Escolar Documentos

Profissional Documentos

Cultura Documentos

Worms Worm Gears-Formulas Self Locking PDF

Enviado por

alexdisu4510Descrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Worms Worm Gears-Formulas Self Locking PDF

Enviado por

alexdisu4510Direitos autorais:

Formatos disponíveis

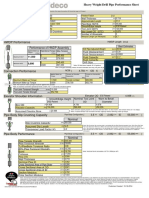

ENGINEERING INFORMATION

WORMS AND WORM GEARS

WORM AND WORM GEAR FORMULAS

To Obtain Circular Pitch (p) Diametral Pitch (P) Lead (of Worm) (L) Addendum (a) Pitch Diameter (D) of Worm (DW) Pitch Diameter of Worm Gear (DG) Center Distance Between Worm & Worm Gear (CD) Whole Depth of Teeth (hT) Bottom Diameter of Worm (Dr) Throat Diameter of Worm Gear (DT) Lead Angle of Worm () Ratio Gear O.D. (DO) Having Diametral Pitch (P) Circular Pitch (p) Number of Threads in Worm & Circular Pitch (p) Diametral Pitch (P) Outside Diameter (d o) & Addendum (a) Circular Pitch (p) & Number of Teeth (N) Pitch Diameter of Worm (d w) & Worm Gear (DG) Circular Pitch (p) Diametral Pitch (P) Whole Depth (h T) & Outside Diameter (d w) Pitch Diameter of Worm Gear (D) & Addendum (a) Pitch Diameter of Worm(D) & The Lead (L) No. of Teeth on Gear (NG) and Number of Threads on Worm Throat Dia. (DT) and Addendum (a) Formula p = 3.1416 P P = 3.1416 p L = p(No. of Threads) a=1 P DW = do 2a DG = NGp 3.1416

WORM GEAR BACK-DRIVING

This is the converse of self-locking and refers to the ability of the worm gear to drive the worm. The same variables exist, making it difficult to predict. However, our experience indicates that for a hardened worm and bronze gear properly manufactured, mounted and lubricated, back-driving capability may be expected, if the lead angle is greater than 11. Again, no guarantee is made and the customer should be so advised.

RATING

The high rate of sliding friction that takes place at the mesh of the Worm and Gear results in a more complex method of rating these Gears as opposed to the other Gear types. Material factors, friction factors and velocity factors must all be considered and applied to reflect a realistic durability rating.

CD = dw + DG 2 hT = .6866 p hT = 2.157 P dr = do 2hT DT = DG + 2a L = tan-1 3.1416d NG Ratio = No. of Threads

DO = DT + .6a

SELF-LOCKING ABILITY

There is often some confusion as to the self-locking ability of a worm and gear set. Boston worm gear sets, under no condition should be considered to hold a load when at rest. The statement is made to cover the broad spectrum of variables effecting self-locking characteristics of a particular gear set in a specific application. Theoretically, a worm gear will not back drive if the friction angle is greater than the worm lead angle. However, the actual surface finish and lubrication may reduce this significantly. More important, vibration may cause motion at the point of mesh with further reduction in the friction angle. Generally speaking, if the worm lead angle is less than 5, there is reasonable expectation of self-locking. Again, no guarantee should be made and customer should be advised. If safety is involved, a positive brake should be used.

Gear Catalog

147

Você também pode gostar

- Basic Gear Terminology and CalculationDocumento10 páginasBasic Gear Terminology and CalculationTesseract spyderAinda não há avaliações

- Basic Gear Terminology and Calculation - KHK Gears PDFDocumento8 páginasBasic Gear Terminology and Calculation - KHK Gears PDFMinhas ArshadAinda não há avaliações

- Optimal Gear Design For Medical Applications: Alexander L. Kapelevich Akgears, LLC, Thomas M. Mcnamara Thermotech CoDocumento7 páginasOptimal Gear Design For Medical Applications: Alexander L. Kapelevich Akgears, LLC, Thomas M. Mcnamara Thermotech CoAvinash KumarAinda não há avaliações

- Basic Gear Terminology and Calculation - KHK GearsDocumento8 páginasBasic Gear Terminology and Calculation - KHK GearsSuyandi SinagaAinda não há avaliações

