Escolar Documentos

Profissional Documentos

Cultura Documentos

Receiving Inspection of Pressure Vessels

Enviado por

ரமேஷ் பாலக்காடுDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Receiving Inspection of Pressure Vessels

Enviado por

ரமேஷ் பாலக்காடுDireitos autorais:

Formatos disponíveis

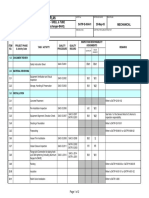

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Inspection of Pressure Vessels- External

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-D-2002

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) LAYOUT DRAWING NUMBER SCHEDULED INSPECTION DATE & TIME SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO INSPECTION LEVEL

EQUIPMENT DESCRIPTION REV. NO. PURCHASE ORDER NUMBER

EQPT CODE

SYSTEM ID.

PLANT NO.

EC / PMCC / MCC NO. QUANTITY INSP. MH's SPENT TRAVEL TIME

ACTUAL INSPECTION DATE & TIME SAUDI ARAMCO ACTIVITY NUMBER CONTRACTOR INSPECTION LEVEL

SAUDI ARAMCO USE ONLY

WORK PERMIT REQUIRED?

ITEM No. A1 A2 A3

ACCEPTANCE CRITERIA Vessel Safety Instruction Sheet (SIS), Form-2694-ENG, is available and has been approved. Non-material Requirements for Pressure Vessels (NMR-7919-1) was on site and verified per SAIC-D-2022. Type of head used is ASME 2:1-Ellipsoidal or ASME Hemispherical. One piece construction is used for heads of vessels with wall thickness greater than 50 mm, and for heads of vessels in cyclic, hydrogen or lethal services. Conical transition sections in thick wall vessels (t >50 mm) were provided by increased plate thickness.(Reinforcing rings prohibited) The quantities, sizes and ratings, facings, elevations and orientation of nozzles and manways conform with the Vessel Data Sheet

REFERENCE SAES-A-005, Par. 5.1 32-SAMSS-020, Par. 15.1 32-SAMSS-004, Par. 7.10.2 32-SAMSS-004, Par. 7.10.4 32-SAMSS-004, Par. 7.10.8 32-SAMSS-004, Par. 8.1.1

PASS

FAIL

N/A

RE-INSP DATE

A4

A5 A6

A7

Flange bolt holes stradle the normal horizontal and vertical centerlines of the vessels. The minimum projections for nozzles and manway necks, as measured from the outside surface of the shell or head to the face of a flange, shall meet the following reqmts: a) 6 inches for NPS 6 nozzles and smaller. 32-SAMSS-004, b) 8 inches for NPS 8 nozzles and larger and manways necks. Par. 8.1.2 c) For insulated vessels, projection shall be sufficient to allow bolting without interference with the insulation. d) For vessel drain connections and other connections, where a process stream is likely to be stagnant, the projection shall not exceed three times the connection nominal diameter. Flanges, nozzles & manways shall be as follows (all services): a) Forged steel long welding neck. b) Forged steel welding neck flange with seamless pipe, or rolled plate with 100% radiography. The bores of nozzle flanges shall match the nozzle neck bore. c) Studded nozzles and proprietary designs may be offered as alternatives provided their design is in accordance with the Codes and approved by the Saudi Aramco Engineer. d) Slip-on type flanges with seamless pipe nozzle necks or rolled plate with 100% radiography are permissible for vessels, other than those exempted in paragraph 1.5 of 32-SAMSS-004 spec, for only air and water services up to and including 121C (250F) design temperature and 1.7 MPA (245 psi) design pressure. Nozzles shall not be less than 2-inch NPS. Nozzles less than 2-inch NPS may only be used in utility services.

A8

32-SAMSS-004, Par. 8.1.3

A9

32-SAMSS-004, Par. 8.1.4

A10

Threaded or socket-welded connections are made with 3000# rating 32-SAMSS-004, welding outlet conforming to ASME B16.11 for 1 inch NPS and Par. 8.1.5 smaller vents, drains and instrument connections, except in in hydrogen, Par. 8.1.6 lethal, wet sour and caustic services. Par. 8.1.7 Threaded connections shall conform to ASME B1.20.1. Vessels in services other than Utility services shall be provided with a minimum 2-inch NPS flanged steam-out connection. 32-SAMSS-004, Par. 8.1.8

A11

Page 1 of 5

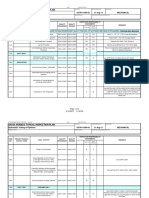

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Inspection of Pressure Vessels- External

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-D-2002

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No.

