Escolar Documentos

Profissional Documentos

Cultura Documentos

CBE Report - Dioxins and Refineries (Scanned)

Enviado por

Ken ComeyDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

CBE Report - Dioxins and Refineries (Scanned)

Enviado por

Ken ComeyDireitos autorais:

Formatos disponíveis

.

-

Dioxins and Refineries:

Analysis in the San Francisco Bay Area.

August 2000

Introduction.

In a June 21, 2000 television interview a Bay Area oil refinery official summarized his indus-

. try's position on why it is not taking action to prevent its ongoing releases of dioxins. saying

that: "[O]ver 95 percent of the dioxin that goes out in our effluent to the Bay comes from

sources outside of our control."

Dioxins cause serious threats to public health. Bay Area communities and most Bay A.rea elect-

_ed officials seek dioxins elimination wherever possible, suggesting that oil refiners should do

their part to stop the pollution. However, public officials charged with protecting environmental

health from refinery pollution have declined to require- or even to investigate- pollution pre-

vention for dioxins and refineries. The San Francisco Bay Regional Water Quality Control

Board explains this inaction by siding with the industry argument. The Water Board says

refineries cause so little of this pollution that most of the dioxins contamination in refineries is

caused by residential wood fires and vehicle use by people in the community.

In fact, no government health agency has ever made a thorough assessment of all the rekases of

dioxins caused by petroleum refineries.

Dioxins and Refineries reports the first comprehensive assessment of the total amount of dioxins

released from all petroleum refinery sources. It reveals oil refining as an important source of

dioxins in the Bay Area. It shows that existing government analyses drastically underestimate

refinery releases of dioxins. As an immediate matter. it sets forth specific steps for cost-effec-

tive elimination of dioxins in refineries.

Communities for a Better Environment ( CBE) Report No. 2000-2

Author:

Dioxins and Refineries:

Analysis in the San Francisco Bay Area.

Communities for a Better Environment (CBE)

CBE Report No. 2000-2. August 10, 2000.

Supporting analysis:

Greg Karras, Senior Scientist

Azibuike Akaba, Staff Scientist

Anne Simon, Senior Attorney

Karen Susag, Community Health Advocate

Sue Tuddenham, Intern

This report was made possible by thousands of CBE's members, friends and

supporters, and by the generous support of the Richard and Rhoda Goldman

Fund, Jenifer Altman Foundation, Patagonia Environmental Grants Program,

Mari Mayeda and Albert Kutchins, through the San Francisco Foundation, and

of the V-Fund through the Tides Foundation.

In addition, many environmental scientists, researchers, community members

and other experts reviewed, guided and substantially improved the research,

analysis and communication of the information. CBE is solely responsible for

the report's content.

Thank you all!

Founded in 1978, Communities for a Better Environment (CBE) is an

environmental health and justice organization that works with urban

communities directly affected by industrial pollution. CBE provides

organizing skills and legal, technical and scientific resources that

assist these communities in taking control of the decisions that affect

their quality of life. We believe that fundamental change comes from the

grass roots up, and that environmental solutions can only be sustained in

concert with social and economic justice.

Currently CBE's staff are:

- Organizing community members and developing their leadership skills to

reduce exposure to environmental hazards.

- Training community members who live in heavily industrial areas to use

low-cost and highly accurate air monitoring devices.

- Fighting for the elimination of dioxin releases into the San Francisco

Bay and promoting community Right-To- Know about dioxin emissions by

industries.

- Using legal strategies to affect policy change and enforce environmental

health protection laws and rules .

Oakland Office

1611 Telegraph Ave., Suite 450

Oakland, CA 94612

510/ 302-0430

Huntington Park Office

5610 Pacific Blvd., Suite 203

Huntington Park, CA 90255

323/ 826-9771

CONTENTS:

Introduction

Contents

Purpose, scope and terms

Approach

Findings

Discussion

Recommendations

Part 1. Multiple sources of preventable dioxin pollution in oil refineries

Confirmed sources:

Reforming catalyst regeneration

Cracking catalyst regeneration

Oil- and waste-fired process heaters and boilers

Contamination of diesel fuel in refineries

Contamination of motor oil in refineries

Suspected sources:

Flares, coking, desalting, distillation and other processes

Contamination of petroleum coke and other products

Process upsets and uncontrolled fires

Contaminated solid waste disposal

page 1

page 2

page 3

page 4

page 5

page 8

page 11

page 12

page 12

page 16

Part 2. Measurement of the dioxins release rate from all Bay Area oil refinery sources page 17

Analysis of dioxins release measurement data quality: page 17

Error and bias related to choice of analytical methods

Error and bias related to test frequency and disclosure

Error and bias when there is no testing of a known or suspected source

Error and bias related to sampling of release pathways

Analysis of source-specific measurements: page 23

Reforming catalyst regeneration

Cracking catalyst regeneration

Oil- and waste-fired process heaters and boilers

Contamination of refined products in refineries

Contamination of effluent in refineries

Other (suspected) refinery sources

Minimum and maximum bounds of total Bay Area oil refining dioxins release page 27

Part 3. Measurements linking dioxins in the Bay Area environment to refinery sources page 28

Analysis of dioxins pollution gradients in sediment, water and fish

Analysis of dioxins profiles at refinery sources and in environmental samples

Comparison of releases with fallout to Bay Area refineries from other sources

Literature cited

2

page 28

page 33

page 35

page 38

Purpose, Scope and Terms.

Dioxins are a group of industrial byproducts and among the most toxic chemicals known. Pre-

industrial dioxin pollution was virtually nonexistent. Today people throughout the general popu-

lation have dioxins in their tissues at or near concentrations that cause a high risk of cancer, and

may cause diabetes, endometriosis and other effects.l,2,3,4 Studies of humans suggest that diox-

ins exposures in the womb and through breast feeding cause effects on learning and the immune

system in 10-20% of children .1 ,2,3.4

Citing high exposure for people who rely on San Francisco Bay fish for food, the U.S.

Environmental Protection Agency overruled the California Regional Water Quality Control

Board in 1999 to designate dioxins pollution as a "high priority" cause of water quality stan-

dards violations throughout the Bay.

5

Nearly ten years earlier, California established a policy

that directs the Water Board to eliminate dioxins discharges to the Bay by the year 2000.

6

The term "dioxins" in this report includes the polychlorinated dibenzo-p-dioxins and diben-

zofurans with chlorine atoms in the 2,3,7 and 8 positions ("CDDs" and "CDFs"), and polychlo-

rinated biphenyls (PCBs) that exhibit dioxin-like toxicity. Refinery releases are reported as the

combined toxicity of these chemicals (including dioxin-like PCBs) using the World Health

Organization consensus (TEQDFP-WH0

98

).

16

When measurements include only CDD/Fs the

combined toxicity of these dioxins is noted as TEQ

0

F (the "P" is left out of the subscript).

Individual dioxins are named using abbreviations (for example: OCDD, OCDF, and PCB-126).

When a larger group of chemicals that includes some dioxins is discussed, the larger group is

referred to by a different term, such as "total CDD/Fs" or "PCB homologue groups."

Petroleum refining is among the world's largest industries, yet the first published evidence

that oil refining is a dioxins source came only 12 years ago, 7 31 years after dioxin was found to

cause health problems in 1957.

4

As recently as November 1999 EPA admitted that it does not

know the total amount of dioxins released by refineries.

8

Importantly, more data exist on refin-

ery dioxin pollution in the Bay Area than in any other region of the country.

Underestimating pollution is a recurrent environmental problem. For example, until late

1990 the Water Board agreed with oil company managers' claims that refineries are not signifi-

cant sources of toxic selenium pollution in S.F. Bay.9 However, the Water Board later admitted

that refineries appeared to be the "predominant" source of this pollution 1 o until citizen suits

forced clean ups.

11

The Water Board also agreed with refinery management claims that dioxins

do not violate water quality standards in the Bay

1

2 before EPA overruled this claim in 1999.

Today, oil industry and Water Board managers assert the hypothesis that refineries are insignifi-

cant sources of dioxins to S.F. Bay, and claim refineries are dioxin "sinks" that remove more

dioxins from the environment than they release.\3.14 Water Board staff say that a focus on refin-

ery dioxin pollution is "really a distraction and a diversion from solving the problem,"

14

and the

Water Board has increased the amount of dioxins it allows to be released.