- Direct Gear DesignDocumento7 páginasDirect Gear DesignFranco Angelo RegenciaAinda não há avaliações

- L12 - Kill Sheets (Compatibility Mode)Documento7 páginasL12 - Kill Sheets (Compatibility Mode)Laxmi Kant PrasadAinda não há avaliações

- Design of Spur Gears in 38 CharactersDocumento29 páginasDesign of Spur Gears in 38 CharactersAishwarya RameshAinda não há avaliações

- Basic Gear Terminology and Calculation - KHK GearsDocumento10 páginasBasic Gear Terminology and Calculation - KHK GearsJoab Max Apaza MartinezAinda não há avaliações

- SEO-Optimized Power and Speed Calculations for Basic ShipDocumento92 páginasSEO-Optimized Power and Speed Calculations for Basic Shiptyagimohit228Ainda não há avaliações

- Spur GearDocumento80 páginasSpur GearLutfhi HanafiAinda não há avaliações

- Reinforcement of Openings On Tori-Dish (Trial)Documento23 páginasReinforcement of Openings On Tori-Dish (Trial)Sajal KulshresthaAinda não há avaliações

- Helical Spring Data SheetDocumento12 páginasHelical Spring Data SheetsachmayaAinda não há avaliações

- GearDocumento81 páginasGeargalataataaddesaaAinda não há avaliações

- Details of GearsDocumento88 páginasDetails of Gearsramchandra rao deshpandeAinda não há avaliações

- (A) Equal To: (B) Less ThanDocumento27 páginas(A) Equal To: (B) Less ThanAtulkumarSutharAinda não há avaliações

- Gears, Splines, and Serrations: Unit 24Documento8 páginasGears, Splines, and Serrations: Unit 24Satish Dhandole100% (1)

- CRT InquiryDocumento2 páginasCRT Inquirysalman buttAinda não há avaliações

- HeavyWeight 3.5 25.58lbs NC-38Documento3 páginasHeavyWeight 3.5 25.58lbs NC-38Инженер Луис А. ГарсиаAinda não há avaliações

- INVOLUTE SPUR GEARS TERMINOLOGY AND MESHINGDocumento13 páginasINVOLUTE SPUR GEARS TERMINOLOGY AND MESHINGjiteshpaul100% (1)

- Actuadores Rotativos DSR DSRLDocumento22 páginasActuadores Rotativos DSR DSRLromeoyesAinda não há avaliações

- Bending Formulas For Tube Bending ToolsDocumento3 páginasBending Formulas For Tube Bending ToolsVikash SharmaAinda não há avaliações

- RDT High Torque ConnectionsDocumento4 páginasRDT High Torque ConnectionsJohan Medina TovarAinda não há avaliações

- Surface Pressure: Federal - Mogul Deva GMBHDocumento3 páginasSurface Pressure: Federal - Mogul Deva GMBHmontavarAinda não há avaliações

- BASIC GEAR TERMINOLOGY AND CALCULATION EXPLAINEDDocumento14 páginasBASIC GEAR TERMINOLOGY AND CALCULATION EXPLAINEDAnimesh ManiAinda não há avaliações

- Safari - May 16, 2022 at 9:00 PMDocumento1 páginaSafari - May 16, 2022 at 9:00 PMDagneAinda não há avaliações

- a R i z m mn b α β fo c x Ψ Ψm ΨyDocumento6 páginasa R i z m mn b α β fo c x Ψ Ψm ΨykuttuasrAinda não há avaliações

- Elbow Plate Development CalculatorDocumento4 páginasElbow Plate Development CalculatorLan TianAinda não há avaliações

- CH08 2Documento52 páginasCH08 2abdallah ghannamAinda não há avaliações

- 1625 de Das 001Documento7 páginas1625 de Das 001Leonardo Alvarez100% (1)

- Worm GearsDocumento13 páginasWorm Gearsutopian_player7192Ainda não há avaliações

- Worm Gears FormulasDocumento11 páginasWorm Gears FormulasTushar MahajanAinda não há avaliações

