Escolar Documentos

Profissional Documentos

Cultura Documentos

GSL Actuator Sizing Calculation

Enviado por

Anonymous yQ7SQr0 notas0% acharam este documento útil (0 voto)

54 visualizações0 páginaactuator sizing example

Direitos autorais

© Attribution Non-Commercial (BY-NC)

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoactuator sizing example

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

54 visualizações0 páginaGSL Actuator Sizing Calculation

Enviado por

Anonymous yQ7SQractuator sizing example

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 0

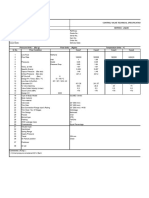

Actuator sizing calculation for Gate & Globe Valves

GSL Actuator sizing calculation of Gate & Globe Valves JB

Information required Examples

1 Bore diameter at seat (use actual diameter if known) 12 inch 3 inch 3 inch

2 Differential pressure, using 30psi minimum, and line psi if higher 200 psi 2250 psi 2250 psi

3 Type of valve and service Wedge gate, oil Globe, steam Globe, steam

4 Stem diameter and lead of screw thread

(pitch x number of starts)

1 x 1/3

rising stem

1 x

rising rotating

1 x

rising stem

5 Travel time/speed in inches per minute (if critical) About 1 minute

Method Having obtained the above information proceed as follows

A Obtain bore area (full bore assumed) (1) 113 sq in 7.06 sq in 7.06 sq in

B Differential psi 200 psi 2250 psi 2250 psi

C Obtain valve factor Table 1 0.35 1.15 1.15

D Multiply A x B x C to obtain seating thrust

For rising stem valves:

7950 lbf

Yes

18200 lbf

No

18200 lbf

Yes

E Add packing friction thrust = 2000 x stem diameter (2)

For gate valves:

3500 lbf

Yes

----

No

3000 lbf

No

F

Add piston effect = 0.785 x diam. of stem^2 x diff. Pressure (For

globe valves, the stem area is included with the disc area, so piston

effect can be ignored)

481 lbf ---- ----

G D+ E+F gives total thrust 11931 lbf 18200 lbf 21200 lbf

H Obtain Stem Factor K Table 2 0.014 0.012 0.012

J

G x H gives torque

For rotating stem valves:

167 lbf-ft

No

218 lbf-ft

Yes

254 lbf-ft

No

K Add gland friction torque = (1000 x stem diameter^2) 12 (2) ---- 188 lbf-ft ----

L J+K gives total thrust (rotating stem) 406 lbf-ft

M Actuator RPM = Speed in inches per min Lead of stem 12 1/3

= 36 RPM

Notes

(1) API-600 and API-603 Gate Valves must have full ports according to Annex

A form ASME B16.34. Valves conforming to API-602 have reduced ports

indicated in this standard. Other valves may differ according to

manufacturing standard or published CV factor. Consult plant for an

specific valve port diameter.

(2) Factors based on Flexible Graphite Packing. For PTFE Packing, the results

can be divided by 2.

(3) Valve factors are based on metallic seats, when valve is new. If you

foresee seats oxidation or aging during the service, multiply this factors by

1.25 to 1.5 depending the severity of seats oxidation or aging. Stroking the

valve frequently, maintain the seats cleaner and the thrust and torque lower.

(4) For inside screw threads multiply factors by 1.5 for exposed sluice gates

(penstocks) multiply factors by 1.25 and insure that thrust estimate is a

minimum of three times the weight of the gate. This factors assume a

proper lubrication on stem threads, if a poor maintenance is predicted

multiply this factors by 1.15 to 1.3. Depending on the specified speed, the

stems can have single, double or triple start. Consult plant for actual stem

diameter, pitch and lead.

