Escolar Documentos

Profissional Documentos

Cultura Documentos

5 S

Enviado por

Lokesh DahiyaDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

5 S

Enviado por

Lokesh DahiyaDireitos autorais:

Formatos disponíveis

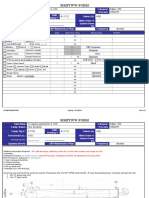

5 S Audit Check Sheet for Shop floor

Sr. No Items Evaluation and Scoring Criteria Score Mark 0 OR 1

Unnecessary Items such as Hand gloves, Cloth, nut-bolt, washers, packing material, etc. are not observed lying away at place Removing Unexplained / unlabelled items not observed in section Unnecessary Necessary Items not observed in section in excess quantity . Items Equipments / Machines / Tools / Fixtures which are in use now are only observed in the section( Even if it is informed to higher ups ) Section is free of unnecessary items (other than above specified) Specified location to keep cleaning equipments Storage of Cleaning Equipments are placed at specified location. 2 Cleaning Storage place for cleaning equipments is accessible / visible Equipment Storage place for cleaning equipments is properly labelled Cleaning equipments are available and in usable condition Sweeping is evident as oil, coolant, etc. are not observed on Floor Floor is free of dirt and chips. Walls, corners of the section are free of Cob-Webs. 3 Floor Cleaning Floors are in safe working conditions (floor peel off, slippery) 1 Toilets are cleaned & maintained Resposibility of cleaning defined and Cleaning Schedule is displayed in section Bulletin Boards displayed in Section Bulletin Boards are displayed at prominent places ( easily readable ) and is clean Old and outdated Bulletins are not displayed on board Torn or soiled bulletins are not displayed on board Bulletins are arranged properly in a neat manner Emergency equipment like Fire extinguisher, Fire hoses available in section Emergency Access Emergency equipments are easily accessible Emergency equipments are stored in prominent place, easy to locate manner Stop Switches or Breakers are marked or colour coded for easy visibility and identification Emergency equipments are serviced as per schedule and schedule displayed Items are observed not lying on floor Trolleys, bins are positioned on the floor in clearly marked areas 6 Items on Floor Proper Labelling for Trolleys, WIP, etc Tools, Tool boxes are arranged and labelled properly Scrapped material disposed off as per schedule and display of schedule Machines and equipments are found clean Window glasses and work surfaces are cleaned regularly Equipment Chips are cleared regularly from chip trolleys 7 Cleanliness

Bulletin Boards

10

Machine Open slide, guideways are free from dust Machine and equipment Cleanliness schedule displayed and adhered to Aisleways and walkways are clearly demarked and can be identified at a glance Aisleways Aisleways markings are pre-dominent Marking Indication Boards ( Layout ) are seen on Aisleways Aisleways and walkways are not conjusted areas Aisleways and walkways are standardised Aisleways are free of material and Obstructions Demarked lines are free of Material/Trollies Aisleways Aisleways are clean Maintenance Objects are placed at right angles to the Aisleways Aisleway marking exists ( if not reduce 2 marks ) Storage areas are clean and accessible Material storage boxes, containers are clean, neat and at right angles Proper Labelling for Trolleys, WIP, etc Storage Items are stored properly( no overflowing ) in storage arrangements Arrangement considering safety Storage arrangements are such that material mixing and FIFO concepts are taken care of All machines and equipments are painted as per company standards and kept clean by daily care( If painting is not possible, cleaning is a must ) Equipment In case of machines and equipments slides, guideways, Oilwindows, greasing nipples found painted ( reduce 3 points for lapse of this ) Painting Uniformity in painting ( pleasant looks ) Machines and equipments are labelled properly Machines and equipments locations are marked clearly Critical points of daily maintenance checks are clearly marked on equipments(eg.Oil levels) Equipment Control of machines are properly labelled Maintenance Equipment check sheets are updated, clean and neatly displayed Machine areas are free of Cobwebs. Machines are with proper gaurds( gaurds are removed or kept on floor ) Machines, cabinets and equipments are free of unnecessary items Items not found leaning against walls or columns Equipment Proper gaurds and deflectors used to avoid chips falling on floor Storage Any special care taken for reducing downtime of equipments / machines. Equipments are adhering to safe work practices( if not reduce 3 marks). Specified place for document storage in section Only necessary documents are being stored at work stations Documents and binders are stored in a neat and orderly manner Document storage system is user friendly Safety And Work instructions are displayed(if not reduce 2 marks). Documents are labelled clearly as to contents, responsibility for control and revision Section free of Obsolete and unrequired documents Proper system in place for document disposal Documents are filed subjectwise Document control Schedule is displayed and adhered to

