Escolar Documentos

Profissional Documentos

Cultura Documentos

Post Graduate Diploma in Industrial Safety, Health and Environment (PGDISHE)

Enviado por

my_khan20027195Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Post Graduate Diploma in Industrial Safety, Health and Environment (PGDISHE)

Enviado por

my_khan20027195Direitos autorais:

Formatos disponíveis

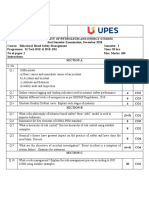

Post Graduate Diploma In Industrial Safety, Health and Environment (PGDISHE)

DEPARTMENT OF ENVIRONMENTAL SCIENCE, M.D.S.UNIVERSITY, AJMER

A) Preamble: Industrialization is basically considered for the comfortable living of human beings. We are getting different types of goods and luxuries due to industrial products though, these are positive aspects of industrialization, along with the development in science and technology the calamities related to industries and environmental pollution problems are increasing day by day. Bhopal Gas Tragedy, Chernobyl Accident, Three Mile Island Nuclear Accident, etc. are some of the examples of safety violation. The above mentioned incidences are to enough to understand the severity of Industrial calamities. To avoid such circumstances various laws and orders implementation is necessary but not the fact is that not only laws but proper training and education about safety rules and their implementation are prior requirements for any industry. In this ever increasing era of industrialization, accidents are becoming a part of process and therefore, there is need of qualified and experienced manpower that can handle the complex industrial situations and avoid the calamities. Nowadays, there is high demand for such safety professionals from different industries. In many nations, it has been made mandatory to appoint well trained and qualified professional for the Industry. Every year around 50 students of Environmental Science from various Universities of Rajasthan complete M. Sc. degree and join Environmental Consultancy or Industry as an Environmental Professional. With their M. Sc. Environmental Science, if they get add-on course as a Post Graduate Diploma in Industrial Safety, which is compulsory under Factories Act, 1948 for a person joining industry as Environment and Safety Officer, these students will get immediate entry in the industry and good salary package after completion of their P.G. Considering the present scenario in mind, Dept of Environmental Science, propose to start P.G. Diploma in Industrial Safety, Health and Environment (PGDISHE). The course is designed for the students and employees from industries who will be exposed to comprehensive and rigorous training covering all areas of Safety, Health and Environmental management.

B) Objectives: To develop highly qualified professional manpower the basic requirement lies on systematic quality based coaching and training in Advanced Science and Technologies. Therefore, the course is designed to train and provide expert human resource to safety management and expected to bring direct benefits to industry and society. The course is based on following objectives:

i. To develop an expert manpower to handle the complex industrial environment.

ii. To give knowledge about occupational health, industrial hygiene, accidental prevention techniques to the students.

iii. To make the student aware about safety auditing and management systems, pollution prevention techniques etc.

iv. To train the students about risk assessment and management.

C) Academic Duration of Course: The duration of the course is 1 year and the lectures will be delivered four days a week, two hours for each paper per week, from 5 pm to 7 pm. Or as decided by the Department. These timings will be suitable for students and working employees from industry. Minimum 75% attendance is required. Workload: Two hours per day for four days in a week i. e. 2 x 4 = 8 per week.

D) Course structure: Candidates will be required to undergo learning in theory, project development and workshop subjects during the academic year. Candidates also will be exposed to industrial exposure through Industrial visits to get familiar with industrial health, safety and environmental management.

E) Scheme: There will be four theory papers and a compulsory project. Each paper will be of 100 marks and three hours duration and project will be of 150 marks and In-plant training will be of three weeks and of fifty marks Paper - I (ISHE 1) Occupational Health and Hazards Paper II (ISHE 2) Safety at Workplace Paper - III (ISHE 3) Accident Prevention Techniques Paper IV (ISHE 4) Safety Management System and Law Paper -V Industrial visit and project report The marks of each paper I to IV are divided as Seminar I - 10 Seminar II - 10 Internal assessment test I -10 Internal assessment test II - 10 Performance - 10 Annual exam - 50 ---------------------------------------------------------------Total marks of each paper = 100 X 4 papers = 400 -----------------------------------------------------------------

Paper V -Industrial visits and project report Project report = In- Plant Training = Total marks = 600 The minimum pass marks required in aggregate are 50% marks subject to a minimum of 40% for each paper subject to this provision the minimum requirement for an I division 60% and II Division 50 %. 150 50 200

F) Expertise Available: Implementation of this type of course is new to the university; therefore, very few experts from various departments of University are available to teach such course. But the experts from industrial sector, labour institute and engineering colleges can

be invited for lecturers. Also, some experts from National and International Institutes related to industrial safety can be invited to deliver lectures and monitor the activities.