Table 1 Valve Factors (3)

Valve type

Liquids

Below

750F

Liquids

Above

750F

Gases/

Steam

below

1000F

Gases/

Steam

above or

close

1000F

Parallel slide and

Flexible or double

disc

0.28 0.3 0.35 0.45

Solid wedge gate 0.35 0.4 0.45 0.5

Globe above 2 1.15 1.15 1.15 1.15

Globe below 2 1.5 1.5 1.5 1.5

Lead Stem

Dia In

Ins 3/4 1 1 1 1 2 2 2 2 3 3 3 3 4 4 4 4 5 5 5 6 6

1/8 .006 .007

1/5 .007 .008 .010 .011

1/4 .007 .009 .010 .012 .013 .015 .016 .018 .019 .021 .022

2/7 .008 .009 .011 .012 .014 .015 .017 .018 .020 .021 .023

1/3 .008 .010 .011 .013 .014 .016 .017 .019 .020 .022 .023

2/5 .009 .010 .012 .013 .015 .016 .018 .019 .021 .022 .024 .025 .027 .028 .030 .031 .033 .034 .036 .037 .040

1/2 .012 .013 .014 .016 .017 .019 .020 .022 .023 .025 .026 .028 .029 .031 .032 .034 .035 .037 .038 .041

2/3 .016 .019 .020 .022 .023 .025 .026 .028 .030 .031 .032 .034 .035 .037 .038 .040 .041 .044 .047

1 .020 .023 .024 .026 .027 .029 .030 .032 .032 .035 .036 .038 .039 .041 .042 .044 .045 .048 .051

1 1/2 .040 .042 .043 .045 .046 .048 .049 .051 .052 .055 .058

2 .048 .050 .051 .053 .054 .056 .057 .059 .062 .065

Table 2 Stem Factors (4)

Factor is lbf-ft per lbf of thrust, for ACME thread, using a coefficient of friction equal to 0.14

Você também pode gostar

- 10 Types of Valves and Their FunctionsDocumento7 páginas10 Types of Valves and Their FunctionsLamar TwitchAinda não há avaliações

- 01 Samss 035Documento28 páginas01 Samss 035Mohamed Ahmed MaherAinda não há avaliações

- Boq For AS BoilerDocumento1 páginaBoq For AS BoilerGayan ChathurangaAinda não há avaliações

- Delta Industrial Knife Gate ValvesDocumento28 páginasDelta Industrial Knife Gate ValvesAlin AllinAinda não há avaliações

- Europe Germany France Italy Belgium Sweden U.K. Canada India Japan International USADocumento6 páginasEurope Germany France Italy Belgium Sweden U.K. Canada India Japan International USAjaya_brbAinda não há avaliações

- BEL - 6D Through Conduit GateDocumento2 páginasBEL - 6D Through Conduit Gateasoka.pwAinda não há avaliações

- Seal Ball ValvesDocumento45 páginasSeal Ball Valvesmetasoniko2014Ainda não há avaliações

- Triple Eccentric Metal Seated ValvesDocumento4 páginasTriple Eccentric Metal Seated ValvesFelipe Gamboa GálvezAinda não há avaliações

- Alsco: Chemical Resistance GuideDocumento55 páginasAlsco: Chemical Resistance GuidejcndAinda não há avaliações

- Pig Trap End Closure105671465 PDFDocumento24 páginasPig Trap End Closure105671465 PDFashishAinda não há avaliações

- En 10029Documento5 páginasEn 10029PHAMTOAIAinda não há avaliações

- Valve Manual Pocket EditionDocumento23 páginasValve Manual Pocket EditionBùi Cảnh Trung100% (1)

- GE Weldstar PDFDocumento4 páginasGE Weldstar PDFJamesAinda não há avaliações

- API 600 Overview - Steel Gate Valves - Flanged and Buttwelding Ends, Bolted BonnetsDocumento2 páginasAPI 600 Overview - Steel Gate Valves - Flanged and Buttwelding Ends, Bolted BonnetsNilesh MistryAinda não há avaliações

- Spe 77-104 Check Valves To Bs 1868Documento8 páginasSpe 77-104 Check Valves To Bs 1868zeke2611Ainda não há avaliações

