Escolar Documentos

Profissional Documentos

Cultura Documentos

Activity-Based Management in A Small Company SD

Enviado por

veda20Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Activity-Based Management in A Small Company SD

Enviado por

veda20Direitos autorais:

Formatos disponíveis

PRODUCTION PLANNING & CONTROL, 2000, VOL. 11, NO.

4, 391 399

Activity-based management in a small company: a case study

A. GUNASEKARAN, R. MCNEIL and D. SINGH

Keywords

activity-based management, SMEs, case study

Abstract. This paper deals with the application of activitybased management (ABM) in a small company. The project took place in G. E. Mustill, a company that produces machines for the photo framing industry. This project aims to develop an ABM system for the company which leads to appropriate improvement actions based on a make or buy decision about di erent parts of the machine, `four-head foiler. Firstly, a theoretical framework for the design of an ABM system is developed. Then, secondly it is used to improve the business performance of four-head foiler manufacturing. The activities required to manufacture this machine are identi ed and then quanti ed

by their consumption of resources. The factors causing or driving the cost (cost driver) of an activity in question have been identi ed and used to identify the value-adding and non-valueadding activities. Also, some suggestions are o ered to improve the performance of the company using the ABM system.

1. Introduction The analysis and cost of activities provide nancial and non- nancial information which is the basis for activitybased management (ABM) . ABM makes this cost and operational information useful by providing a value

A uthors: A. Gunasekaran and R. McNeil, Department of Management, University of Massachusetts, North Dartmouth, MA 02747-2300, USA, e-mail: agunasekaran@ umassd.edu, and D. Singh, Department of Manufacturing and Engineering Systems, Brunel University, Uxbridge, Middlesex UB8 3PH, UK. A. GUNASEKA RA N is an Associate Professor of Operations Management in the Department of Management at the University of Massachusetts, Dartmouth, MA 02747, USA. He has a PhD in Industrial Engineering and Operations Research from the Indian Institute of Technology, Bombay (India). Dr Gunasekaran has held academic positions at Brunel University ( UK) , Monash University ( Australia) , the University of Vaasa (Finland) , the University of Madras ( India) and the University of Toronto, Laval University and Concordia University (Canada) . He has over 100 articles published in journals, e.g. International J ournal of Production Research, International J ournal of systems Science , International J ournal of Operations and Production M anagement , Computers in Industrial Engineering : A n International J ournal , European J ournal of Operational Research , Logistics Information M anagement , T QM M agazine , M anagement Decision , M anagerial A uditing J ournal , International J ournal of Advanced M anufacturing T echnolog y , International J ournal of Production Economics , J ournal of Operational Research Society , Enterprise Innovation and Change , International J ournal of T echnology M anagement , T echnovation, Computers in Industry: An International J ournal , T otal Quality M anagement , International J ournal of Quality & Reliability M anagement , International J ournal of Computer-Integrated M anufacturing . He has presented over 50 papers in conferences and given a number of invited talks in more than 20 countries. He is on the Editorial Board of over 12 international journals that include International J ournal of Production Planning & Control , International J ournal of Systems Science , Computers in Industry: A n International J ournal , CERA , T echnovation, J ournal of Product and Process D evelopment , Log istics Inf ormation M anagement , Business Process M anagement J ournal , J ournal of Operations M anagement , Supply Chain M anagement: A n International J ournal , International J ournal of Quality & Reliability M anagement. He has edited special issues for a number of highly reputed international journals. Dr Gunasekaran has been involved in several national and international collaborative projects that are funded by private and government agencies. He has supervised more than 40 dissertations and several industrial projects. Most of the projects are industrial based. Dr Gunasekaran is currently interested in researching agile manufacturing, concurrent engineering, management information systems, technology management, supply chain management, computer-integrated manufacturing, and total quality management.

Production Planning & Control ISSN 0953 7287 print/ISSN 1366 5871 online # 2000 Taylor & Francis Ltd http://www.tandf.co.uk/journals

392

A . Gunasekaran et al.

R ONALD M CN E IL received his undergraduate degree in England and graduate degrees in the United States. Ron was employed by a management-consulting rm and focused on the energy eld with utility, petro-chemical and coal companies. He designed, managed and delivered organizational and management development programmes to a host of Fortune 500 companies. He also has held executive positions as president of a mining company and as Director of Management Development for a consulting rm. In 1982 he entered the academic eld and progressed to a tenured, full professor of management, Director of a Small Business institute, Director of large Graduate Program in Business ( a programme with over 600 students), and Associate Dean. In 1992 he accepted the position of Dean of the College of Business and Industry at the University of Massachusetts Dartmouth. He continues his strong ties with industry, the community and academic associations. He has published and presented over 50 academic papers at regional, national and international meetings. D A LJ IT SINGH has completed his BEng ( Production engineering) from Shivaji University, India. then he worked for about three years with Jindal Aluminium in Bangalore, India as a production engineer where he was responsible for capacity planning, quality assurance and costing of products. Later he came to the UK and completed his MSc in Advanced Manufacturing Systems from Brunel University. His areas of research interests are six-sigma process control, costing of product and kanban and kaizen.