G) Space Required: The course includes theory papers and industrial training. The theory part can be taught in the Department of Environmental Science, M.D.S. University, Ajmer. The remaining part of industrial training can be completed in the industry as the project is based on industrial safety, health and management. The students have to complete it in the industry and therefore, laboratory space is not required for the project. The department has well equipped teaching classrooms and Laboratories for the practical. The course will be run only in Environmental Science Department.

H) Eligibility for Admission: The students having science and engineering background will be eligible i.e. any graduate from Science, Engineering and Technology.

I) Examination: The students will be undergoing continuous assessment throughout the academic year through seminars, tests, tutorials etc. The evaluation will consist of internal assessment, external assessment and viva voce for the project. Passing will be as per university rules.

J) Intake capacity: Maximum 20 students in which priority will be given to the university students (60%) and others (40%). Other fee will be applicable as per university rules/ norms

K) Justification:

This activity aims to start Post Graduate Diploma in Industrial Safety, Health and Environment in the Department of Environmental Science. The course aims at i. M. Sc. Environmental Science students will get an add on diploma. ii. It will produce well trained, qualified and expert manpower for the Industrial sector. iii. Better placement opportunity for M. Sc. Environmental Science students. iv. Course will be useful for in-service people from the industry. v. More interaction between University and Industry.

Department of Environmental Science

M.D.S.University, Ajmer Syllabus for P. G. Diploma in INDUSTRIAL SAFETY, HEALTH AND ENVIRONMENT (PGDISHE) Paper - I (ISHE 1) Occupational Health and Hazards Unit - I Safety and Health Management: i. Occupational Health Hazards, Promoting Safety, Safety and Health training, Stress and Safety. ii. Ergonomics - Introduction, Definition, Objectives, Advantages. Ergonomics Hazards - Musculoskeletal Disorders and Cumulative Trauma Disorders. iii. Importance of Industrial safety. Unit - II Radiation and Industrial Hazards: i. Types and effects of radiation on human body, Measurement and detection of radiation intensity. Effects of radiation on human body, Measurement disposal of radioactive waste, Control of radiation ii. Different air pollutants in industries, Effect of different gases and particulate matter, acid fumes, smoke, fog on human health iii. Industrial Hygiene. Unit -III Electrical Hazards and Hazards in Construction Industry: i. Safe limits of amperages, voltages, distance from lines, etc., Joints and connections, Overload and Short circuit protection, Earthing standards and earth fault protection , Protection against voltage fluctuations, Effects of shock on human body Hazards from Borrowed nutrals, Electrical equipment in hazardous atmosphere, Criteria in their selection, installation, maintenance and use, Control of hazards due to static electricity, ii. Introduction of Construction industry:- Scaffolding and Working plat form, Welding and Cutting, Excavation Work, Concreting and Cementing work, Transportation of men and material, Handling and Storage of compressed gas. Unit - IV Fire and other Hazards: i. General causes and classification of fire, Detection of fire, extinguishing methods, fire fighting installations with and without water. ii. Machine guards and its types, automation. High pressure hazards, safety, emptying, inspecting, repairing, hydraulic and nondestructive testing, hazards and control in mines.