- Kirloskar Valves Technical Specification CatalogueDocumento24 páginasKirloskar Valves Technical Specification CatalogueAbhinay SuratkarAinda não há avaliações

- Knife Gate Valve - AVKCMSDocumento2 páginasKnife Gate Valve - AVKCMSjuantamad02Ainda não há avaliações

- Connectorsubsea 20502 0210 CSS Split Sleeve Repair ClampsDocumento2 páginasConnectorsubsea 20502 0210 CSS Split Sleeve Repair ClampsTTAinda não há avaliações

- LiquidDocumento2 páginasLiquidsiddhesh_guessAinda não há avaliações

- Orbit Parts List and Ordering InstructionsDocumento24 páginasOrbit Parts List and Ordering Instructionskeertiraj09Ainda não há avaliações

- Low Temperature and Cryogenic Ball ValvesDocumento4 páginasLow Temperature and Cryogenic Ball Valves윤병택100% (1)

- Steel Tube Handbook WebDocumento130 páginasSteel Tube Handbook Webwferry27100% (1)

- Fittings Din11852 Din11850Documento14 páginasFittings Din11852 Din11850dingobk1Ainda não há avaliações

- Specification for Titanium-Stabilized Carbon Steel ForgingsDocumento5 páginasSpecification for Titanium-Stabilized Carbon Steel Forgingslucecita1902Ainda não há avaliações

- Mehmet Cagirici Department of Metallurgical and Materials Engineering, METU, 06800 Ankara, TurkeyDocumento5 páginasMehmet Cagirici Department of Metallurgical and Materials Engineering, METU, 06800 Ankara, TurkeyErickAinda não há avaliações

- Oooom Om Om: International StandardDocumento32 páginasOooom Om Om: International StandardNizarHamrouniAinda não há avaliações

- Din Flange Din 2627: (Dimensions in MM.)Documento12 páginasDin Flange Din 2627: (Dimensions in MM.)Wisüttisäk PeäröönAinda não há avaliações

- DS 058-Rev-02 Epilux 155 High Build MIO CoatingDocumento2 páginasDS 058-Rev-02 Epilux 155 High Build MIO CoatingsojeckAinda não há avaliações

- API 607 Fire Test Report - Copeland - 2 Inch Class 900 Ball Valve - June 9 2017.22172258Documento16 páginasAPI 607 Fire Test Report - Copeland - 2 Inch Class 900 Ball Valve - June 9 2017.22172258Nilesh SargaraAinda não há avaliações

- Inspection of CastingDocumento23 páginasInspection of CastingRaghu SanthAinda não há avaliações

- L&T Double Block and Bleed Plug ValvesDocumento12 páginasL&T Double Block and Bleed Plug Valvesvijay10484Ainda não há avaliações

- The A To Z of Valve MaterialsDocumento4 páginasThe A To Z of Valve Materialscool47guy09Ainda não há avaliações

- Astm F 541-04Documento6 páginasAstm F 541-04Jorge ToribioAinda não há avaliações

- EN10255 Pipe SizeDocumento3 páginasEN10255 Pipe SizeStefan CristescuAinda não há avaliações

- Flans Chen Prospekt EngDocumento2 páginasFlans Chen Prospekt Englorenzinho290Ainda não há avaliações

- Analysis of Fiber Reinforced Plastic Needle Gate For K.T. WeirsDocumento5 páginasAnalysis of Fiber Reinforced Plastic Needle Gate For K.T. WeirsIJIRAE- International Journal of Innovative Research in Advanced EngineeringAinda não há avaliações

- ASME Section 1 and Pressure Equipment DirectiveDocumento5 páginasASME Section 1 and Pressure Equipment DirectivealextentwentyAinda não há avaliações

- Kat A 1331 Lug Cerex300 L Wasser en 03 12Documento6 páginasKat A 1331 Lug Cerex300 L Wasser en 03 12Sathishkumar DhamodaranAinda não há avaliações

- Technical Manual for Steel TubesDocumento122 páginasTechnical Manual for Steel TubesAlejandroBolanos100% (1)