analysis, cost drivers and performance measures to initiate, drive or support improvement e orts, and hence to improve the decision-making processes. Cost Accounting Management-International (CAM-I) de nes ABM as `a discipline that focuses on the management of activities as the route to improving the value received by the customer and the pro t achieved by providing this value . This discipline includes cost drivers analysis, activity analysis and performance measurements. ABM draws on activity-based costing (ABC) as its major source of information (Berliner and Brimson 1988) . The goals of ABC can be achieved by managing the activities. It is important to realize that managing activities is not a custodial task. Rather, it is a process of relentless and continuous improvement of all aspects of a business. This involves a continual search for opportunities to improve which in turn involves a careful and methodical study of activities (Kaplan 1984) . In this paper, a real life example of the photo framing industry, G. E. Mustill (GEM) , has been considered to explain the application of ABM in a small company. In this project, an ABC system is used to accurately calculate the cost of the company s main product (four-head foiler) and cost of di erent subassemblies to a make or buy decision. ABC helps to analyse di erent activities in the company and to di erentiate between value-added and non-value-added activities. The aim of ABM is to guide improvement e orts of management in the right direction by providing accurate information about activities. The organization of the paper is as follows: section 2 deals with a conceptual model for ABM. A case study is presented in section 3 to illustrate the application of the

model in a small company. The conclusions are presented in section 4.

2. A ctivity-based management Each organization requires information to make decisions, set priorities, allocate resources and monitor the actions taken. ABC performs the arithmetic to provide accurate cost information, and ABM is focused on using this information to manage activities. Improving business based on the information obtained from ABC is called as ABM. ABM is a management analysis that brings the full bene ts of ABC to an organization. A conceptual model developed as shown in gure 1 is used to describe ABM. Di erent stages of ABM in managing and improving activities are discussed in the following sections. 2.1. Analysis of activities In this section, the details of the analysis of activities are discussed. The analyses of activities involve: (i) identi cation of value-added and non-value-added activities; (ii) analysis of critical activities; and (iii) comparison of the performance of those activities with that of benchmarked. 2.1.1. Identif y value-added and non-value-added activities Once activities are speci ed and the cost of each activity is calculated, the next step is to identify value-added

Activity-based manag ement in a small company

393

Improvement of Activities

Reduce time/effort required to perform an activity, Eliminate unnecessary activities, Select low cost activities, Share activities wherever possible

A

Identify value-added and Non-value adding activities, Analysis of critical activities, Compare activities with that of benchmarked

Performance Improvement

B

Financial, non-financial measures, Multiple performance measures, Cost drivers, Eliminate non-value adding activities

Analysis of Activities

Performance Measurements

Figure 1. A conceptual framework for activity-based management.

and non-value-added activities. This judgement should be made within the context of company-wide and wellunderstood de nitions for the terms. A non-value-added activity is often de ned as `an activity that can be eliminated with no deterioration of product attributes (e.g. performance, functionality, quality, perceived value) (Miller 1992) . Making non-value-added cost visible is one of the major bene ts of ABM, but also the most di cult to achieve (David and Robert 1995) . Also, de ning what is value added versus what is non-value added can be problematic. De nition of a value-added and nonvalue-added activity is often confused and misunderstood. Some think that non-value-added activity means waste, to others it might mean the cost of quality and to others it might mean everything other than the labour. The reporting of non-value-added activities and costs can quickly become a people s issue because no one wants to be labelled as performing non-value-added activities, e.g. labelling can easily be considered a threat to job security. Therefore, ABM should focus on the activities, not on the people who perform the activities. Clarity and understanding between value-added and non-value-added activities are achieved when people understand and accept the reasons why an activity is classi ed as non-value added or value added (Miller 1996) . Most people perform their value-added analysis by simply designating an activity value added or nonvalue added. This level of analysis is insu cient because every value-added activity includes non-value-added

steps or tasks. A more thorough analysis should be undertaken to identify the potential for improvement in valueadded activities. The following are a few examples of non-value-added activities in an organization. . Machine setup is a non-value-added activity (as the machine is not producing anything while being setup) . . Logistics in the factory is another non-value-added activity (moving a product does not make it more valuable) . . Inspection is a non-value-added activity. . Stock holding is a non-value-added activity (inventories do not add value to a product or customers) . Rework is one of the non-value-added activities that can be found in any industry. Nevertheless, this activity is a value-added activity for an operator who performs rework on a job because he/she increases the value of a product by rework. Therefore, all aspects of an organization should be considered while identifying valueadded and non-value-added activities. 2.1.2. Analysis of critical activities In a SME, generally the number of activities in a business may range from 10 to 200. It is not possible to analyse all of them at once due to limited time and resources. The key is then to focus on the most critical