Reference Books: 1. R.K.Jain and Sunil S.Rao- Industrial Safety, Health and Environment Management Systems, Khanna publishers, New Delhi (2006) 2. Slote.L,Handbook of Occupational Safety and Health, John Willey and Sons, NewYork . 3. Dr. K. U. Mistry - Fundamentals of Industrial Safety & Health, Siddharth Prakashan, Ahmadabad. Paper II (ISHE 2) Safety at Workplace Unit I - Safe use of machines and tools: i. Safety in the use of: 1) Grinding 2) CNCs ( computer numeric control ) 3) Shearing 4) Bending 5) Milling 6) Boring 7) Shaping Safe use of hand tools: Safe use of various types of hand tools used for metal cutting, torsion tools, shock tools, non sparking tools, portable power tools ii. Ergonomics of machine guarding, Guarding of different types of machinery including special precautions for paper, rubber and printing machinery, wood working. iii. Working in different areas: Working in confined spaces, Working Underground, Working at heights - use of stairways, clamps, working platforms, ladders of different types, Boatswains chair and safety harness working on roofs, Lifting machinery lifts and hoists, iv. Operation, inspection and maintenance of industrial trucks, loose gears conveyors, Safe working load for mechanical material handling equipments. Unit II - Plant design and Housekeeping: i. Plant layout, design and safe distance, Ventilation and heat stress, Significance of ventilation, Natural ventilation, Mechanical ventilation Air conditioning ii. National Building code part VIII and Building service, Thermal comfort, Indices of heat stress, Physiology of heat regulation, iii. Safety and good housekeeping, Disposal of scrap and other trade wastes Spillage prevention, Use of colour as an aid of housekeeping, Cleaning methods, Inspection and Checklists, Advantages of good housekeeping Unit III - Industrial Lighting: Purpose of lighting, Uses of good illumination, recommended optimum standards of illumination, Design of lighting installation, Standards for lighting and color. Unit IV - Vibration and Noise:

Vibration- effects, Measurement & control, Activities related to vibrations, its impact on human health, Sources. Industrial Noise- sources & its control, effects of noise on man, Measurement and evaluation of noise, Silencers, Practical aspects of control of noise Reference Books: 1. Frank P Lees - Loss of prevention in Process Industries, Vol. 1 and 2, Butterworth- Heinemann Ltd., London (1991). 2. Industrial Safety -National Safety Council of India. 3. Dr. K. U. Mistry - Fundamentals of Industrial Safety & Health, Siddharth Prakashan, Ahmadabad.

Paper - III (ISHE 3) Accident Prevention Techniques Unit - I Principles of accidents prevention: Definition: Incident, accident, injury, dangerous occurrences, unsafe acts, unsafe conditions, hazards, error, oversight, mistakes, etc. Accident Prevention : Theories / Models of accident occurrences, Principles of accident prevention, Accident and Financial implications, Hazard identification and analysis: fault tree analysis, Event tree analysis, failure modes and effects analysis, Hazop studies, Job safety analysis examples, Plant safety inspection - objectives and types check procedure inspection report. Unit - II Theories and principles of accident causation: i. The effect of accident, unsafe act, unsafe condition, unpredictable performance, Human factors contributing to accidents - causes for unsafe acts, ii. Safety and psychology -Theories of motivation and their application to safety. Consequences of accident, accident prevention programmers, Role of safety. iii. Accidents related with maintenance of machines & advantages of Maintenance of machines, work permit system- significance of Documentation. Unit - III First aid: Body structure and Functions, Position of causality, the unconscious casualty, fracture and dislocation, Injuries in muscles and joints, Bleeding, Burns, Scalds and accidents caused by electricity, Respiratory problems, Rescue and Transport of Casualty. Cardiac massage, poisoning, wounds.

Unit IV - Personal Protective Equipments Personal Protective Equipments: Need, selection, supply, use, care and maintenance, Personal protective devices for head, ear, face, eye, foot, knee and body protection, Respiratory personal protective devices. Reference Books: 1. Frank P Lees Loss of prevention in Process Industries, Vol. 1,ButterworthHeinemann Ltd., London (1991). 2. R. K. Jain and Sunil S. Rao , Industrial Safety , Health and Environment Management Systems, Khanna publishers , New Delhi (2006) 3. Dr. K. U. Mistry - Fundamentals of Industrial Safety & Health, Siddharth Prakashan, Ahmadabad.

