Escolar Documentos

Profissional Documentos

Cultura Documentos

Trailer PM

Enviado por

Arnulfo LavaresDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Trailer PM

Enviado por

Arnulfo LavaresDireitos autorais:

Formatos disponíveis

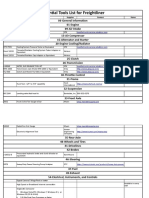

PREVENTIVE MAINTENANCE INSPECTION SHEET

PLEASE MAIL A COPY OF THIS INSPECTION ALONG WITH YOUR INVOICE TO WARNER FLEET SERVICES UPON COMPLETION.

VEHICLE & SERVICE CENTER INFO

SHOP NAME: __________________________PHONE#_________________ INSPECTOR NAME: _________________________ UNIT #:_________________________WFS PO#________________________ VIN #: ___________________________________ THIS INSPECTOR MEETS THE QUALIFICATIONS PURSUANT TO 49 CFR SECTION 396.19 __YES __NO DATE: ___________________ YEAR: ___________________ MODEL: _________________ MILEAGE: _______________

Trailer PM--90 Days Please Mark Body Damage On Trailer Image

VISUALLY INSPECT AND ADVISE / CHECK EACH ITEM AS COMPLETED = Satisfactory O = Adjustments or Repairs Made X=Repairs Needed

_____ ADJUST ALL BRAKES _____ GREASE ALL FITTINGS

_______ DOT

INSPECTION CURRENT?

BRAKES

______ ______ ______ ______ ______ ______ Slack Adjusters S-Cams & Bushings Brake Drums ______ ______ ______ ______ ______ ______ Glad Hands Hoses Drain Air Tank ______ ______

SAFETY

Placards & Holders Fire Extinguishers ______ ______

KINGPIN

Check For Wear Check Kingpin Plate For Cracks ______ ______ ______ ______ ______ ______ ______ ______ ______

BODY

Damage Electrical Side Panels Graphics Door Operation/Seals Door Roller / Hinge Lube and inspect. Hose Carriers/Valves Floor Damage Inspect Welds

SUSPENSION

Springs Spring Hangers Equalizers U-Bolts Cross Members For Cracks Air Bags and Height ______ ______ ______ ______

WHEELS

Oil Seals Wheels & Tires Studs & Lug Nuts Flaps & Hangers

_____/32 Brake Linings

ELEC

______ ______ ______ ______ ______ Turn Signals Tail Lights Clearance Lights And Reflectors 7 Way Plug and Junction Boxes WiringRouting and chaffing

CODE LIFT GATE (form lg101)

_______ Completed and attached the Airgas lift gate supplemental checklist (form lg101).

COMMENTS:_______________________________________________________________________________

__________________________________________________________________________________________ __________________________________________________________________________________________

CERTIFICATION: This vehicle has passed all items for the annual vehicle inspection report in accordance with 49 CFR 396 CERTIFIED INSPECTOR (please print)___________________________SIGNATURE:____________________________________

SUPPLEMENTAL LIFTGATE PREVENTATIVE MAINTENANCE CHECKLIST (FORM LG101)

Odometer or Hubometer_______________ Liftgate Make or model:__________________ Mechanic:____________________________ Date of last hydraulic fluid change____________ Truck or Trailer VIN________________________ W/O # _________________ Date:_____/_______/______ Location:__________________

Gate Serial # ________________________ WFS PO#___________________

PM Interval: 90 days

SUPPLEMENTAL LIFTGATE INSPECTION FOR ALL MODELS

Check Upon Completion " "

Verify if the Quarterly or Annual PM is Due by checking the PM sticker on the Roadside Liftgate column Check for Oil Leaks at: cylinders, fittings, hoses, valves, oil filter and fittings inside of pump box Check for damage: bent ramps, platform, column, runners and runners hydraulic tubes Check for loose or missing nuts, bolts, covers, roll pins, screws and pins Check for cracked welds at: Columns, runners, platform, chain arms, pump box and door frame Check platform pins and couplers. Check roller assemblies Check platform raising speed: Range is 20-40 seconds Check switches, circuit breaker and wiring connections at the gate as well as inside pump box. Also check ground straps Check the gear pump for unusual noise. I.e.. Squealing or extreme RPM output Checking oil level: Check for contamination, change if needed. Check batteries on Trailer gates: load test, corrosion, cables, hold downs and water level Check chains for twisting wear or link damage Check operation of cart stop ramps Inspect wear on slide pads. See if shimming is required Check all charging and ground cable connections

MAXON BMRA Series ADDITIONAL INSPECTION ITEMS

Check Upon Completion " "

Dual pump units: If equipped, alternate switch position to alternate pump and motor Replace spin on filter in pump box and change hydraulic fluid.