ACCEPTANCE CRITERIA The Vessel Manufacturer shall design nozzles that are required for the supporting of mechanical mixers and shall include the additional loads and dimensional tolerances as specified on the data sheet. As a minimum, four gusset plates for reinforcement of nozzles supporting mixers shall be provided. All nozzles and manways in thick wall vessels (T>50mm) are weld neck, long weld neck or contour forged with inside corner radius of 13 mm minimum. Flanged connections with stud bolts of diameter 1 inch and above have clearance dimensions that permits use of a stud and bolt tensioner device. Integrally reinforced openings (with no reinforcing pads) are provided for vessels under the following services and design conditions: 1) Cyclic services 2) Carbon steel with thickness 50 mm and greater 3) Low chrome steels with thickness 25 mm and greater 4) Openings which are 900 mm and larger with design temperatures 400C and greater. 5) Vessels with design temperatures above 425C 6) Hydrogen services Pressure ratings for standard flanges are per the following: 1) ASME B16.5 for flanges NPS 24 and smaller. 2) ASME B16.47, Series A for flanges larger than NPS 24.

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

A12

32-SAMSS-004, Par. 8.1.10 & Par 8.1.11

A13

32-SAMSS-004, Par. 8.1.12

A14

32-SAMSS-004, Par. 8.1.14

A15

32-SAMSS-004, Par.8.2.3

A16

32-SAMSS-004, Par. 8.3.2

A17

Gasket seating surfaces shall comply with the following: a) Spiral wound gasket = 125 to 250 AARH (except for hydrogen service. 32-SAMSS-004, Special care shall be taken to prevent damage. Par. 8.3.3 b) For spiral wound gaskets in hydrogen service, 125 to 150 AARH. c) The side-walls of rings joint flanges in all services, 63 AARH. d) For Nonmetallic gaskets, 250 to 500 AARH. All manways shall be circular. The manway covers shall be hinged or provided with handling davits as specified on the data sheet, according to PIP VEFV1100. Utilize sketches of three types allowed by PIPVEFV1116, PIPVEFV1117, & PIPVEFV1118 Weld Attachment Details meet the specific code requirements as listed for the various types utilized. API 510 Inspector may verify suspected substandard attachments against code reqmts. All supports and structural attachments (clips) are continuously welded to the vessel. Vessels supported on legs shall have a minimum of 4 legs and anchor bolts spaced equally. Skirts of vertical vessels have a minimum thickness of 6 mm. Vessel skirts are provided with access openings as follows: a. Minimum of 500 mm diameter opening for vessels with diameters equal to and larger than 1200 mm. b. Minimum of one half of the vessel diameter for vessels with less than 1200 mm. 32-SAMSS-004, Par. 8.4.2

A18

A19

32-SAMSS-004, Par. 8.5 32-SAMSS-004, 10.1.3. & 11.1.2 32-SAMSS-004, Par. 10.4.5 32-SAMSS-004, Par. 10.2.3

A20

A21 A22

A23

32-SAMSS-004, Par. 10.2.6

A24

The bottom head-to-shell weld in thick wall (t>50mm) vessels and 32-SAMSS-004, vessels in cyclic, hydrogen or lethal services are not covered by the skirt. Par. 10.2.9

Page 2 of 5

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Inspection of Pressure Vessels- External

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-D-2002

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

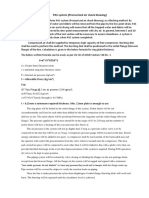

ITEM No. A25

ACCEPTANCE CRITERIA Horizontal vessel are supported by two saddles. The vessel is fixed at one saddle support and free to slide at the other saddle. Wear pads supplied at the junction of the saddle of horizontal vessels conforms with all of the following: a) A minimum thickness of 10 mm. b) Continuously welded to the shell. c) All corners are rounded to a 50 mm minimum radius, and d) One inch NPT vent hole at the lowest elevation. The anchor bolt holes on the sliding-end saddle are slotted. Critical to allow for Thermal expansion. Anchor bolts straddle vessel centerlines on the north-south, east- west axes. Anchor bolts shall not be less than 19 mm minimum nominal diameter.

