Escolar Documentos

Profissional Documentos

Cultura Documentos

Grinder Auto

Enviado por

Mike Nichlos0 notas0% acharam este documento útil (0 voto)

203 visualizações3 páginasGrinder will take wheels up to 12 in. In diameter, and it can be made either in a floor or bench type. The speed of 12-in. G. Wheels should not exceed 2,000 1,800 r.p.m. Is better for a wheel diameter.

Descrição original:

Direitos autorais

© Attribution Non-Commercial (BY-NC)

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoGrinder will take wheels up to 12 in. In diameter, and it can be made either in a floor or bench type. The speed of 12-in. G. Wheels should not exceed 2,000 1,800 r.p.m. Is better for a wheel diameter.

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

203 visualizações3 páginasGrinder Auto

Enviado por

Mike NichlosGrinder will take wheels up to 12 in. In diameter, and it can be made either in a floor or bench type. The speed of 12-in. G. Wheels should not exceed 2,000 1,800 r.p.m. Is better for a wheel diameter.

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 3

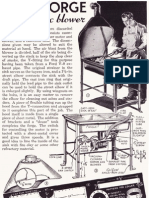

TURDINESS and accuracy are incor-

porated in this inexpensive, roller-

bearing grinder, which you can make

from an old auto-differential assembly.

The grinder will take wheels up to 12 in.

in diameter, and it can be made either in

a floor or bench type. The work can be

done with ordinary tools with the excep-

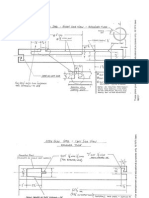

Use glue between the

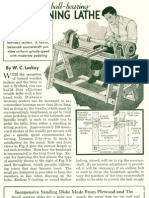

angle, it -is best to drill them with a Indicator for Setting Tailstoc

-in. bit, and then. enlarge them with a

earner. In order to tighten the bolts ef- Of Lathe at Zero Position

ively, sleeves are cut from M-in. pipe After turning a taper on work by means

placed over the threaded ends of the of the tailstock setover method, you can

between the kt-iron supporting bars move the tailstock back to align the cen-

the housing as in Figs. 4 and 6. One ters without loss

of each sleeve is beveled so that it fits of time if this in-,

ugly against the housing. The assembly dicator is used. It

f the wheel guards is shown in Figs. 8 consists of a sheet-

9, the latter giving the essential di- metal pointer piv-

sions. The wheel guard is bolted to oted to a pin in the

supporting bar at the back. It is not .lathe bed, and a.,

ened to the housing. The balance of length of spring

assembly for the floor-type grinder wire, which is fas-

overhead belt drive is clearly shown tened rigidly in

ig. 5, while the bench type is shown the pin and

wrapped around

y requires that the speed of 12-in.

g . wheels should not exceed 2,000 wire causes the point

1,800 r.p.m. is better for a wheel stop pin in the tailstoc

diameter. Smaller wheels can be follows the pln. A f t r

proportionately higher speeds. perfectly, mark the po

end on the tailstock

f you have occasion to use a drill that is Then if the tailstock

small to fit pour brace, slip a piece of it back to bring the

and !he centers will

.

Você também pode gostar

- 6th Central Pay Commission Salary CalculatorDocumento15 páginas6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Timing An M16Documento1 páginaTiming An M16Mike Nichlos89% (9)

- CutoffsawDocumento4 páginasCutoffsawFrenchwolf420Ainda não há avaliações

- Sten Blueprints Parts Mk2 ADocumento22 páginasSten Blueprints Parts Mk2 Aapi-374043498% (43)

- American 180 Rifle PDFDocumento25 páginasAmerican 180 Rifle PDFValeriy Zadorozhnyi100% (1)

- Sten mk2 Complete Machine InstructionsDocumento24 páginasSten mk2 Complete Machine Instructionsmic2996% (83)

- Mini Tube BenderDocumento4 páginasMini Tube BenderMartin OngAinda não há avaliações

- Practical Aquaponics For Everyone 4Documento12 páginasPractical Aquaponics For Everyone 4Mike Nichlos100% (2)

- Semiplans Sten MK2Documento4 páginasSemiplans Sten MK2Mike Nichlos69% (13)

- Hot AirEngine PDFDocumento9 páginasHot AirEngine PDFHenry PannellAinda não há avaliações

- Simplified Steam Engine and Boiler 1937Documento5 páginasSimplified Steam Engine and Boiler 1937Anghel Curty Jr.100% (1)

- Press Brake PlansDocumento4 páginasPress Brake PlansMeme Here100% (1)