- To Help Design Shafts in Torsion by Alex Slocum, Last Modified 2/12/2004 by Alex Slocum Enters Numbers in BOLD, Results inDocumento2 páginasTo Help Design Shafts in Torsion by Alex Slocum, Last Modified 2/12/2004 by Alex Slocum Enters Numbers in BOLD, Results inRomoex R RockAinda não há avaliações

- Vessel Design CalculationDocumento54 páginasVessel Design CalculationPohn Myint Han50% (2)

- Coupling - Hoist Cam Switch PDFDocumento14 páginasCoupling - Hoist Cam Switch PDFvozefjadavAinda não há avaliações

- Recondition Bearing PivotDocumento17 páginasRecondition Bearing PivotMaimun maimunAinda não há avaliações

- Locking Assemblies Ringfeder RFN 7012Documento4 páginasLocking Assemblies Ringfeder RFN 7012Benjamin BenjaAinda não há avaliações

- WO2013072747A1Documento64 páginasWO2013072747A1MahnooshAinda não há avaliações

- 321 Chapter 5 Splice DesignDocumento91 páginas321 Chapter 5 Splice DesignHemant Ramesh NarkarAinda não há avaliações

- Chapter 8 - Kinematics of GearsDocumento37 páginasChapter 8 - Kinematics of GearskbashokAinda não há avaliações

- EWC CatalogDocumento4 páginasEWC Catalogthirumular thiruAinda não há avaliações

- CH3 Worm Gear Design-1Documento38 páginasCH3 Worm Gear Design-1Abaziz Mousa OutlawZzAinda não há avaliações

- Onforming: X X X XDocumento13 páginasOnforming: X X X XMd. Jahidul IslamAinda não há avaliações

- Thread Gauge ISO1502 PDFDocumento5 páginasThread Gauge ISO1502 PDFantonio87Ainda não há avaliações

- Nachi Ballscrew BearingsDocumento8 páginasNachi Ballscrew BearingsHakan AdaAinda não há avaliações

- Calculation Sheet: Tubular Brace ParametersDocumento52 páginasCalculation Sheet: Tubular Brace ParametersRamesh SelvarajAinda não há avaliações

- Optimization Technique For The Geometry of Twin Screw Cryogenic ExtruderDocumento5 páginasOptimization Technique For The Geometry of Twin Screw Cryogenic ExtruderIJSTEAinda não há avaliações

- Improving Gear Train Performance Through Nonstandard Tooth Proportions and Center DistanceDocumento9 páginasImproving Gear Train Performance Through Nonstandard Tooth Proportions and Center Distanceluis_dominguezeAinda não há avaliações

- Thread Gauge ISO1502 PDFDocumento5 páginasThread Gauge ISO1502 PDFBaldev SinghAinda não há avaliações

- Powershift SpecificationsDocumento3 páginasPowershift SpecificationsEVCY0% (1)

- Worm Gear Design and ApplicationsDocumento8 páginasWorm Gear Design and Applicationsrahul_patil85100% (2)

- NASTRAN Nonlinear ElementsDocumento90 páginasNASTRAN Nonlinear Elementssons01Ainda não há avaliações

- FIN PLATE - Beam To BeamDocumento71 páginasFIN PLATE - Beam To BeamHemant Ramesh Narkar100% (3)

- Drilling Torque & DragDocumento66 páginasDrilling Torque & DragShamit Rathi100% (1)

- HDADocumento13 páginasHDAnetozxAinda não há avaliações

- Uplift With Moment CalculationDocumento4 páginasUplift With Moment CalculationdennykvgAinda não há avaliações

- Southern Marine Engineering Desk Reference: Second Edition Volume INo EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IAinda não há avaliações

- Lathe CenterDocumento3 páginasLathe Centeralexdisu4510Ainda não há avaliações

- Lsi/Csi: Using A Light Dimmer Ic For Ac Motor Speed ControlDocumento2 páginasLsi/Csi: Using A Light Dimmer Ic For Ac Motor Speed Controlalexdisu4510Ainda não há avaliações

- Worms Worm Gears-Formulas Self Locking PDFDocumento1 páginaWorms Worm Gears-Formulas Self Locking PDFalexdisu4510Ainda não há avaliações

- DonkeyWoodimalPattern 244696265 PDFDocumento1 páginaDonkeyWoodimalPattern 244696265 PDFalexdisu4510Ainda não há avaliações