THIS ONLY NEEDS TO BE DONE ONCE ANNUALLY.

Check platform lowering speed: Range is 15 - 25 seconds. Check "D" valves for proper operation Check open and close speed: Range is 4-7 seconds in either direction. Adjust if necessary Checking oil level: Gravity Down with the liftgate open and on the ground the sight glass should be at half level. Power Down open liftgate and raise to bed height the sight glass should be at half level. Check for contamination, change if needed.

For more detailed information please refer to the product maintenance manuals. Use only Genuine OE replacement parts.

Você também pode gostar

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyNo EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyNota: 5 de 5 estrelas5/5 (1)

- Argosy Driver's ManualDocumento222 páginasArgosy Driver's ManualRodolfo Alberto Muñoz CarcamoAinda não há avaliações

- Frenos HPBDocumento107 páginasFrenos HPBcarmelo galota100% (3)

- Columbia Driver's Manual PDFDocumento180 páginasColumbia Driver's Manual PDFKAMELIXAinda não há avaliações

- Hydraulic Power Brake System (HPB)Documento105 páginasHydraulic Power Brake System (HPB)Wilber Anibal MoralesAinda não há avaliações

- tp99124 PDFDocumento20 páginastp99124 PDFDieselkAinda não há avaliações

- Hydro-Boost: GM Full Size Vans 1987-1997 Repair GuideDocumento7 páginasHydro-Boost: GM Full Size Vans 1987-1997 Repair GuideEndry Enrique Rincón VargasAinda não há avaliações

- 2011 Mad PogDocumento81 páginas2011 Mad PogBruno Pilieci100% (1)

- 2014 Truck Products Catalogue (Usa)Documento28 páginas2014 Truck Products Catalogue (Usa)Adolfo CisnerosAinda não há avaliações

- Pv776 K Ved7 EngineDocumento11 páginasPv776 K Ved7 EngineHamilton Miranda100% (3)

- Brake ValveDocumento72 páginasBrake ValveEduardo TorresAinda não há avaliações

- Air Bladder Filling Valve and Cap PDFDocumento1 páginaAir Bladder Filling Valve and Cap PDFsidhuAinda não há avaliações

- Service Manual - Manual HVAC (HEATING, VENTILATION, AND AIR CONDITIONING)Documento53 páginasService Manual - Manual HVAC (HEATING, VENTILATION, AND AIR CONDITIONING)Jairo MoralesAinda não há avaliações

- Apads Air Conditioning Protection and Control System Technical Help Frequently Asked Questions Subject Areas CoveredDocumento6 páginasApads Air Conditioning Protection and Control System Technical Help Frequently Asked Questions Subject Areas CoveredYoSelf UbigDummy100% (1)

- L30030W Trailer Service Manual PLC, PLC-Plus, PLC-Select 6-03 Web-OnlyDocumento99 páginasL30030W Trailer Service Manual PLC, PLC-Plus, PLC-Select 6-03 Web-Onlyenzo7259Ainda não há avaliações

- 02b2462c f0d8 41f7 8c8c D6ce304e67cc Sterling Acterra Driver's ManualDocumento148 páginas02b2462c f0d8 41f7 8c8c D6ce304e67cc Sterling Acterra Driver's ManualEnrique GiesbrechtAinda não há avaliações

- The Theory Behind The Engine BrakeDocumento3 páginasThe Theory Behind The Engine BrakeJoseGarzaAinda não há avaliações

- Fuel SystemDocumento7 páginasFuel SystemখালিদহাসানAinda não há avaliações

- Maxxforce DT, 9 and 10 Turbocharger Repair: Study Guide Tmt-121003Documento26 páginasMaxxforce DT, 9 and 10 Turbocharger Repair: Study Guide Tmt-121003Sicein Sas100% (1)

- QuickServe Online - (4021271) ISB, ISBe, ISBe4, QSB4.5, QSB5.9, and QSB6 PDFDocumento6 páginasQuickServe Online - (4021271) ISB, ISBe, ISBe4, QSB4.5, QSB5.9, and QSB6 PDFmds9185Ainda não há avaliações

- tk270 PDFDocumento50 páginastk270 PDFDocelAinda não há avaliações

- Section 5 - Maintenance Schedule and Service ProceduresDocumento42 páginasSection 5 - Maintenance Schedule and Service ProceduresHipolito Caraballo100% (1)

- 2018 Fleetrite Catalog - FINALDocumento138 páginas2018 Fleetrite Catalog - FINALSheeran SiddiquiAinda não há avaliações