- Stirling Walking Beam EngineDocumento13 páginasStirling Walking Beam EngineTomescu PaulAinda não há avaliações

- ReamersDocumento1 páginaReamersvikash kumarAinda não há avaliações

- Small Scale Fish FarmingDocumento84 páginasSmall Scale Fish FarmingMike Nichlos89% (9)

- Rolling Element Bearing Failure AnalysisDocumento4 páginasRolling Element Bearing Failure AnalysisYanuar KrisnahadiAinda não há avaliações

- Simple Boring BarDocumento3 páginasSimple Boring BarMike Nichlos100% (1)

- Woodlathe TreadleDocumento3 páginasWoodlathe Treadleexper626Ainda não há avaliações

- A Fine Vertical Steam Engine - Hobbies - Apr 1931Documento8 páginasA Fine Vertical Steam Engine - Hobbies - Apr 1931dsdffgfgfssfdgsfgdAinda não há avaliações

- Lathe Cross-Sli Olders.: " DuplexDocumento3 páginasLathe Cross-Sli Olders.: " Duplexjohnboy183100% (1)

- Web QCGBDocumento19 páginasWeb QCGBpramponiAinda não há avaliações

- US Marine Corps - MWTC Winter Survival Course HandbookDocumento187 páginasUS Marine Corps - MWTC Winter Survival Course HandbookDave Whitefeather100% (1)

- Pyrotechnics: The History and Art of Firework MakingNo EverandPyrotechnics: The History and Art of Firework MakingAinda não há avaliações

- Building A Six-Inch Turret LatheDocumento5 páginasBuilding A Six-Inch Turret LatheJan SteinmanAinda não há avaliações

- Radojcic - On High Speed Mono.2010.SYMPDocumento19 páginasRadojcic - On High Speed Mono.2010.SYMPnavalarchmarine100% (1)

- Engineering Drawing Ii: Department of Mechanical EngineeringDocumento32 páginasEngineering Drawing Ii: Department of Mechanical EngineeringMike Nichlos100% (3)

- Belt SanderDocumento2 páginasBelt SanderFrenchwolf420Ainda não há avaliações

- Spring MakingDocumento6 páginasSpring MakingMike NichlosAinda não há avaliações

- Sharpening Small ToolsDocumento123 páginasSharpening Small ToolsMike Nichlos100% (2)

- Tap & Drill Chart W - Decimal Inch & MetricDocumento10 páginasTap & Drill Chart W - Decimal Inch & MetricGanesh NatarajanAinda não há avaliações

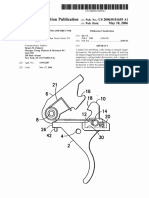

- Us 20060101695Documento11 páginasUs 20060101695galak12001100% (1)

- Precision PressDocumento4 páginasPrecision PressFrenchwolf420Ainda não há avaliações

- Popularmechanics - How To Build A ForgeDocumento1 páginaPopularmechanics - How To Build A ForgeChuck Achberger100% (1)

- DigitalNimbusLabs Invader G19 Build ManualDocumento35 páginasDigitalNimbusLabs Invader G19 Build Manualhans landa100% (1)

- Surface Grinder ManualDocumento11 páginasSurface Grinder ManualRandyWilsonAinda não há avaliações

- Plans For Bench GrinderDocumento2 páginasPlans For Bench GrinderFernando Morocho100% (1)

- Gyro Skipper PlansDocumento5 páginasGyro Skipper PlansJayantha KandegamaAinda não há avaliações

- Manuale CZ200Documento11 páginasManuale CZ200gatto61Ainda não há avaliações

- Raising Meat RabbitsDocumento4 páginasRaising Meat RabbitsMike NichlosAinda não há avaliações

- FM3-05 70survivalmanualDocumento443 páginasFM3-05 70survivalmanualgeodkytAinda não há avaliações

- Ruger MkIIEjectorDimmedDocumento1 páginaRuger MkIIEjectorDimmedMike NichlosAinda não há avaliações

- Homemade Bandsaw From Pipe Fittings and Auto PartsDocumento4 páginasHomemade Bandsaw From Pipe Fittings and Auto PartsJan Steinman100% (2)

- Ruger MkII Ejector Dimension Ed FlatDocumento1 páginaRuger MkII Ejector Dimension Ed FlatMike NichlosAinda não há avaliações

- Ruger MkIIEjectorTemplate NewDocumento1 páginaRuger MkIIEjectorTemplate NewMike Nichlos0% (1)

- Cartridge InterchangiblityDocumento4 páginasCartridge Interchangiblitywienslaw5804Ainda não há avaliações

