Escolar Documentos

Profissional Documentos

Cultura Documentos

Mathcad V1 B

Enviado por

Doğan ArslanDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Mathcad V1 B

Enviado por

Doğan ArslanDireitos autorais:

Formatos disponíveis

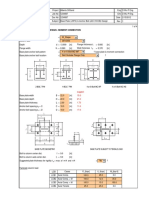

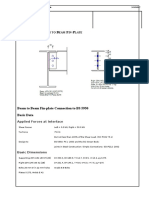

JOINT NO: 19 IPE500-to-IPE500 SHEAR CONNECTION DESIGN

References;

1. BS EN 1993-1-1:2005 / Eurocode 3: Design of steel structures - General rules and rules for buildings

2. BS-EN1993-1-8:2005 / Eurocode 3: Design of steel structures -Design of joints

3. Joints-in-Steel-Construction-Simple-Joints-to-Eurocode-3-P358

4. Manual for the design of steelworkbuilding structures to Eurocode-3-British Institutution of Structural

Engineers

Loads and dimensions: Supported beam section properties: IPE500

V

Ed

725kN := Supported beam depth: D 500mm :=

Shear force :

N

Ed

0kN := Supported beam flange width: B 200mm :=

Axial force :

Supported beam web thickness: t

ws

10.2mm :=

t

f

20mm :=

Fin plate thickness:

Supported beam flange thickness: t

fb

16mm :=

p

1

60mm :=

Vertical bolt distance:

Radius: r

b

21mm :=

e

1

40mm :=

Edge distance vertical:

Bolt diameter : d

b

20mm :=

e

2

40mm :=

Edge distance horizontal. :

e

3

40mm := Hole diameter : D

h

22mm :=

e

b

100mm := Number of bolt rows: n

1

6 :=

e

t

100mm := Number of bolts in a row : n

2

2 :=

p

2

60mm := Total number of bolts: n n

1

n

2

12 = :=

Horizontal bolt distance:

l

f

n

1

1

( )

p

1

2e

1

+ 380 mm = :=

Fin plate length:

Supporting beam section properties: IPE500

Supporting beam flange width: B

b

200mm :=

Supporting beam depth: D

b

500mm :=

Supporting beam flange thickness: t

fbs

16mm :=

Supporting beam web thickness: t

wb

10.2mm :=

Radius of supporting beam: r

2

21mm :=

Distance between supporting beam and supported beam: g

h

20mm :=

a

p

2

2

e

2

+

'

2

B

b

2

t

wb

2

g

h

+

'

+ 299.8 mm = :=

The angle between supporting and supported beam differs at almost every connection because of the radial

axis lines.

For not to list every angle between beams, all the angles were taken into calculations as "30 degrees"

conservatively and the changed part of eccentricity was multiplied by 2.

When the angle is smaller than this value, connection type will change.

Weld properties:

Design strength of fillet weld:

p

w

241MPa := BS EN 1993-1-8:2005, clause 4.5.3.3 (1) & National Annex

Design strength of partial butt weld:

p

bw

355MPa := BS EN 1993-1-8:2005, clause 4.7.2 & National Annex

Bolt properties:

f

yb

900MPa := BS EN 1993-1-8:2005, Table 3.1.

Design yield strength:

Design ultimate strength:

f

ub

1000MPa := BS EN 1993-1-8:2005, Table 3.1.

Main Steel Material : S355

Design strength :

f

y

355.MPa := BS EN 1993-1-1:2005, Table 3.1.

Ultimate tensile strength :

f

u

470MPa := BS EN 1993-1-1:2005, Table 3.1.

Plate Material : S355

Design strength :

f

yp

345MPa := BS EN 1993-1-1:2005, Table 3.1.

Ultimate tensile strength :

f

up

470MPa := BS EN 1993-1-1:2005, Table 3.1.

