Escolar Documentos

Profissional Documentos

Cultura Documentos

15950

Enviado por

Waleed Abd El-HamiedDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

15950

Enviado por

Waleed Abd El-HamiedDireitos autorais:

Formatos disponíveis

Crown Home Consultants

SECTION 15950 TESTING, ADJUSTING, AND BALANCING PART 1 1.1 GENERAL

SUMMARY A. Section includes testing, adjusting, and balancing of air systems, testing, adjusting, and balancing of hydronic steam and refrigerating systems, measurement of final operating condition of HVAC systems, sound measurement of equipment operating conditions, vibration measurement of equipment operating conditions.

1.2

REFERENCES A. B. AABC (Associated Air Balance Council) or National Standards for Total System Balance. ASHRAE 111 (American Society of Heating, Refrigerating and Air-Conditioning Engineers) Practices for Measurement, Testing, Adjusting, and Balancing of Building Heating, Ventilation, Air-conditioning, and Refrigeration Systems. NEBB (National Environmental Balancing Bureau) or Procedural Standards for Testing, Adjusting, and Balancing of Environmental Systems.

C. 1.3

SUBMITTALS A. B. C. D. E. Test Reports: Indicate data on AABC National Standards for Total System Balance forms, forms prepared following ASHRAE 111 or NEBB Report forms Field Reports: Indicate deficiencies preventing proper testing, adjusting, and balancing of systems and equipment to achieve specified performance. Prior to commencing Work, submit report forms or outlines indicating adjusting, balancing, and equipment data required. Submit draft copies of report for review prior to final acceptance of Project. Furnish final copies for Architect/Engineer and for inclusion in operating and maintenance manuals. Furnish reports in soft cover, letter size, 3-ringbinder manuals, complete with table of contents page and indexing tabs, with cover identification at front and side. Include set of reduced drawings with air outlets and equipment identified to correspond with data sheets, and indicating thermostat locations. Include detailed procedures, agenda, sample report forms and copy of AABC National Project Performance Guaranty and Copy of NEBB Certificate of Conformance Certification prior to commencing system balance.

F.

Cleopatra Plaza Tower (Nasr City) Specifications

15950/1

Rev.0 March.2012

Crown Home Consultants

1.4 CLOSEOUT SUBMITTALS A. 1.5 Project Record Documents: Record actual locations of flow measuring stations, balancing valves and rough setting.

QUALITY ASSURANCE A. Perform Work in accordance with AABC National Standards for Field Measurement and Instrumentation, Total System Balance, ASHRAE 111, NEBB Procedural Standards for Testing, Balancing and Adjusting of Environmental Systems Maintain one copy of each document on site.

B. 1.6

QUALIFICATIONS A. B. Agency: Company specializing in testing, adjusting, and balancing of systems specified in this section with minimum three years experience Perform Work under supervision of AABC Certified Test and Balance Engineer, NEBB Certified Testing, Balancing and Adjusting Supervisor, registered professional engineer experienced in performance of this Work and licensed

1.7

PRE-INSTALLATION MEETING A. B. Administrative Requirements: Pre-installation meeting. Convene minimum one week prior to commencing Work of this section.

1.8

SEQUENCING A. Sequence balancing between completion of systems tested and Date of Substantial Completion.

1.9

SCHEDULING A. Schedule and provide assistance in final adjustment and test of life safety, smoke evacuation, and smoke control system with Fire Authority. EXECUTION

PART 2 3.1

EXAMINATION A. Verify systems are complete and operable before commencing work. Verify the following: 1. Systems are started and operating in safe and normal condition. 2. Temperature control systems are installed complete and operable. 3. Proper thermal overload protection is in place for electrical equipment. 4. Final filters are clean and in place. If required, install temporary media in addition to final filters. 5. Duct systems are clean of debris. 6. Fans are rotating correctly. 7. Fire and volume dampers are in place and open. 15950/2

Rev.0 March.2012

Cleopatra Plaza Tower (Nasr City) Specifications

Crown Home Consultants

8. 9. 10. 11. 12. 13. 14. 15. B. 3.2 Air coil fins are cleaned and combed. Access doors are closed and duct end caps are in place. Air outlets are installed and connected. Duct system leakage is minimized. Hydronic systems are flushed, filled, and vented. Pumps are rotating correctly. Proper strainer baskets are clean and in place or in normal position. Service and balancing valves are open.

Submit field reports. Report defects and deficiencies noted during performance of services, preventing system balance.

PREPARATION A. Furnish instruments required for testing, adjusting, and balancing operations. Make instruments available to Architect/Engineer to facilitate spot checks during testing.

3.3

INSTALLATION TOLERANCES A. B. C. Air Handling Systems: Adjust to within plus or minus 10 percent of design. Air Outlets and Inlets: Adjust total to within plus 10 percent and minus 5 percent of design to space. Adjust outlets and inlets in space to within plus or minus 10 percent of design. Hydronic Systems: Adjust to within plus or minus 10 percent of design.