Equipment Cleanliness

11

12

13

14

Documents Storage

15

Documents Control

Tools, jigs and fixtures, gauges are clean Tools and Tools and gauges are kept at identified place 16 Gauges Tools, jigs and fixtures, are arranged neatly and free of any risk of damage Arrangement Tools and gauges are properly labelled Tools, jigs and fixtures are free of rust Tools, jigs and fixtures are arranged properly such that they are accessible when required Tools and Gauges and measuring instruments are properly arranged and easily 17 Gauges accessible Convenience Tools and Gauges are stored considering frequency of use Measuring instruments with valid calibrations are only used and stored Callibration freq. and schedule displayed ofTools, Jigs, fixtures, gauges Shelves and work benches are identified and neatly arranged Only valid documents with defined period of storage are kept in shelves / filing cabinets Shelves, Shelves and work benches are labelled properly so that items are stored only 18 Benches, Arrangement at the right locations Appropriate number of shelves are kept in section. Shelves and benches are uniformly arranged and easy accesable. Shelves, benches are free of un required objects including files and documents Tools and fixtures are cleaned before kept in storage areas

Shelves, 19 Benches, and shelves and benches are not obstructing movements. Desks Control Items stored in shelves, benches are categorywise. Shelves, benches should be easy for upkeeping. All defined frequencies of cleaning, callibration, documentation are strictly followed 5 'S' Control 5 ' S ' is known to people 20 and Maintenance 5 ' S ' drill is practised regularly and daily Auditor feels pleasant in the area Confident 5 ' S ' literate people to uphold the level of their section

Total 5 S Level = Addition of score / (100-Non Valid Points) * 5

5S Level (5*Total score /(100-(Not Applicable+Not checked))

Special/ Unique 5S System Identified:

Auditor Area DATE

0 0.00

Você também pode gostar

- Kenny Dorham 30 CompositionsDocumento49 páginasKenny Dorham 30 CompositionsRezahSampson97% (35)

- Case Study Solution Unilever Brazil IDocumento117 páginasCase Study Solution Unilever Brazil Iprasant goel67% (3)

- 5S Technique DataDocumento9 páginas5S Technique DataMuhammad Luqman FarooquiAinda não há avaliações

- GUILLERMO - Medium and TechniqueDocumento16 páginasGUILLERMO - Medium and TechniqueAlthea Mola CruzAinda não há avaliações

- Saint Peter's BasilicaDocumento67 páginasSaint Peter's Basilicaimanolkio100% (4)

- BF Area - 5S Check ListDocumento30 páginasBF Area - 5S Check ListVi KraAinda não há avaliações

- 5S Action Plan 12-3-2020xlsxDocumento6 páginas5S Action Plan 12-3-2020xlsxbuddikalrAinda não há avaliações

- Chap 2Documento28 páginasChap 2Keyredin SelmanAinda não há avaliações

- Quick Change OverDocumento14 páginasQuick Change Overghaos1Ainda não há avaliações

- FS 508 Installation ManualDocumento8 páginasFS 508 Installation ManualleolamiaAinda não há avaliações

- An Introduction To 6S: Tim Mcmahon August, 2008Documento43 páginasAn Introduction To 6S: Tim Mcmahon August, 2008Ester Hope HuraAinda não há avaliações

- 1 Six Sigma Project Review: Executive SummaryDocumento6 páginas1 Six Sigma Project Review: Executive Summaryanjo0225Ainda não há avaliações