Check-1:Recommended detailing practice:

(Joints-in-Steel-Construction-Simple-Joints-to-Eurocode-3-P358 - Page 103)

* Requirement for the height of the fin plate to give adequate nominal torsional restraint:

Check l

f

0.6D >

( )

l

f

380 mm = 0.6 D 300 mm =

380mm 300mm > OK

* Minimum and maximum bolt spacing, end and edge distance requirements:

Check 1.2D

h

e

2

< 40mm 4t

f

+ <

( )

1.2 D

h

26.4 mm =

40mm 4t

f

+ 120 mm =

e

2

40 mm = OK

Check 1.2D

h

e

1

< 40mm 4t

f

+ <

( )

1.2 D

h

26.4 mm =

40mm 4t

f

+ 120 mm =

e

1

40 mm = OK

Check 2.2D

h

p

2

min 14t

f

200mm ,

( )

( )

2.2D

h

48.4 mm =

min 14t

f

200mm ,

( )

200 mm =

p

2

60 mm = OK

Check 2.4D

h

p

1

min 14t

f

200mm ,

( )

( )

2.4D

h

52.8 mm =

min 14t

f

200mm ,

( )

200 mm =

p

1

60 mm = OK

Check 2: Supported beam - Bolt group shear check :

(Joints-in-Steel-Construction-Simple-Joints-to-Eurocode-3-P358 - Page 104

Basic requirement : V

Ed

n F

VRd

>

Bolt Shear Resistance:

v

0.5 :=

m2

1.25 := (BS EN 1993-1-1:2005, Section 6.1.)

A

b

245mm

2

:= Bolt Area

F

VRd

v

f

ub

A

b

m2

98 kN = :=

Ratio1

V

Ed

n F

VRd

0.62 = :=

Check 2 (continued): Fin plate - Bolt group bearing check :

(Joints-in-Steel-Construction-Simple-Joints-to-Eurocode-3-P358 - Page 105

Bolt bearing in the fin plate:

k

1

min 2.8

e

2

D

h

1.7 2.5 , 1.4

p

2

D

h

1.7 ,

'

2.12 = :=

b

min 1

e

1

3 D

h

,

p

1

3 D

h

0.25 ,

f

ub

f

up

,

'

0.61 = :=

F

bRdv

k

1

b

d

b

t

f

f

up

m2

193.1 kN = :=

z e

2

p

2

2

+ 70 mm = :=

l

n

1

2

p

2

2

n

1

6

n

1

2

1

'

p

1

2

+ 1368 cm

2

= :=

z p

2

2l

0.015 = :=

V

rd1

n

1 n +

F

bRdv

'

2

1956.5 kN = :=

Ratio2

V

Ed

V

rd1

0.37 = :=

Check 2 (continued) : Supported beam - Bolt group bearing che ck in Supported Beam Web:

(Joints-in-Steel-Construction-Simple-Joints-to-Eurocode-3-P358 - Page 106

Bolt Bearing in Supported Beam Web:

k

1b

min 2.8

e

2

D

h

1.7 2.5 , 1.4

p

2

D

h

1.7 ,

'

2.12 = :=

bb

min 1

e

b

3 D

h

,

p

1

3 D

h

0.25 ,

f

ub

f

u

,

'

0.66 = :=

F

bRdv2

k

1b

bb

d

b

t

ws

f

u

m2

107.1 kN = :=

V

rd2

n

1 n +

F

bRdv2

'

2

1085.1 kN = :=

Ratio3

V

Ed

V

rd2

0.67 = :=

Check 3 - Fin Plate : Shear Resistance of the fin plate

(Joints-in-Steel-Construction-Simple-Joints-to-Eurocode-3-P358 - Page 106

1) Shear

Basic Requrement :

V

Ed

V

Rdmin

<

A

v

l

f

t

f

7600 mm

2

= := A

vnet

A

v

n

1

D

h

t

f

4960 mm

2

= :=

A

nt

t

f

p

2

e

2

+

3.D

h

2

'

1340 mm

2

= :=

m0

1 := Resistance of members and cross sections,

(BS EN 1993-1-1:2005, Section 6.1.)