3.4

ADJUSTING A. B. C. D. E. F. G. Execution Requirements: Testing, adjusting, and balancing. Verify recorded data represents actual measured or observed conditions. Permanently mark settings of valves, dampers, and other adjustment devices allowing settings to be restored. Set and lock memory stops. After adjustment, take measurements to verify balance has not been disrupted. If disrupted, verify correcting adjustments have been made. Leave systems in proper working order, replacing belt guards, closing access doors, closing doors to electrical switch boxes, and restoring thermostats to specified settings. At final inspection, recheck random selections of data recorded in report. Recheck points or areas as selected and witnessed by Owner. Check and adjust systems approximately six months after final acceptance and submit report.

3.5

AIR SYSTEM PROCEDURE A. Adjust air handling and distribution systems to obtain required or design supply, return, and exhaust air quantities 15950/3

Rev.0 March.2012

Cleopatra Plaza Tower (Nasr City) Specifications

Crown Home Consultants

B. C. D. E. Make air quantity measurements in main ducts by Pitot tube traverse of entire cross sectional area of duct. Measure air quantities at air inlets and outlets. Adjust distribution system to obtain uniform space temperatures free from objectionable drafts. Use volume control devices to regulate air quantities only to extent adjustments do not create objectionable air motion or sound levels. Effect volume control by using volume dampers located in ducts. Vary total system air quantities by adjustment of fan speeds. Provide sheave drive changes to vary fan speed. Vary branch air quantities by damper regulation. Provide system schematic with required and actual air quantities recorded at each outlet or inlet. Measure static air pressure conditions on air supply units, including filter and coil pressure drops, and total pressure across fan. Make allowances for 50 percent loading of filters. Adjust outside air automatic dampers, outside air, return air, and exhaust dampers for design conditions. Measure temperature conditions across outside air, return air, and exhaust dampers to check leakage. At modulating damper locations, take measurements and balance at extreme conditions. Balance variable volume systems at maximum airflow rate, full cooling, and at minimum airflow rate, full heating. Measure building static pressure and adjust supply, return, and exhaust air systems to obtain required relationship between each to maintain approximately 0.05 inches positive static pressure near building entries Check multi-zone units for motorized damper leakage. Adjust air quantities with mixing dampers set first for cooling, then heating, then modulating. For variable air volume system powered units set volume controller to airflow setting indicated. Confirm connections properly made and confirm proper operation for automatic variable-air-volume temperature control. On fan powered VAV boxes, adjust airflow switches for proper operation.

F. G. H. I. J. K.

L.

M. N.

O. 3.6

WATER SYSTEM PROCEDURE A. B. Adjust water systems, after air balancing, to obtain design quantities. Use calibrated Venturi tubes, orifices, or other metered fittings and pressure gauges to determine flow rates for system balance. Where flow-metering devices are not installed, base flow balance on temperature difference across various heat transfer elements in system. 15950/4

Rev.0 March.2012

Cleopatra Plaza Tower (Nasr City) Specifications

Crown Home Consultants

C. Adjust systems to obtain specified pressure drops and flows through heat transfer elements prior to thermal testing. Perform balancing by measurement of temperature differential in conjunction with air balancing. Effect system balance with automatic control valves fully open or in normal position to heat transfer elements. Effect adjustment of water distribution systems by means of balancing cocks, valves, and fittings. Do not use service or shut-off valves for balancing unless indexed for balance point. Where available pump capacity is less than total flow requirements or individual system parts, simulate full flow in one part by temporary restriction of flow to other parts.

D. E.

F.

3.7 SCHEDULES Equipment Requiring Testing, Adjusting, and Balancing Air Cooled Refrigerant Condensers Packaged Roof Top Heating/Cooling Units Packaged Terminal Air Conditioning Units Unit Air Conditioners Air Coils Fans Air Filters Air Terminal Units Air Inlets and Outlets Heat Exchangers A. Report Forms 1. Title Page: a. Name of Testing, Adjusting, and Balancing Agency b. Address of Testing, Adjusting, and Balancing Agency c. Telephone and facsimile numbers of Testing, Adjusting, and Balancing Agency d. Project name e. Project location f. Project Architect g. Project Engineer h. Project Contractor i. Project altitude j. Report date 2. Summary Comments: a. Design versus final performance b. Notable characteristics of system c. Description of systems operation sequence d. Summary of outdoor and exhaust flows to indicate building pressurization e. Nomenclature used throughout report f. Test conditions 3. Instrument List: a. Instrument b. Manufacturer c. Model number d. Serial number 15950/5