- Measurement System Analysis: - Two Sources of Variation: 1. Part - To - Part Variation 2. Measurement System VariationDocumento4 páginasMeasurement System Analysis: - Two Sources of Variation: 1. Part - To - Part Variation 2. Measurement System Variationhan seongAinda não há avaliações

- Cellular Manufacturing Flexible OperationsDocumento16 páginasCellular Manufacturing Flexible OperationsAlpha Excellence consultingAinda não há avaliações

- Session Plan: Admas University Meskel TVET College Department of Business and FinanceDocumento5 páginasSession Plan: Admas University Meskel TVET College Department of Business and Financeyigrem abAinda não há avaliações

- 5S For OfficesDocumento3 páginas5S For OfficesckopoletoAinda não há avaliações

- Examples Line BalancingDocumento11 páginasExamples Line BalancingTee Hor ChangAinda não há avaliações

- 13 Nested ANOVA 2012Documento15 páginas13 Nested ANOVA 2012rahsarahAinda não há avaliações

- Apply Quality StandardDocumento6 páginasApply Quality Standardyigrem abAinda não há avaliações

- Session Plan: Admas University Meskel TVET College Department of Business and FinanceDocumento2 páginasSession Plan: Admas University Meskel TVET College Department of Business and Financeyigrem abAinda não há avaliações

- Five S Implementation: SORT (Clearing Up Space) OrganizationDocumento8 páginasFive S Implementation: SORT (Clearing Up Space) OrganizationDONAinda não há avaliações

- Lecture 1 Introduction Methods of Work Measurement 13 FebDocumento17 páginasLecture 1 Introduction Methods of Work Measurement 13 FebSolomon NgussieAinda não há avaliações

- Inching Towards Lean Manufacturing: Prepared By: Cutting Process ImprovementDocumento64 páginasInching Towards Lean Manufacturing: Prepared By: Cutting Process ImprovementsnaveseekerAinda não há avaliações

- The 5S Number GameDocumento7 páginasThe 5S Number GameSaurabh SaoAinda não há avaliações

- Jidoka SampleDocumento9 páginasJidoka SampleJohn OoAinda não há avaliações

- 6S in HealthcareDocumento13 páginas6S in HealthcareChannel MedicalAinda não há avaliações

- Roller (Did-428) PFDDocumento1 páginaRoller (Did-428) PFDVikas KashyapAinda não há avaliações

- Participate Enviromental Work PracticesDocumento3 páginasParticipate Enviromental Work Practicesyigrem abAinda não há avaliações

- F Test&AnovaDocumento17 páginasF Test&AnovaRica Angela Manahan MillonteAinda não há avaliações

- 5S Ew 09 05 16Documento49 páginas5S Ew 09 05 16Ahmed AliAinda não há avaliações

- Midterm Tos and MidtermExam in Analytic Geometry 2Documento3 páginasMidterm Tos and MidtermExam in Analytic Geometry 2vonAinda não há avaliações

- One-Way Analysis of Variance by Abhishek VijayvargiyaDocumento2 páginasOne-Way Analysis of Variance by Abhishek VijayvargiyaVipul GuptaAinda não há avaliações

- Kano Model PDFDocumento5 páginasKano Model PDFdanielmugaboAinda não há avaliações

- Simptww S-1105Documento3 páginasSimptww S-1105Vijay RajaindranAinda não há avaliações

- 5S (Methodology) - WikipediaDocumento4 páginas5S (Methodology) - WikipediaBORRELAinda não há avaliações

- 6'S Audit Sheet: Step S.No Item Rating (0-5) Comments 5 4 3 2 1Documento5 páginas6'S Audit Sheet: Step S.No Item Rating (0-5) Comments 5 4 3 2 1stylish eagleAinda não há avaliações

- MeasurementSystemsAnalysis PDFDocumento37 páginasMeasurementSystemsAnalysis PDFJorge MartinezAinda não há avaliações

- Use Business Equipment and ResouresDocumento3 páginasUse Business Equipment and Resouresyigrem abAinda não há avaliações