1

5

This case study attempts a comprehensive review of existing information on petroleum refin-

ery dioxins pollution in the S.F. Bay Area. It allows the first thorough public review of the

hypothesis that refineries are "insignificant" dioxins sources. It attempts to quantify releases

from refineries themselves. This analysis is specific to the Bay Area, where there are relatively

more refinery dioxins data, but it can be used by communities near refineries everywhere.

3

Approach .

In general, there are four ways to investigate a pollution source: 1) by measuring

how pollution is caused and prevented at the source; 2) by measuring the pollution released

from the source and from other similar sources; 3) by measuring the flow of pollution from the

source into the environment where this pollution accumulates; and 4) by measuring health

effects caused by the pollution source in humans and other organisms. The first three types of

measurements are used here to investigate dioxins released from Bay Area petroleum refineries.

Part I investigates the ways in which dioxins are created and released by refineries, and how

this can be prevented. This pollution prevention engineering analysis is useful in answering the

central question of how to improve health protection. It also tells us whether refinery activities

are sources creating dioxins, or merely pathways carrying them from some other source.

Part 2 investigates measurements of the amounts of dioxins released from all refinery sources.

It builds on the engineering analysis in part 1 and uncovers the amount of dioxins refineries

release to the environment through all pollution pathways, based on a detailed analysis of what

is - and is not - known from existing measurements of each refinery source. This analysis is

useful because despite public debate over the significance of this pollution, there is no govern-

ment estimate today of overall releases of dioxins from all refinery sources.

Part 3 analyzes measurements in the environment to investigate the extent to which environmen-

tal accumulations of dioxins can be traced to refinery sources. It builds on CBE's comprehen-

sive inventory of Bay Area sources of dioxins. When other sources are accounted fm;, one can

get a more complete picture of the pollution gradients stretching from refineries into the envi-

ronment. It analyzes new information on how dioxins might (in some cases) be traced to their

source using the "profile" of the relative amounts of specific dioxin compounds. Information

explored here links releases to environmental exposures, and provides a "check" on the source

measurements of pollution amounts in part 2.

A discussion of findings and recommendations looks at the data as a whole and puts the new

findings in perspective based on what is known now, what we can learn quickly, and what can

be done now to improve environmental health protection from refinery dioxin pollution.

Readers should note that despite important new data, few data exist to describe exactly

"how much" dioxin is released from most sources. This analysis benefits from a comprehensive

assessment of Bay Area data on all dioxins, sources in refineries, and release pathways from

refineries into the environment. Further, it looks at releases of these persistent, trans-generation

taxies from the more relevant perspective of long-term release, allowing more data to be consid-

ered. Nevertheless, poor monitoring has led to many gaps in scientific information. In order to

interpret the incomplete data accurately, this analysis takes the approach of estimating that Bay

Area refineries as a group release more than a minimum amount of dioxin pollution, and less

than a larger maximum amount of this pollution.

These region-wide refining estimates should not be applied to an individual source: this could

overestimate or underestimate the amount of dioxins released, and the measurement accura-

cy, depending upon the source. Data and analysis methods are detailed in parts 1, 2 and 3.

4

Findings.

Multiple sources create oil refineries' releases of dioxins.

Six San Francisco Bay Area oil refineries use many process units that create dioxins.

Reformers, crackers, and oil-fired heaters and boilers that process a total of more than 25 mil-

lion gallons of petrochemicals each day in Bay Area refineries are confirmed sources of dioxins.

This is based on measurements of CDD/Fs in the initial releases from these processes at Bay

Area refineries, and the presence of chlorine inputs and process conditions that create dioxins in

these processes. Measurements of PCBs homologue groups also confirm the creation and

release of newly-formed PCBs in Bay Area refineries' reforming and oil-fired processes.

In addition to these known sources, there is suggestive evidence that flares, cokers, desalters,

distillation towers, and/or uncontrolled fires in refineries create and release dioxins, although no

tests of these suspected sources for dioxins have been reported publicly.

Releases of dioxins from refineries are confirmed by direct measurements of smoke stacks,

waste water discharges, and rain storm runoff discharges at Bay Area refineries and by direct

measurements of newly-refined diesel fuel and motor oil at southern California refineries.

Newly-refined diesel also contains chlorine, which could cause more dioxins to form in vehi-

cles. Although the diesel pollution pathway to the environment is through vehicle exhaust pipes,

it is important to recognize the refinery source because - regardless of how much of the dioxins

emitting from the tailpipe form in the refinery and how much form in the vehicle - getting the

dioxins and the chlorine out at the refinery may be the most practical way to stop this pollution.

Refineries are poorly monitored for releases of dioxins.

Despite relatively better monitoring of dioxins at S.F. Bay Area oil refineries than at refineries

elsewhere, many refinery sources, pollution pathways to the environment, chemicals in the

"dioxins" group, and pollution-causing events have not been measured at Bay Area refineries.

Direct measurements for dioxins are not reported in releases from flares, cokers, desalters, distil-

lation towers, or uncontrolled fires at any Bay Area refinery. None of the major Bay Area

refineries reports measurements of dioxins from every one of the confirmed source types it uses.

No Bay Area refinery reports these measurements for most of its smoke stacks, or for any of the

diesel, motor oil and other products it refines. Despite direct measurements confirming release

of PCB homologue groups that contain dioxin-like PCBs, no Bay Area refinery reports direct

measurements that isolate dioxin-like PCBs from other PCBs it releases. Further, most of the

measurements that have been done were not planned to be sensitive enough to fully quantify

many of the individual CDD/F chemicals above analytical detection limits.

Finally, even monitored releases are measured only a small fraction (one-ten thousandth) of the

time that the releases are occurring, and these tests are announced in advance, raising the possi-

bility that only the low end of the highly variable releases from refineries is measured directly.

Because of this poor monitoring, the true rate of dioxins release from refineries is only known

within a wide range (of minimum to maximum release).

5

Bay Area oil refineries release more than 1.8 billion picograms of dioxins per

day, and up to a maximum of 171 billion picograms of dioxins/day, on average.

This is measured as the toxicity of CDD/Fs and dioxin-like PCBs (TEQDFP-WH0

98

).

The minimum rate of dioxins release (1.8 billion pg/day) is based on direct measurements of

confirmed refinery sources and release pathways, and the minimum plausible amount of

CDD/Fs and dioxin-like PCB compounds that were present but not fully quantified in confirmed

releases due to analytical problems. However, Bay Area refineries actually release an amount as

low as this minimum amount of dioxins only if all the following conditions exist:

- none of the many suspected, but unconfirmed sources in refineries release dioxins;

- dioxins known to be released that are not fully quantified in releases due to analytical prob-

lems are released at only the lowest rate that measurements show is possible;

- on-road diesel is the only refined product causing environmental release of dioxins; and

- releases are not larger during refinery fires or when refiners know "they are not being tested.

While it is possible that all these conditions exist in reality, the detailed analysis in this report

shows that the probability of this is very low.

It is equally possible (and equally unlikely) that all of the opposite conditions exist: one or

more suspected refinery sources release dioxins; dioxins present but not fully quantified in

releases are released at only the highest rate existing measurements indicate is possible; other

refined products release dioxins; and releases are much larger when refineries are not tested. If

all these conditions exist, refineries could release up to a maximum of 171 billion pg/day of

dioxins TEQ.

Of course, the most likely situation is that some of these conditions exist (for example, an

unconfirmed source releases dioxins), and some other conditions exist in between the minimum

and maximum possible extremes (for example, dioxins below detection are released at rates

between the lowest and highest possible rates defined by analytical detection limits).

Thus, Bay Area oil refineries release more than 1.8 billion pg/day and less than 171 billion

pg/day of dioxins TEQ, and their true release rate is likely to be closer to the middle than the

extremes of this 1.8 - 171 billion pg/day range.

Environmental measurements support the finding that Bay Area refineries

release more than 1.8 billion picograms per day of dioxins toxicity.

Average concentrations of dioxins (TEQDFP-WH0

98

) in San Francisco Bay fish are 30 to 250

times larger than those in fish from a comparable location in northern California that should

receive similar amounts of dioxins from distant sources. The greater fish contamination in the

Bay Area suggests that there are important Bay Area sources of dioxins.

