Escolar Documentos

Profissional Documentos

Cultura Documentos

ADSS-EKE 80 (37-72c) E

Enviado por

Tình Tử TếDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

ADSS-EKE 80 (37-72c) E

Enviado por

Tình Tử TếDireitos autorais:

Formatos disponíveis

VINA OFC

VINA-OFC., JSC

ISSUED : Sept. 2013 PAGE : 1 OF 6

FOR Single Mode of All Dielectric Self Supporting Optical Fiber Cable (ADSS Type) (37-72 cores)

[ Span length: 80m ]

Prepared by ___________________

TRAN DINH HUY

Checked by ____________________

PHAN VAN TUE

Approved by ____________________

BOD

VINA OFC

VINA-OFC., JSC

SPEC : SP13-EKE8-0612-CB ISSUED : Sept, 2013 REV. : 1

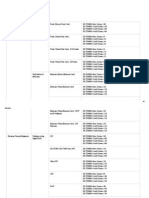

1. SCOPE 1.1 Application This specification covers the general requirements of self-supporting cable for aerial application (ADSS cable). 1.2 Cable Description Color coded fibers, filled color coded loose tubes, PE filler (if necessary), swelling water blocking yarn, SZ form -stranded around the dielectric central strength member (FRP), water blocking tape, inner PE jacket, outer strength member (Aramid yarn - Kevlar) and outer PE jacket. 2. OPTICAL FIBER 1) Fiber type: Matched clad fiber 2) The optical, geometrical, mechanical and environmental performance of the optical fiber shall be in accordance with Table 1 below. Table 1. The Optical and Geometrical Performance of Single Mode Fiber (ITU-T G.652D) ITEMS at 1310nm at 1383nm 3nm at 1550nm at 1310nm-1625nm at 1530nm-1625nm UNITS SPECIFICATION 0.37 0.39 0.24 0.39 0.275 3.5 at 1310nm 18 at 1550nm 22 at 1625nm 1300 ~ 1324 0.089 0.2 1260 1100~1280 0.10 at 1310nm & 1550nm 9.2 0.5 at 1310nm 10.5 1.0 at 1550nm 0.5 125 1.0 1.0 0.05 at 1310nm 0.05 at 1550nm 240 5 255 10 12

PAGE 2 OF 6

Attenuation

dB/km

Chromatic Dispersion Zero Dispersion Wavelength Zero Dispersion Slope Polarization Mode Dispersion (PMD) Cable cut-off Wavelength (cc) Fiber cut-off Wavelength (c) Point Discontinuity Mode Field Diameter Core-Clad Concentricity Cladding Diameter Cladding Non-circularity Attenuation vs. Bending (60mm x 100turns) Coating Diameter (Uncolored) Coating Diameter colored Coating Cladding Concentricity error

ps/nm.km nm ps/nm2.km ps/(km)1/2 nm dB

m m m %

dB

m m m

VINA OFC

VINA-OFC., JSC

SPEC : SP13-EKE8-0612-CB ISSUED : Sept, 2013 REV. : 1

3. CABLE CONSTRUCTION 3.1 Cross-sectional Drawing of Cable Colored Loose Tube Colored Fiber Thixotrophic Jelly Water Blocking Tape Outer Strength Member(Kevlar) Inner Sheath (HDPE) Outter Sheath (HDPE) Strength Member (FRP) Swellable Water Blocking Yarn Filler (if necessry) Ripcord Table 2 Diameter, Composition and Weight Nominal Minimum Bending Radius (mm) No. of Approx. Cable Weight Cable Diameter Fiber (kg/km) Under Load No Load (mm) 37-72 13.3 0.3 140-143 266 133 The construction of the cable shall be in accordance with Table 3 below. Table 3. Construction of the Cable ITEMS Number of Fibers Number of Fibers per Tube Loose Buffer Tube Material Diameter DESCRIPTION Max 72C Max. 12 Fibers PBT (Polybutylene Terephthalate) 2.6mm 0.1mm Thixotropic Jelly Compound Polyethylene rod FRP 2.7mm 0.1mm Water Blocking SwellableYarn Water Blocking Tape SZ direction Black HDPE (Density 0.941-0.946) 1.0mm 0.1mm Kevlar of Aramid Yarn Black HDPE (Density 0.941-0.946) 1.5mm 0.1mm

Filling Compound in Loose Buffer Tube Filler (if necessary) Central Strength Member Material Diameter

Water Blocking between Loose Tubes Core Wrapping Tape Stranding Inner Jacket Outer Strength Member Outer Jacket Material Thickness Material Thickness

4. FIBER AND LOOSE BUFFER TUBE IDENTIFICATION

PAGE 3 OF 6

VINA OFC

VINA-OFC., JSC

SPEC : SP13-EKE8-0612-CB ISSUED : Sept, 2013 REV. : 1

The color code of the loose buffer tubes and the individual fibers within each loose buffer tube shall be in accordance with Table 4 below. Table 4. The Color Code of the Individual Fibers and Loose Buffer Tubes (TIA/EIA-598-A) No. 1 2 3 4 5 6 Color Blue Orange Green Brown Grey White No. 7 8 9 10 11 12 Color Red Black Yellow Violet Rose (Pink) Aqua (Light Blue)