394

A . Gunasekaran et al. example, the time to set up a machine can be reduced by improved training, eliminating con icts in employee assignments, placing tools and dies in convenient location, and changes in the product design. For example, a reduction of 90% in setup time is not unusual (Turney 1996) . Reduction in time and e ort may come not from the activity in question, but may be from the preceding activity. For example, the defect rate of parts received by a machining activity is a cost driver for that activity. Improving quality in the preceding activity reduces the quantity of this cost driver and hence the overall e orts required by the machining process. 2.2.2. Eliminate unnecessary activities

activities that will add value to customers or help the e ective operation of the business. Moreover, these are the activities that provide the signi cant opportunities for improvement. The Pareto analysis can be used to determine the critical activities. This analysis should be carried out separately for both the value-added and nonvalue-added activities. The activities can be ranked in descending order of cost and the cumulative percentage of the cost of all the activities can be calculated. Then, it can be found that 20% of the activities causes 80% of the total cost, and those activities are worth analysing. 2.1.3. Compare activities with benchmarking All activities should be compared with similar activities in another company or within the organization which performs the best in class. Benchmarking should be carried out for both value-added and non-value-added activities. Comparing an activity with a benchmarked of good practice helps to determine the scope for further improvement. The activities should be measured based on factors, e.g. quality, lead-time, exibility, cost and customer satisfaction. Then, each activity should be rated against an identi ed best practice (Coburn et al. 1995) . A company with a number of di erent departments can improve the e ciency and e ectiveness of each activity by comparing similar activities of di erent departments. Obtaining information from other companies is quite di cult. Therefore, benchmarking within the company or with the best practice is mostly used in real-life situations. For example, on-time delivery of customer orders is an essential activity and it can be performed manually. The best practice, however, uses electronic data interchange (EDI) that costs less per transaction, has a lower error rate and provides a faster service. This clearly shows that there is room for improvement over manual order taking (Turney 1992) . 2.2. Improvement of activities The following are some of the improvement strategies/ methods that have been generally considered for improving the performance of any organization using the information obtained from an ABC system. 2.2.1. Reduce the time or e ort required to perform an activity A key element of improvement is to reduce the time and e ort needed to perform an activity. This reduction can come from a process or a product improvement. For

Some activities are candidates for elimination because they are not valued by customers or not essential to running the organization. It is possible, e.g. to eliminate material handling activities through changes to the process or products, e.g. reducing the number of components, using GT cells or even by outsourcing (Turney 1996) . There are a number of di erent options to eliminate any unnecessary activities. In any organization, steps should be taken to ensure that all incoming materials and parts are t for use. The parts can then be delivered directly to the shop oor as needed. For instance, changes can be requested in the vendor s production process to improve quality, exibility and increase the responsiveness. The parts that cause quality problems can be eliminated by instilling the responsibility of delivering quality products onto suppliers. Once these changes have been made, all the activities of a storeroom can be eliminated. Activities, e.g. material handling and inspection will be reduced automatically. Eliminating these activities will reduce the overall cost and the cost of products that no longer use these activities. 2.2.3. Select low-cost activities Designers of products and processes often have choices among competing activities. This o ers a means for reducing cost by picking the lowest cost activity (Miller 1996) . A designer of a product may be able to specify the type of activity required for the assembly of a product. Depending on the design of components, several automatic assembly lines can be used for the assembly of a product instead of manual assembly of a product. Each of these activities has a di erent set of resources associated with it. Manual assembly is a direct labour activity. An automatic assembly, however, requires equipment, software, skilled workers, and additional pro-