REFERENCE 32-SAMSS-004, Par. 10.3.1

PASS

FAIL

N/A

RE-INSP DATE

A26

32-SAMSS-004, Par. 10.3.4

A27 A28

32-SAMSS-004, Par. 10.3.5 32-SAMSS-004, Par. 10.4.2 32-SAMSS-004, Par. 10.4.3

A29

A30

Vessels supported on skirts, lugs or legs shall be provided with an even 32-SAMSS-004, number of anchor bolts with a minimum of four anchor bolts. Par. 10.4.5 Vessels supported on saddles have an even number of anchor bolts with & Par. 10.4.6 a minimum of two anchor bolts per saddle. Vertical vessels, which are externally insulated, are provided with insulation supports in accordance with SAES-N-001. The bottom heads of vertical vessels that are externally insulated are provided with 12 mm blank nuts. Blank nuts are welded on edge and located on 300 mm square centers. Vertical vessels, which are not externally insulated, shall be provided with a 5 mm thick steel weather cap on the skirt to provide a flashing for fire-proofing. Pressure vessels have grounding lug connection welded to the vessel support in accordance with PIP VEFV1100. A davit for the lifting of equipment shall be supplied when specified on the data sheet & shall be in accordance with PIP VEFV1100. Spiral wound gaskets are flexible graphite filled and made of the following materials: 1) For vessels with design metal temperatures from -100C to 0C: Type 304 or 316 Stainless Steel (SS) windings with solid Type 304 or 316 Stainless Steel outer centering rings. 2) For vessels with design metal temperatures from 1C to 425C: Type 304 or 316 SS windings with solid carbon steel outer centering rings. 3) For vessels with design metal temperatures above 425C: Type 321 or 347 SS windings with solid Type 304 or 316 for inner and outer centering rings. 4) For vessels in vacuum or catalyst services, inner ring shall be either Type 304 or 316 Stainless Steel (SS). External welded attachment pads have their corners rounded to a minimum radius of 50 mm radius and are fully seal-welded. Arc strikes, gouges, and other indications of careless workmanship (such as surface porosity, uneven weld profiles, and undercut) were removed by grinding. 32-SAMSS-004, Par. 11.2.2 32-SAMSS-004, Par. 11.2.3

A31

A32

A33

32-SAMSS-004, Par. 11.2.4 32-SAMSS-004, Par. 11.4 32-SAMSS-004, Par. 11.5

A34

A35

A36

32-SAMSS-004, Par. 12.3.1

A37

32-SAMSS-004, 13.2.11 SAES-W-010, Par. 11.6

A38

Page 3 of 5

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Inspection of Pressure Vessels- External

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-D-2002

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No. A39

ACCEPTANCE CRITERIA All temporary welded attachments or temporary tack welds were ground off. External attachment pads are vented through a " NPT telltale hole. Vent holes shall be plugged with grease, wooden plugs or other nonpressure retaining material to prevent moisture from entering.

REFERENCE SAES-W-010, Par. 11.7 32-SAMSS-004, Par. 13.2.12

PASS

FAIL

N/A

RE-INSP DATE

A40

A41

The nameplate is stamped or engraved with the following information as minimum per ASME Sec VIII, Par. UG-116: a) Applicable ASME Stamp Symbol b) Name of Manufacturer c) Max. Allowable Working Pressure (MAWP) d) Minimum Design Metal Temperature (MDMT) 32-SAMSS-004, e) Manufacturer's Serial Number Par. 17.1& 17.3, f) Year Built 17.6 g) Type of Construction Used h) Category of Radiography i) Indication for Post Weld Heat treated Vessel (HT or PHT) j) Additional markings for internally coated vessels per 34-SAMSS-04, Par. 17.6 are, the Saudi Aramco Painting System Numbers, type of coating, brand name, and date of application. Nameplate of vessels are installed as follows: a) Nameplates and nameplate mounting brackets are not covered by insulation and are easily readable from grade or a platform. b) Brackets extend from the outside of vessel to clear insulation, and with sufficient access for surface preparation, and painting. c) Nameplates are 3-mm minimum thickness and manufactured from type 304 stainless steel or Monel and continuously welded to the mounting bracket according to PIP VEFV1100. d) The mounting bracket material shall conform to Table 1 of 34-SAMSS-004. The brackets are continuously seal welded and positioned such as not to allow for collection of moisture or rain. External Shell and attachments showed no dents or physical damages. External coating has no physical damage (gouge, cracks, runs, sags, drips, dry spray, porous, foreign matter) or pre-mature breakdown/rusting and meet the DFT requirements as follows: a) APCS-1A&B -----275-375 microns b) APCS-1C ---------250-375 microns c) APCS-1D&F -----190-315 microns d) APCS-1E ---------175-315 microns e) APCS-2A/B/C ---275-375 microns f) APCS-1D ---------200-250 microns g) APCS-4 ----------115-180 microns h) APCS-22 ---------300-400 microns i) Others ------------- as specified by the Purchase Order