- Maxxforce DT, 9, and 10 Fuel Management System: Study Guide Tmt-120704Documento35 páginasMaxxforce DT, 9, and 10 Fuel Management System: Study Guide Tmt-120704Tim WorkmanAinda não há avaliações

- Axsm 0046Documento114 páginasAxsm 0046igoraryskinAinda não há avaliações

- Nexiq Pocket Iq HW SW ManualDocumento195 páginasNexiq Pocket Iq HW SW ManualGAinda não há avaliações

- Coronado Maintenance ManualDocumento124 páginasCoronado Maintenance Manualssmith6582100% (1)

- Service Manual Trucks Group 87 Air Heater Espar D1LC CompactDocumento58 páginasService Manual Trucks Group 87 Air Heater Espar D1LC CompactNeojai jaiyuAinda não há avaliações

- Service Bulletin Trucks: Lubrication and Oil System, Design and FunctionDocumento8 páginasService Bulletin Trucks: Lubrication and Oil System, Design and FunctionHarris RaoAinda não há avaliações

- mm38 PDFDocumento32 páginasmm38 PDFDieselkAinda não há avaliações

- 2 Ats 07Documento12 páginas2 Ats 07carlos maradiagaAinda não há avaliações

- Service Manual: Airglide 400 / 460 / 690 Air Spring SuspensionDocumento21 páginasService Manual: Airglide 400 / 460 / 690 Air Spring Suspensionj100% (2)

- 04 - (2011) HVAC Manual (S16053) PDFDocumento151 páginas04 - (2011) HVAC Manual (S16053) PDFluis eduardo corzo enriquezAinda não há avaliações

- Allison ManualDocumento8 páginasAllison Manualkamikazeee100% (1)

- Modelo 680A & BDocumento20 páginasModelo 680A & BCarlos Enrique Vega OrtegaAinda não há avaliações

- Freightliner BC M2 Driver Manual PDFDocumento197 páginasFreightliner BC M2 Driver Manual PDFRubén GonzàlezAinda não há avaliações

- Wabasto Ops GuideDocumento46 páginasWabasto Ops GuideDavid MortonAinda não há avaliações

- MM 0112Documento112 páginasMM 0112Rob PenndotAinda não há avaliações

- PDF Yammar Manual Tk486v Tk486e1 DLDocumento156 páginasPDF Yammar Manual Tk486v Tk486e1 DLTaller TranspiscisAinda não há avaliações

- Service ManualDocumento332 páginasService ManualfalcoAinda não há avaliações

- Essential Tool List For Freightliner - MasterDocumento4 páginasEssential Tool List For Freightliner - MasterAngel FraustoAinda não há avaliações

- Eges175 - Troubleshooting ManualDocumento598 páginasEges175 - Troubleshooting Manualhighnote32hotmail.comAinda não há avaliações

- VT3651Documento21 páginasVT3651Pepe CuelloAinda não há avaliações

- Trig1110en-Us 0313Documento112 páginasTrig1110en-Us 0313duongpndngAinda não há avaliações

- 2013-01!26!194634 Peterbilt Model 387 Operators Manual Prior To 12-06 LowDocumento188 páginas2013-01!26!194634 Peterbilt Model 387 Operators Manual Prior To 12-06 LowyamilmrAinda não há avaliações

- SC1000 and Smart Tow ManualDocumento37 páginasSC1000 and Smart Tow ManualJerry WoodsAinda não há avaliações

- Freightliner Coronado SD: SectionDocumento23 páginasFreightliner Coronado SD: SectionhoangnhuphuocAinda não há avaliações

- Ajuste de Eaton EmbragueDocumento5 páginasAjuste de Eaton EmbragueHamilton Miranda100% (1)

- Codigos ESC PDFDocumento212 páginasCodigos ESC PDFRuthAnayaAinda não há avaliações

- Cylinder Head Removal D13A 211 76 1-8-06Documento12 páginasCylinder Head Removal D13A 211 76 1-8-06Minn Thet NaingAinda não há avaliações

- IC-F70 Series PDFDocumento58 páginasIC-F70 Series PDFTopcom Toki-VokiAinda não há avaliações

- Turbo ChargersDocumento8 páginasTurbo ChargersPhil B.Ainda não há avaliações

- Heavy-Duty Diagnostic: Product CatalogDocumento12 páginasHeavy-Duty Diagnostic: Product CatalogSonthi MooljindaAinda não há avaliações

- Wabco C Type - p38Documento0 páginaWabco C Type - p38Richard Andrianjaka LuckyAinda não há avaliações