Activity-based manag ement in a small company cess engineering and training. Because these activities have di erent costs, the selection of an activity has an important impact on the cost. The process designer faces similar choices. For example, a part designed for machine insertion might also be inserted manually. A process designer may choose to have the part inserted manually because a reduction in the batch size makes it uneconomical to program and setup an insertion machine. 2.2.4. Sharing of activities If a customer has unique needs, it is necessary to perform activities speci c to that customer. However, if customers have common needs, it is wasteful not to serve those needs with the same activities. For example, product designers can use the common parts in new product designs. A common part is one which is used in several products to perform the same function (e.g. a gasket used in several car models) . The only parts that need to be unique are those that add product-di erentiating functions as valued by the customers (Turney 1996) . The activities associated with the common parts, e.g. part number maintenance, scheduling and vendor relations, are shared by all products that use them. This sharing increases the volume of parts produced each time when an activity is carried out, thus reducing the cost per part. The process designer can also cut costs by grouping of products into work cells. This is possible when products have similar designs (members of a product family) and when the manufacturing process is su ciently exible to handle any di erences in parts. The cost has decreased because the products in the cell share activities, e.g. supervision, testing, training, scheduling, material handling, storage and documentation. 2.3. Performance measurements In an ABM system, performance measures include both nancial and non- nancial measures, and are designed to in uence the behaviour of cost management. A fundamental issue is that a single performance measure will not re ect all the aspects of a company. Managers may require multiple performance measures even from individuals (Innes et al . 1994) . Generally, activities involve groups of employees, and the performance measures therefore usually relate to the group rather than the individual and to the process as well as the output or result. The ABM system uses cost drivers of a company s activities as a basis for changing the performance meas-

395

urement system. In particular, some companies are concentrated on non- nancial operational performance measures to monitor the improvements in their business processes. It is important to appreciate those performance measures which not only attempt to measure the performance, but also control and evaluate the performance, and motivate the people. The behavioural impact of performance measures is one of the most signi cant aspects of ABM. Cost drivers, e.g. the number of purchase orders or the number of engineering changes, are used as a part of the performance measurement system. Some companies use physical measures, but others monitor the unit cost per driver, e.g. the cost of a purchase order. Performance measures should be selected carefully and tailored to the individual processes or organization. Each company must consider the activities which are critical to its business success. Greene and Flentov (1991) suggest certain general guidelines for selecting performance measures. . The performance measures chosen should assist in monitoring the progress of controlling activity costs. These include throughput time, and the number of engineering changes and production schedule changes. . The performance measures selected should be reviewed periodically. As the business and the internal and external environments of a business change, performance measures may have to also change accordingly. . Everyone should be able to understand the performance measures. These not only must be clearly de ned, but also the relationship to the company s strategic objectives must be explained. . The performance indicators relevant for one individual or group should not be too many. . Daily operations should be managed on the basis of these key measures. . The evaluation of employees should be linked to the performance indicators selected. . The selection of these performance indicators is a critical process and the success of this process depends upon a sound analysis of the critical activities for that particular business. . Whilst activities-based approaches are not a panacea nor even an end in themselves, they do at least recognize the need to e ectively manage the activities of a business. This should be re ected in the way the costs are reported and performance measures are employed (Marrow 1992) . The analysis of activities as value added and non-value added is the basis of ABM. The main task of ABM is to direct improvement e orts in eliminating or reducing the

396

A . Gunasekaran et al. volume of non-value-added activities and improving value-added activities. machines. Then, this amount is divided by eight because the annual sale of a four-head foiler is eight machines. Therefore, the marketing cost for this product is 729.06. . Inventory carrying cost. The cost driver for inventory carrying is the stock value. The total stock value in GEM is 20 000. For a four-head foiler, the stock value is 1600. Hence, the inventory carrying cost for this machine is 491.20. . Engineering support. The cost driver for this activity is the time spent by the engineering support sta s for a particular product. For this machine, a total of 80 h is spent by the engineering sta and hence the cost of engineering support activity is 1480. . Assembly. The assembly of the machine is performed manually. The cost driver for assembly activity is the labour hours and the volume of the cost driver is 82 h. This leads to the total assembly cost as 886.42.

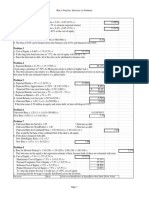

3. A ctivity-based management at G. E. Mustill a case study G. E. Mustill (GEM) is a small company with 0.5 million annual turnover. It employs about 20 people and is located in Essex, England. The main products of GEM are four types of machines (viz. sander, splitter, shaper and foiler) for the picture framing industry. The foiler and sander machines are produced in di erent numbers of heads varying from 1 to 6. They produce machines in standard speci cations and according to customers requirements. The company manufactures only 22% of parts of the machine in-house and purchases 78% of parts from subcontractors and suppliers. The assembly of all these parts is the main activity of the company. The company works in a traditional way and all activities are performed manually. Information provided by an ABC system is used to nd the opportunities of improvement in organization at the activity level. The analysis of activities involves classi cation of activities into value added and non-value added, and then compare these with that of the world class company or the best practices. Benchmarking with the best practice o ers avenues for improvement in value-added activities. This also explains how management can use the cost drivers as the performance measures and control the volume of cost drivers. The ideal cost object is `products that are sold to customers. The cost of all activities is calculated in a similar way to that of parts. The total cost of a four-head foiler is shown in table 1. . Marketing. The annual cost of marketing is 23 330 which is divided equally between four types of