5. PHYSICAL / MECHANICAL / ENVIRONMENTAL PERFORMANCE AND TESTS 5.1 Temperature Range For the cables covered by this specification, the following temperature ranges apply: - Operation - Storage/Shipping 5.2 Tensile of the Cable Tensile strength: Installation: 4.5 kN Operation : 3 kN 5.3 Mechanical and Environmental Performance of the Cable The mechanical and environmental performance of the cable shall be in accordance with Table 5 below. Unless otherwise specified, all attenuation measurements required in this section shall be performed at 1550nm for single mode fiber Table 5. The Mechanical and Environmental Performance of the Cable ITEMS TEST METHOD AND ACCEPTANCE CRITERIA # Test method: IEC 60794-1-2 Method E1 - Mandrel diameter: 20D (D = cable diameter) - Length under tension: 50 m - Max tensile load shall be 3kN. # Acceptance Criteria - Attenuation increment: 0.1 dB - No jacket cracking and fiber breakage # Test method: IEC 60794-1-2 Method E3 - Applied load: 2500 N/100 mm - No of points: 1 point # Acceptance Criteria after completion of the test - Attenuation Increment: 0.1 dB - No jacket cracking and fiber breakage : -40 C to +80C : -40 C to +75C

Tensile Strength

Compression Test

PAGE 4 OF 6

VINA OFC

VINA-OFC., JSC

SPEC : SP13-EKE8-0612-CB ISSUED : Sept, 2013 REV. : 1

Impact resistance

Repeated Bending

Twisted Test

Temperature Cycling

Compound Flow (Drip)

# Test method: IEC 60794-1 Method E4 - Height of impact: 1 m - Drop hammer mass: 1 kg - Radius impact surface: 300 mm - No. of impact per point: 1 time - No. of impact points: 3 points (500mm interval) # Acceptance Criteria after completion of the test - Attenuation Increment : 0.1 dB - No jacket cracking and fiber breakage # Test method: IEC 60794-1-2 Method E6 - Sheave diameter: 15D (D = cable diameter) - Flexing speed: Minimum 12 cycles/minute - Applied mass: 3kg - No. of flexing cycles: 50 cycles # Acceptance Criteria after completion of the test - Attenuation Increment: 0.1 dB - No jacket cracking and fiber breakage # Test method: IEC 60794-1-2-E7 - Cable length twisted: 2m - No. of twist cycles: 10 cycles - Twist angle: 180 # Acceptance Criteria after the completion of the test - Attenuation Increment: 0.1 dB - No jacket cracking and fiber breakage # Test method: IEC 60794-1-2 Method F1 - Cable length: at least 500m - At least 6 fibers shall be spliced and tested. - Temperature cycling schedule : 23C -30C 70C -30C 70C - Soak time at each temperature: 24 hours # Acceptance Criteria - Attenuation increment: 0.02 dB/km # Test method: IEC 60794-1- Method E14 -.Length of specimen: 0.3m - Test time: 24 hours - Test temperature: 60C # Acceptance Criteria - No compound driped from LT - No fibers moved # Test method: IEC 60794-1-2 Method F5 - Length of specimen: 3m. -.Height of pressure head: 1m -.Test time: 24 hours # Acceptance Criteria - No leakage through the open cable end

Water Penetration

PAGE 5 OF 6

VINA OFC

VINA-OFC., JSC

SPEC : SP13-EKE8-0612-CB ISSUED : Sept, 2013 REV. : 1

6. PACKING AND MARKING 6.1 Cable and Length Marking The sheath shall be marked with white characters at intervals of one meter with following information. Other marking is also available if requested by customer. 1) 2) 3) 4) Cable type, code and Fiber counts (ex, "ADSS-EKE SM 48FO") Name of the manufacturer (VINA-OFC) Year of manufacture (201x) Length marking

OFC EKE80 VINA-OFC 48FO 2013 002M

001M

6.2 Cable Packing 6.2.1 Standard length of cable shall be 4,000m 10%. Other cable length is also available if requested by customer. 6.2.2 Each length of the cable shall be wound on a separate wooden reel. 6.2.3 Both ends of the cable shall be sealed with suitable plastic caps to prevent the entry of moisture during shipping, handling and storage. 6.2.4 The cable ends shall be securely fastened to the reel to prevent the cable from becoming loose in transit or during placing operations. 6.2.5 At least 1 meter of the cable inner end shall be accessible for test purpose. 6.2.6 Circumference battens or wood-fiber board shall be secured with steel bands to protect the cable during normal handling and shipping. 6.3 Cable Reel 6.3.1 Details given below shall be distinctly marked with a weather proof materials on both outer sides of the reel flange: (1) (2) (3) (4) (5) (6) (7) (8) (9) Purchasers Name (" xxx ") Cable type and fiber counts (ex. OFC SM 48FO) Length of cable in meters Gross weight in kilograms Reel number Name of the manufacturer (VINA-OFC) Year of manufacture Country of Origin Arrow showing the direction the drum shall be rolled

Other shipping mark is also available if requested by customer. 6.3.2 The cable shall be shipped on reels designed to prevent damage to the cable during shipment and installation.