The average concentration of CDD/Fs (TEQ

0

F-WH0

98

) in aquatic sediment of a Bay Area

refinery discharge canal is 20 to 140 times larger than the concentrations of TEQDFP-WH0

98

in

the northern reach of the S.F. Bay/Delta and two of its tributary rivers, and 600 times larger than

the concentrations of TEQ

0

F-WH0

98

in sediment of two of its other tributary rivers. The rela-

tive levels of different individual CDD/F chemicals in the refinery's canal sediment and one of

its process releases (the "profiles" of dioxins within each homologue group) are similar, support-

ing the conclusion that refinery caused the accumulation of dioxins in its discharge canal.

6

Maximum concentrations of CDD/Fs (TEQ

0

F-WH0

94

) in changing rain storm runoff are up to

70 times greater at refineries than at sites 15 to 25 kilometers from refineries and other industrial

sources of dioxins, and these maximum levels taper off for at least six miles from the sources.

Further, particulate pollution follows this same pollution gradient from refineries: This is impor-

tant because dioxins often attach to particulate pollutants from refineries and other sources, and

this enhances their fallout near sources and their movement into this storm water runoff.

Finally, a disproportionate number of runoff tests at refineries have high dioxins levels that can-

not be explained by the suspended solids levels in the runoff: This provides another indication

that refinery sources are contributing to the dioxins gradient observed in the runoff.

All these measurements indicate a gradient of pollution with higher levels of dioxins near

refineries and other industrial sources, and gradually decreasing levels as the pollution disperses

far into the Bay Area environment. These measurements show that oil refineries contribute

important amounts of the dioxins found in the Bay Area environment.

The pollution gradient in runoff is also of interest with respect to another type of dioxins release.

According to the Bay Area Air Quality Management District, residential wood burning releases

as much dioxins as any Bay Area source: an estimated 2.2 billion pg/day of TEQ

0

F-WH0

94

.1

4

However, the levels of dioxins at runoff sites near residential wood burning but far from indus-

trial sources are among the lowest found in the Bay Area, and these sites are at the low end of

the pollution gradient, while refineries are at the high end of the pollution gradient. This indi-

cates that refinery releases could not be significantly smaller than residential wood burning

releases (2.2 billion pg/day), and it suggests that refinery releases are larger.

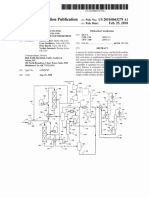

The comparison in Figure ES-1 shows that the minimum refinery release discussed above is at

least 30 times the amount of dioxins from other sources that is estimated to fall out to a land

area of the size used by Bay Area refineries. This is consistent with the much greater dioxins

levels in sediment and runoff at refineries than those at sites far from industrial sources.

Environmental measurements support the source measurements that indicate Bay Area refineries

release more than 1.8 billion pg/day of dioxins TEQ. Indeed, if refinery releases were much

smaller than those from residential fireplaces (estimated at 2.2 billion pg/day) and much less

than 30 times fallout from other sources, the 20-600 times greater concentrations of dioxins

TEQ found at refineries than at other Bay Area sites would be very difficult to explain.

Oil refineries can prevent dioxin pollution now.

Chlorinated dioxins cannot be created without chlorine. Refiners can block the chemical reac-

tions that create dioxins by removing chlorine from their processes. They can also trace the

chlorine entering their processes to its sources and prevent chlorine from entering the processes.

One small refiner in the South Bay community of Newark has committed to do this - and thus

virtually eliminate dioxins from a process heater- within two years. Dioxins have no industrial

use, and chlorine has no use in cracking or heater or boiler processes. Thus, dioxins can be

eliminated in these refinery processes immediately.

Refiners do use chlorine to regenerate reforming catalyst; but even here, the creation of dioxins

can be eliminated by a concerted effort to find and install methods that protect, clean and repair

this catalyst without burning chlorine. Thus, at every process that is a known source of dioxins

and in every Bay Area oil refinery, steps can be taken today to eliminate the creation of dioxins.

7

Discussion .

This report shows that preventable sources in Bay

Area oil refineries release at least as much dioxins

as the biggest pollution sources cited by regional

government officials, and contribute significantly to

health threats affecting subsistence anglers.

It also highlights a health concern for the general

food supply, when one begins to consider the toxi-

cological significance of more than 1.8 billion

pg/day of dioxins toxicity release from Bay Area

refineries, and where some of it may be going. One

picogram of dioxin exposure per day can cause a

person to exceed the lowest lifetime cancer risk

threshold considered "acceptable" by public health

officials. Most dioxins released will end up in soil

and sediment rather than in our food, but prevailing

winds from the Pacific Ocean could carry signifi-

cant amounts of dioxins emitted by Bay Area

refineries to parts of California that EPA says are

among the major U.S. food producing regions.

4

This pollution should be prevented starting now .

This analysis suggests refineries release amounts of

dioxins significantly within the extremes of the 1.8-

171 billion pg/day range shown in Figure ES-1.

Nevertheless, given the size and scope of this indus-

try, its release rate needs to be known better. If the

industry's releases nationwide approach the median

of this range, refineries may cause more release of

dioxins than all but one source estimated by EPA.

4

One might speculate that releases approach the geo-

metric mean of this range (and refineries are the sixth

largest source) but in any case, such speculation real-

ly only highlights a need to monitor refineries.

A program to organize monitoring of dioxins in the

confirmed and suspected refinery sources and

release pathways is needed now. This should be

done before Toxics Release Inventory reports on

dioxins8 are released nationwide next year.

Figure ES-1 shows that even the minimum amount

of dioxins released by Bay Area oil refineries is

165 times greater than that estimated by the San

Francisco Bay Regional Water Quality Control

Board, and 13 times greater than that estimated by

8

Figure ES-1. Lower and upper bounds of

dioxins release from Bay Area oil refineries

(pg/day other estimates,

and fallout on refineries from other sources.

171

billion

pglday

or less

(Scale compressed)

tt

1.82

billion

pglday

or more

Key

II

D

D

t

Lower bound of amount

Upper bound of amount

Estimates by others

Arrows point to

increasing likelihood

of true release rate

Bay Area Refineries Refineries Fallout on

refineriesa (Bay Area (Water Bay Area

AQMD)b Board)C refineriesd

NOTES: aThis analysis. bBAAQMD refinery (refonning)

estimate from reference 34. CRWQCB refinery (effluent)

estimate from reference 53. dEstimated from national data

in reference 4. refinery acreage, and methods in part 3.

the Bay Area Air Quality Management District. The maximum possible release found by this

analysis exceeds these regional health officials' estimates of refinery release rates by

1,200-15,000 times. The Water Board's estimate that Bay Area refineries release an amount of

dioxins equal to 11 million pg/day is documented in its February 1998 staff report entitled

Dioxins in the Bay Environment, and in its May 25, 1999 and June 21, 2000 staff reports regard-

ing the Tosco Avon Refinery.t3,14,53 The Air District's estimate that these refineries release an

amount of dioxins equal to 137 million pg/day is documented in its March 27, 1996 staff report

entitled Air emissions of dioxins in the Bay Area environment.3

4

However, these Water Board and Air District analyses exclude many considerations that prove

important based on the evidence in this report:

- The Air District estimate does not report any amount of release from known refinery sources

in cracking and oil-fired processes, or from suspected sources in flares, cokers, distillation

units, desalters or fires. The Water Board analyses rely on this Air District estimate.

- The Water Board and Air District estimates do not report any amount of refinery release via

storm water runoff, refinery products, or fugitive emissions from fires.

- The Water Board and Air District estimates do not report dioxin-like PCBs releases.

- The Water Board estimate does not report any release of CDD/Fs known to be created and

released by refineries when the chemicals are below detection limits due to poor monitoring.

- Refinery releases of dioxins are tested only a small fraction (one-ten thousandth) of the time,

release rates can change by hundreds of times, and advance warning of tests may result in

sampling when releases are low. However, the Air District and Water Board estimates

assume refineries never release more dioxins when they are not looking (testing the releases).

The cumulative error caused by excluding many refinery sources, release pathways, dioxins, and

measurements of greater release explains how the Water Board and Air District have drastically

underestimated oil refinery releases of dioxins.

Amounts of dioxins in the environment near Bay Area refineries provide a second important

measurement of this pollution, confirming the refinery release rate from source measurements.

The analysis in this report finds links between refineries and pollution in fish, sediment, and

runoff, that were missed by public health officials' earlier assessments.

In fish, a 30-250 times greater concentration of dioxins is linked to Bay Area sources by consid-

ering a key site-specific factor, and comparing Bay Area fish with other fish near the Pacific

Ocean. These fish are more comparable due to the lower rate of dioxins fallout near the Pacific.