A

nv

t

f

l

f

e

1

n

1

0.5

( )

D

h

4380 mm

2

= :=

Fin plate in shear gross section Fin plate in shear: net section

V

Rdn

A

vnet

f

up

3

m2

1076.7 kN = :=

V

Rdg

A

v

1.27

f

yp

3

m0

'

1192 kN = :=

Fin plate in shear: block shear

V

Rdb

0.5 f

up

A

nt

m2

f

yp

A

nv

3

m0

+ 1124 kN = :=

V

Rdmin

min V

Rdn

V

Rdb

, V

Rdg

,

( )

1077 kN = := Ratio4

V

Ed

V

Rdmin

0.67 = :=

Check 3.2: Fin plate section bending check and check of the vertical fin-plate

The horizontal welds were not considered in the

calculations against M

v

for staying on conservative

side. This gives the connection reserve strength.

1) Weld shear check;

V

Ed

A

w

p

w

<

Basic requirement :

t

f

20 mm = t

f

s > OK

Leg length of vertical weld: s 9mm :=

Effective thickness of vertical weld: a

w

s

2

6.4 mm = :=

* Requirement for effective thickness of the weld:

t

wb

10.2 mm = t

wb

s > OK

Leg length of horizontal weld: s

wh

10mm :=

Effective thickness of horizontal partial butt weld:

a

wh

s

wh

:=

B

ad

120mm :=

Stiffener width:

Length of vertical weld: L

w

D

b

2 t

fbs

2 r

2

3mm +

( )

420 mm = :=

Weld area: A

w

2 L

w

a

w

4 B

ad

2a

w

2 3 mm

( )

a

wh

+ :=

Ratio5

V

Ed

A

w

p

w

0.32 = :=

2) Weld bending check;

Static moment of vertical weld: S

wv

2 a

w

L

w

2

6

374.2 cm

3

= :=

Moment on the weld: M

v1

V

Ed

a 217.4 kN m = :=

x t

fbs

r

2

+ 25mm + t

f

+ := L

s

D

b

2

x :=

Moment of inertia

of horizontal weld:

I

hw

4

B

ad

a

wh

3

12

B

ad

2s 2 3 mm

( )

a

wh

L

s

2

+

(

(

(

:=

Static moment of horizontal weld: S

wh

I

hw

L

s

:=

S

w

S

wh

S

wv

+ :=

p

p1

M

v1

S

w

213.2 MPa = :=

Ratio6

p

p1

p

w

0.88 = :=

3)Fin plate bending check for M

v1

Static moment vertical plate section: S

pv

t

f

L

w

2

6

588 cm

3

= :=

Moment of inertia of horizontal plate:

I

2

4

B

ad

t

f

3

12

B

ad

t

f

L

s

2

+

'

:=

Static moment horizontal plate section: S

ph

I

2

L

s

:=

S

p

S

pv

S

ph

+

( )

:=

p

p2

M

v1

S

p

99 MPa = := Ratio7

p

p2

f

yp

0.29 = :=

4)Fin plate bending check for M

v2

Static moment of the fin plate section: S

p2

t

f

l

f

2

6

481.3 cm

3

= :=

Moment of the section: M

v2

V

Ed

e

2

p

2

2

+

'

50.8 kN m = :=

p

p3

M

v2

S

p2

105.4 MPa = := Ratio8

p

p3

f

yp

0.31 = :=

Check 4-Supported Beam Web in Shear: Shear Resistance of HE 600B

(Joints-in-Steel-Construction-Simple-Joints-to-Eurocode-3-P358 - Page 110

1 ) Shear

Basic Requirement V

Ed

V

Rdmin2

<

A

beam

115.5cm

2

:=

A

v1

A

beam

2B t

fb

t

ws

2 r

b

+

( )

t

fb

+ 59.9 cm

2

= :=

Gross area subjected to shear:

A

vnet2

A

v1

n

1

D

h

t

ws

46.4 cm

2

= :=

Net area subjected to shear:

Beam web in shear, gross section

V

Rdg2

A

v1

f

y

3

m0

1226.7 kN = :=

Beam web in shear, net section

V

Rdn2

f

u

A

vnet2

3

m2

1007 kN = :=

min V

Rdg2

V

Rdn2

,

( )

1007 kN =

Ratio9

V

Ed

min V

Rdg2

V

Rdn2

,

( )