A42

32-SAMSS-004, Par. 17.3, 17.4,17.5

A43

SAES-H-100

A44

SAES-H-100

Page 4 of 5

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - December 2005)

Rev 2 SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Inspection of Pressure Vessels- External

PROJECT TITLE

31-Dec-05 DATE APPROVED QR NUMBER

SAIC-D-2002

WBS / BI / JO NUMBER

1-Dec-06

MECH-

CONTRACTOR / SUBCONTRACTOR

ITEM No.

ACCEPTANCE CRITERIA For Vessels that were insulated, insulations are not damaged and meets the following: a) Stainless steel, galvanized steel, or aluminized steel jackets for insulation systems that require fireproofing b) Aluminum metal jackets for non-fire hazardous areas within process plant battery limits. c) Elastomeric coatings used for weatherproofing on plastic foam and cellular glass when there is no requirement for metal jackets. d) Corrugated jacketing shall not be used to cover cold insulation. Removable insulated covers shall be provided for manways and designed so that their removal shall not disturb the surrounding permanently fixed insulation. Removable insulation plugs are provided to permit on-stream ultrasonic inspection when required by the operating proponent. Plugs shall be vapor tight, ultra violet resistant and be such that they can be opened & reclosed without disturbing adjacent insulation. All metallic protrusions through insulation systems are caulked with a sealant.

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

A45

SAES-N-001, Par. 7.7.2

A46

SAES-N-001, Par. 8.2.1

A47

SAES-N-001, Par. 8.2.2 SAES-N-001, Par. 7.4.4

A48

REMARKS:

NOTES: 1. Utilize any referenced PIPs & 32-SAMSS-004 with this checklist during checks. REFERENCE DOCUMENTS: 1. SAES-A-005, Safety Instruction Sheet (28 February 2005) 2- 32-SAMSS-004 -- Manufacture of Pressure Vessels, 30 March 2005 3- SAES-W-010 -- Welding Requirements for Pressure Vessels, 30 June 2002 4- SAES-N-001 -- Basic Criteria, Industrial Insulation, 30 July 2003 5- SAES-H-101 -- Approved Protective Coating Systems, 28 September 2005 6- ASME -- Section VIII, 2005

Contractor / Third-Party

Construction Representative*

Work is Complete and Ready for Inspection: Name, Initials and Date: Name, Initials and Date:

Saudi Aramco

PMT Representative

T&I Witnessed QC Record Reviewed Work Verified

QC Inspector

Performed Inspection Name, Initials and Date: Work / Rework May Proceed

PID Representative

T&I Witnessed Name, Initials and Date: QC Record Reviewed Work Verified

QC Supervisor

Quality Record Approved: Name, Sign and Date: *Person Responsible for Completion of Quality Work / Test

Proponent and Others

Name, Organization, Initials and Date: T&I Witnessed QC Record Reviewed Work Verified

Y = YES

N = NO F = FAILED

Page 5 of 5

Você também pode gostar

- SAUDI ARAMCO PRESSURE VESSEL INSPECTION CHECKLISTDocumento2 páginasSAUDI ARAMCO PRESSURE VESSEL INSPECTION CHECKLISTnisha_khanAinda não há avaliações

- 32 Samss 005Documento33 páginas32 Samss 005naruto256100% (1)

- 1 SATIP-E-004-01 H Exc Installation-Shell and Tube-Rev1Documento2 páginas1 SATIP-E-004-01 H Exc Installation-Shell and Tube-Rev1Anonymous S9qBDVkyAinda não há avaliações

- Saudi Aramco Inspection ChecklistDocumento3 páginasSaudi Aramco Inspection ChecklistAbdul HannanAinda não há avaliações

- Satr W 2012Documento1 páginaSatr W 2012Mohammed Hamed BaganAinda não há avaliações

- SATR-L-2001 Rev. 5Documento10 páginasSATR-L-2001 Rev. 5Neelam AhmadAinda não há avaliações

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDocumento2 páginasSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh100% (1)

- Design and fabrication requirements for scraper trapsDocumento13 páginasDesign and fabrication requirements for scraper trapsJeck MaquitedAinda não há avaliações