In contrast, the Water Board's February 1998 staff report

5

3 does not account for this ocean influ-

ence, compares S.F. Bay fish with fish from U.S. waters far from the Pacific that receive fallout

from many land-based sources to windward, and fails to find the clear difference revealed here.

In sediment, a 20-600 times greater concentration of dioxins is linked to refinery sources by

considering environmental processes that affect dioxins. Dioxins build up in sediment near

sources for a long time, and move back into the water only slowly. The report accounts for this,

comparing dioxins in sediment with long-term releases. In contrast, in its June 21, 2000 and June

16, 1999 staff presentation reports 14 the Water Board agrees that the dioxins buildup in sediment

could cause discharges from a refinery canal for years, then contradicts itself by claiming that dis-

charge from the refinery's canal during a five-month plant shutdown was from another source.

9

Environmental processes also shift the mix

(the "profile") of dioxins so that sediment has

higher levels of dioxins with more chlorine

atoms, and lower levels of dioxins with less

chlorines, as compared to sources. The report

accounts for this factor, and finds that the

"profile" of dioxins in sediment of the refin-

ery discharge canal is (not surprisingly) simi-

lar to that of the refinery source. In contrast,

the Water Board's May 25, 1999 staff reportl3

does not account for this factor, and fails to

notice this similarity in the profiles.

In storm runoff, dioxins, particulate pollution

associated with dioxins, and changes in the

ratio of dioxins to particulates are each linked

to refinery sources when one accounts for all

the nearby industrial sources of this pollution.

Figure ES-2 shows the location of sources,

illustrating how runoff far from refineries

might be near other sources of dioxins.

Figure ES-3 shows that when the distance

from all these sources is accounted for,

refineries (gray bars) are shown to influence

all three pollution-related factors. As shown

in the Figure, this analysis reveals pollution

gradients starting from maximum dioxins and

suspended solids levels at refineries, and

instances of high dioxins at refineries even

when suspended solids levels are moderate.

Thus, refineries influence a pollution gradient

with 70 times greater maximum runoff levels

that taper off for miles into the environment.

In contrast, the Water Board's June 21, 2000

staff reportl3 compares runoff between only

two types of sites: refineries and all others

(even if other sources are nearby). This does

not account for the effects of other industrial

sources. Thus, the Water Board has missed

refinery effects on this pollution gradient.

Most important, this report reveals immediate

steps that can eliminate creation of dioxins in

refineries by blocking chlorine inputs. This

will stop this pollution via all routes - includ-

ing stack and tailpipe discharge to the Bay.

Therefore, it is within the Water Board's man-

date to address all discharges to water.

Figure ES-2. Oil refineries and other industrial

dioxin sources identified in the S.F. Bay Area.

Source key:

oil refineries

incinerators

0

scrap

furnaces

chemical

drum

furnaces

0

foundries

0

other

industries

NOTES: Data from references 2 and 47.

0

Figure ES-3. Dioxins and suspended solids in Bay Area

runoff v. distance from industrial sources.

7o

~

so

40

Jo

20

IO

- Runoff sample at refineries

I Runoff sample at

other sites

7o

~ ~

~

so!-'

...:.

4 ~

-5

Jo]

...

.!!

20-11

"' .s

Io ~

Q

NOTES: 47 s:unples with CDD/F and solids doUI; from references 2. 47. 97 ond 98.

10

RECOMMENDATIONS:

1. The San Francisco Bay Regional Water Quality Control Board, State Water Resources

Control Board and U.S. Environmental Protection Agency should reverse their deci-

sions to allow ongoing dioxin pollution by Bay Area oil refineries. The agencies should:

Reverse the June 21, 2000 decision to weaken the effluent limit on dioxins discharge by

the Tosco Avon Refinery. The Regional Board based this decision on its drastic under-

estimate of refinery dioxin pollution, but it did not raise this reason in its proposal until

after its comment deadline, and it did not accept written comments thereafter.

Revise the permit allowing dioxins discharge by the Chevron Richmond Refinery to S.F.

Bay, which expired by its own terms in 1997, to require dioxins elimination.

Conduct a basin planning process with formal public debate on how Federal require-

ments for total maximum "loads" of all dioxins release to S.F. Bay can best meet the

existing State policy goal to eliminate dioxins discharge to the Bay by the year 2000.

2. The Regional Board, State Board and EPA should require pollution prevention audits

of all root sources creating dioxins at the Chevron, Tosco, Equilon (formerly Shell), and

Valero (formerly Exxon) refineries in the Bay Area, and fund experts hired and directed

by the community and workers to ensure independently verifiable results. Within two

years audits should identify, test and effect options that:

Protect reforming catalyst or repair and clean it without incinerating chlorine .

Identify, trace and prevent chlorine inputs to cracking processes .

Identify, trace and prevent chlorine inputs to oil/waste-fired process heaters/boilers.

Identify, trace and prevent or remove chlorine inputs to other refinery processes .

3. The Regional and State water boards, State Air Resources Board and EPA should

design a monitoring program that is capable of confirming oil refinery dioxins release

rates within 25% of the true rates, and implement this program so that dioxins reports

to the Toxics Release Inventory, which are required for the first time in 2001, will pro-

vide useful information. This program should include:

Identification, direct measurement, and ongoing monitoring of all sources of dioxins .

Monitoring of all dioxins (CDD/Fs and PCBs) and all release pathways from refineries .

Adequate sensitivity (design for quantitation) and greatly increased sample frequency .

Comprehensive measurement of dioxins release during and after upsets and fires .

4. To improve health protection against refinery dioxin pollution, the public needs to take

action. Community members joining with CBE can demand actions by our public offi-

cials and engage refinery managers who still refuse to cooperate in open investigations

of ways to eliminate dioxins at the source. Elected officials should organize and con-

duct hearings to investigate the ongoing problems in public health officials' responses to

oil refinery dioxin pollution, and hold the Water Board, Air District and EPA account-

able for actions to prevent this pollution and protect our health.

11

Part 1. Multiple sources of preventable dioxin pollution in oil refineries .

From years of direct measurements in laboratories, industrial processes and the environment it is

now known that the primary cause of dioxins pollution involves the introduction of chlorine into

various high-energy (usually high-heat) industrial processes. Sources of chlorine in the high-

heat processes of petroleum refineries cause some of this dioxin pollution.

U.S. refineries process approximately 5.5 billion barrels- 700 million metric tons assuming 45

API crude - of crude petroleum annually. This production rate far exceeds that of any other

industry believed to cause major dioxins releases.

2

-

17

.18 One of the three largest oil refining cen-

ters on the U.S. west coast surrounds San Francisco Bay and refines nearly 300 million barrels

per year.I7.I9 Major refineries are run by San Francisco-based Chevron Corp. in the community

of Richmond, Tosco (in Avon and Rodeo), Equilon (Martinez), and Valero (Benicia). A sixth

plant run by Evergreen Oil, Inc. in Newark (near Hayward) is classified as a "lube" refinery.

Generally, refiners remove unwanted chemicals, distill the crude, "crack" the distillate into

smaller fuel-size molecules, "reform" the shapes of these molecules to boost octane, and sell the

fuels, lubricants, and side products such as petroleum coke that result. These steps are done by

applying massive amounts of energy in dozens of different hot process units (distillation towers.

catalytic crackers, reformers, etc.). Part of the output stream from many process units is fed

back into other processes. This is why refineries look like a maze of interconnected pipes- and

why putting chlorine into one refining process can lead to dioxins formation in other processes.

CONFIRMED SOURCES:

Catalytic reforming boosts fuel octane by reshaping

petrochemical molecules. Six reformers process

170,000 barrels/day at the Chevron, Tosco, Equilon

(formerly Shell) and Valero (formerly Exxon) plants.

The reforming reaction is aided by a catalyst that con-

tains platinum and/or rhenium. The catalyst becomes

less effective with carbon deposits and wear. The

refiner cleans the catalyst in a "regeneration" process

that involves incinerating the carbon deposits.

The chlorine source for dioxins formation in this

process is the addition of chlorine to aid during clean-

ing and reactivation of the catalyst. When dioxins

were discovered in refinery sludge in 1988, this was

the first refinery process tested for dioxins.?

Tests of waste water directly exiting reformer catalyst

regenerators find high concentrations of 17 CDD/Fs

from reformers at the Chevron, Tosco (Avon and

Rodeo) and Valero refineries.

