsHari PurwadiAinda não há avaliações

- EGT001 Roller Bearings Lubrication TrainingDocumento10 páginasEGT001 Roller Bearings Lubrication TrainingJom BonhayagAinda não há avaliações

- The Effects of Soot-Contaminated Engine Oil On Wear and FrictionDocumento22 páginasThe Effects of Soot-Contaminated Engine Oil On Wear and FrictionAssimilator1Ainda não há avaliações

- Machinery Lubrication Level IIDocumento6 páginasMachinery Lubrication Level IILot SalasAinda não há avaliações

- PQ Index - General LimitDocumento1 páginaPQ Index - General Limitgilar herliana putraAinda não há avaliações

- ROTALIGN Ultra Is Shaft Handbook Edition 1 DOC 40 200-06-12 Web enDocumento156 páginasROTALIGN Ultra Is Shaft Handbook Edition 1 DOC 40 200-06-12 Web enCeliocp PinheiroAinda não há avaliações

- Level I Machinery Lubrication Technician (Body of Knowledge)Documento2 páginasLevel I Machinery Lubrication Technician (Body of Knowledge)Anonymous OFwyjaMyAinda não há avaliações

- OEM Engine Oil Lubricant Specifications: White PaperDocumento4 páginasOEM Engine Oil Lubricant Specifications: White Papermohamed100% (1)

- Pinion Backlash Measurement 100714Documento3 páginasPinion Backlash Measurement 100714Anand KesarkarAinda não há avaliações

- Steps To Optimize Lubricants Use PDFDocumento113 páginasSteps To Optimize Lubricants Use PDFPrabhu LohakareAinda não há avaliações

- MLI May June 2016Documento40 páginasMLI May June 2016Dhruv SolankiAinda não há avaliações

- Wear Debris AnalysisDocumento3 páginasWear Debris AnalysisPrakash SomasundaramAinda não há avaliações

- Chevron Y Texaco TablaDocumento40 páginasChevron Y Texaco TablasofelsbabaAinda não há avaliações

- Petro Canada Duron HP - 15w-40 PDFDocumento10 páginasPetro Canada Duron HP - 15w-40 PDFPubcrawl100% (1)

- Iso 13379 2003 en FR PDFDocumento11 páginasIso 13379 2003 en FR PDFClaudio Carrasco Navarrete100% (1)

- Machinery Lubrication Training in JakartaCompanyAddressCity/State/ZipPhoneDocumento7 páginasMachinery Lubrication Training in JakartaCompanyAddressCity/State/ZipPhoneediwski100% (1)

- Mount Meru Product Catalogue First VersionDocumento20 páginasMount Meru Product Catalogue First Versionilovem2foodAinda não há avaliações

- Wear Debris AnalysisDocumento28 páginasWear Debris AnalysisAman Kumar SaranAinda não há avaliações

- Microsoft PowerPoint - ARP-E Practice Quiz v1Documento23 páginasMicrosoft PowerPoint - ARP-E Practice Quiz v1enjiniring sbklAinda não há avaliações

- Failure Analysis of A Diesel Generator Connecting Rod PDFDocumento8 páginasFailure Analysis of A Diesel Generator Connecting Rod PDFLeyner Ignacio CorreaAinda não há avaliações

- Oil Sampling Mistakes Avoid Ensure Data QualityDocumento2 páginasOil Sampling Mistakes Avoid Ensure Data QualityrobjowssAinda não há avaliações

- AMMJ266Documento60 páginasAMMJ266Virojana TantibadaroAinda não há avaliações

- TRIBOLOGY & LUBRICATION TECHNOLOGY Sep 2016Documento92 páginasTRIBOLOGY & LUBRICATION TECHNOLOGY Sep 2016Jorge Cuadros BlasAinda não há avaliações

- Bearing Failure PDFDocumento5 páginasBearing Failure PDF01666754614100% (2)

- Bearings With Solid Grease: NTN CorporationDocumento11 páginasBearings With Solid Grease: NTN Corporationshan_1299Ainda não há avaliações

- Shovel Lubrication PDFDocumento2 páginasShovel Lubrication PDFSounak SasmalAinda não há avaliações

- PQ IndexDocumento2 páginasPQ IndexVíctor Miguel ClAinda não há avaliações

- Ball Bearing Case Studies enDocumento8 páginasBall Bearing Case Studies ensubodh ranjanAinda não há avaliações

- OMA Reading PDFDocumento2 páginasOMA Reading PDFSantos Junnior Hipolito SandovalAinda não há avaliações