Paper IV (ISHE 4) Safety Management System and Law Unit - I Legislative measures in industrial safety: Factories Act, 1948, Workmans Compensation Act, 1943, Employees State Insurance Act, 1948. Mines Act, Air (Prevention and control) Pollution Act, 1981, Water (Prevention and Control) Pollution Act, 1974, Boiler Vessels Act. Child Labour and Women Employee Act. The factories rules, History, Provisions under the factories Act and rules made there under with amendments, Functions of safety management. ILO Convention and Recommendations in the furtherance of safety, health and welfare, Environment Protection Act. Unit II Occupational Safety, Health and Environment Management : Bureau of Indian standards on safety and health 14489 - 1998 and 15001 2000 OSHA, Process Safety Management (PSM) as per OSHA, PSM principles, OHSAS 18001, EPA Standards, Performance measurements to determine effectiveness of PSM Unit III Safety Management : Organising for safety, Health and Enviornment. Organisation : Structure, Function and responsibilities Safety Committee : Structure and function The competent person in relation to safety legislation - duties and responsibilities. Competence Building Technique (CBT), Concept for training, application of computer, multimedia, communication. Relevance of WTO regarding safety, Health and environment. Employee participation in safety - Role of Trade union in safety,

health and environment. Safety promotion and safety awards, safety, competitions, audio visual publication. Unit IV Directing safety: Definition, process, principles and techniques. Leadership - role, function and attribution of a leader. Essential rules in communication with employees with conducting training, team building and group dynamics. Financial cost to individual worker and family, organization and society. Procedures for compilation, utility and limitations of cost data, budgeting for safety. Reference Books : 1. The Factories Act with amendments 1987, Govt. of India Publications DGFASLI, Mumbai 2. Grimaldi and Simonds , Safety Management, AITBS Publishers , New Delhi (2001) 3. Industrial Safety National Safety Council of India ISHET. 4. Dr. K. U. Mistry - Fundamentals of Industrial Safety & Health, Siddharth Prakashan, Ahmadabad.

Paper V: Industrial visits and project report A- Compulsory project on Industrial safety is to be completed and a report is to be submitted to the department. B- In-plant Training and Industrial Visits. i. In-plant training of 3 weeks is compulsory and a Report to be submitted to the Department with due Certification of the industry where training is done. ii. Minimum 3 Industrial Visits are compulsory.

Você também pode gostar

- Transformer Short Circuit Current Calculation and SolutionsDocumento37 páginasTransformer Short Circuit Current Calculation and Solutionsmano_bacsi100% (1)

- Safety Anglo Hindi 20tlsDocumento22 páginasSafety Anglo Hindi 20tlsliewananda91% (11)

- Fire Safety in Industrial EstablishmentsDocumento37 páginasFire Safety in Industrial EstablishmentsSavantAinda não há avaliações

- Theory Accident - OshaDocumento38 páginasTheory Accident - Oshabotakzxc91% (23)

- Root Cause AnalysisDocumento16 páginasRoot Cause AnalysisPat TejAinda não há avaliações

- 9 Unit 2 Accident TheoriesDocumento61 páginas9 Unit 2 Accident TheoriesSaru ArjunanAinda não há avaliações

- Quantitative Research DesignsDocumento5 páginasQuantitative Research DesignsMisha MehtaAinda não há avaliações

- READING AND WRITING - Q1 - W1 - Mod1Documento13 páginasREADING AND WRITING - Q1 - W1 - Mod1Lilani Gonzaga Boco Elmedulan91% (34)

- Industrail Safety: Sixth Semester B E June/July 2018Documento55 páginasIndustrail Safety: Sixth Semester B E June/July 2018Priyadarshi MAinda não há avaliações

- Golden Peacock Occupational Health & Safety Award GuidelinesDocumento14 páginasGolden Peacock Occupational Health & Safety Award GuidelinesKeshav Singh RaoAinda não há avaliações

- IE 443 Course Overview: Industrial Safety, Maintenance and Failure AnalysisDocumento44 páginasIE 443 Course Overview: Industrial Safety, Maintenance and Failure AnalysisdaudiAinda não há avaliações