- Saudi Aramco Test Report: PWHT Report Form SATR-W-2005 31-Aug-11Documento1 páginaSaudi Aramco Test Report: PWHT Report Form SATR-W-2005 31-Aug-11Mohammed Hamed BaganAinda não há avaliações

- 77 - 103Documento13 páginas77 - 103raja100% (2)

- SAIC-A-2009 Rev 2Documento5 páginasSAIC-A-2009 Rev 2ரமேஷ் பாலக்காடுAinda não há avaliações

- PMS-V32-Ball Valves - FlangedDocumento2 páginasPMS-V32-Ball Valves - FlangedMB Azharudeen100% (1)

- Pip PNSM0105Documento6 páginasPip PNSM0105romerobernaAinda não há avaliações

- Insp Checklist - Piping AlignmentDocumento1 páginaInsp Checklist - Piping AlignmentRickesh NunkooAinda não há avaliações

- 34 Samss 611Documento8 páginas34 Samss 611naruto256Ainda não há avaliações

- SAIC-K-2026 Rev 0Documento2 páginasSAIC-K-2026 Rev 0philipyapAinda não há avaliações

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Documento2 páginasSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan MohammadAinda não há avaliações

- Materials System SpecificationDocumento7 páginasMaterials System Specificationaanouar77Ainda não há avaliações

- Eil Spec For PmiDocumento8 páginasEil Spec For Pmisachinchavan1981Ainda não há avaliações

- Satip - S-050-01Documento4 páginasSatip - S-050-01LIJINAinda não há avaliações

- I Object: Repair Procedure For Tank BottomDocumento6 páginasI Object: Repair Procedure For Tank BottomZouhair BenmabroukAinda não há avaliações

- Saudi Aramco Test ReportDocumento7 páginasSaudi Aramco Test ReportziaAinda não há avaliações

- 1 Checklists Index (Dec 2006-Rev 2 - A SATIP)Documento2 páginas1 Checklists Index (Dec 2006-Rev 2 - A SATIP)احمد حسنAinda não há avaliações

- III. Applicable Codes & Standards for Aramco ProjectsDocumento5 páginasIII. Applicable Codes & Standards for Aramco ProjectsZain Ali KidwaiAinda não há avaliações

- Inspection Procedure for Determining Retirement Thickness of PipingDocumento6 páginasInspection Procedure for Determining Retirement Thickness of Pipingmalika_00Ainda não há avaliações

- SAES-N-001 PDF Download - Basic Criteria, Industrial Insulation - PDFYARDocumento7 páginasSAES-N-001 PDF Download - Basic Criteria, Industrial Insulation - PDFYARZahidRafique100% (1)

- PSV FarrisDocumento20 páginasPSV FarrisIkhsan Arif100% (1)

- Vessel/S&T Heat Exchanger Standard Details (Metric Units)Documento7 páginasVessel/S&T Heat Exchanger Standard Details (Metric Units)Jamil AhmadAinda não há avaliações

- 34 Samss 711 PDFDocumento26 páginas34 Samss 711 PDFFlorin Daniel AnghelAinda não há avaliações

- Spring Support Inspection & MaintenanceDocumento4 páginasSpring Support Inspection & MaintenanceSonaliAinda não há avaliações

- SAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsDocumento2 páginasSAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsAnonymous S9qBDVkyAinda não há avaliações

- Satip A 004 03Documento3 páginasSatip A 004 03Anonymous 4e7GNjzGW100% (1)

- Saudi Aramco Air Cooled Heat Exchanger Inspection PlanDocumento2 páginasSaudi Aramco Air Cooled Heat Exchanger Inspection PlanAnonymous S9qBDVkyAinda não há avaliações

- Saic L 2008 PDFDocumento4 páginasSaic L 2008 PDFHesham HelalAinda não há avaliações

- P P NG Abbrev at Ons: AFC A F CDocumento11 páginasP P NG Abbrev at Ons: AFC A F COlajide AkekeAinda não há avaliações

- Saudi Aramco Test ReportDocumento2 páginasSaudi Aramco Test ReportEswari AnandAinda não há avaliações

- SAIC-L-2136 Rev 0Documento3 páginasSAIC-L-2136 Rev 0philipyapAinda não há avaliações

- SAIC-A-2015 Saudi Aramco Inspection ChecklistDocumento8 páginasSAIC-A-2015 Saudi Aramco Inspection Checklistkarthi51289Ainda não há avaliações