- Flowjet Valves Product BrochureDocumento18 páginasFlowjet Valves Product BrochureUday GokhaleAinda não há avaliações

- Certificates and Test Reports DPV Pumps and Booster SystemsDocumento48 páginasCertificates and Test Reports DPV Pumps and Booster SystemstsikasAinda não há avaliações

- Face To Face Valve Dimensions En-558-1 - ValviasDocumento3 páginasFace To Face Valve Dimensions En-558-1 - ValviasAntonio CeiAinda não há avaliações

- Previews - 2033457 PIP VEFV1100MDocumento5 páginasPreviews - 2033457 PIP VEFV1100Mabdulloh_99100% (1)

- Texas Flange Product CatalogDocumento76 páginasTexas Flange Product CatalogVicky GautamAinda não há avaliações

- Rotary JointDocumento7 páginasRotary JointGlobe Star Engineers Pvt LtdAinda não há avaliações

- Globe Valve PresentationDocumento11 páginasGlobe Valve Presentationmayur22785Ainda não há avaliações

- Seamless Carbon Steel Boiler Tubes For High-Pressure ServiceDocumento2 páginasSeamless Carbon Steel Boiler Tubes For High-Pressure ServiceChandra ClarkAinda não há avaliações

- GD 1020 Bandlock GD en A4Documento8 páginasGD 1020 Bandlock GD en A4Anuj VermaAinda não há avaliações

- Is 210Documento16 páginasIs 210Debopriyo GhoshAinda não há avaliações

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987No EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonAinda não há avaliações

- The Complete Guide to Telephone Interview Questions and AnswersNo EverandThe Complete Guide to Telephone Interview Questions and AnswersAinda não há avaliações

- Fisher 9500 Butterfly Control ValveDocumento12 páginasFisher 9500 Butterfly Control ValveOscarAinda não há avaliações

- 'C' Series Control ValvesDocumento12 páginas'C' Series Control Valvesابزار دقیق100% (1)

- H1000e K FJDocumento8 páginasH1000e K FJSyarif HidayatullahAinda não há avaliações

- Olaer EhvDocumento12 páginasOlaer EhvandinoAinda não há avaliações

- Deublin Roto CouplerDocumento2 páginasDeublin Roto Couplerzanella88Ainda não há avaliações

- Catalog Keystone Butterfly ValveDocumento4 páginasCatalog Keystone Butterfly ValvePawrij Suriyaaroonroj100% (2)

- Elastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsDocumento6 páginasElastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsAdhie_ginthinkAinda não há avaliações

- Ice Handbook For EngineersDocumento31 páginasIce Handbook For EngineersruayoAinda não há avaliações

- Zick AnalysisDocumento12 páginasZick AnalysisrksahayAinda não há avaliações

- SMathStudio.0 85.NumericFunctions - Article.Eng PDFDocumento8 páginasSMathStudio.0 85.NumericFunctions - Article.Eng PDFpiramidonAinda não há avaliações

- MSDS Eng FoamglasDocumento4 páginasMSDS Eng FoamglasAnonymous yQ7SQrAinda não há avaliações

- ProgrammingWithSMathStudio2012 PDFDocumento30 páginasProgrammingWithSMathStudio2012 PDFMarioAinda não há avaliações

- DBYBHY2007 English Chapters1,2Documento28 páginasDBYBHY2007 English Chapters1,2Ergin ÇelikAinda não há avaliações

- User-Defined Functions in Smath StudioDocumento21 páginasUser-Defined Functions in Smath StudiobricemikAinda não há avaliações

- Materials Selection Guide for Sulfuric Acid PlantsDocumento6 páginasMaterials Selection Guide for Sulfuric Acid PlantsrivrsideAinda não há avaliações

- Smath StudioDocumento47 páginasSmath StudiokeikunbrAinda não há avaliações

- SMathStudio.0 85.IOFiles - Article.engDocumento8 páginasSMathStudio.0 85.IOFiles - Article.eng_mikkaAinda não há avaliações