0.72 = :=

Check 5: Supporting beam shear and bearing

(Joints-in-Steel-Construction-Simple-Joints-to-Eurocode-3-P358 - Page 117&118

Basic Requirement:

V

Ed

2

F

RD

<

A

v2

L

w

2 B

ad

2 3 mm

( )

+

t

wb

6609.6 mm

2

= :=

Shear resistance of supporting beam web

F

RD

A

v2

f

y

3

m0

1354.7 kN = :=

V

Edt

1.5

V

Ed

L

w

2 B

ad

2 3 mm

( )

+

L

w

2 B

ad

2 3 mm

( )

+

1087.5 kN = :=

"An approach is taken to increase the V

Ed

by 1.5 because there

might be another beam connected to the supporting beam web

from the opposite side. This will increase demand for shear

capacity of web."

Ratio10

V

Edt

2 F

RD

0.40 = :=

Punching can be neglected. Because fin-plate is welded to supported beam's flanges.

Você também pode gostar

- Discrete Element Method to Model 3D Continuous MaterialsNo EverandDiscrete Element Method to Model 3D Continuous MaterialsAinda não há avaliações

- Connection No.: 66: Load Ver. Brace L120X120X10 AxialDocumento5 páginasConnection No.: 66: Load Ver. Brace L120X120X10 Axialrts123Ainda não há avaliações

- Mathcad - Pipe To Shoe Weld CheckDocumento3 páginasMathcad - Pipe To Shoe Weld CheckValentinAinda não há avaliações

- Bolt TighteningDocumento6 páginasBolt TighteningahmedbeaetAinda não há avaliações

- Extracts From Ec3 For Students 2012Documento6 páginasExtracts From Ec3 For Students 2012Alexandru MarincuAinda não há avaliações

- Stuewe 201708 Catalogue Type-HsdDocumento25 páginasStuewe 201708 Catalogue Type-HsdJorge A VilalAinda não há avaliações

- Pile StirrupDocumento1 páginaPile Stirrupbuffyto5377Ainda não há avaliações

- Beam Connection of Conventional Configuration Based On AISC Manual 13th Edition (AISC 360-05)Documento2 páginasBeam Connection of Conventional Configuration Based On AISC Manual 13th Edition (AISC 360-05)Yisrael AshkenazimAinda não há avaliações

- Vortex Shedding Different CodesDocumento16 páginasVortex Shedding Different CodesMakhzumi Muhammad UmarAinda não há avaliações

- Anchor Calculation - Case 2Documento10 páginasAnchor Calculation - Case 2MdShahbazAhmedAinda não há avaliações

- #160 Lifting Fixture 38tons 020807Documento14 páginas#160 Lifting Fixture 38tons 020807halder_kalyan9216Ainda não há avaliações

- Gusset Plate Connection DesignDocumento3 páginasGusset Plate Connection DesignMin Khant KyawAinda não há avaliações

- Thermal Stress ExamplesDocumento10 páginasThermal Stress ExamplesVishal V BhagwatAinda não há avaliações

- Elastic Constants KetulDocumento21 páginasElastic Constants KetulRambabu Vurimi67% (3)

- Wind Load CalculationsDocumento1 páginaWind Load Calculationsfrog15Ainda não há avaliações

- As Combined Stress Ratio Is Below 1 So Anchor Bolt Is OKDocumento1 páginaAs Combined Stress Ratio Is Below 1 So Anchor Bolt Is OKNaresh KumarAinda não há avaliações

- Base PLT For IT CentreDocumento13 páginasBase PLT For IT CentreUday UdmaleAinda não há avaliações

- Shearing Force & Bending Moment DiagramDocumento17 páginasShearing Force & Bending Moment DiagramdearsaswatAinda não há avaliações

- Swedish Requests For OHL-s - Rev04Documento50 páginasSwedish Requests For OHL-s - Rev04vladaukiAinda não há avaliações

- Pile Horizontal CheckDocumento8 páginasPile Horizontal CheckDINESHAinda não há avaliações

- Bolted Splice ConnectionDocumento6 páginasBolted Splice ConnectionSeetharam Mahanthi100% (1)

- Mathcad - Design Resistance For Individual FastnersDocumento3 páginasMathcad - Design Resistance For Individual FastnersValentinAinda não há avaliações