- Piping Components Spec for Low Temp ServiceDocumento6 páginasPiping Components Spec for Low Temp ServiceFlorante NoblezaAinda não há avaliações

- SAIC-D-2006 Rev 2Documento2 páginasSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுAinda não há avaliações

- CSWIP Plant Inspection - Levels 1,2 and 3: An Internationally Recognised Certification of CompetenceDocumento1 páginaCSWIP Plant Inspection - Levels 1,2 and 3: An Internationally Recognised Certification of Competenceafiq ahmadAinda não há avaliações

- SAIC-D-2012 Rev 2Documento4 páginasSAIC-D-2012 Rev 2ரமேஷ் பாலக்காடுAinda não há avaliações

- Saes A 206Documento16 páginasSaes A 206Malcolm F Beall100% (1)

- Dokumen - Tips Saep-1135pdfDocumento12 páginasDokumen - Tips Saep-1135pdfArsalan HaiderAinda não há avaliações

- Inspection Procedure EDRDocumento8 páginasInspection Procedure EDRaamirtec301Ainda não há avaliações

- 01-SAMSS-049 Reinforced Thermoset Resin (RTR) Pipe, Fittings and Adhesive Packing, Handling, Transportation and Storage 21-FEB-2012 PDFDocumento8 páginas01-SAMSS-049 Reinforced Thermoset Resin (RTR) Pipe, Fittings and Adhesive Packing, Handling, Transportation and Storage 21-FEB-2012 PDFasiqnaAinda não há avaliações

- Piping Reinstatement Checklist: Form TP-09Documento1 páginaPiping Reinstatement Checklist: Form TP-09minhnnAinda não há avaliações

- Saudi Aramco Inspection ChecklistDocumento6 páginasSaudi Aramco Inspection ChecklistAnonymous 4e7GNjzGWAinda não há avaliações

- Inspection and Testing of Piping Systems GuideDocumento44 páginasInspection and Testing of Piping Systems Guideiran1362Ainda não há avaliações

- Welker 2Documento2 páginasWelker 2faradbAinda não há avaliações

- Pressurized Air Shock BlowingDocumento3 páginasPressurized Air Shock BlowingEmir PayAinda não há avaliações

- Mechanical Completion Procedure for HPCL Visakh ProjectDocumento18 páginasMechanical Completion Procedure for HPCL Visakh ProjectLegend AnbuAinda não há avaliações

- SAIC-A-2008 Rev 0Documento3 páginasSAIC-A-2008 Rev 0Kristine Caye DatarioAinda não há avaliações

- Jacobs (HPCL) Standard On Pressure Vessel & He PDFDocumento52 páginasJacobs (HPCL) Standard On Pressure Vessel & He PDFAnit100% (1)

- SAIC-D-2009 Rev 2Documento6 páginasSAIC-D-2009 Rev 2ரமேஷ் பாலக்காடுAinda não há avaliações

- MM ZTK 1B WPX MEC DTS 0013 Rev.C1 Diesel Oil Filter With InternalDocumento9 páginasMM ZTK 1B WPX MEC DTS 0013 Rev.C1 Diesel Oil Filter With Internalpragatheesk100% (1)

- SAIC-D-2022 Rev 2Documento5 páginasSAIC-D-2022 Rev 2ரமேஷ் பாலக்காடுAinda não há avaliações

- WCDocumento6 páginasWCSheraz TariqAinda não há avaliações

- Saudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 MechDocumento3 páginasSaudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 Mechரமேஷ் பாலக்காடுAinda não há avaliações

- Technical Notes and Specifications Part CDocumento29 páginasTechnical Notes and Specifications Part Cهيمنت بيلوديا100% (1)

- Online Reg Certfct PDF PDFDocumento2 páginasOnline Reg Certfct PDF PDFரமேஷ் பாலக்காடுAinda não há avaliações

- SAIC-D-2022 Rev 2Documento5 páginasSAIC-D-2022 Rev 2ரமேஷ் பாலக்காடுAinda não há avaliações

- Saudi Computer Exam For QC WeldingDocumento4 páginasSaudi Computer Exam For QC Weldingரமேஷ் பாலக்காடு100% (1)

- Online Reg Certfct PDF PDFDocumento2 páginasOnline Reg Certfct PDF PDFரமேஷ் பாலக்காடுAinda não há avaliações