- Foamglas Data Sheet EngDocumento2 páginasFoamglas Data Sheet EngAnonymous yQ7SQrAinda não há avaliações

- Brochure Foamglas EngDocumento36 páginasBrochure Foamglas EngAnonymous yQ7SQrAinda não há avaliações

- Am2 To Sii 413Documento18 páginasAm2 To Sii 413amit sharmaAinda não há avaliações

- Tables - TechnicalProperties - EN 10088 PDFDocumento24 páginasTables - TechnicalProperties - EN 10088 PDFeugenio.gutenbertAinda não há avaliações

- Tecnicas para Cartas de Amor U OdioDocumento4 páginasTecnicas para Cartas de Amor U OdioChristian Gabriel Stampacchio100% (16)

- Fluoraz - FEPM797 - TypicalPropsDocumento3 páginasFluoraz - FEPM797 - TypicalPropsAnonymous yQ7SQrAinda não há avaliações

- Stud-Type and Yoke-Type Track Rollers SpecsDocumento1 páginaStud-Type and Yoke-Type Track Rollers SpecsAnonymous yQ7SQrAinda não há avaliações

- Israeli Standard SI 413Documento30 páginasIsraeli Standard SI 413rrrrmmmm1100% (1)

- UG-37 F FactorDocumento7 páginasUG-37 F FactorjamesAinda não há avaliações

- Smath StudioDocumento47 páginasSmath StudiokeikunbrAinda não há avaliações

- Corrosion Comparision Between SS Steel in H2SO4Documento20 páginasCorrosion Comparision Between SS Steel in H2SO4Anonymous yQ7SQrAinda não há avaliações

- Actuator sizing calculation for Gate & Globe ValvesDocumento1 páginaActuator sizing calculation for Gate & Globe ValvesAnonymous yQ7SQrAinda não há avaliações

- Comparison of Recent Us Seismic CodesDocumento8 páginasComparison of Recent Us Seismic CodesAnonymous yQ7SQrAinda não há avaliações

- Zick AnalysisDocumento12 páginasZick AnalysisrksahayAinda não há avaliações

- UG-37 F FactorDocumento7 páginasUG-37 F FactorjamesAinda não há avaliações

- Flange DesignDocumento10 páginasFlange DesignAnonymous yQ7SQrAinda não há avaliações

- Tecnicas para Cartas de Amor U OdioDocumento4 páginasTecnicas para Cartas de Amor U OdioChristian Gabriel Stampacchio100% (16)

- EMCO Floating Suctions enDocumento2 páginasEMCO Floating Suctions enAnonymous yQ7SQrAinda não há avaliações

- Loads On FlangesDocumento16 páginasLoads On Flangesccoollest100% (3)

- Corrosion Comparision Between SS Steel in H2SO4Documento20 páginasCorrosion Comparision Between SS Steel in H2SO4Anonymous yQ7SQrAinda não há avaliações

- DoosanDocumento186 páginasDoosanAriadny Coelho100% (12)

- 32 Equipo de Termofusion TracStar900Documento1 página32 Equipo de Termofusion TracStar900coorporativo asociadosAinda não há avaliações

- Boiler Retrofit PDFDocumento44 páginasBoiler Retrofit PDFTim KuAinda não há avaliações

- M.E. Laws, Contracts and Ethics PresentationDocumento28 páginasM.E. Laws, Contracts and Ethics PresentationLeo Paulo Del Rosario0% (1)

- Promotion Policy at Indian Oil Corporation LTDDocumento43 páginasPromotion Policy at Indian Oil Corporation LTDShweta Pankhania100% (1)

- Water Cheat SheetDocumento4 páginasWater Cheat Sheet04dpt06f036Ainda não há avaliações

- Chapter 4 Combustion and Combustion Chamber Design NotesDocumento18 páginasChapter 4 Combustion and Combustion Chamber Design Notesahmed jemalAinda não há avaliações