- Pin Base ModuleDocumento16 páginasPin Base ModuleMd Ahsanul KabirAinda não há avaliações

- Module 3 Steel Beam With Web Opening PDFDocumento35 páginasModule 3 Steel Beam With Web Opening PDFkarthiksampAinda não há avaliações

- Combined FootingDocumento7 páginasCombined FootingMohammed ElemamAinda não há avaliações

- Mathcad - Control Room - Depth 3mDocumento14 páginasMathcad - Control Room - Depth 3mJuli NirwantoAinda não há avaliações

- Design Aid For Triangular Bracket Plates Using AISC SpecificationsDocumento10 páginasDesign Aid For Triangular Bracket Plates Using AISC SpecificationsRicardo MendozaAinda não há avaliações

- 5.15 Swing Barrier v.1.0Documento190 páginas5.15 Swing Barrier v.1.0rfvz6sAinda não há avaliações

- ASD Vs LRFDDocumento4 páginasASD Vs LRFDEkky CecilAinda não há avaliações

- Beam & Col FormulaeDocumento9 páginasBeam & Col FormulaeAnonymous ciKyr0t100% (1)

- Manual Técnico de Parafusos - BOSSARDDocumento85 páginasManual Técnico de Parafusos - BOSSARDRenato Caldas100% (1)

- ExcelFEM - 2D (For Excel 2007 & Excel 2010)Documento248 páginasExcelFEM - 2D (For Excel 2007 & Excel 2010)motiur basumAinda não há avaliações

- Lifting PadeyeDocumento16 páginasLifting PadeyeCHEAinda não há avaliações

- Example: Calculation of Effective Section Properties For A Cold-Formed Lipped Channel Section in BendingDocumento10 páginasExample: Calculation of Effective Section Properties For A Cold-Formed Lipped Channel Section in BendingVarga ZoranAinda não há avaliações

- Breviar de Calcul - Cos C.R.Documento63 páginasBreviar de Calcul - Cos C.R.tulvyAinda não há avaliações

- Comp 2Documento9 páginasComp 2YYo YudiAinda não há avaliações

- Det-1 Ub457x191x67Documento4 páginasDet-1 Ub457x191x67ihpeterAinda não há avaliações

- Pinned Base Design Calculation: (Aisc 360-05 - LRFD Design Method) GeometryDocumento4 páginasPinned Base Design Calculation: (Aisc 360-05 - LRFD Design Method) GeometryTuanQuachAinda não há avaliações

- MSS SP-97-2012Documento21 páginasMSS SP-97-2012Marco CarrieriAinda não há avaliações

- WE-5-2 Fin Plate ConnectionDocumento10 páginasWE-5-2 Fin Plate ConnectionPedro AlmeidaAinda não há avaliações

- Calculo de Brida Segun ASMEDocumento29 páginasCalculo de Brida Segun ASMEakarcz6731Ainda não há avaliações

- Baseplate: DL LL WLDocumento13 páginasBaseplate: DL LL WLJayson RamosAinda não há avaliações

- Breeder House FoundationDocumento16 páginasBreeder House FoundationRobbyTeresaAinda não há avaliações

- Mathcad - Concrete Crushing Strength Check.Documento1 páginaMathcad - Concrete Crushing Strength Check.Ragunath KarthickAinda não há avaliações

- Stress Strain Laws - Lect05Documento16 páginasStress Strain Laws - Lect05Manoj VermaAinda não há avaliações

- UB 254 146 31 B B F - P: X X EAM TO EAM IN LateDocumento7 páginasUB 254 146 31 B B F - P: X X EAM TO EAM IN LateihpeterAinda não há avaliações

- Lattice TowerDocumento15 páginasLattice TowerAmlan DasAinda não há avaliações

- Firewall Geometric Design-SaiTejaDocumento9 páginasFirewall Geometric Design-SaiTejanaveenAinda não há avaliações

- Bolt Load Calculation StepsDocumento2 páginasBolt Load Calculation StepsSrikanth ShankarAinda não há avaliações