- Computer Kerala - 4 Folder LockDocumento2 páginasComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுAinda não há avaliações

- Responabilities of A Welding InspectorDocumento13 páginasResponabilities of A Welding Inspectorரமேஷ் பாலக்காடுAinda não há avaliações

- Duties of A Welding Inspector 1Documento12 páginasDuties of A Welding Inspector 1ரமேஷ் பாலக்காடுAinda não há avaliações

- SA JER PUAAA SKEC 50 3004 - Packing, Marking and Shipping Inst. - Rev.02Documento62 páginasSA JER PUAAA SKEC 50 3004 - Packing, Marking and Shipping Inst. - Rev.02ரமேஷ் பாலக்காடுAinda não há avaliações

- Codes Standards and SpecificationsDocumento15 páginasCodes Standards and Specificationsரமேஷ் பாலக்காடுAinda não há avaliações

- Welding Processes ModuleDocumento27 páginasWelding Processes Moduleரமேஷ் பாலக்காடு100% (1)

- Air Carbon Arc Gouging: ElectrodeDocumento1 páginaAir Carbon Arc Gouging: Electrodeரமேஷ் பாலக்காடுAinda não há avaliações

- Computer Kerala - 4 Folder LockDocumento2 páginasComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுAinda não há avaliações

- Gouging 01Documento2 páginasGouging 01ரமேஷ் பாலக்காடுAinda não há avaliações

- Pew205 Slide ShowDocumento23 páginasPew205 Slide Showரமேஷ் பாலக்காடுAinda não há avaliações

- SAIC-E-2001 Rev 2Documento7 páginasSAIC-E-2001 Rev 2ரமேஷ் பாலக்காடுAinda não há avaliações

- SAIC-D-2023 Rev 2Documento2 páginasSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுAinda não há avaliações

- Vedic Maths TutorialDocumento12 páginasVedic Maths TutorialNitin Jain100% (15)

- SAIC-D-2023 Rev 2Documento2 páginasSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுAinda não há avaliações

- SAIC-E-2002 Rev 2Documento7 páginasSAIC-E-2002 Rev 2ரமேஷ் பாலக்காடுAinda não há avaliações

- Practical Guide To Pressure Vessel Manufacturing - SUNIL PULLARCOTDocumento362 páginasPractical Guide To Pressure Vessel Manufacturing - SUNIL PULLARCOTrodrigoperezsimoneAinda não há avaliações

- 0 Wis10 Contents ListDocumento1 página0 Wis10 Contents ListSangram RoutarayAinda não há avaliações

- API 510 Examination Sample ItemsDocumento3 páginasAPI 510 Examination Sample ItemsMagira PasaribuAinda não há avaliações

- Computer Kerala - 4 Folder LockDocumento2 páginasComputer Kerala - 4 Folder Lockரமேஷ் பாலக்காடுAinda não há avaliações

- SAIC-F-2007 Rev 2Documento1 páginaSAIC-F-2007 Rev 2ரமேஷ் பாலக்காடுAinda não há avaliações

- Saudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 MechDocumento4 páginasSaudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 Mechரமேஷ் பாலக்காடுAinda não há avaliações

- SAIC-D-2023 Rev 2Documento2 páginasSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுAinda não há avaliações

- Saudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 MechDocumento3 páginasSaudi Aramco Inspection Checklist: Inspection of Tank Trim Installation SAIC-D-2020 1-Dec-06 Mechரமேஷ் பாலக்காடுAinda não há avaliações

- Saudi Aramco Inspection Checklist: SAIC-D-2018 1-Dec-06 Mech-Insp of Under-Tank Leak Detection, Sub-Grade ProtectionDocumento1 páginaSaudi Aramco Inspection Checklist: SAIC-D-2018 1-Dec-06 Mech-Insp of Under-Tank Leak Detection, Sub-Grade Protectionரமேஷ் பாலக்காடுAinda não há avaliações

- SAIC-D-2006 Rev 2Documento2 páginasSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுAinda não há avaliações

- SAIC-D-2006 Rev 2Documento2 páginasSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுAinda não há avaliações

- Is 12466 2012 PDFDocumento11 páginasIs 12466 2012 PDFlokeshras12Ainda não há avaliações

- FILL IN THE GAPS - OdtDocumento74 páginasFILL IN THE GAPS - OdtMateu Marimon RomanAinda não há avaliações

- Final Presentation 1Documento11 páginasFinal Presentation 1api-654901704Ainda não há avaliações