2

0.2I Three days of stack

tests at the Tosco Avon No.3 Reformer measured

high levels of CDD/Fs and high levels of newly-

formed PCBs.

22

(See tables 1 and 2.)

12

I. Reformer stack tests (Tosco Avon Refinery)

picogrnmslharrcl reformed Day I Day 2 Dayj

2,3,7, K-TCDD 7 12 22

1,2,3,7.K-PcCDD <)(, 202 -'j2

1.2.3.4,7 .K-HxCDD <JS 245 5+1

1.2,3.6,7.8-HxCDD 251 521 1377

1.2.3.7,K,<J-HxCDD 161 322 9.!X

1.2.3.4.6.7.K-HpCDD 702 1563 5391

OCDD 471 974 2895

2.3,7,K-TCDF 266 -143 ~ 7

1.2.3.7.K-PcCDF 525 1010 2822

2,3.4.7 ,8-PcCDF 62 1 12Stl .t0 54

1.2.3,4,7,K-HxCDF IIX)I 2573 8 ~ 1

1.2.3,6.7.8-HxCDF 76 1 1 ~ 3 1 63K7

2.3,4,6,7.K-HxCDF 616 136ll ssa9

1.2,3,7.8.9-HxCDF IlK 245 738

1.1.3.4.6,7,8-HpCDF !W4 ~ 0 1 8 29.l.IS

1.1.3.4,7,8,<J-HpCOF 342 M3 !SOS

OCDF 929 2229 6387

Mnnochloro-PCBs 2636 2867 4163

Dichlorn-PCBs (m5 675(1 7837

Trichlorn-PCBs 120.5(1 139.52 17 123

Tetra-CBs 11 .552 15130 !!514

Pc-CBs IIS.S2 17123 2.10)\l

Hx-CBs 101'!3 1513() 1'.157(1

Hp-CBs 16(,7() :6274 .l81i86

Ocla-CBs li\131 115.52 21563

Nonachlom-CBs 1.572 2K61 SSS9

Dccachloro-CBs 2777 S\IS IS IS

NOTES: Data from reference 22.

The mechanism that creates dioxins starts when chlo-

rine is added. Some of the chlorine reacts with the

hot carbon atoms and compounds in the reaction

chamber and its exhaust piping to form dioxins.

Dioxin formation is catalyzed by combustion-induced

changes in oxygen chemistry, by metals, and by the

ash/soot/carbon buildup (which on a micro-scale has

a high surface area that aids the reactions). Carbon

skeletons of the CDD, CDF and PCB molecules form

by slightly differing trace chemistries, and chlorine

atoms attach to these molecules. These side-reactions

take seconds in the primary reactor and the down-

stream sections of the process_2,7,23-30

In other words, the chemistry that governs the kinds

and amounts of dioxins formed is dynamic and com-

plex, but it is clear that because chlorine is put into

this process that burns waste carbon off metal cata-

lyst, dioxins form in the process and emit into the

environment. These chlorinated dioxins cannot form,

however, if the chlorine source to these reactions is

blocked.

Immediate next steps toward zero dioxin: Dioxins

have no useful purpose in refining. Since a primary

chlorine source causing dioxins creation in reformers

is already identified, an immediate next step

involves blocking the chlorine source to the chemi-

cal side-reaction that creates dioxins. Options to

protect reforming catalyst, or repair and clean it

without putting chlorine into an incineration process,

can be tested for their effectiveness starting today.

Steps toward zero dioxin in refinery reformers are

summarized in Figure 1.

2. Reformer water tests (3 Bay Area refineries)

picogramslliler

Chevron Tosco Tosco

Richmond A\on Rodeo

2,3,7,8-TCDD 170 BD 22

1,2,3,7,8-PeCDD 730 BD 85

1.2,3,4,7,8-HxCDD 740 8700 90

1,1,3,6,7,8-HxCDD 910 15700 90

I .2.3.7 ,8,9-HxCDD 440 16900 190

1,2,3,4,6,7 ,8-HpCOD 2640 55900 890

OCDD 11 70 63400 1400

2,3,7,8-TCDF 3350 5300 150

1,2,3.7,8-PeCDF 9150 -14000 120

2,3,4,7,8-PeCDF 4600 111 500 180

1,2,3,4,7,8-HxCDF 14700 128500 340

I ,2,3,6, 7 .8-HxCDF 5800 131000 240

2,3,4,6, 7 ,8-HxCDF 1320 2.5000 190

1,2,3,7,8,9-HxCDF 1700 177000 230

1,2,3,4,6,7,8-HpCDF 17100 599000 970

1.2,3.4.7,8,9-HpCDF 7500 566000 520

OCDF 10250 279500 1900

NOTES: Average BD=below detecuon

limit. Data from reference 20.

I. Reforming Unit Pollution Prevention.

Spent Reformer Catalyst

_t_

Remove carbon buildup &

regenerate metal catalyst

without forming dioxin

"'

'

Process gases for recovery I

disposal without liquid (dry

"

process)

NOTES: Figure from reference 2.

#1: How to regener-

ate catalyst without

chlorinated solvents?

#2: How to confirm

dioxin elimination &

safety of new option?

Catalytic cracking breaks large petroleum molecules into smaller, fuel-sized molecules in

order to make more gasoline, diesel and jet fuel out of each barrel of cnide oil. Including cat-

alytic hydrocracking, at least seven crackers process more than 500,000 barrels/day at the

Chevron, Tosco, Equilon, and Valero refineries.l7-J9 This process uses a silica-alumina catalyst

that is cleaned of carbon deposits by incineration in cracking catalyst regenerators.

In the first dioxins tests of this process ever reported, dioxins were detected in three tests of

stack exhaust from the Chevron Richmond Refinery catalyst regenerator.

2

3

2

See Table 3.

Measurements confirm chlorine in partially refined materials fed into cracking processes.

2

31

Incinerating cracking catalyst with this chlorine creates dioxins in side-reactions that are cat-

alyzed by high surface area and metals of the silica-alumina catalyst, the carbon deposited on

(and burned from) the catalyst and the process unit interior structures_2.23-30.3

3

13

Immediate next steps toward zero dioxin: The dioxin-

forming reactions in this process can be blocked by get-

ting the chlorine out of the cracker feed stream. Chlorine

can be removed from oil before processing (see oil-fired

heaters below). Since methods to measure chlorine in oil

are readily available,

31

testing in refineries can trace

cracker chlorine inputs to their sources and prevent chlo-

rine inputs to all refining processes. (See Figure 2.)

2. Cracking Unit Pollution Prevention.

Spent Crucker C;ualyst

'

Remove carbon buildup

from silica-alumina catalyst

without forming dioxin

1'-

y

Block the chlorine source to

the dioxin-forming reaction

in the process

NOTES: Figure from reference 2.

#1: Chlorine soun:es

can be traced by in-

plant testing.

#2: Chlorine can be

removed from inputs,

before dioxins fonn.

Oil- and waste-fired process heaters and boilers

provide some of the enormous amount of heat used in oil

refining, and can also reduce the amount of "leftover"

material that refiners must pay to dispose of as liquid or

solid wastes. Generally, all refineries bum some of the

fuels they are refining, ranging from No. 2 fuel oil

(diesel) to tank-bottom sludge. A cumulative total of

more than 2.6 million barrels/day of crude and partially

refined oil is put through heated distillation, cracking,

coking, reforming, hydrotreating and other processes in

the Bay Area.

17

A conservative estimate (that only 1.5-

6% of this cumulative throughput is burned with natural

gas and other energy to heat the rest) puts oil burning by

Bay Area refineries at 40,000-160,000 barrels/day.

The chlorine source for dioxins formation in this process

is the same as that for catalytic cracking, except that

some refinery residuals contain relatively high chlorine

content due to process chemistry or contamination.31,35

Oil-fired boilers and heaters are known dioxins sources

from testing elsewhere.

2

Table 4 shows results from

three tests that found dioxins and PCBs in stack exhaust

from an oil-fired process heater at the Evergreen Oil. Inc.

used oil refinery in Newark.