- KT Type Truss Connection - LRFDDocumento11 páginasKT Type Truss Connection - LRFDkalpanaadhiAinda não há avaliações

- Stiffener Local Check SampleDocumento2 páginasStiffener Local Check SampleAulia MirzaAinda não há avaliações

- 5 To 6: A To B: Twin VillaDocumento1 página5 To 6: A To B: Twin VillamohammedAinda não há avaliações

- Calculation of Beam/Column Splice: HB-300x300x10x15Documento5 páginasCalculation of Beam/Column Splice: HB-300x300x10x15amachmouchiAinda não há avaliações

- Column Flange Simple ConnectionDocumento5 páginasColumn Flange Simple Connectiona.b.a.c.u.sAinda não há avaliações

- End-Plate - Beam To Beam Connection Design 3Documento8 páginasEnd-Plate - Beam To Beam Connection Design 3gianniorlatiAinda não há avaliações

- UB Fin Plate DesignDocumento8 páginasUB Fin Plate DesignWin ThanAinda não há avaliações

- Cold Formed BendingDocumento8 páginasCold Formed BendinggeorgeispasoiuAinda não há avaliações

- PF2Documento4 páginasPF2nhulugallaAinda não há avaliações

- Interior Column According To ACI 318-05 (NONPRESTRESSED SLABS)Documento2 páginasInterior Column According To ACI 318-05 (NONPRESTRESSED SLABS)HAITHAM ALIAinda não há avaliações

- HEICO-LOCK Ring Lock Washers Provide High-Quality, User-Friendly Bolt Securing For The Most Demanding of Applications and Are Ideal For Repeated UseDocumento1 páginaHEICO-LOCK Ring Lock Washers Provide High-Quality, User-Friendly Bolt Securing For The Most Demanding of Applications and Are Ideal For Repeated UseDoğan ArslanAinda não há avaliações

- Lori Lightfoot in " ": Chicago Story Film, LLCDocumento1 páginaLori Lightfoot in " ": Chicago Story Film, LLCDoğan ArslanAinda não há avaliações

- Ethan Hawke and Joshua Caleb Johnson in "The Good Lord Bird"Documento1 páginaEthan Hawke and Joshua Caleb Johnson in "The Good Lord Bird"Doğan ArslanAinda não há avaliações

- 5 PDFDocumento1 página5 PDFDoğan ArslanAinda não há avaliações

- The HEICO-LOCK Wheel Nut Is The Reliable Solution For The Problem of Self-Loosening of Wheel Nuts On Both Roads and Rough TerrainDocumento1 páginaThe HEICO-LOCK Wheel Nut Is The Reliable Solution For The Problem of Self-Loosening of Wheel Nuts On Both Roads and Rough TerrainDoğan ArslanAinda não há avaliações

- Note: This List Is Up-To-Date As of December 28, 2020Documento1 páginaNote: This List Is Up-To-Date As of December 28, 2020Doğan ArslanAinda não há avaliações

- Connections Add-On Modules: Structural Analysis and Design SoftwareDocumento1 páginaConnections Add-On Modules: Structural Analysis and Design SoftwareDoğan ArslanAinda não há avaliações

- Customer Projects: Interesting Customer Projects Designed With The Structural Analysis Programs by Dlubal SoftwareDocumento1 páginaCustomer Projects: Interesting Customer Projects Designed With The Structural Analysis Programs by Dlubal SoftwareDoğan ArslanAinda não há avaliações

- Tüv Certified Quality: Wedge Lock Washers Ring Lock Washers Wedge Lock NutsDocumento1 páginaTüv Certified Quality: Wedge Lock Washers Ring Lock Washers Wedge Lock NutsDoğan ArslanAinda não há avaliações

- RF-/JOINTS Steel - Tower Add-On Module For RFEM/RSTABDocumento1 páginaRF-/JOINTS Steel - Tower Add-On Module For RFEM/RSTABDoğan ArslanAinda não há avaliações

- Newsletter: VideoDocumento1 páginaNewsletter: VideoDoğan ArslanAinda não há avaliações