- Murray Roberts (Willy Cocquyt PR Eng 860106) Calculation Sheet Input SheetDocumento23 páginasMurray Roberts (Willy Cocquyt PR Eng 860106) Calculation Sheet Input SheetMbalekelwa MpembeAinda não há avaliações

- Air Conditioning LiebheerDocumento298 páginasAir Conditioning Liebheerdiasfm100% (2)

- Running Your System Using TimersDocumento6 páginasRunning Your System Using TimersMike Nichlos100% (1)

- Practical Aquaponics For Everyone 1Documento12 páginasPractical Aquaponics For Everyone 1Mike Nichlos100% (4)

- Center Punch Grinding JigDocumento2 páginasCenter Punch Grinding JigmododanAinda não há avaliações

- Steel To Concrete Joints Design-Manual II enDocumento292 páginasSteel To Concrete Joints Design-Manual II enSujeevan Tharmakulasingam100% (2)

- M48 Disassembly ReassemblyDocumento7 páginasM48 Disassembly ReassemblypoinkerAinda não há avaliações

- Hunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.No EverandHunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.Nota: 5 de 5 estrelas5/5 (1)

- Tilapia Seed ProductionDocumento63 páginasTilapia Seed ProductionMike Nichlos100% (1)

- M1 Garand Barrel Replacement  " New BarrelDocumento35 páginasM1 Garand Barrel Replacement  " New BarrelToschanoAinda não há avaliações

- How-To - Build Your Own Spot Welder - HackadayDocumento17 páginasHow-To - Build Your Own Spot Welder - HackadayAndrew McLarenAinda não há avaliações

- Crane JigDocumento2 páginasCrane Jigradio-chaserAinda não há avaliações

- Tell Me Aboot - Building FALs From Parts Kits - AR15Documento12 páginasTell Me Aboot - Building FALs From Parts Kits - AR15Pedro VianaAinda não há avaliações

- Building or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsNo EverandBuilding or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsAinda não há avaliações

- Percussion Lock TerminologyDocumento2 páginasPercussion Lock TerminologyCharlie0% (1)

- 22tcm PDFDocumento4 páginas22tcm PDFPaul MatquisAinda não há avaliações

- 870 Detent Staking PunchDocumento1 página870 Detent Staking PunchZardoz1090Ainda não há avaliações

- Strung de LemnDocumento3 páginasStrung de LemnJohn JohnbAinda não há avaliações

- Pressure Air GunDocumento7 páginasPressure Air GunyuehanAinda não há avaliações

- ChicopeerfDocumento15 páginasChicopeerfRomG78Ainda não há avaliações

- Floating Reamer InstructionsDocumento1 páginaFloating Reamer InstructionsAndrew DeutschmanAinda não há avaliações

- 1E9ZF 9mm Austen MK1 & 9mm Owen MK1 SMG Part4Documento11 páginas1E9ZF 9mm Austen MK1 & 9mm Owen MK1 SMG Part4Erich HoneckerAinda não há avaliações

- Ruger SR-556 Takedown RifleDocumento1 páginaRuger SR-556 Takedown RifleAmmoLand Shooting Sports NewsAinda não há avaliações

- Shrapnel Shell Manufacture 1915 1Documento312 páginasShrapnel Shell Manufacture 1915 1Andrej Buber100% (2)

- Chauchat LMG PDFDocumento9 páginasChauchat LMG PDFS84SAinda não há avaliações

- Orca Docs V5.3Documento25 páginasOrca Docs V5.3camlasutriAinda não há avaliações

- Us 5596162Documento9 páginasUs 5596162Stanley PinesAinda não há avaliações

- Functional Composite Materials: Manufacturing Technology and Experimental ApplicationNo EverandFunctional Composite Materials: Manufacturing Technology and Experimental ApplicationAinda não há avaliações

- Hunting with Muzzleloading Shotguns and Smoothbore Muskets: Smoothbores Let You Hunt Small Game, Big Game and Fowl with the Same GunNo EverandHunting with Muzzleloading Shotguns and Smoothbore Muskets: Smoothbores Let You Hunt Small Game, Big Game and Fowl with the Same GunAinda não há avaliações

- Churchills Mauser C96: Notes on -The blow-up in Sydney Street- from the London DecameroneNo EverandChurchills Mauser C96: Notes on -The blow-up in Sydney Street- from the London DecameroneAinda não há avaliações

- TIL1 Intro To TilapiaDocumento16 páginasTIL1 Intro To TilapiaMike NichlosAinda não há avaliações