- GeneratorsDocumento27 páginasGeneratorsthecodekingAinda não há avaliações

- Factories Act Safety OfficerDocumento4 páginasFactories Act Safety OfficerSafetyboss100% (8)

- Constitutional MedicineDocumento77 páginasConstitutional MedicineJOUO20009167Ainda não há avaliações

- Behavior-based safety A Clear and Concise ReferenceNo EverandBehavior-based safety A Clear and Concise ReferenceAinda não há avaliações

- Safety Organisation & Safety Committee and Its Effective FunctioningDocumento37 páginasSafety Organisation & Safety Committee and Its Effective FunctioningVikas MoreAinda não há avaliações

- Industrial Safety and Legislative Acts: (6 MARKS)Documento34 páginasIndustrial Safety and Legislative Acts: (6 MARKS)jsaylichinu_68833121Ainda não há avaliações

- Industrial SafetyDocumento133 páginasIndustrial SafetyAsif Hameed100% (1)

- 01the Gujarat Factories Rules 1963Documento365 páginas01the Gujarat Factories Rules 1963Siddhrajsinh Zala100% (1)

- Chemical Process Plant SafetyDocumento37 páginasChemical Process Plant Safetyvenky437Ainda não há avaliações

- Cable Design and Testing SolutionsDocumento2 páginasCable Design and Testing Solutionsmy_khan20027195Ainda não há avaliações

- Cable Design and Testing SolutionsDocumento2 páginasCable Design and Testing Solutionsmy_khan20027195Ainda não há avaliações

- A Scientific Approach To Determining Root Cause NOTESDocumento118 páginasA Scientific Approach To Determining Root Cause NOTESSTEVEN DELAHUNTYAinda não há avaliações

- Assessment I - Project Risk ManagementDocumento24 páginasAssessment I - Project Risk ManagementCamilo Andres ESTUPINAN RODRIGUEZ100% (2)

- CLI - Safety DiplomaDocumento9 páginasCLI - Safety Diplomamanoj50% (4)

- 3786 Frequency & Severity Rates For Industrial InjuriesDocumento30 páginas3786 Frequency & Severity Rates For Industrial InjuriesVk Seshadri100% (1)

- Advamce Diploma in Industrial Safety & Security Management (FF)Documento21 páginasAdvamce Diploma in Industrial Safety & Security Management (FF)Dr Shabbir75% (4)

- G 5 News Letter - Who We Are EnglishDocumento2 páginasG 5 News Letter - Who We Are Englishapi-269131865Ainda não há avaliações

- K U M SAFETY BOOK - INDEX With HYPERLINKDocumento4 páginasK U M SAFETY BOOK - INDEX With HYPERLINKsachivkumar100% (4)

- FiatDocumento19 páginasFiatHdxChdAinda não há avaliações

- Feed Mills Engineering, High Quality Feed Milling Machines and Animal Feed Mills - Muyang MachineryshopsDocumento14 páginasFeed Mills Engineering, High Quality Feed Milling Machines and Animal Feed Mills - Muyang Machineryshopsmy_khan20027195Ainda não há avaliações

- Feed Mills Engineering, High Quality Feed Milling Machines and Animal Feed Mills - Muyang MachineryshopsDocumento14 páginasFeed Mills Engineering, High Quality Feed Milling Machines and Animal Feed Mills - Muyang Machineryshopsmy_khan20027195Ainda não há avaliações

- Promoting Worker Health and Safety in FactoriesDocumento83 páginasPromoting Worker Health and Safety in FactoriesRaju VeluruAinda não há avaliações

- Industrial SafetyDocumento33 páginasIndustrial SafetyahdabmkAinda não há avaliações

- P2011 - The Analysis and Valuation of Disruption - Derek NelsonDocumento31 páginasP2011 - The Analysis and Valuation of Disruption - Derek NelsonPameswaraAinda não há avaliações

- Industrial Safety Course PlanDocumento11 páginasIndustrial Safety Course Planpradeep Y DAinda não há avaliações

- Industrial Safety Engineering SyllabusDocumento27 páginasIndustrial Safety Engineering SyllabusBalamurugan83% (6)

- Insulect Specification PDFDocumento10 páginasInsulect Specification PDFThuan NguyenAinda não há avaliações