- Manual SpicerDocumento36 páginasManual SpicerLeoAinda não há avaliações

- Truck PM Inspection TemplateDocumento2 páginasTruck PM Inspection TemplateTonya100% (1)

- MBE900 Fuel Filter HousingDocumento3 páginasMBE900 Fuel Filter HousingJosue Alvarez VegaAinda não há avaliações

- Installation Instructions For DC and AC Electric Rewind ReelsDocumento4 páginasInstallation Instructions For DC and AC Electric Rewind ReelsGinoGuanAinda não há avaliações

- Peterbuilt Model - 220 - Body - Builder - Manual - 2017Documento85 páginasPeterbuilt Model - 220 - Body - Builder - Manual - 2017Raj ChoudharyAinda não há avaliações

- Drawing RubricDocumento1 páginaDrawing RubricArnulfo LavaresAinda não há avaliações

- Resistance WorksheetDocumento2 páginasResistance WorksheetArnulfo LavaresAinda não há avaliações

- A B C D: What Base Ten Number Is Represented by The Above Binary Fingers?Documento1 páginaA B C D: What Base Ten Number Is Represented by The Above Binary Fingers?Arnulfo LavaresAinda não há avaliações

- Laboratory Manual For Ac Electrical CircuitsDocumento75 páginasLaboratory Manual For Ac Electrical CircuitsArnulfo LavaresAinda não há avaliações

- Manual Motor Starter MS132: Data SheetDocumento8 páginasManual Motor Starter MS132: Data SheetArnulfo LavaresAinda não há avaliações

- When Good Grounds Go Bad PDFDocumento7 páginasWhen Good Grounds Go Bad PDFArnulfo LavaresAinda não há avaliações

- Basic Circuits WorksheetDocumento1 páginaBasic Circuits WorksheetArnulfo LavaresAinda não há avaliações

- Experiment No. 3: 1.0 TitleDocumento5 páginasExperiment No. 3: 1.0 TitleArnulfo LavaresAinda não há avaliações

- The D.C. Power Supply: Experiment ADocumento6 páginasThe D.C. Power Supply: Experiment AArnulfo LavaresAinda não há avaliações

- Pcea: ": Electrical Preventive Maintenance - Spend A Little - Save A Lot"Documento30 páginasPcea: ": Electrical Preventive Maintenance - Spend A Little - Save A Lot"Arnulfo LavaresAinda não há avaliações

- 3 PhaseDocumento9 páginas3 PhaseArnulfo LavaresAinda não há avaliações

- Lecture 01 - IntroductionDocumento6 páginasLecture 01 - IntroductionArnulfo LavaresAinda não há avaliações

- Introduction To Electrical Circuits: Basic DefinitionsDocumento16 páginasIntroduction To Electrical Circuits: Basic DefinitionsArnulfo LavaresAinda não há avaliações

- Ac Output SSRS: Panel MountDocumento2 páginasAc Output SSRS: Panel MountArnulfo LavaresAinda não há avaliações

- Equipment Used in Support of Cold Chain Distribution1Documento17 páginasEquipment Used in Support of Cold Chain Distribution1Arnulfo LavaresAinda não há avaliações

- Mitsubshi Sec 3Documento68 páginasMitsubshi Sec 3vinaygvmAinda não há avaliações

- Circuit Breaker Trainer BoardDocumento2 páginasCircuit Breaker Trainer BoardArnulfo LavaresAinda não há avaliações

- Power Distribution Systems BrochureDocumento4 páginasPower Distribution Systems BrochureArnulfo LavaresAinda não há avaliações

- SS112 PadFused Sec 0110 0Documento2 páginasSS112 PadFused Sec 0110 0Arnulfo LavaresAinda não há avaliações

- Nec 2011 IndexDocumento25 páginasNec 2011 IndexSamiullah Amarkhel100% (1)

- Cost-Effective Way To Add Capacitance To A Distribution FeederDocumento2 páginasCost-Effective Way To Add Capacitance To A Distribution FeederArnulfo LavaresAinda não há avaliações

- Chapter 12 - Electric Motor Drive Start-Up ProceduresDocumento19 páginasChapter 12 - Electric Motor Drive Start-Up ProceduresArnulfo LavaresAinda não há avaliações

- Rules On Governing RME, REE, and PEE Under RA 7920Documento49 páginasRules On Governing RME, REE, and PEE Under RA 7920Arnulfo Lavares100% (1)

- Tesca Technologies Pvt. LTD.: Order Code - 46521 Study of Triac and A.C. Phase ControlDocumento1 páginaTesca Technologies Pvt. LTD.: Order Code - 46521 Study of Triac and A.C. Phase ControlArnulfo LavaresAinda não há avaliações