- PEHP6001 - Good Oil SampleDocumento2 páginasPEHP6001 - Good Oil SampleAndre Paul MektronikAinda não há avaliações

- How To Write A Lubrication ProcedureDocumento5 páginasHow To Write A Lubrication ProceduremawooaAinda não há avaliações

- 8mm Video Mechanical Adjustment Manual IX - 992986111Documento45 páginas8mm Video Mechanical Adjustment Manual IX - 992986111Franco GaitanAinda não há avaliações

- Inspection Plug GuideDocumento3 páginasInspection Plug GuideAbdul AzisAinda não há avaliações

- The Next Generation Gas Engine Oil Mobil Pegasus 1005Documento46 páginasThe Next Generation Gas Engine Oil Mobil Pegasus 1005Sandeep100% (1)

- Fire Retardant Hydraulic FluidsDocumento12 páginasFire Retardant Hydraulic FluidsPRASAD SANAPAinda não há avaliações

- Lube Tech 113 The Impact of SAE Critical Specifications To The Formulating and Manufacture of Automotive Oils PDFDocumento5 páginasLube Tech 113 The Impact of SAE Critical Specifications To The Formulating and Manufacture of Automotive Oils PDFAaron SaidAinda não há avaliações

- Petro Canada Lubricants Handbook 2012 English PDFDocumento212 páginasPetro Canada Lubricants Handbook 2012 English PDFsoumya ghoshAinda não há avaliações

- Technology Forum - Indoneusa - Gas Engines (Oct.2014) V2Documento42 páginasTechnology Forum - Indoneusa - Gas Engines (Oct.2014) V2Frana HadiAinda não há avaliações

- Torque Converter InspectionDocumento2 páginasTorque Converter InspectionTilleya MadramootooAinda não há avaliações

- 3017e PDFDocumento26 páginas3017e PDFedgarpolAinda não há avaliações

- Finding The Root Causes of Oil DegradationDocumento12 páginasFinding The Root Causes of Oil Degradationtehnicar1Ainda não há avaliações

- Timken Seal Specification GuideDocumento204 páginasTimken Seal Specification GuideRupesh DesaiAinda não há avaliações

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionNo EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionAinda não há avaliações

- Reliability Centered Maintenance Rcm A Complete Guide - 2020 EditionNo EverandReliability Centered Maintenance Rcm A Complete Guide - 2020 EditionAinda não há avaliações

- Failure Reporting Analysis And Corrective Action System A Complete Guide - 2020 EditionNo EverandFailure Reporting Analysis And Corrective Action System A Complete Guide - 2020 EditionAinda não há avaliações

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityNo EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityNota: 3 de 5 estrelas3/5 (4)

- Valve ActuatorsDocumento10 páginasValve Actuatorsluagu100% (1)

- Materials HandlingDocumento10 páginasMaterials HandlingluaguAinda não há avaliações

- Aker SolutionsDocumento34 páginasAker Solutionsluagu100% (3)

- Separator Pressure OptimizationDocumento86 páginasSeparator Pressure OptimizationluaguAinda não há avaliações

- 75-Centrifugal Pump Vibration Caused by Supersynchronous Shaft Instability - DRS&SMPDocumento14 páginas75-Centrifugal Pump Vibration Caused by Supersynchronous Shaft Instability - DRS&SMPمحمد جوادAinda não há avaliações

- Pinch and Approach Point On HRSGDocumento12 páginasPinch and Approach Point On HRSGluaguAinda não há avaliações

- Roto Desihn AuditsDocumento17 páginasRoto Desihn AuditsluaguAinda não há avaliações

- Calgonpump@Hydropneumatic Tank SizingDocumento4 páginasCalgonpump@Hydropneumatic Tank Sizingcyong7788Ainda não há avaliações

- Deaerator PrincipleDocumento1 páginaDeaerator PrincipleluaguAinda não há avaliações

- Combined Cycle Heat Recovery OptimizationDocumento6 páginasCombined Cycle Heat Recovery OptimizationluaguAinda não há avaliações

- Understanding Iso CodesDocumento2 páginasUnderstanding Iso CodesluaguAinda não há avaliações

- Armstrong Air TrapsDocumento2 páginasArmstrong Air TrapsluaguAinda não há avaliações

- Part II Proper Filter SizingDocumento5 páginasPart II Proper Filter SizingluaguAinda não há avaliações

- ISO Code Vs Life ExtensionDocumento3 páginasISO Code Vs Life ExtensionluaguAinda não há avaliações

- Southern Co HRDocumento43 páginasSouthern Co HRluaguAinda não há avaliações

- Design data chapter summaryDocumento16 páginasDesign data chapter summaryjunhe898Ainda não há avaliações