- Safety in Chemical Industries and MSDSDocumento104 páginasSafety in Chemical Industries and MSDSWahid AkramAinda não há avaliações

- Quiz competition questions on safety standardsDocumento1 páginaQuiz competition questions on safety standardsSahabuddin AhmedAinda não há avaliações

- Japan - Guidebook For Industrial Safety 2006 EditionDocumento176 páginasJapan - Guidebook For Industrial Safety 2006 EditionchedinthrashAinda não há avaliações

- Industrial HygineDocumento43 páginasIndustrial HygineSamaksh Bansal100% (1)

- An Adirondack Chronology No. 78Documento512 páginasAn Adirondack Chronology No. 78Union CollegeAinda não há avaliações

- Safety AuditSDocumento5 páginasSafety AuditSsanjeev kumarAinda não há avaliações

- Ans Sheet SHEL 23114Documento139 páginasAns Sheet SHEL 23114Chetan PatilAinda não há avaliações

- Ans Sheet Safety Engg Industry. 23109Documento80 páginasAns Sheet Safety Engg Industry. 23109Chetan PatilAinda não há avaliações

- K U Mistry - Textbook PDFDocumento1.705 páginasK U Mistry - Textbook PDFmd100% (7)

- Emergency Planning and Preparedness - On-Site & Off-SiteDocumento17 páginasEmergency Planning and Preparedness - On-Site & Off-SiteDebasis MishraAinda não há avaliações

- Safety in MaintenanceDocumento5 páginasSafety in MaintenanceKavindra MishraAinda não há avaliações

- Diagnostic Test Research 2Documento3 páginasDiagnostic Test Research 2Lubeth CabatuAinda não há avaliações

- Safety Management and Accident PreventionDocumento30 páginasSafety Management and Accident PreventionenvsandyAinda não há avaliações

- Industrial SafetyDocumento15 páginasIndustrial SafetyKishore RckzAinda não há avaliações

- 14C PM SN 050101 & Up PDFDocumento604 páginas14C PM SN 050101 & Up PDFManuais De Catálogos Jose Carlos100% (3)

- PDISDocumento49 páginasPDISdeba819967% (3)

- Construction Safety Equipments: Apeksha Hemanth Nishant Nikhil PrajwalDocumento19 páginasConstruction Safety Equipments: Apeksha Hemanth Nishant Nikhil Prajwalshivarajs12340987Ainda não há avaliações

- Safety in Engineering IndustryDocumento6 páginasSafety in Engineering IndustryJaved KhanAinda não há avaliações

- Unit GC2 Revision NotesDocumento65 páginasUnit GC2 Revision NotesBobAinda não há avaliações

- NSAT 2022: Syllabus and Marking SchemeDocumento3 páginasNSAT 2022: Syllabus and Marking SchemeAmit SinghAinda não há avaliações

- Module-2 Fire SafetyDocumento19 páginasModule-2 Fire SafetyBuddies Da Neeghe PuroAinda não há avaliações

- Central Labour InstituteDocumento15 páginasCentral Labour InstituteSmita KAinda não há avaliações

- Chemical Process Safety Management QuestionsDocumento1 páginaChemical Process Safety Management QuestionsmkkamarajAinda não há avaliações

- PGD in Occupational Safety Engineering and Risk ManagementDocumento1 páginaPGD in Occupational Safety Engineering and Risk ManagementRichard BaileyAinda não há avaliações

- QuestionnaireDocumento2 páginasQuestionnairetusharthakreAinda não há avaliações

- 14 M Behavioural Based Safety MGMT UpdatedDocumento5 páginas14 M Behavioural Based Safety MGMT UpdatedSri NivasAinda não há avaliações

- Safety & Health Issue in Textile IndustryDocumento4 páginasSafety & Health Issue in Textile Industrythongtn2007Ainda não há avaliações

- Study Material Safety Supervisor - Vol 1Documento64 páginasStudy Material Safety Supervisor - Vol 1ahmadmonu7258Ainda não há avaliações

- Accident Causation Theory ExplainedDocumento3 páginasAccident Causation Theory ExplainedvuongAinda não há avaliações