3.1. Analysis of activities ABC provides detailed information about the company and its activities. This detailed information can be used by the management to initiate improvements and decision-making. The percentage cost of all activities is shown in gure 2. This shows that engineering support activities carry 22.21% of the total cost of all activities. In the traditional costing system, there is no such information available on this. Once the cost of each activity is calculated, the next step is to identify the value-added and non-value-added activities. According to the de nition of a non-valueadded activity (an activity that can be eliminated with no deterioration of product attributes) , all activities are

Table 1. Cost of a four-head foiler. Activity Assembly Material handling Inspection Purchasing Marketing Inventory Engineering support Personnel Misc. overhead Manufactured parts Direct material Cost driver labour hours no. of movements no. of inspection no. of orders no. of product stock value sta hours labour hours labour hours Cost driver rate 10.81 0.2 0.41 20.65 729.06 0.307 18. 5 0.64 1.6 Cost driver volume 82 h 1020 movements 450 inspection 16 orders 1 1600 80 h 470 h 520 h Cost 886.42 204.00 184.50 330.40 729.06 491.20 1480.00 300.80 832.00 1306.88 9773.0 16 518.3

Total cost

Activity-based manag ement in a small company

Misc. overhead 15.3% Assembly 16.30%

397

Inspection 21.01%

Material handling 3.75 % Inspection 3.4% Purchasing 6.08%

Personnel 5.53%

Inventory 55.81%

Material Handling

Engineering support 27.2% Marketing 13.41% Inventory 9 .03 %

23.18%

Figure 4. Cost of non-value-added activities.

Figure 2. Percentage cost of activities.

Non-Value Added Activities 16.18%

Value-Added Activities 83.82%

Figure 3. Percentage of value-added and non-value-added activities.

non-value added except activities, e.g. assembly, machining and engineering support. Activities, e.g. marketing, personnel and purchasing do not add value to the product, but these are necessary and cannot be eliminated. Therefore, there are three non-value-added activities, viz. inspection, material handling and inventory. Figure 3 shows the percentage of value-added and nonvalue-added activities. It indicates that non-value-added activities are 16.18% of the total cost of activities. These activities can be eliminated without deterioration of product attributes, e.g. quality, performance and function. By using di erent quality assurance methods, e.g. TQM, ISO9000 and dynamic process control, quality can be maintained during production and hence there is no need for an inspection. Similarly, material handling and inventory-related activities can be eliminated using di erent methodologies and techniques, e.g. JIT, EDI, CIM and BPR.

It may not be possible to eliminate or reduce all nonvalue-adding activities at the same time. The key is then to focus on the critical activities which form a major portion of the total cost. Figure 4 shows that the inventory carrying cost is 55.81% of the total cost of nonvalue-added activities. Therefore, activities related to carrying inventory should be eliminated rst. The cost driver for inventory carrying activity is the value of stock. The company should not maintain any stock in order to eliminate related activities. This could be possible by the introduction of just-in-time purchasing. At the same time, the cost of purchasing should be closely monitored. The purchasing department will place more purchasing orders to maintain the minimum stock level. If the company eliminates inventory-related activities and increases the cost of purchasing activity, then there are no bene ts in eliminating non-value-added activities. Similarly, the cost of maintaining quality in processes should be considered in eliminating the inspection activity. Material handling activities cannot be eliminated at the cost that is di cult to justify. Sometime, non-valueadded activities can be clearly identi ed, but di cult to eliminate completely. However, it is always possible to reduce the cost of these activities.

3.2. Compare activities with benchmarking All activities related to the manufacturing of a fourhead foiler should be compared to similar activities in other companies or within the organization. Benchmarking should be carried out for both valueadded and non-value-added activities because valueadded-activities include non-value-added tasks. The comparison of some of the activities of the company with the best in class company s activities is presented below.

398

A . Gunasekaran et al. value-added activity which should be eliminated. However, it is di cult because the purchasing cost of the present system will increase as the company places more purchased orders with the objective to reduce inventories. Therefore, it indicates that the purchasing activity should also improve. The comparison of this purchasing activity with the best practice (purchasing using EDI) indicates the scope for improvements. ABM uses ABC information to motivate the people in improving and monitoring the performance of their activities.