- Jalcom D 14 09005R2Documento57 páginasJalcom D 14 09005R2d_nagarajanAinda não há avaliações

- Metal Fabricator WelderDocumento2 páginasMetal Fabricator WelderPravin VisputeAinda não há avaliações

- Types of Synthetic RubbersDocumento3 páginasTypes of Synthetic RubbersKamal KishoreAinda não há avaliações

- Superplasticizers GuideDocumento19 páginasSuperplasticizers GuideDanysh ShafeeAinda não há avaliações

- Coefficient of Friction LabDocumento4 páginasCoefficient of Friction LabVElan RathakrishnanAinda não há avaliações

- Kevlar-Glass With CNT - Project PresentationDocumento19 páginasKevlar-Glass With CNT - Project Presentationrobinston jeyasinghAinda não há avaliações

- Iso 6691 en PDFDocumento11 páginasIso 6691 en PDFPAWAN KAinda não há avaliações

- L11 PolyXtal - Plast Aniso3 25feb16Documento110 páginasL11 PolyXtal - Plast Aniso3 25feb16Neeraj KumarAinda não há avaliações

- Design of Water TanksDocumento18 páginasDesign of Water TanksAmmar Civil100% (2)

- Near Bit GammaDocumento2 páginasNear Bit GammaQiang ZhangAinda não há avaliações

- NG30-02JBK - Next PolymersDocumento4 páginasNG30-02JBK - Next PolymersdigiarkanandAinda não há avaliações

- Kisssoft Tut 016 E WormgearDocumento11 páginasKisssoft Tut 016 E WormgearBeytullah AcarAinda não há avaliações

- CVG 3106 Chp1 ReviewDocumento31 páginasCVG 3106 Chp1 ReviewOusama KadriAinda não há avaliações

- Chem Xi FB Mcqs & Short QDocumento95 páginasChem Xi FB Mcqs & Short QficpeshawarAinda não há avaliações

- ME 2254 Strength of Materials Two Mark QuestionsDocumento26 páginasME 2254 Strength of Materials Two Mark QuestionsRohit MunaAinda não há avaliações

- 1 JournalDocumento12 páginas1 JournalmahendranAinda não há avaliações

- Eiffel Tower Final RuffDocumento4 páginasEiffel Tower Final Ruffapi-208377715Ainda não há avaliações

- Strain Gage LabDocumento9 páginasStrain Gage LabAnonymous ep7LE5ZdP5Ainda não há avaliações

- LAMINATION SUITABILITYDocumento3 páginasLAMINATION SUITABILITYSwapnesh GoswamiAinda não há avaliações

- Article Acta MaterDocumento37 páginasArticle Acta MaterBryanaAinda não há avaliações

- VonRoll US - Broschüre - LV-MotorsGenerators - 2021 - 02Documento13 páginasVonRoll US - Broschüre - LV-MotorsGenerators - 2021 - 02Hector CanAinda não há avaliações

- Drill BitsDocumento45 páginasDrill Bitsfrizzooooo100% (1)

- Experimental investigation of mechanical properties of glass/jute fiber hybrid compositeDocumento15 páginasExperimental investigation of mechanical properties of glass/jute fiber hybrid composite436MD siribindooAinda não há avaliações

- Electrode Position Mechanism, Adhesion and Corrosion Performance ofDocumento10 páginasElectrode Position Mechanism, Adhesion and Corrosion Performance ofmogirevansAinda não há avaliações

- TP 95Documento2 páginasTP 95M J VoraAinda não há avaliações

- Alamsyah Et Al., 2008Documento6 páginasAlamsyah Et Al., 2008Luana BouvieAinda não há avaliações

- Soil Laboratory Manual-DasDocumento165 páginasSoil Laboratory Manual-Dassavsengineering93% (15)

- Industrial Tribology 1983Documento541 páginasIndustrial Tribology 1983simonkeppas100% (4)

- Technical Data Sheet TECHSTRAP 2020Documento1 páginaTechnical Data Sheet TECHSTRAP 2020BalrajAinda não há avaliações

- CH 11 SlidesDocumento77 páginasCH 11 SlidestasrifAinda não há avaliações