- 5S Implementation Manual Part 2Documento63 páginas5S Implementation Manual Part 2jgprasadAinda não há avaliações

- 5 S Presentation - NewDocumento86 páginas5 S Presentation - Newkalyanjammula100% (1)

- SPCDocumento49 páginasSPCJosephi_abbasAinda não há avaliações

- 5S Audit Form 20070118Documento7 páginas5S Audit Form 20070118prabathnilanAinda não há avaliações

- 5SDocumento56 páginas5SInderpreet Singh AhujaAinda não há avaliações

- 5S Implementation Audit: 5S To-Do Items Observed Condition Improvement ActionDocumento2 páginas5S Implementation Audit: 5S To-Do Items Observed Condition Improvement ActionJavier GutierrezAinda não há avaliações

- What Is Total Productive Maintenance?Documento5 páginasWhat Is Total Productive Maintenance?YeabsraAinda não há avaliações

- Lecture 4: Overview: Principles For Implementing Lean ManufacturingDocumento20 páginasLecture 4: Overview: Principles For Implementing Lean Manufacturingthedjoss2000Ainda não há avaliações

- Module 1-B Emergency PreparednessDocumento11 páginasModule 1-B Emergency PreparednessRobin RubinaAinda não há avaliações

- Gage R&RDocumento24 páginasGage R&RLuis ConstanteAinda não há avaliações

- Method Study: by Kunal PatelDocumento28 páginasMethod Study: by Kunal PatelPatel KunalAinda não há avaliações

- A3 Single Point Lesson 8 X 11Documento1 páginaA3 Single Point Lesson 8 X 11sbtharanAinda não há avaliações

- Cellular LayoutsDocumento10 páginasCellular Layoutssidd88Ainda não há avaliações

- Session 24 - 5S Principles in Lean 5-S in LEANDocumento4 páginasSession 24 - 5S Principles in Lean 5-S in LEANshabarinathanAinda não há avaliações

- SPC Average and Moving RangeDocumento48 páginasSPC Average and Moving RangeAnonymous 3tOWlL6L0UAinda não há avaliações

- Megaworld Global Estate Inc. 18 Jan 2013Documento48 páginasMegaworld Global Estate Inc. 18 Jan 2013vishvendan100% (1)

- 5s Basic Training PPT 204Documento15 páginas5s Basic Training PPT 204Sheila Ibay VillanuevaAinda não há avaliações

- Contents: Introduction and History or TPM Why TPM Implementation of TPM ConclusionDocumento32 páginasContents: Introduction and History or TPM Why TPM Implementation of TPM ConclusionVajram Ramesh - IP100% (1)

- Process Check Hot ShopDocumento12 páginasProcess Check Hot ShopSumeet RatheeAinda não há avaliações

- Meaning of Management Process and Diff Betn MGMT and AdminDocumento7 páginasMeaning of Management Process and Diff Betn MGMT and Adminsharathmalode0% (1)

- Presentation Total Productive Maintenance (TPM)Documento14 páginasPresentation Total Productive Maintenance (TPM)jaanus143Ainda não há avaliações

- R&R Excel ExampleDocumento16 páginasR&R Excel ExamplemanishxlriAinda não há avaliações

- Total Quality Management (TQM) ToolsDocumento84 páginasTotal Quality Management (TQM) ToolsSameer_Khan_60Ainda não há avaliações

- Tact Time StudyDocumento10 páginasTact Time StudyAtul SharmaAinda não há avaliações

- Agile Essentials You Always Wanted To Know: Self Learning ManagementNo EverandAgile Essentials You Always Wanted To Know: Self Learning ManagementAinda não há avaliações

- 5S ChecklistsDocumento5 páginas5S ChecklistsRheneir MoraAinda não há avaliações

- Concept Note 2017Documento1 páginaConcept Note 2017Lokesh DahiyaAinda não há avaliações

- GRE WordlistDocumento23 páginasGRE WordlistLokesh DahiyaAinda não há avaliações

- Hyperloop Alpha PDFDocumento58 páginasHyperloop Alpha PDFmleslieAinda não há avaliações