- TIL5 Reproduction Pond SystemDocumento9 páginasTIL5 Reproduction Pond SystemMike NichlosAinda não há avaliações

- Skinning and Dressing RabbitsDocumento3 páginasSkinning and Dressing Rabbitspseed_sakAinda não há avaliações

- Rabbit From Farm To TableDocumento3 páginasRabbit From Farm To Tablekarthik kumarAinda não há avaliações

- Ruger MK 1 Receiver BlueprintsDocumento2 páginasRuger MK 1 Receiver BlueprintsMike Nichlos67% (3)

- PracticalAquaponicsForEveryone3, Muy InteresanteDocumento12 páginasPracticalAquaponicsForEveryone3, Muy InteresanteCarlos Perez GarciaAinda não há avaliações

- Rabbits DiseasesDocumento2 páginasRabbits DiseasesMike NichlosAinda não há avaliações

- Shindaiwa 500man PDFDocumento20 páginasShindaiwa 500man PDFesequiel fernandezAinda não há avaliações

- Essential Conditions For Efficient Engine OperationDocumento4 páginasEssential Conditions For Efficient Engine OperationMelanie Saldivar CapalunganAinda não há avaliações

- Aptitude & ReasoningDocumento112 páginasAptitude & ReasoningShajinAndersonAinda não há avaliações

- Airy Stress FunctionDocumento2 páginasAiry Stress FunctionNaga Manikanta TatikondaAinda não há avaliações

- 343r 95Documento158 páginas343r 95INGIMFBAinda não há avaliações

- 2023 Annexure-1 Calibration CylinderDocumento2 páginas2023 Annexure-1 Calibration CylinderShiv Shankar YadavAinda não há avaliações

- Catalogue Perkins 1103A 33TG1Documento8 páginasCatalogue Perkins 1103A 33TG1Aris PrabowoAinda não há avaliações

- 4D Seismic Analysis: Robertson Research International LTDDocumento35 páginas4D Seismic Analysis: Robertson Research International LTDHanan KakiAinda não há avaliações

- Isuzu Exp Ubs Workshop Manual Part 2Documento20 páginasIsuzu Exp Ubs Workshop Manual Part 2jerome100% (53)

- AiraDocumento1 páginaAiraVivek KapadiaAinda não há avaliações

- ELAFLEX Information 5.08EDocumento2 páginasELAFLEX Information 5.08Enader0123Ainda não há avaliações

- NDMA Geotech Sitharam August 16 2011Documento198 páginasNDMA Geotech Sitharam August 16 2011Saksham Bahati0% (1)

- Mom Assignment 3Documento3 páginasMom Assignment 3Sasi VardhanAinda não há avaliações

- Check Valves WaferDocumento1 páginaCheck Valves WaferwfjerrAinda não há avaliações

- Francis Urbines Litostroj Power Product SheetDocumento2 páginasFrancis Urbines Litostroj Power Product SheetНенад АритоновиќAinda não há avaliações

- Starter Assy (1.3Kw) (1Az-Fe) : OverhaulDocumento6 páginasStarter Assy (1.3Kw) (1Az-Fe) : OverhaulHenry SilvaAinda não há avaliações

- CE 3141 Structural Theory Lecture 1 2023Documento27 páginasCE 3141 Structural Theory Lecture 1 2023Cyan SethAinda não há avaliações

- Performance Analysis II - Steady Climb, Descent and Glide - 3 TopicsDocumento9 páginasPerformance Analysis II - Steady Climb, Descent and Glide - 3 TopicsChegrani AhmedAinda não há avaliações

- The Future of Rock Bolting 1692444089Documento4 páginasThe Future of Rock Bolting 1692444089Raul Bracamontes JimenezAinda não há avaliações

- Nonlinear Material Properties of StructuralDocumento9 páginasNonlinear Material Properties of Structuralkhawaja AliAinda não há avaliações

- PurifierDocumento5 páginasPurifierPanagiotis MouzenidisAinda não há avaliações

- Equivalent To: Rim Size Tyre Width Profile Diameter Change Wanted Diameter RangeDocumento2 páginasEquivalent To: Rim Size Tyre Width Profile Diameter Change Wanted Diameter RangeBean McBeaningtonAinda não há avaliações

- Practice - Mechanical Waves BasicsDocumento6 páginasPractice - Mechanical Waves Basicsfrancis solivenAinda não há avaliações

- Navigating The New Aisc: Steel Construction ManualDocumento31 páginasNavigating The New Aisc: Steel Construction ManualAdhi ErlanggaAinda não há avaliações