. Purchasing. World-class companies have a direct link with suppliers and subcontractors by the electronic data exchange (EDI) system, and it places orders automatically whenever materials are required. This leads to a reduction in ordering cost, lead time and overall purchasing cost as compared with that of manual order processing. Hence, there is room for improvement in the purchasing activity of GEM. . Assembly. The assembly activity is performed manually in GEM. Compared to an automatic assembly activity, there are many chances of improvements. The cost of automation should be justi ed based on the labour cost and response time including tangible and intangible costs and bene ts. . Material handling. There are a number of machining stations in GEM, e.g. drilling, milling and turning. The movement of materials between these stations is the cost driver. It is possible to reduce this movement by using multipurpose machines (AS/RS, robots, AGVs) to perform various operations. The movement of materials can also be reduced by changing the layout of machines. . Machining operations (drilling, milling, turning, etc.) . GEM uses very old machines to perform these activities and these are labour intensive. Therefore, these machining operations can be compared with that of the CNC machine tools. Similarly, all the activities can be compared with the best practices. Benchmarking at each activity level helps to determine the scope of improvements. 3.3. Performance measurements In ABM, performance of GEM should be measured at an activity level, and performance measures include both nancial and non- nancial measures. The cost drivers are performance measures for all activities. The volume of the cost driver indicates the performance level of each activity. For example, the cost driver for an assembly activity is labour hours. If labour hours required to perform the assembly activity increases, then this indicates that the performance of the assembly activity is poor. If labour hours decrease, then the performance of the assembly activity improves which in turn leads to a reduction in the cost of the product and hence an increase in the pro t level. Similarly, appropriate cost drivers are performance measures for all identi ed activities in the company. From the analysis of activities, the value-added and non-value-added activities are clearly identi ed. In GEM, the inventory carrying activity is the major non-

4. Conclusions Management practices and methods have been changed over the last decade, and organizations are moving from managing vertically to managing horizontally. Activity-based costing and activity-based management provide cost and operating information that mirror the horizontal view. ABC provides accurate cost information and ABM uses this information to initiate improvements. ABC systems produce a large amount of information that is used by the ABM. The costing at part level or subassembly level helps the management in a make or buy decision. The analysis of activities to identify value-added and non-value-added activities and benchmarking at the activity level direct improvement e orts in the right direction. In this paper, an attempt has been made to study the application of ABM in a small company. Firstly, a conceptual model is developed to describe the major components of ABM. Secondly, a case study is presented to discuss the application of the model in a real-life small company. The bene ts of ABC and ABM can only be achieved if it is applied for the whole organization. Therefore, GEM should use activity-based analysis to identify non-value-added activities (e.g. inventory carrying, material handling and inspection) , and then try to eliminate these activities by using the number of available management methods and techniques. Also, there are possibilities to improve value-added activities. The cost driver of activities should be used to measure the performance of activities.

References

BERL INER , C. , and BRIMSON , J . A., 1988, Cost M anagement for T odays A dvanced M anufacturing T he CAM -I Conceptual Desig n ( Boston, MA: Harvard Business School). C OBURN , S., GROVE , H. , and F UKA MI , C., 1995, Benchmarking with ABCM. M anagement A ccounting , J anuary , 56 60. DA VID, E. K. , and R OB ERT , J . L., 1995, Departmental activity based management. M anagement Accounting , J anuary , 27 30.

Activity-based manag ement in a small company

E VA NS, H. , and A SHW ORTH , G., 1995, Activity based management moving beyond adolescence. M anagement Accounting , December, 26 30. G REE N, A. H. , and F LE NTOV, P., 1991, Maximising the bene t of activity based costing. J ournal of Cost M anagement , 2, J5-1 J5-9. I NNES, J ., M ITCHE LL , F. , and Y OSHIKAW A , T., 1994, A ctivity Costing For Engineers (Chichester, UK: Wiley) . K A P LA N , R. S., 1984, Yesterdays accounting undermines production. Harvard Business Review , J uly-A ugust, 95 101. M A RROW , M ., 1992, Activity Based M anagement ( Hertfordshire, UK: BPCC Wheatons).

399

M IL L ER , A. J ., 1992, Designing and implementing a new cost management system. Cost M anagement , Winter , 41 53. M IL L ER , J . A., 1996, Activity Based M anagement in D aily Operation ( Chichester, UK: Wiley) . T URNEY , B. B. P., 1992, Activity based management. M anagement Accounting , J anuary , 20 25. T URNEY , B. B. P., 1996, Activity Based Costing: T he Performance Breakthrough ( London: CLA) . T URNEY , B. B. P. , and STRA TTON, A. J ., 1992, Using ABC to support continuous improvement. M anagement Accounting , Sept., 46 50.