- Embrague Freno BasicoDocumento284 páginasEmbrague Freno BasicoCarlos Eduardo Acosta MateusAinda não há avaliações

- Question Bank Automobile EngineeringDocumento5 páginasQuestion Bank Automobile EngineeringAjay Kumar AgarwalAinda não há avaliações

- 500 Series Technical Review October 2012Documento41 páginas500 Series Technical Review October 2012Melinda Hudson100% (1)

- BW9ASW 2pg PDFDocumento2 páginasBW9ASW 2pg PDFshamen amarasekaraAinda não há avaliações

- Objective of ABSDocumento3 páginasObjective of ABSMayur PanchalAinda não há avaliações

- Model S2RHG - T65 Maintenance ManualDocumento272 páginasModel S2RHG - T65 Maintenance ManualHeiri100% (1)

- Wal Ridge CatDocumento176 páginasWal Ridge Catfosterz1777100% (2)

- TVS Raider - Owners ManualDocumento93 páginasTVS Raider - Owners ManualThrinadh saiAinda não há avaliações

- 2012 Wave 110i The Easy, Affordable Cub: 1. Model OverviewDocumento7 páginas2012 Wave 110i The Easy, Affordable Cub: 1. Model OverviewIms MiesAinda não há avaliações

- 09.2 Detailed Technical SpecificationsDocumento18 páginas09.2 Detailed Technical SpecificationsPreetiAinda não há avaliações

- Roadworthiness Requirements AUDocumento12 páginasRoadworthiness Requirements AUDrey GoAinda não há avaliações

- Conceptual Design of An Electric BikeDocumento22 páginasConceptual Design of An Electric BikemehmetAinda não há avaliações

- Maintenance Hino Medium Bus FB / DutroDocumento24 páginasMaintenance Hino Medium Bus FB / DutroDimas Dhita PrabowoAinda não há avaliações

- Required-Curriculum For Driver LicenseDocumento43 páginasRequired-Curriculum For Driver Licenseturkish pizzaAinda não há avaliações

- Automotive Handbook: 7Th EditionDocumento9 páginasAutomotive Handbook: 7Th EditionGeorgiana Busuioc0% (1)

- Combo 5000 Operator ManualDocumento133 páginasCombo 5000 Operator ManualSergioAinda não há avaliações

- Cat Forklift Vc60d Service ManualDocumento27 páginasCat Forklift Vc60d Service Manualethanmann190786ikm99% (88)

- D) EBS3-Failurecodelist / SAE-DTC (SPN-FMI)Documento10 páginasD) EBS3-Failurecodelist / SAE-DTC (SPN-FMI)Дмитро ПоловнякAinda não há avaliações

- Anti Lock Braking SystemDocumento23 páginasAnti Lock Braking SystemManish BejAinda não há avaliações

- Case Hydraulic Excavators Poclan 1288 & 1488C Shop ManualDocumento222 páginasCase Hydraulic Excavators Poclan 1288 & 1488C Shop ManualAgustínAcuña90% (21)

- WTG64.Punch List 2Documento9 páginasWTG64.Punch List 2IbraHim RaGabAinda não há avaliações

- MB Parts Catalog-CINA Auto Parts Catalog For MercedesDocumento292 páginasMB Parts Catalog-CINA Auto Parts Catalog For MercedesCINA auto partsAinda não há avaliações

- WA1200-6 Shop ManualDocumento2.053 páginasWA1200-6 Shop ManualRodolfo Mata100% (4)

- Global Service Learning: 300D Series Hydraulic Excavators - Tier Iii EnginesDocumento49 páginasGlobal Service Learning: 300D Series Hydraulic Excavators - Tier Iii EnginesKJDNKJZEFAinda não há avaliações

- Clutches and BrakesDocumento171 páginasClutches and BrakesPaulo SerranoAinda não há avaliações

- Automatic Braking System For Automobiles Using IR SensorDocumento4 páginasAutomatic Braking System For Automobiles Using IR SensorSourabh SharafAinda não há avaliações

- English For Engineer 2Documento8 páginasEnglish For Engineer 2Raka Setiawan0% (1)

- Electrical GuideDocumento38 páginasElectrical GuideJason d HernandezAinda não há avaliações

- f1c GuideDocumento14 páginasf1c GuideSérgio DominguesAinda não há avaliações

- Drilling Rig Selection Guidelines Only PDFDocumento79 páginasDrilling Rig Selection Guidelines Only PDFRafael Charry AndradeAinda não há avaliações