- Safety Statistics and Information System: Chapter - 5Documento69 páginasSafety Statistics and Information System: Chapter - 5AbhishekAinda não há avaliações

- Machine Safety in ConstructionDocumento27 páginasMachine Safety in ConstructionSawyu Nandar100% (1)

- Industrial StandardsDocumento11 páginasIndustrial StandardsJayaprakash Kesavan100% (2)

- IGC-3 Full AssessmentDocumento13 páginasIGC-3 Full AssessmentMuhammad100% (1)

- Lab ThesisDocumento62 páginasLab ThesiszombieAinda não há avaliações

- Industrial Safety Management-IISM IndiaDocumento10 páginasIndustrial Safety Management-IISM IndiaNakul SharmanAinda não há avaliações

- ADIS - P-4 (@1-04) Criteria For Plant Siting and Layout - (64) - 2017Documento64 páginasADIS - P-4 (@1-04) Criteria For Plant Siting and Layout - (64) - 2017mkkamarajAinda não há avaliações

- OME553-Industrial Safety EngineeringDocumento11 páginasOME553-Industrial Safety EngineeringBala SubramanianAinda não há avaliações

- Annamalai University: P.G.Diploma in Health, Safety & EnvironmentDocumento8 páginasAnnamalai University: P.G.Diploma in Health, Safety & EnvironmentKannan Jagan50% (2)

- Variation of Funding Agreement: PO Box Telephone: Facsimile: Email: Website: TtyDocumento7 páginasVariation of Funding Agreement: PO Box Telephone: Facsimile: Email: Website: Ttymy_khan20027195Ainda não há avaliações

- Grid Standards RegDocumento19 páginasGrid Standards RegEzhil Vendhan PalanisamyAinda não há avaliações

- Heart BookDocumento96 páginasHeart BookskilmagAinda não há avaliações

- 2 OPRD JulyDocumento213 páginas2 OPRD Julymy_khan20027195Ainda não há avaliações

- Calculating Short-Circuit Currents in Low-Voltage Electrical SystemsDocumento0 páginaCalculating Short-Circuit Currents in Low-Voltage Electrical SystemsMuruganantham ChandrappanAinda não há avaliações

- ICD-10 Classification of Mental DisordersDocumento267 páginasICD-10 Classification of Mental DisordersBharath HollaAinda não há avaliações

- IEEECSStyleGuide2013 PDFDocumento109 páginasIEEECSStyleGuide2013 PDFmy_khan20027195Ainda não há avaliações

- Building Faster Rapport With Coaching Clients 140828155405 Phpapp01Documento18 páginasBuilding Faster Rapport With Coaching Clients 140828155405 Phpapp01my_khan20027195Ainda não há avaliações

- 978 3 86922 146 5 - DatenblattDocumento1 página978 3 86922 146 5 - Datenblattmy_khan20027195Ainda não há avaliações

- An Open Letter To Any Service Provider Who Works With ClientsDocumento3 páginasAn Open Letter To Any Service Provider Who Works With Clientsmy_khan20027195Ainda não há avaliações

- Cec 500 2010 043Documento172 páginasCec 500 2010 043my_khan20027195Ainda não há avaliações

- ADP 2014-15 HealthDocumento29 páginasADP 2014-15 Healthmy_khan20027195Ainda não há avaliações

- Electric Motors Whitepaper PDFDocumento8 páginasElectric Motors Whitepaper PDFCesario GillasAinda não há avaliações

- AJTips No8 Solarnet v7n1 2005Documento5 páginasAJTips No8 Solarnet v7n1 2005my_khan20027195Ainda não há avaliações

- Convective Solar DryerDocumento28 páginasConvective Solar Dryermy_khan20027195100% (1)

- Hany Et AlDocumento13 páginasHany Et AlprevrtljivacAinda não há avaliações

- Cas Sample Application FormDocumento2 páginasCas Sample Application Formmy_khan20027195Ainda não há avaliações