- Manual Motor Crrcpro26iDocumento8 páginasManual Motor Crrcpro26ieduardo_albornoz_5Ainda não há avaliações

- Chapter Three:: Kinetics of Particles: Newton's Second LawDocumento44 páginasChapter Three:: Kinetics of Particles: Newton's Second LawSalahadin ShemsuAinda não há avaliações

- Die Casting Machines Core Pins & Ejector PinsDocumento1 páginaDie Casting Machines Core Pins & Ejector PinsJayden BarnesAinda não há avaliações

- Project Cover Sheet and Drawing List for MAN Engine CraneDocumento16 páginasProject Cover Sheet and Drawing List for MAN Engine CraneYuseriAinda não há avaliações

- Assingment 2Documento1 páginaAssingment 2Aliaa TarekAinda não há avaliações

- Service Manual: MU-A07YV - MU-A09YV - MU-A12YVDocumento28 páginasService Manual: MU-A07YV - MU-A09YV - MU-A12YValessandroAinda não há avaliações

- Salford Journal of Bridge Engineering Jan-18Documento24 páginasSalford Journal of Bridge Engineering Jan-18Swaminathan VivekananthamAinda não há avaliações

- Technical Data Sheet: Ft041En - A - 0313 - 160atjDocumento2 páginasTechnical Data Sheet: Ft041En - A - 0313 - 160atjElaine Malazzab PublikoAinda não há avaliações

- EJOT ASYST Component System Flyer 10.17Documento5 páginasEJOT ASYST Component System Flyer 10.17Eren GülayAinda não há avaliações

- Manual NovaturnDocumento86 páginasManual NovaturnVictor SerranoAinda não há avaliações

- Training Report HPGCLDocumento34 páginasTraining Report HPGCLSidhant BhayanaAinda não há avaliações

- Catalogue ACDelco RemanEnginesDocumento90 páginasCatalogue ACDelco RemanEnginesphamnhatlinh467Ainda não há avaliações

- Product Information: Diesel Extra LD 15W40Documento2 páginasProduct Information: Diesel Extra LD 15W40movie hunterAinda não há avaliações

- Renault Master BrochureDocumento37 páginasRenault Master BrochureAdriano Freire SilvaAinda não há avaliações

- 5 Desain CVDocumento5 páginas5 Desain CVInda Sela GifariAinda não há avaliações

- BS en 12334-2001Documento14 páginasBS en 12334-2001Udit Kumar SarkarAinda não há avaliações

- 'Westerbeke: Parts ListDocumento106 páginas'Westerbeke: Parts ListasdrubalaraujoAinda não há avaliações

- Tutorial 7 MomentumDocumento4 páginasTutorial 7 Momentumapi-3827354Ainda não há avaliações

- Genie Scc755psDocumento2 páginasGenie Scc755psWellington Xavier Pazmiño RodríguezAinda não há avaliações

- Service News: Installation of Stage 2 Long MK Ii Onzr4 Priority: Iv Gac: 48 Ecb Aif 1357/C1 Date: 17/07/2004Documento30 páginasService News: Installation of Stage 2 Long MK Ii Onzr4 Priority: Iv Gac: 48 Ecb Aif 1357/C1 Date: 17/07/2004Muhammad HardiusAinda não há avaliações

- Bearing Capacity of Rockspub101172495Documento13 páginasBearing Capacity of Rockspub101172495Mehdi Mir100% (1)

- Modular 85 System, (MS-02-208) R3Documento8 páginasModular 85 System, (MS-02-208) R3herysyam1980Ainda não há avaliações

- Sany 230C - Sy230c8c3kDocumento268 páginasSany 230C - Sy230c8c3kLS Hidráulica ManilhaAinda não há avaliações

- Andromeda V1.2 Assembly GuideDocumento19 páginasAndromeda V1.2 Assembly Guidenajoko6753Ainda não há avaliações

- Volvo Ecr50D: Parts CatalogDocumento469 páginasVolvo Ecr50D: Parts CataloggiselleAinda não há avaliações

- Memoria Muro Mamposteria Escalera QuickMasonryDocumento7 páginasMemoria Muro Mamposteria Escalera QuickMasonryJulio Marcial Ramos QuinteroAinda não há avaliações

- R070T Parts ManualDocumento43 páginasR070T Parts ManualDieselkAinda não há avaliações

- Second Law of Thermodynamics 1Documento16 páginasSecond Law of Thermodynamics 1Lone KnightAinda não há avaliações