- Mechanical October AttendanceDocumento4 páginasMechanical October AttendanceLokesh DahiyaAinda não há avaliações

- Mechanical August AttendanceDocumento4 páginasMechanical August AttendanceLokesh DahiyaAinda não há avaliações

- The Fellowship of The RingDocumento1 páginaThe Fellowship of The RingLokesh DahiyaAinda não há avaliações

- Indian Tex Users Group LaTex Tutorials - A Primer (Indian Tex User Grupo)Documento155 páginasIndian Tex Users Group LaTex Tutorials - A Primer (Indian Tex User Grupo)Diego MorenoAinda não há avaliações

- Piyawat2 PresentDocumento46 páginasPiyawat2 PresentLokesh DahiyaAinda não há avaliações

- A1ME414Documento2 páginasA1ME414Lokesh DahiyaAinda não há avaliações

- Paper 13Documento14 páginasPaper 13jamshed20Ainda não há avaliações

- Society and ClubDocumento5 páginasSociety and ClubLokesh DahiyaAinda não há avaliações

- ML13 349Documento7 páginasML13 349worldontopAinda não há avaliações

- About Chandigarh: Chandigarh Is Known For ItsDocumento16 páginasAbout Chandigarh: Chandigarh Is Known For ItsLokesh DahiyaAinda não há avaliações

- CATIA V5 Best Practices in Part DesignDocumento29 páginasCATIA V5 Best Practices in Part DesignLokesh Dahiya100% (1)

- The Objectives of The Undergraduate Programmes AreDocumento18 páginasThe Objectives of The Undergraduate Programmes AreLokesh DahiyaAinda não há avaliações

- Acadamic PolicyDocumento3 páginasAcadamic PolicyLokesh DahiyaAinda não há avaliações

- CBR 600Rr Engine+GearboxDocumento2 páginasCBR 600Rr Engine+GearboxLokesh DahiyaAinda não há avaliações

- Engineering & Design: Geometric Dimensioning: SectionDocumento34 páginasEngineering & Design: Geometric Dimensioning: SectionVinaya Almane DattathreyaAinda não há avaliações

- DepartmentsDocumento21 páginasDepartmentsLokesh DahiyaAinda não há avaliações

- Preliminary Calculations of Flow in Channel With Triangular and Rectangular ObstacleDocumento10 páginasPreliminary Calculations of Flow in Channel With Triangular and Rectangular ObstacleLokesh DahiyaAinda não há avaliações

- ExerciseDocumento137 páginasExerciseLokesh DahiyaAinda não há avaliações

- Preliminary Calculations of Flow in Channel With Triangular and Rectangular ObstacleDocumento10 páginasPreliminary Calculations of Flow in Channel With Triangular and Rectangular ObstacleLokesh DahiyaAinda não há avaliações

- Assembly CatiaDocumento55 páginasAssembly CatiaLokesh DahiyaAinda não há avaliações

- Department Drawing StandardDocumento0 páginaDepartment Drawing StandardLokesh DahiyaAinda não há avaliações

- Engineering Drawing NotesDocumento81 páginasEngineering Drawing NotesLokesh DahiyaAinda não há avaliações

- 21 Centrifugal CompressorsDocumento26 páginas21 Centrifugal CompressorsPRASAD326100% (9)

- Engineering Drawings IntrodroductionDocumento39 páginasEngineering Drawings Introdroductionadnan100% (3)

- Bonded Rubber Tyre WheelsDocumento2 páginasBonded Rubber Tyre WheelsLokesh DahiyaAinda não há avaliações

- SoftwareDocumento166 páginasSoftwareLokesh DahiyaAinda não há avaliações

- Drywall Manual 2017 - FinishingDocumento15 páginasDrywall Manual 2017 - Finishingomar100% (1)

- 1st ChapterDocumento7 páginas1st ChapterkrithicuttieAinda não há avaliações

- The Accidental Pornographer: An Entrepreneurial Story About Having A Go at Starting A BusinessDocumento31 páginasThe Accidental Pornographer: An Entrepreneurial Story About Having A Go at Starting A BusinessCapstone PublishingAinda não há avaliações