- Performance Evaluation of Biomass Fired Dryer For Copra Drying A Comparison With Traditional Drying in Subtropical Climate 2157 7110.1000294Documento5 páginasPerformance Evaluation of Biomass Fired Dryer For Copra Drying A Comparison With Traditional Drying in Subtropical Climate 2157 7110.1000294my_khan20027195Ainda não há avaliações

- How Boilers WorkDocumento18 páginasHow Boilers Workhozipek5599100% (1)

- AG Potato-BrochureDocumento4 páginasAG Potato-Brochuremy_khan20027195Ainda não há avaliações

- Grid Standards RegDocumento19 páginasGrid Standards RegEzhil Vendhan PalanisamyAinda não há avaliações

- Convective Solar DryerDocumento28 páginasConvective Solar Dryermy_khan20027195100% (1)

- CH 4Documento19 páginasCH 4Raman KulkarniAinda não há avaliações

- The Evolution of Institutional Theory in Organizational AnalysisDocumento20 páginasThe Evolution of Institutional Theory in Organizational AnalysiswalterAinda não há avaliações

- Stat 231 Final SlidesDocumento100 páginasStat 231 Final SlidesRachel LAinda não há avaliações

- W. T. Stace Compatibilism or Soft DeterminismDocumento5 páginasW. T. Stace Compatibilism or Soft DeterminismOn YoungAinda não há avaliações

- L9 Incident Investigation Student Handout PDFDocumento73 páginasL9 Incident Investigation Student Handout PDFkenan100% (1)

- Sociological Investigation: Three Ways of Doing SociologyDocumento5 páginasSociological Investigation: Three Ways of Doing SociologyMarc Arnel VanguardiaAinda não há avaliações

- Lesson 2-Doing PhilosophyDocumento16 páginasLesson 2-Doing PhilosophyFrancis Lawrence TubidAinda não há avaliações

- Philosophy Class Xi - Final - 2011Documento145 páginasPhilosophy Class Xi - Final - 2011Miyamoto Yoshinobu100% (2)

- Modern Epidemiology, 4Th Edition. TL Lash, TJ Vanderweele, S Haneuse, KJ Rothman. Wolters Kluwer, 2021Documento3 páginasModern Epidemiology, 4Th Edition. TL Lash, TJ Vanderweele, S Haneuse, KJ Rothman. Wolters Kluwer, 2021Mubariz Mirzayev100% (1)

- Ilovepdf MergedDocumento160 páginasIlovepdf MergedJeanalyn BuycoAinda não há avaliações

- Science Writing Heuristic: Beginning QuestionsDocumento2 páginasScience Writing Heuristic: Beginning QuestionsJoseph M. SalvadorAinda não há avaliações

- 11 - Semua Jurusan - EnglishDocumento11 páginas11 - Semua Jurusan - EnglishYoe ZakieAinda não há avaliações

- John Dunn The Identity of The History of IdeasDocumento21 páginasJohn Dunn The Identity of The History of IdeasCosmin KoszorAinda não há avaliações

- Sample Science LessonDocumento6 páginasSample Science Lessonapi-284029251Ainda não há avaliações

- An Introduction: Fibers, Yarns & Threads Industry OverviewDocumento41 páginasAn Introduction: Fibers, Yarns & Threads Industry OverviewDipak KashyapAinda não há avaliações

- Notes on Avoiding PlagiarismDocumento14 páginasNotes on Avoiding PlagiarismemaazizAinda não há avaliações

- International Studies Perspectives Volume 2 Issue 2 2001 (Doi 10.1111/1528-3577.00047) John S. Odell - Case Study Methods in International Political Economy PDFDocumento16 páginasInternational Studies Perspectives Volume 2 Issue 2 2001 (Doi 10.1111/1528-3577.00047) John S. Odell - Case Study Methods in International Political Economy PDFbelelou2010Ainda não há avaliações

- Explaining The Placebo Effect: Aliefs, Beliefs, and ConditioningDocumento33 páginasExplaining The Placebo Effect: Aliefs, Beliefs, and ConditioningDjayuzman No MagoAinda não há avaliações

- Heidegger Question Concerning TechnologyDocumento11 páginasHeidegger Question Concerning TechnologyFRANCOIS-GHISLAIN MORILLIONAinda não há avaliações