- WFCM Wood Frame Construction Manual For One-And Two-Family Dwellings and WFCM Commentary, 2018 EditionDocumento1 páginaWFCM Wood Frame Construction Manual For One-And Two-Family Dwellings and WFCM Commentary, 2018 EditionDoğan ArslanAinda não há avaliações

- Heico LockDocumento7 páginasHeico LockDoğan ArslanAinda não há avaliações

- RF-/JOINTS Steel - Pinned Add-On Module For RFEM/RSTABDocumento1 páginaRF-/JOINTS Steel - Pinned Add-On Module For RFEM/RSTABDoğan ArslanAinda não há avaliações

- E' E C C C E' 160, 550 Psi E' E C C C C E' 690, 000 PsiDocumento1 páginaE' E C C C E' 160, 550 Psi E' E C C C C E' 690, 000 PsiDoğan ArslanAinda não há avaliações

- Beam Design Ratio: Formula 12Documento1 páginaBeam Design Ratio: Formula 12Doğan ArslanAinda não há avaliações

- E' E C C C E' 160, 550 Psi E' E C C C C E' 690, 000 PsiDocumento1 páginaE' E C C C E' 160, 550 Psi E' E C C C C E' 690, 000 PsiDoğan ArslanAinda não há avaliações

- F' F C C C C C C C C: B B D M T L F Fu I RDocumento1 páginaF' F C C C C C C C C: B B D M T L F Fu I RDoğan ArslanAinda não há avaliações

- Timber Beam Design Per The 2018 NDS Standard: Technical ArticleDocumento1 páginaTimber Beam Design Per The 2018 NDS Standard: Technical ArticleDoğan ArslanAinda não há avaliações

- F' F C C C C C C C C: B B D M T L F Fu I RDocumento1 páginaF' F C C C C C C C C: B B D M T L F Fu I RDoğan ArslanAinda não há avaliações

- A B D (3. 50 In.) (13. 25 In.) 46. 38 inDocumento1 páginaA B D (3. 50 In.) (13. 25 In.) 46. 38 inDoğan ArslanAinda não há avaliações

- Timber Beam Design Per The 2018 NDS Standard: Technical ArticleDocumento1 páginaTimber Beam Design Per The 2018 NDS Standard: Technical ArticleDoğan ArslanAinda não há avaliações

- 5 PDFDocumento1 página5 PDFDoğan ArslanAinda não há avaliações

- A B D (3. 50 In.) (13. 25 In.) 46. 38 inDocumento1 páginaA B D (3. 50 In.) (13. 25 In.) 46. 38 inDoğan ArslanAinda não há avaliações

- Beam Design Ratio: Formula 12Documento1 páginaBeam Design Ratio: Formula 12Doğan ArslanAinda não há avaliações

- You May Also Be Interested In: TagsDocumento1 páginaYou May Also Be Interested In: TagsDoğan ArslanAinda não há avaliações

- 3 PDFDocumento1 página3 PDFDoğan ArslanAinda não há avaliações

- 2018 Wood Design Package: Save 10% O On Everything - Every Day!Documento1 página2018 Wood Design Package: Save 10% O On Everything - Every Day!Doğan ArslanAinda não há avaliações

- LRFD Wood Design Per AWC-NDS 2015/2018 Codes: Tips & TricksDocumento1 páginaLRFD Wood Design Per AWC-NDS 2015/2018 Codes: Tips & TricksDoğan ArslanAinda não há avaliações

- 2018 International Residential Code (IRC) Soft Cover: Save 10% O On Everything - Every Day!Documento1 página2018 International Residential Code (IRC) Soft Cover: Save 10% O On Everything - Every Day!Doğan ArslanAinda não há avaliações

- CLFMI Product Manual Revised March 2017 1Documento34 páginasCLFMI Product Manual Revised March 2017 1Joe NadakkalanAinda não há avaliações

- 7-1. Minimum Maintenance Activities For Engine Intake and Exhaust SystemsDocumento10 páginas7-1. Minimum Maintenance Activities For Engine Intake and Exhaust SystemsegrabuanaAinda não há avaliações

- INKA General Catalogue - 2021Documento276 páginasINKA General Catalogue - 2021Armağan DemirelAinda não há avaliações