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- End Game: Number of Firms Beta ROE Cost of Equity (Roe - Coe) BV of Equity Equity EVA ROCDocumento18 páginasEnd Game: Number of Firms Beta ROE Cost of Equity (Roe - Coe) BV of Equity Equity EVA ROCCinthiaAinda não há avaliações

- RiskpracDocumento4 páginasRiskpracveda20Ainda não há avaliações

- Primer StatsDocumento4 páginasPrimer Statsveda20Ainda não há avaliações

- DivginzuDocumento34 páginasDivginzuveda20Ainda não há avaliações

- PV PrimerDocumento15 páginasPV Primerveda20Ainda não há avaliações

- End Game: Number of Firms Beta ROE Cost of Equity (Roe - Coe) BV of Equity Equity EVA ROCDocumento18 páginasEnd Game: Number of Firms Beta ROE Cost of Equity (Roe - Coe) BV of Equity Equity EVA ROCCinthiaAinda não há avaliações

- End Game: Number of Firms Beta ROE Cost of Equity (Roe - Coe) BV of Equity Equity EVA ROCDocumento18 páginasEnd Game: Number of Firms Beta ROE Cost of Equity (Roe - Coe) BV of Equity Equity EVA ROCCinthiaAinda não há avaliações

- Packet 3 SPR 17Documento164 páginasPacket 3 SPR 17veda20Ainda não há avaliações

- Pamela Peterson Drake, James Madison UniversityDocumento4 páginasPamela Peterson Drake, James Madison Universityveda20Ainda não há avaliações

- Calculating Forward Rates: Practice ProblemsDocumento1 páginaCalculating Forward Rates: Practice Problemsveda20Ainda não há avaliações

- City BrochureDocumento16 páginasCity Brochureveda20Ainda não há avaliações

- Pamela Peterson Drake, James Madison UniversityDocumento4 páginasPamela Peterson Drake, James Madison Universityveda20Ainda não há avaliações

- Advt. Deputation 2018Documento8 páginasAdvt. Deputation 2018veda20Ainda não há avaliações

- LCR Calculation Tool - For PublicationDocumento6 páginasLCR Calculation Tool - For PublicationAlper BayramAinda não há avaliações

- Brazilian Stagflation 2015Documento1 páginaBrazilian Stagflation 2015Victor Zhiyu Lee100% (4)

- Pamela Peterson Drake, James Madison UniversityDocumento4 páginasPamela Peterson Drake, James Madison Universityveda20Ainda não há avaliações

- Brochure 2016 17Documento10 páginasBrochure 2016 17veda20Ainda não há avaliações

- CBSE - NEET TEST 2016 ResultsDocumento2 páginasCBSE - NEET TEST 2016 Resultsveda20Ainda não há avaliações

- Enterprise ValueDocumento3 páginasEnterprise Valueveda20Ainda não há avaliações

- How To Fill Application Form EMed UGET 2016Documento19 páginasHow To Fill Application Form EMed UGET 2016aayuAinda não há avaliações

- Technology: Hardware: Research IN Motion (RIMM: $73.39) 1 /buyDocumento12 páginasTechnology: Hardware: Research IN Motion (RIMM: $73.39) 1 /buyveda20Ainda não há avaliações

- Accounting SyllabusDocumento3 páginasAccounting Syllabusveda20Ainda não há avaliações

- Syllabus MGMT E-2790 Private Equity Spring 2016 1-1Documento8 páginasSyllabus MGMT E-2790 Private Equity Spring 2016 1-1veda20Ainda não há avaliações

- Bank - Model Commerzbank 1Documento10 páginasBank - Model Commerzbank 1Khryss Anne Miñon MendezAinda não há avaliações

- TelomereTimebombs Chapter3Documento15 páginasTelomereTimebombs Chapter3veda20100% (1)

- Key Words: Covid-19, Credit Cycle, High-Yield Bonds, Leveraged Loans, Clos, Default Rates, Recovery Rates, Rating/Inflation, Crowding-Out, ZombiesDocumento26 páginasKey Words: Covid-19, Credit Cycle, High-Yield Bonds, Leveraged Loans, Clos, Default Rates, Recovery Rates, Rating/Inflation, Crowding-Out, Zombiesveda20Ainda não há avaliações

- Syllabus MGMT S-2790 Private Equity Summer 2019 DRAFT 02-15Documento8 páginasSyllabus MGMT S-2790 Private Equity Summer 2019 DRAFT 02-15veda20Ainda não há avaliações

- Venture Capital MarshallDocumento9 páginasVenture Capital Marshallveda20Ainda não há avaliações

- M&A at Columbia Business School: Program CurriculumDocumento6 páginasM&A at Columbia Business School: Program Curriculumveda20Ainda não há avaliações

- Immunology Standalone ModuleDocumento4 páginasImmunology Standalone Moduleveda20Ainda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Stata Book - Manual - Panel Data AnalysisDocumento35 páginasStata Book - Manual - Panel Data AnalysisIzaniey Ismail100% (4)