3

6 An old stack test at the

Shell (Martinez) CO boilers failed to detect dioxins

(though the Air District presumed it is a source).3

4

14

3 Cracker stack tests (Chevron Refinery)

picogrnms per second Test I Test 2 Tcst3

2.3,7,8-TCOO 80!110) 80( 130) 80(96)

I ,2,3,7.8-0eCDO 80{110) 80(801 80(42)

1,2.3.4.7,8-HxCOO 8[)(130) 80(95) 80(81)

1,2,3 ,6,7 ,8-HxCOD 80(120) 80(98) 80(76)

1.2.3.7.8,9-HxCDD 80(110) 80<88) 80(72)

1.2.3,4,6,7,8-HpCDD 190 80(57) 80(140)

OCOD 2200 530 1300

2,3,7,8-TCOF 80(12) 80(82) 80(86)

1.2.3,7,8-PeCDF 8[)(85) 80(61) 80(68)

2.3,4,7,8-PeCDF 80(75) 80(55) 80(64)

I ,2,3,4,7 ,8-HxCDF 80(89) 80(39) 80(54)

1.2.3,6,7,8-HxCOF 80(75) 80(33) 80(42)

2.3.4.6.7.8-HxCOF 80(92) 80(41) 80(51)

1.2.3,7.8,9-HxCOF 80(100) 8'0 (45) 80(60)

1.2.3,4,6,7,8-HpCOF 80(75) 80(45) 80(51)

1.2.3.4,7,8,9-HpCOF 80(75) 80(65) 80(81)

OCOF 430 80(29) 80(2HO}

:-IOTES: 80=below detectton hnut (detecuon hnut). PC8s

results (80) not shown. Data from reference 32.

4. Oil-fired heater stack tests (Evergreen Oil)

picograms/test Test I Test2 Test3

2.3,7.8-TCOO 14.0 11.0 13.0

1.2.3,7.8-PeCOO 80(3.6) 3.7 80(3.6)

1,2.3.4.7,8-HxCOO 12.0 12.0 12.0

1.2.3.6,7.8-HxCOO B0(2.S) 3.1 80(2.9)

1.2.3.7.8.9-HxCOO 80(7. 1) 4.1 8'0(3.6)

1.2.3,4,6. 7 .8-HpCOO 7. 1 13.0 6.8

OCOO 13.0 20.0 14.0

2.3,7,8-TCOF 40.0 24.0 29.0

1,2.3,7,8-PeCOF 80(1 7) 60( 15) 8 0 (1 4)

2.3,4.7,8-PeCDF 9.6 11.0 9.1

1.2,3.4, 7.8-HxCOF 8.6 12.0 8.4

1,2,3,6, 7,8-HxCDF 4.8 6.2 4.4

2.3.4.6.7,8-HxCOF 80(4.1) 4.6 80{4.21

1,2,3.7.8,9-HxCOF 16.0 14.0 13.0

1,2,3.4.6.7 ,8-HpCDF 80(61 80(11) 80(7.11

1.2.3.4. 7,8,9-HpCOF BO(S.Ol 80(5.3) 80(5.0)

OCOF 7.8 8.1 8.4

Monoch1oro-PC8s (2. 1000) (9000) (31000)

Oichloro-PCBs (35000) (20000) (24000)

Trichloro-PCBs (460001 (23000) l50000)

Tetra-CBs (150001 030001 ( Hi0001

Pe-CBs (17000) (380001 (180001

Hx-CBs ( 190001 150000 (200001

HJ>-CBs ( 190001 110000 (20000)

Octa-CBs (48000) (260001 (24000)

Nonachlor<rCBs (3 1000) (270001 !31000)

Decach1or<rCBs 4 ~ 0 0 0 ) (370001 (43000)

NOTES: BD=below sample-specific detection limit

(detection limit for test). Data from reference 36.

The mechanism of dioxin formation in oil-fired boilers and process heaters is generally similar

to that in other combustion or incineration sources, as described above.

2

23

-

30

However, the rela-

tive amounts of CDDs, CDFs and PCBs produced may differ from these other sources due to

differences in the material burned, the substances that catalyze dioxins formation, and combus-

tion conditions. The mix of dioxins produced by oil/waste-fired boilers tested elsewhere differs

from the mix of dioxins produced by incinerators.

4

Immediate next steps toward zero dioxin:

Dioxins formation in this process can be

blocked by getting the chlorine out of the mate-

rial burned. In fact, the steps to virtually elimi-

nate dioxins from this process source are start-

ing now at one Bay Area refinery. In a March,

2000 settlement agreement with CBE, the

Evergreen Oil Inc. refinery committed to

remove at least 99% of chlorine from the feed

burned in its process heater within two years.

Evergreen will measure the effect of its process

change and the data will be independently veri-

fiable. In the event that the process change is

not effective, Evergreen will use a different

energy source for heat.37 See Figure 3.

3. Oil-fired Heater/boiler Pollution Prevention.

Material burned to heat process

t

Block the chlorine source to

the dioxin-forming reaction

in the process

..

Verify the effectiveness of

process/production system

change with direct testing

f'.

#1: Get chlorine out

of oil through pre-

vention or removal.

#2: Use other zero-

chlorine energy

source to heat the

process if necessary.

Contamination of diesel fuel in refineries is a contributing source to dioxins release from

motor vehicles and a pathway by which dioxins created in refineries enter the environment. On

average, from December 1999 through June 2000 California refineries processed 1,680,000 bar-

rels/day of crude and, in addition to other products, produced 290,000 bbl/day of distillates, of

which 170,000 bbl/day was diesel for on-road use. IS Bay Area refineries process an average of

779,400 bbl/day of crude.I7,19 Thus, based on proportionate production Bay Area refineries pro-

duce an estimated 80,000 bbl/day of on-road diesel and 136,000 bbl/day of total distillates.

Tests of diesel taken directly from southern California refineries found CDD/F TEQ in on-road

and off-road diesel at concentrations ranging from 0.07 to 300 picograms per liter (detection

limit problems contribute to the range).38 These diesel fuels were sampled before use in any

vehicle: thus; dioxins measured in the fuel were not created by combustion in vehicles. Instead,

diesel and the partially refined oil it is made from accumulate some of the dioxins formed in

refining processes that produce it. Indeed, this accumulation is expected, because dioxins have

high affinity for lipids (fats and oils) and extremely low volatility and solubility in water.

The known sources of chlorine for the dioxins found in diesel are described for reforming,

cracking and oil-fired processes above. In addition, diesel as it leaves the refinery contains

chlorine and other dioxin precursors from refinery processes.31.3

8

Dioxin releases are measured

from diesel vehicles.2.3

4

.38,39.40.41 Dioxins formation in the vehicle is widely suspected, but it is

also possible that dioxins "present in the fuel may be detected in the exhaust because some of

the fuel is not burned during combustion."38 In either case, refinery sources of dioxins, chlo-

rine and dioxins precursors are preventable sources of dioxins released from vehicle tailpipes.

Contamination of motor oil in refineries is shown by a test of new oil that found one dioxin

compound at 2000 picograms per liter, 38 and occurs by similar mechanisms as those for diesel.

15

SUSPECTED SOURCES:

Flares, coking, desalting, distillation and other processes that were not tested for dioxins

run a total throughput of 1.9 million barrels of crude and partially refined petroleum in the Bay

Area daily. These processes appear to create conditions that favor dioxin formation: chlorine

inputs (in partially refined materials as shown for cracking and oil-fired processes above); car-

bon precursors in the feed; soot or ash that catalyzes formation; and combustion or high heat.

Tests that detected dibenzofuran as a combustion product of oil-field flaring strongly suggest

that CDFs can be created from refinery flares.

4

2 Findings that reformer materials containing

chlorine may enter cokers,

4

and that dioxins are present in a Bay Area refinery's coke pile

4

3 fur-

ther suggest that coking may form and emit dioxins. The desalting process uses technology sim-

ilar to that used in chlorine production from brine, which is a known dioxins source.

2

Finally,

distillation subjects large quantities of material to temperatures that favor dioxins formation:

incomplete desalting might introduce chlorine to crude distillation; and other distillation

processes are susceptible to the same chlorine sources that affect the cracking and oil-fired

process sources discussed above.

Catalytic cracking catalyst regeneration was an undiscovered dioxins source until this source

was tested for the first time - as recently as 1997 - at the Chevron Richmond Refinery. Taken

together, the evidence strongly suggests that additional dioxins sources may exist in refineries.

This likelihood can be confirmed or ruled out only by further investigation.

Contamination of petroleum coke and other products with dioxins has not been confirmed

by testing of these refined materials, yet this contamination is likely. Dioxins are found in the

refined products that have been tested,38 and in runoff from a refinery coke pile.

43

The combus-

tion of petroleum coke after it leaves the refinery (in Bay Area power plants, metal foundries

and smelters, and a cement kiln) is associated with dioxins release.