- Penguin - Test Your Vocabulary 2Documento64 páginasPenguin - Test Your Vocabulary 2Iwai Moto100% (1)

- (Modern Concrete Technology) Alva Peled, Arnon Bentur, Barzin Mobasher-Textile Reinforced Concrete-CRC Press (2017) PDFDocumento490 páginas(Modern Concrete Technology) Alva Peled, Arnon Bentur, Barzin Mobasher-Textile Reinforced Concrete-CRC Press (2017) PDFLong Ct100% (3)

- China Apparel Retail 71782Documento39 páginasChina Apparel Retail 71782Kyle Osbert TolentinoAinda não há avaliações

- Wooden Gear Clock Instructions 10-2 PDFDocumento78 páginasWooden Gear Clock Instructions 10-2 PDFLuca Alberti50% (2)

- Letter of Support - Written by Natalie PottsDocumento2 páginasLetter of Support - Written by Natalie Pottsapi-240203048Ainda não há avaliações

- Queen Movie ScriptDocumento137 páginasQueen Movie ScriptJyoti Khatri85% (39)

- Bittersweet Jul 16 2013Documento490 páginasBittersweet Jul 16 2013imogeniousAinda não há avaliações

- Great Expectations: Links To Behind The Scenes at The Museum and The Wife of Bath Chapters 1 - 3Documento29 páginasGreat Expectations: Links To Behind The Scenes at The Museum and The Wife of Bath Chapters 1 - 3Jonathan WarrenAinda não há avaliações

- Renzo Novatore The Dream of My AdolescenceDocumento4 páginasRenzo Novatore The Dream of My AdolescenceGuilherme AmorimAinda não há avaliações

- LZ457A New Three StepDocumento2 páginasLZ457A New Three StepAndre Medeiros AlmeidaAinda não há avaliações

- Quilt Fest Quilt Scene 2011 TOCDocumento2 páginasQuilt Fest Quilt Scene 2011 TOCInterweave11% (9)

- SOP Pines Tube Bender #10021234567891123456Documento3 páginasSOP Pines Tube Bender #10021234567891123456saturnelAinda não há avaliações

- Áo Len Kẻ NgangDocumento5 páginasÁo Len Kẻ Ngangbanhbeo1992002Ainda não há avaliações

- Charterhouse November Antiques Silver and Jewellery CatalogueDocumento32 páginasCharterhouse November Antiques Silver and Jewellery CatalogueabromellAinda não há avaliações

- Sexual Desire ChecklistDocumento31 páginasSexual Desire Checklistporq85% (13)

- Sourcebook 6 - Southern Cross (v0.7)Documento66 páginasSourcebook 6 - Southern Cross (v0.7)James Myers83% (6)

- 12th English Mar 1 Live PDF - Synonyms & AntonymsDocumento9 páginas12th English Mar 1 Live PDF - Synonyms & AntonymshasiniharsonmurugananthamAinda não há avaliações

- Alyssa Brooks - Dragon's DesireDocumento52 páginasAlyssa Brooks - Dragon's Desired4d42937100% (2)

- Stetson MKTG PlanDocumento66 páginasStetson MKTG Planapi-198961485Ainda não há avaliações

- Product InnovationIn The Global FashionDocumento158 páginasProduct InnovationIn The Global Fashion娜杨Ainda não há avaliações

- Executive Shirt Company Inc Case StudyDocumento14 páginasExecutive Shirt Company Inc Case StudyPuneet AgarwalAinda não há avaliações

- My Geeky Shelf Miss GrinchDocumento10 páginasMy Geeky Shelf Miss Grinchmalu diaz67% (3)

- Presentacion Estandar Gps AchsDocumento112 páginasPresentacion Estandar Gps AchsFrancisco100% (1)

- Chapter-6 Critical Analyais Of: 2 StatesDocumento34 páginasChapter-6 Critical Analyais Of: 2 StatesShruthee KAinda não há avaliações

- Gawad Manlilikha NG BayanDocumento23 páginasGawad Manlilikha NG BayanLhen Unico Tercero - Borja50% (4)

- IPS Puducherry 2012 PDFDocumento30 páginasIPS Puducherry 2012 PDF1l0veuAinda não há avaliações

- Lavadora Manual Del Usuario Modelo WFSL 1532EKDocumento76 páginasLavadora Manual Del Usuario Modelo WFSL 1532EKIsrael MendietaAinda não há avaliações