- A V228 StationaryDocumento4 páginasA V228 StationaryMike FinazziAinda não há avaliações

- A Technical Report On (Final)Documento27 páginasA Technical Report On (Final)Nohid Chougle50% (2)

- Libro Partes D7E 48ADocumento371 páginasLibro Partes D7E 48ARamón ManglesAinda não há avaliações

- PACCAR MX 11 Coach Bus Engine Folder 2013Documento4 páginasPACCAR MX 11 Coach Bus Engine Folder 2013HASANAinda não há avaliações

- Catalog 2010 RetailDocumento13 páginasCatalog 2010 RetailmonibroAinda não há avaliações

- Coal Briquetting Technology GuideDocumento10 páginasCoal Briquetting Technology GuideAgrim KhatryAinda não há avaliações

- LNG International Seaborne Trade - MaroudiDocumento59 páginasLNG International Seaborne Trade - MaroudiKaterina Elikonida Maroudi67% (3)

- Auxiliary Engine SafetyDocumento4 páginasAuxiliary Engine Safetyasep achmad mAinda não há avaliações

- ENGINEERING DESIGN GUIDELINE-LPG Rev 01 Web PDFDocumento23 páginasENGINEERING DESIGN GUIDELINE-LPG Rev 01 Web PDFadeel_jamelAinda não há avaliações

- Engine Power: SAE J1995, Gross 156 KW (212 HP) @ 2,100 RPM Operational Weight: 17,640 KG - STD. Bucket Capacity (SAE) : 2.7 3.3 M (3.3 4.3 Cu - Yd)Documento8 páginasEngine Power: SAE J1995, Gross 156 KW (212 HP) @ 2,100 RPM Operational Weight: 17,640 KG - STD. Bucket Capacity (SAE) : 2.7 3.3 M (3.3 4.3 Cu - Yd)yewlimAinda não há avaliações

- Final Cits TractorDocumento22 páginasFinal Cits Tractorparveenrathee123Ainda não há avaliações

- Bio-Batteries: An Eco-Friendly Energy AlternativeDocumento25 páginasBio-Batteries: An Eco-Friendly Energy AlternativeShahid FarooqiAinda não há avaliações

- Piawaian PKK Yang Tidak Perlu Pengeluaran Sijil Perakuan BahanDocumento5 páginasPiawaian PKK Yang Tidak Perlu Pengeluaran Sijil Perakuan BahanAshiteru BestAinda não há avaliações

- Maintenance Engineering: Lubrication BasicsDocumento23 páginasMaintenance Engineering: Lubrication BasicsAhmed Zawad ShovonAinda não há avaliações

- Conversion of Crude Glycerol to BiodieselDocumento12 páginasConversion of Crude Glycerol to BiodieselIngJesusGutierrezZenilAinda não há avaliações

- Kiturami Turbo Oil Boiler User Manual and SpecificationsDocumento27 páginasKiturami Turbo Oil Boiler User Manual and SpecificationsAnonymous iDJw3bDEW2Ainda não há avaliações

- Top Drive Tesco 250 Hmis 475Documento2 páginasTop Drive Tesco 250 Hmis 475Draghiceanu VasileAinda não há avaliações

- Basics of FiltersDocumento22 páginasBasics of FiltersneilstarAinda não há avaliações

- Crude Oil Grades and Refinery TypesDocumento5 páginasCrude Oil Grades and Refinery TypesibrahimkhansahilAinda não há avaliações

- Wheel Loader HL740TM-3 Shop Manual PDFDocumento349 páginasWheel Loader HL740TM-3 Shop Manual PDFedgaralbe75% (4)

- PETRONASDocumento10 páginasPETRONASSARAVANAAinda não há avaliações

- Electrical Installation Can Interface Issue 10Documento93 páginasElectrical Installation Can Interface Issue 10Ricardo LunaAinda não há avaliações

- Explosion Deep Oil WellDocumento375 páginasExplosion Deep Oil WellVincent J. CataldiAinda não há avaliações