2

3

4

The extremely low

volatility and water solubility of dioxins can result in their accumulation in coke and ash just as

they accumulate in diesel and motor oil. Ash from other combustion sources is known to con-

tain dioxins,

44

and refinery furnace ash may be used in clinker by cement kilns - which release

dioxins. Dioxins are probably released from refineries in petroleum coke and furnace ash .

. Process upsets and uncontrolled fires that result from such upsets have obvious potential to

generate dioxins from the chlorine and petrochemicals that are present with metals and other

dioxin formation catalysts throughout refineries. Dioxins formation is confirmed in combustion

of oil (see above), and during fires in buildings.2.4.3

4

At least 19 major incidents involving

uncontrolled fires occurred in Contra Costa County oil refineries between March 1989 and April

1997.

45

.46 In 1999 major fires killed workers at the Avon plant and damaged the Chevron refin-

ery's cracker. Yet despite the clear potential for dioxins creation in some of these major events,

no properly designed testing of Bay Area refinery fires for dioxins has been conducted.

Contaminated solid waste disposal almost certainly transports dioxins from refineries, how-

ever, EPA has excluded disposal of dioxins in landfills from its estimate of release to the envi-

ronment.4 EPA's approach is open to criticism because landfills sometimes leak, and as EPA

admits, dioxins emit from landfills to the air.

4

.34 While supporting this valid criticism, this

analysis uses a release estimate that excludes landfill releases in order to avoid the potential for

inaccuracies as communities compare the results reported here with EPA's estimates.

16

Part 2. Measurement of the dioxins release rate from refinery sources.

RELEASE MEASUREMENT DATA QUALITY:

Error and bias related to choice of analytical

methods: The quality of dioxins data is often limited

by two analytical choices: one about the volume of

sample collected; and one about the dioxins to analyze.

Some effects of small sample volume are shown in

Table 5. For example, Bay Area refinery effluent tests

that collected one liter samples failed to detect TCDD

at levels below about one picogram per liter, but tests

elsewhere that collected more than 1,000 liters of water

per sample measured TCDD at concentrations more

than a thousand times smaller. The smaller sample

volumes collected in these refinery tests did not allow

for concentrating enough dioxins for the lab instrument

to detect and quantify.51,52 In air samples, tests at a

Bay Area refinery failed to detect TCDD below about

one pg per cubic meter of emission, but tests that col-

lected more air detected 50 times smaller levels.

Figure 4 shows the potential for error caused by the

choice of small sample volume. In a typical test of a

refinery's final effluent discharge to San Francisco

Bay, the amount of CDD/Fs toxicity that could be pre-

sent at the detection limits of the analysis is 50 times

the amount detected by this analysis. In stack tests of

a Bay Area refinery cracker, the amount of TEQ that

could be present at the detection limits of the analysis

is 370 times the amount detected. In diesel as it leaves

refineries (before use as a fuel), the amount of TEQ

that could be present at the detection limits of the

analysis is 900 times the amount detected.

When a chemical is measured below the detection limit

of the sample-specific analysis, this test really only

measured this chemical at a concentration between

zero and the sample-specific detection limit. The exact

level is not measured. Assuming the true level is zero

could underestimate this release, but assuming it equals

the detection limit could overestimate this release.

Unless other data suggest that releases approximate

half the detection limit, this analysis reports the

amounts of undetected dioxins in the test as the labora-

tory reports them: at a level between zero and the sam-

ple-specific detection limit of the analysis.

17

5. Effect of sample volume collected on sensitivity

of the analysis: examples for 2,3,7,8-TCDD.

Sample Amount Detection

volume detected limit

WATER TESTS Li ters pg!L pg!L

Tosco effluent l - 1.3

Baltic Sea 1.500-2.200 0.00025 o.ooos

AIR TESTS Cubic m t ~ r s pgfm3 pgtm3

Chevron stack 112-162 - 1.16

So. Cal. ambient 350-540 0.021 0.022

NOTES: average of sample-specific results; average

detection limits exceed amounts detected due to higher

detection limits for some samples. m3=cubic meter.

pg=picogram. L=liter. Data from references 32.48.49.50

4. Effect of sample v9lume collected on the

possible dioxins release that is not measured:

examples from measurements of refineries.

TEQ

detected

0.13 pg!L

6.55 pg/L

Possible

TEQ

released

Typical refinery effluent test: 88% of CDD/Fs

below detection due to small sample volume.

TEQ

detected

0.78 pg/second

289 pg/second

Possible

TEQ

released

Refinery cracker stack tests: 90% of CDD/Fs

below detection due to small sample volume.

TEQ

detected

0.07 pg!L

65.6 pg/L

Possible

TEQ

released

Test of Cal. reformulated diesel directly from

refineries: 94% of CDD/Fs below detection.

NOTES: Data from references 32.38.48.

A second problem stems from the choice to measure PCBs homologue groups (PCBs with the

same number of chlorine atoms), but not to measure individual dioxin-like PCBs. Refmeries

create relatively large amounts of newly-formed PCBs, and some of these are dioxin-like PCBs.

Assuming none of these PCBs are dioxin-like will underestimate TEQ

0

FP released, and assum-

ing all these PCBs are dioxin-like will overestimate releases. A better measurement is needed.

Laboratory and field studies confirm the formation

and release of dioxin-like PCBs from incinerators,

cement kilns, and other sources.2,44,54,56,57

Refinery sources create similar conditions for for-

mation of dioxin-like PCBs as incinerators and

cement kilns_7.22-

2

5 This is reflected in the similar

mix of specific CDD/Fs that is measured in these

source types. Figure 5 shows that in all three

sources: HpCDD and especially OCDD dominate

among CDDs; 1,2,3,4,6,7,8-HpCDF dominates

among HpCDFs; 1,2,3,7,8,9-HxCDF is very low;

other HxCDFs exceed HxCDDs; PeCDFs exceed

PeCDD; and TCDF exceeds TCDD.

In addition to these clear similarities, however, the

refinery source produces more PeCDFs, HxCDFs,

and HpCDFs than the other sources. Conditions

favoring formation of CDFs also favor formation of

PCBs.23-25 This suggests that refineries may create

more dioxin-like PCBs than these other sources.

In Figure 6, total PCB concentrations at a Bay Area

refinery and a municipal waste incinerator located

elsewhere are compared. This homologue compari-

son shows a clear increase in the amount of PCBs

relative to CDD/Fs from the refinery. PeCBs

include the most toxic dioxin-like PCB and make up

13% of the total CDD/Fs and PCBs from the refin-

ery source but only 3% of this total from the incin-

erator. HxCBs, which include the second most toxic

dioxin-like PCB, make up 11% of the total from the

refinery source versus 3% from the incinerator.

Existing measurements show dioxin-like PCBs

range from 5-25% of total TEQ in municipal incin-

erators, and 60% of the total TEQ in cement kiln

emissions.

2

44,5

4

,56,57 Greater PCBs and CDFs mea-

sured at the refinery source suggest PCBs are more

of the total TEQ from refineries than incinerators.

This analysis reports the dioxin-like portion of PCBs

releases from refineries as I 0-60% of total TEQ.

18

5. Congener profiles: refineries and other sources

Individual CDD or CDF/total CDD+CDF

O.ll2 0.04 0.06 0.08 0. 1 0.12

2.3.7.8-TCDD

Refinery reformers

1.2.3.7.8-PeCDD

0 Municipal incinerators

1.2.3.4.7 .8-HxCDD

1.2.3.6.7.8-HxCDD

D Cement kilns

1.2.3.7 .8.9-HxCDD

1.2.3.4.7.8.9-HpCDF

:-;oTES: Data from references and 55.

6. Total PCBs profiles: refinery and incinerator

PCB homologue/total CDD+CDF+PCB'

MonoCBs

DiCBs

TriCBs

TCBs

PeCBsb

HxCBsc

HpCBs

OCBs

Nona CBs

DecaCB

0 0.05 0.1 0.15 0.2 0.25

Refi nery

reformer

-------'

Municipal

0

incinerator

----'

-'

.....

Each PCBs group (mono-chlorinated.

etc.) is divided by the sum of total COOs, CDFs.

:llld PCBs. CDD/F portion of profile not shown.

blncludes PCB-126. clncludes PCB-169.

Dam from references 22 and 54.