== End of Specification ==

PAGE 6 OF 6

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Ptkctr3rtst3s EngDocumento1 páginaPtkctr3rtst3s EngnormAinda não há avaliações

- Manual Optimux 4E1Documento100 páginasManual Optimux 4E1greezlee1319100% (1)

- Wire Line Procedure EniDocumento318 páginasWire Line Procedure EniMahmoud Ahmed Ali Abdelrazik100% (4)

- Mobile TV SeminarDocumento24 páginasMobile TV SeminarRamlal Chavan0% (1)

- 0012 Box KDocumento5 páginas0012 Box K911ledsAinda não há avaliações

- GT I9500 Tshoo 7 PDFDocumento73 páginasGT I9500 Tshoo 7 PDFValmirSousaSilvaAinda não há avaliações

- Nokia AssignmentDocumento14 páginasNokia AssignmentMd. Rahat Chowdhury100% (1)

- Blackberry PlayBookDocumento17 páginasBlackberry PlayBookAmlan SahaAinda não há avaliações

- Nokia RMA IW End User Template 30092019-1 PDFDocumento1 páginaNokia RMA IW End User Template 30092019-1 PDFSourabh ShrivastavaAinda não há avaliações

- MFJ 9440Documento12 páginasMFJ 9440EdelCamachoCastilloAinda não há avaliações

- Imei Tac To Ue Model 20101026Documento930 páginasImei Tac To Ue Model 20101026rusdianto.mahmud23567% (3)

- Wapda Telephone Policy PDFDocumento5 páginasWapda Telephone Policy PDFKhan Khwar Control Room100% (1)

- Contacts 4.csvDocumento14 páginasContacts 4.csvnico sahrulAinda não há avaliações

- Filtri Tvrtke MFC: Product Report Visokofrekvencijski FiltriDocumento4 páginasFiltri Tvrtke MFC: Product Report Visokofrekvencijski FiltriAlexander WieseAinda não há avaliações

- Bharat Sanchar Nigam Limited: Form For New Isdn ConnectionDocumento4 páginasBharat Sanchar Nigam Limited: Form For New Isdn ConnectionshyaaaaAinda não há avaliações

- Elliptical ANTENNA Installation ManualDocumento5 páginasElliptical ANTENNA Installation ManualCaesar HeyneAinda não há avaliações

- How To SIM Unlock Samsung Galaxy S4 GT-I9505 For Free - Redmond PieDocumento10 páginasHow To SIM Unlock Samsung Galaxy S4 GT-I9505 For Free - Redmond Piebalazspal77Ainda não há avaliações

- KX-TDE600: PBX Ip-PbxDocumento5 páginasKX-TDE600: PBX Ip-Pbxfiqur1Ainda não há avaliações

- Byte Mobile Mobile Analytics Report Feb2012Documento6 páginasByte Mobile Mobile Analytics Report Feb2012Arda KutsalAinda não há avaliações

- 104 ManualDocumento16 páginas104 ManualArokiaraj RajAinda não há avaliações

- Philippine Electronics Code Volume 2Documento18 páginasPhilippine Electronics Code Volume 2JMSquaredAinda não há avaliações

- Konig DVB-S2 Rec20Documento93 páginasKonig DVB-S2 Rec20ornotAinda não há avaliações

- Sony Xperia XA1 Ultra - Schematic Diagarm PDFDocumento130 páginasSony Xperia XA1 Ultra - Schematic Diagarm PDFCami&coz Camí&coz0% (3)

- Converged NetworksDocumento10 páginasConverged Networksganjuvivek85Ainda não há avaliações

- M8B7CDocumento2 páginasM8B7CvinothAinda não há avaliações

- Mobile TricksDocumento43 páginasMobile TricksVijaya Kumar S RAinda não há avaliações

- Introduction To SymbianDocumento27 páginasIntroduction To SymbianDijo AntoAinda não há avaliações

- ITA503 Mobile ComputingDocumento215 páginasITA503 Mobile ComputingkhadarnawasAinda não há avaliações

- Emergency Manual Stations MS-403U/404U: FeaturesDocumento2 páginasEmergency Manual Stations MS-403U/404U: FeaturesJMAC SupplyAinda não há avaliações

- Tesla Coil.... Bobina Tesla PDFDocumento16 páginasTesla Coil.... Bobina Tesla PDFYrkls Gtierrz D JAinda não há avaliações