- RP FoodpandaDocumento4 páginasRP FoodpandaDanish HadiAinda não há avaliações

- WHITEHOUSE - The State of Design History As A DisciplineDocumento18 páginasWHITEHOUSE - The State of Design History As A DisciplinelluettaAinda não há avaliações

- Lecture Note of Chapter OneDocumento30 páginasLecture Note of Chapter OneAwet100% (1)

- Output SPSSDocumento9 páginasOutput SPSSawancustomsAinda não há avaliações

- Mam Elaine Pangasinan Chapter 1Documento7 páginasMam Elaine Pangasinan Chapter 1Elaine Pimentel FortinAinda não há avaliações

- Updated Standard Thesis Format 08252023Documento26 páginasUpdated Standard Thesis Format 08252023Jannarie JardinAinda não há avaliações

- Coplan Definición 2011Documento27 páginasCoplan Definición 2011Paw GröennAinda não há avaliações

- Unit 5Documento33 páginasUnit 5Ram KrishnaAinda não há avaliações

- Thesis Ibanag) )Documento17 páginasThesis Ibanag) )Rahc Engam Gahyadap100% (20)

- Calibration ProcedureDocumento2 páginasCalibration ProcedureSairam Edupuganti100% (1)

- Causal Inference The MixtapeDocumento657 páginasCausal Inference The Mixtape何旭波Ainda não há avaliações

- Soe FDP Ftresm 8feb19Documento2 páginasSoe FDP Ftresm 8feb19Raghvendra TiwariAinda não há avaliações

- Factors That Cause Anxiety in Learning English Speaking Skills Among College Students in City of Malabon University: Basis For 1 Year Action PlanDocumento27 páginasFactors That Cause Anxiety in Learning English Speaking Skills Among College Students in City of Malabon University: Basis For 1 Year Action PlanMarlon OlivoAinda não há avaliações

- Chapter 06 PDFDocumento18 páginasChapter 06 PDFMonicaFrensiaMegaFisheraAinda não há avaliações

- Crossing Functional LinesDocumento7 páginasCrossing Functional LinesmanmeetassignmentAinda não há avaliações

- 11 CH 11Documento54 páginas11 CH 11nikunjpatel12345Ainda não há avaliações

- Expository Writing vs. Research Papers What Is The DifferenceDocumento8 páginasExpository Writing vs. Research Papers What Is The Differenceb0pitekezab2Ainda não há avaliações

- Math T Coursework 2020 Sem 3Documento14 páginasMath T Coursework 2020 Sem 3Melody OngAinda não há avaliações

- Sex Differences in Positive Well-Being: A Consideration of Emotional Style and Marital StatusDocumento16 páginasSex Differences in Positive Well-Being: A Consideration of Emotional Style and Marital StatusWidyaUtamiAinda não há avaliações

- University of Leicester Research Ethics Code of Practice: December 2006 IDocumento10 páginasUniversity of Leicester Research Ethics Code of Practice: December 2006 Istxavier5000Ainda não há avaliações

- Stability of Tapered and Parallel-Walled Dental Implants: A Systematic Review and Meta-AnalysisDocumento12 páginasStability of Tapered and Parallel-Walled Dental Implants: A Systematic Review and Meta-AnalysisBagis Emre GulAinda não há avaliações

- 2023 - Article - 5356Documento9 páginas2023 - Article - 5356indahrizkygAinda não há avaliações

- NRSP Annual Report 2019 20Documento98 páginasNRSP Annual Report 2019 20عادل حسین عابدAinda não há avaliações

- PGDM II HR ElectivesDocumento20 páginasPGDM II HR ElectivesSonia BhagwatAinda não há avaliações

- Adolescent Perspectives About Online Hate Speech: Qualitative Analysis in The SELMA ProjectDocumento13 páginasAdolescent Perspectives About Online Hate Speech: Qualitative Analysis in The SELMA ProjectEleni PanagouliAinda não há avaliações

- Btec HN Computing l4 Pearson Set Release 2023 2024 PDFDocumento12 páginasBtec HN Computing l4 Pearson Set Release 2023 2024 PDFMarium BhalaAinda não há avaliações

- Systematic Literature Review: Kemampuan Pembuktian MatematisDocumento15 páginasSystematic Literature Review: Kemampuan Pembuktian MatematisAdam SIAinda não há avaliações

- Downloadable Solution Manual For Information Technology Auditing 3rd Edition James Hall Solutions 1Documento4 páginasDownloadable Solution Manual For Information Technology Auditing 3rd Edition James Hall Solutions 1Diane Lorenzo0% (1)

- Bank MarketingDocumento5 páginasBank MarketingArindam BhowmickAinda não há avaliações