- MIS Catalog 2011Documento152 páginasMIS Catalog 2011euAinda não há avaliações

- Heatsink Fan Replacement Instruction - MI38X102Documento8 páginasHeatsink Fan Replacement Instruction - MI38X102Junie TayrusAinda não há avaliações

- Alternator Toyota Alphard - Vellfire - HVDocumento4 páginasAlternator Toyota Alphard - Vellfire - HVIrfan BuchariAinda não há avaliações

- F200aet'09 F225aet'09 Fl200aet'09 Fl225aet'09: (60L8) (69J8) (60M8) (69K8)Documento102 páginasF200aet'09 F225aet'09 Fl200aet'09 Fl225aet'09: (60L8) (69J8) (60M8) (69K8)Hesham BakrAinda não há avaliações

- Workshop Manual Phaeton 2003Documento262 páginasWorkshop Manual Phaeton 2003Anonymous 639KCl3100% (2)

- Rexroth ValveDocumento20 páginasRexroth ValvesatriaAinda não há avaliações

- M90-Users ManualDocumento27 páginasM90-Users ManualadictosalasteclasAinda não há avaliações

- Chapter 05 Bolted ConnectionsDocumento9 páginasChapter 05 Bolted ConnectionsJaper WeakAinda não há avaliações

- 031 Procedure Rigging Slinging and LiftingDocumento18 páginas031 Procedure Rigging Slinging and LiftingMohamed Hadjkacem100% (2)

- Troy Bilt Trimmer ManualDocumento40 páginasTroy Bilt Trimmer ManualshanaAinda não há avaliações

- Transmission Mono Poles-SERCDocumento49 páginasTransmission Mono Poles-SERCtmmsekar100% (2)

- 2 4 Hole 2 3 Hole 4 Hole Puncher Unit A1 SMDocumento91 páginas2 4 Hole 2 3 Hole 4 Hole Puncher Unit A1 SMAashish ChaudhariAinda não há avaliações

- BFV 300Documento9 páginasBFV 300Adriana Agundiz RomeroAinda não há avaliações

- EN ISO 5211 - Part Turn ActuatorsDocumento17 páginasEN ISO 5211 - Part Turn Actuatorsyashif aliAinda não há avaliações

- Large ValvesDocumento41 páginasLarge ValvesBembotas BembaAinda não há avaliações

- Kohler Magnum Twin Cylinder Engine Torque Values and Specs For Fasteners PDFDocumento4 páginasKohler Magnum Twin Cylinder Engine Torque Values and Specs For Fasteners PDFBillW56Ainda não há avaliações

- R7 190 210 DCRDocumento872 páginasR7 190 210 DCRKaloyan100% (1)

- Tablet Compression Accessories Catalog - 7th EditionDocumento112 páginasTablet Compression Accessories Catalog - 7th EditionRizki StiawanAinda não há avaliações

- Apoios Anti Vibratótios SunnexDocumento32 páginasApoios Anti Vibratótios SunnexFábio LeiteAinda não há avaliações

- Ceo 51-43-00 - Alternative and Oversize5122214382885977576Documento424 páginasCeo 51-43-00 - Alternative and Oversize5122214382885977576Anonymous lQ0rXlvAD100% (2)

- Brazilian Test ApparatusDocumento2 páginasBrazilian Test ApparatusfarhanHEAinda não há avaliações

- Appendix 03 Equipment List (Total Scope of Supply)Documento30 páginasAppendix 03 Equipment List (Total Scope of Supply)Anish SinghAinda não há avaliações

- Indent For Anchor RodsDocumento18 páginasIndent For Anchor Rodsmanmadhan89Ainda não há avaliações

- AV-C Butterfly ValveDocumento20 páginasAV-C Butterfly ValveSopon SrirattanapiboonAinda não há avaliações

- D4B802A2B8E Gearbox - 0D9 DSGDocumento153 páginasD4B802A2B8E Gearbox - 0D9 DSGAndrei Baluse75% (4)

- Carbon and Alloy Steel Nuts: Standard Specification ForDocumento2 páginasCarbon and Alloy Steel Nuts: Standard Specification ForEvert RiveraAinda não há avaliações