- Pub Modern HarmonyDocumento260 páginasPub Modern HarmonyPolymnia Kotone100% (6)

- Drawing ProjectionsDocumento43 páginasDrawing ProjectionsGangu Maheswar ReddyAinda não há avaliações

- Game Design FoundationsDocumento469 páginasGame Design FoundationsjonasoftmAinda não há avaliações

- Urnfield Culture in SloveniatDocumento61 páginasUrnfield Culture in SloveniatMax BergerAinda não há avaliações

- It Is The Art of Cutting, Framing, and Joining Timber or Wood. It Is Generally Known As WoodworkingDocumento39 páginasIt Is The Art of Cutting, Framing, and Joining Timber or Wood. It Is Generally Known As WoodworkingRemuel S. MandigalAinda não há avaliações

- Hospitality - Trends For 2024Documento6 páginasHospitality - Trends For 2024Nishant DeoAinda não há avaliações

- A Conceptual Framework For Understanding Photographs Author(s) - Terry Barrett.Documento11 páginasA Conceptual Framework For Understanding Photographs Author(s) - Terry Barrett.ferlacerdaAinda não há avaliações

- Tajemnica Pieczęci Ostatnich Książąt - CZ Iia - 01 enDocumento35 páginasTajemnica Pieczęci Ostatnich Książąt - CZ Iia - 01 enAdam SzymskiAinda não há avaliações

- Abstraction in Modern Indian Art: A Study in The Post-Independence INDIAN PAINTING (1955-2005)Documento14 páginasAbstraction in Modern Indian Art: A Study in The Post-Independence INDIAN PAINTING (1955-2005)Ov SarkarAinda não há avaliações

- Nicki Minaj - Wikipedia, The Free EncyclopediaDocumento35 páginasNicki Minaj - Wikipedia, The Free EncyclopediafskslfdkjAinda não há avaliações

- Presentation IndianFestival Eng 0912Documento3 páginasPresentation IndianFestival Eng 0912Christophe LèguevaquesAinda não há avaliações

- Quarter 1 - Module 2: Eastern Classical Arts Tradition: Mood, Idea, Message, and Function of Art WorksDocumento24 páginasQuarter 1 - Module 2: Eastern Classical Arts Tradition: Mood, Idea, Message, and Function of Art WorksAlyssa FloresAinda não há avaliações

- Downing TheoryandPracticeDocumento470 páginasDowning TheoryandPracticecathrynAinda não há avaliações

- Art in Renaissance EraDocumento21 páginasArt in Renaissance EraDanny ParaonAinda não há avaliações

- Character Sheet v6.44 (A4) PDFDocumento6 páginasCharacter Sheet v6.44 (A4) PDFpipninjaAinda não há avaliações

- Rhythm: Month-LY Music - Ure LiteratDocumento60 páginasRhythm: Month-LY Music - Ure LiteratmukixyzAinda não há avaliações

- Jonathan Rosenbaum - David Lynch Twin PeaksDocumento6 páginasJonathan Rosenbaum - David Lynch Twin PeaksalexrgnAinda não há avaliações

- Handicrafts of Gujarat Thesis - 01 PDFDocumento6 páginasHandicrafts of Gujarat Thesis - 01 PDFShivaniAinda não há avaliações

- Mechanics NDRRMC Logo-Making ContestDocumento2 páginasMechanics NDRRMC Logo-Making ContestdanballaisAinda não há avaliações

- Vintage Poster Lenormand 2013Documento25 páginasVintage Poster Lenormand 2013Magdalena Sighild Petersson100% (2)

- QGuide 12152011 Emmett WigglesworthDocumento12 páginasQGuide 12152011 Emmett WigglesworthColin DeVriesAinda não há avaliações

- Arts 08 Curriculum MapDocumento12 páginasArts 08 Curriculum MapJosefino HapitanAinda não há avaliações

- WyrdsistersDocumento6 páginasWyrdsistersapi-360626105Ainda não há avaliações