Error and bias related to test frequency and disclosure: On average, the Bay Area

refinery source releases that are tested at all are tested only a small fraction (one-ten thousandth)

of the time that the releases are occurring. See Table 6. This is true despite relatively better

dioxins testing of Bay Area refinery releases than those elsewhere.

6. Timing of refinery dioxins releases and release testing in the Bay Area, June 1990-June 2000.

Tested Cumulative Testsb Test Cumulative Portion of

sources release-days

0

typeC test-days time tested

Effluent 6 21900.0 :!00 grab 0. 139 0.000006

Storm runoff 5 912.5 31 mix 0.354 0.000388

Air emission 4 14600.0 12 composite 4.000 0.000274

Refined products - 0

-

Totals 37412.5 4.493 0.000120

NOTES: acumulative days of release per source pathway over 10 years. Rain runoff set at 5% per year.

b Actual test number may be lower. Includes some water tests of combined refinery and non-refinery releases.58

CGrab samples set at I minute duration; composite samples set at 8 hours: one runoff sample was a composite.

Data from references 17,19,22,32,34,36,48,57,58.

A large variability exists in the concentration of dioxins in emissions. (See Table 7 .) Dioxins

release increased by 6.8 times in three consecutive days of testing at one Bay Area reformer.

22

At the Chevron cracker, stack emissions detected on all three test days changed by four times.

32

These tests on a few days show that releases at single sources change dramatically from day to

day, but they do not capture the full range of refinery release amounts.

On a burn rate basis, releases vary by 20,000 times in two sets of tests at the Shell and

Evergreen boiler/heater stacks.2,32,36,59 Emissions varied by 3,000 times between two sets of

tests done on two reformer stacks at refineries in Avon and Bakersfield_4,22,55 Tests of other

sources confirm similar hundred-fold to thousand-fold changes in dioxins emission rates.

2

4-Z9,

44

7. Variability in rate of dioxins release at refinery sources, and similar sources

Change in

Measurements compared

dioxins release

6.8 times

Stack tests of a Bay Area reformer on three consecutive days22

4 times Detected emission from three days at one refinery cracker stack32

300 times Average reformer process water at three refineries20

20,000 times Emission/kg burned at two Bay Area refinery boiler/heaters_234,36,59

3,000 times Emissionlbbl from refinery reformers at Avon and Bakersfield4,22.5S

100-2,700 times

Full scale tests of similar (non-refinery) processes during different

operating conditions. grouped by process type27.29,44

100-2,000 times

Lab & pilot tests of a single boiler or incinerator that measured changes

in chlorine, catalyst, heat distribution, & upsets (sooting)24-26,28

Further, the average that is directly measured may not represent the true long-term release, espe-

cially for stack tests. This is because existing tests taken during only a small fraction of the time

that releases occur may not measure a representative sample of overall releases. Lab- and pilot-

scale experiments show that variability in dioxins release (a hundred-fold or greater change, like

those shown in Table 7) can be caused by changes in process or chlorine input, catalyst activity,

19

heat distribution in the process, and com-

bustion efficiency.23-29 Even a relatively

minor 'upset' in combustion efficiency

increased dioxins generation greatly for

hundreds of hours afterward, because car-

bon buildup (sooting) continued to cat-

alyze dioxins formation.26

These conditions exist in refineries, as

shown by the routine regeneration of

reformer and cracking catalyst needed to

clean carbon deposits from process materi-

als. In fact, frequent upsets in refineries

suggest that periods when these conditions

do not exist may be the exception rather

than the rule.

Table 8 lists 41 incidents that were classi-

fied as "major" by Contra Costa County

officials at five refineries operating in the

County from March 1989 to April 1997 -

nearly one major spill, fire or explosion

per refinery each year. In one case where

independent analysis was performed (the

fatal January 21, 1997 cracking unit fire at

the Tosco Avon plant), the process was

operating inefficiently for much of the

year before the major incident.60.61

Closer inspection of Table 8 reveals that

for each plant, major upsets tend to be

grouped around the same time. There were

other upsets that were not classified as

8. "Major incidents" in Contra Costa refineries 1989-97.

Plant County-classified "major" incident

3/25/89 Tosco Fatal lube oil sumo exolosion

4/10/89 Chevr lsomax Uni t explosion and fire

9/5/89 Shell Hvdrotreater explosions and fire

9/9/89 Paciti Pioe nioole break. soilJ and fire

2/28/90 Shell Tank liner fire

1/4/91 Shell LDU Lube Crude heater spill and fare

4129/91 Tosco Relief valve hvdroeen sulfide soill to air

10n9/91 Chevr Catalytic Cracking Unit fire

12/5/91 Chevr Cracking Unit catalyst spill to air

3/31/92 Pacifi Heat exchanger tube rupture and fire

5/29/92 Pacifi Flare overload spill to air and homes

6/23/92 Chevr Cracker pump failure. smoke release

8112/92 Tosco Refinery fire trig,eers explosion

9/20/92 Tosco Power failure and flarine soark fire

12/11/92 Tosco Major flare odor release to air

3n/93 Tosco Major butane/hydrocarbons spill to air

4/1/93 Shell Sludge storaee tank explosion

6/18/93 Tosco Hydrocarbon/hydroeen sulfide soillto air

10/5/93 Shell Acid tank exQiosion and fireball

10n/93 Tosco Oil spill to Hastings Slough

214/94 Pacifi Fire in crude oil tank seals

2/10/94 Chevr Sulfur Recovery Unit spill to air

3/30/94 Chevr Instrument & flare failure spill to air

8/22194 Unoc 16-dav. I 00-ton catacarb so ill to air

9115/94 Unoc Compressor failure H2S spill to air

619195 Tosco Heat exchaneer fire

6116/95 Unoc Tank fire

9/25/95 Tosco Boiler malfunction/ bvpass spill to air

9/27/95 Pacifi Naotha and sulfur chemicals soill to air

2/1196 Shell Hydrogen Unit explosion

411/96 Shell Hydrot:reater explosion and fi re

5117/96 Unoc Coker fire

8/1/96 Pacifi Heavy vacuum eas spill to air

8/10/96 Chevr Power outaee causes flare smoke

8/16/96 Unoc Compressor malfunction. H2S to air

9/21196 Unoc Malfunction spills H2S to a1r

9122196 Unoc Tank leak releases sulfuric acid

1/21/97 Tosco Fatal hydrocracker explosion and fire

2/17/97 Unoc Odor release traced to refinery

4/13/97 Chevr Hydrocarbon and sour eas leak

4/16/97 Tosco Hydrogen sulfide and S02 spill to air

"major incidents." Flaring- a sort of NOTES: Data from reference 45.

"safety valve" for the buildup of explosive

gases in refineries6

2

- is an indirect mea-

surement of such process problems.

Data from special study of Bay Area refin- 9. Flaring by four Bay Area refineries

ery flares are summarized in Table 9.

Flaring was reported in all 18 months

studied, and the largest refineries flared

virtually all the time. Major refinery

processes could be involved in flaring for

hours every month (as a per-process grand

average), based on these data.62

Upsets that could increase dioxins may be

occurring on a monthly basis in refineries.

Flare-hours Percent Hours/pro-

per month a of time cesslmonthb

Chevron

338 46% 8

Shell (Martinez)c

989 100% 25

Tosco (A von)d

730 100% 18

Unocal (Rodeo)e

89 13% 2

Totals 2146 100% 13

Notes: a Reported for March 1988 through December 198961

hAssumes 40 major process units/refinery. CNow Sheli/Equilon. dsale to

Ultramar announced in June, 2000. eNow Tosco. Data from reference 62.

20

The effect of such minor upsets was reported this year from a controlled experiment that mea-

sured changes in total CDD/F formation and emission from an industrial boiler.2

6

Relatively

poor combustion efficiency was created by increasing the feed rate and slightly misaligning a

burner nozzle for about 50 hours. This formed carbon deposits contaminated with chlorine and

dioxins precursors and catalysts, that in tum created more dioxins with continued source opera-

tion long after the upset.

2

6 As shown in Figure 7 stack release increased from 4 to 1,953 pglm

3

100 hours after the beginning of this upset, increased further (based on deposit testing) until

about 250 hours after the beginning of the upset, and remained elevated for approximately 300

hours after the upset ended. (Due to sampling and analysis considerations noted in the figure,

the stack tests provide the best measurement of the extent of dioxins increase while the tests of

carbon deposits in the unit provide the best measurement of its duration.)

7. Timing and extent of dioxins source generation after upset in combustion efficiency.

2000

r::: 1800