Rev.0 March.2012

Cleopatra Plaza Tower (Nasr City) Specifications

Crown Home Consultants

e. f. 4. Range Calibration date Electric Motors: a. Manufacturer b. Model/Frame c. HP/BHP and kW d. Phase, voltage, amperage; nameplate, actual, no load e. RPM f. Service factor g. Starter size, rating, heater elements h. Sheave Make/Size/Bore V-Belt Drive: a. Identification/location b. Required driven RPM c. Driven sheave, diameter and RPM d. Belt, size and quantity e. Motor sheave diameter and RPM f. Center to center distance, maximum, minimum, and actual Pump Data: a. Identification/number b. Manufacturer c. Size/model d. Impeller e. Service f. Design flow rate, pressure drop, BHP and kW g. Actual flow rate, pressure drop, BHP and kW h. Discharge pressure i. Suction pressure j. Total operating head pressure k. Shut off, discharge and suction pressures l. Shut off, total head pressure m. Gas flow rate n. Heat input o. Burner manifold gas pressure p. Percent carbon monoxide (CO) q. Percent carbon dioxide (CO2) r. Percent oxygen (O2) s. Percent excess air t. Flue gas temperature at outlet u. Ambient temperature v. Net stack temperature w. Percent stack loss x. Percent combustion efficiency y. Heat output Air Cooled Condenser: a. Identification/number b. Location c. Manufacturer d. Model number e. Serial number f. Entering DB air temperature, design and actual g. Leaving DB air temperature, design and actual 15950/6

Rev.0 March.2012

5.

6.

7.

Cleopatra Plaza Tower (Nasr City) Specifications

Crown Home Consultants

h. 8. Number of compressors

9.

10.

Exchanger: a. Identification/number b. Location c. Service d. Manufacturer e. Model number f. Serial number g. Steam pressure, design and actual h. Primary water entering temperature, design and actual i. Primary water leaving temperature, design and actual j. Primary water flow, design and actual k. Primary water pressure drop, design and actual l. Secondary water leaving temperature, design and actual m. Secondary water leaving temperature, design and actual n. Secondary water flow, design and actual o. Secondary water pressure drop, design and actual Cooling Coil Data: a. Identification/number b. Location c. Service d. Manufacturer e. Air flow, design and actual f. Entering air DB temperature, design and actual g. Entering air WB temperature, design and actual h. Leaving air DB temperature, design and actual i. Leaving air WB temperature, design and actual j. Water flow, design and actual k. Water pressure drop, design and actual l. Entering water temperature, design and actual m. Leaving water temperature, design and actual n. Saturated suction temperature, design and actual o. Air pressure drop, design and actual Heating Coil Data: a. Identification/number b. Location c. Service d. Manufacturer e. Air flow, design and actual f. Water flow, design and actual g. Water pressure drop, design and actual h. Entering water temperature, design and actual i. Leaving water temperature, design and actual j. Entering air temperature, design and actual k. Leaving air temperature, design and actual l. Air pressure drop, design and actual a. b. Air Moving Equipment Location Manufacturer 15950/7

Rev.0 March.2012

11.

Cleopatra Plaza Tower (Nasr City) Specifications

Crown Home Consultants

c. Model number d. Serial number e. Arrangement/Class/Discharge f. Air flow, specified and actual g. Return air flow, specified and actual h. Outside air flow, specified and actual i. Total static pressure (total external), specified and actual j. Inlet pressure k. Discharge pressure l. Sheave Make/Size/Bore m. Number of Belts/Make/Size n. Fan RPM Return Air/Outside Air Data: a. Identification/location b. Design air flow c. Actual air flow d. Design return air flow e. Actual return air flow f. Design outside air flow g. Actual outside air flow h. Return air temperature i. Outside air temperature j. Required mixed air temperature k. Actual mixed air temperature l. Design outside/return air ratio m. Actual outside/return air ratio Exhaust Fan Data: a. Location b. Manufacturer c. Model number d. Serial number e. Air flow, specified and actual f. Total static pressure (total external), specified and actual g. Inlet pressure h. Discharge pressure i. Sheave Make/Size/Bore j. Number of Belts/Make/Size k. Fan RPM Duct Traverse: a. System zone/branch b. Duct size c. Area d. Design velocity e. Design air flow f. Test velocity g. Test air flow h. Duct static pressure i. Air temperature j. Air correction factor Duct Leak Test: a. Description of ductwork under test b. Duct design operating pressure 15950/8

Rev.0 March.2012

12.

13.

14.

15.

Cleopatra Plaza Tower (Nasr City) Specifications

Crown Home Consultants

c. d. e. f. Duct design test static pressure Duct capacity, air flow Maximum allowable leakage duct capacity times leak factor Test apparatus 1) Blower 2) Orifice, tube size 3) Orifice size 4) Calibrated g. Test static pressure h. Test orifice differential pressure i. Leakage j. Manufacturer k. Type, constant, variable, single, dual duct l. Identification/number m. Location n. Model number o. Size p. Minimum static pressure q. Minimum design air flow r. Maximum design air flow s. Maximum actual air flow t. Inlet static pressure Air Distribution Test Sheet: a. Air terminal number b. Room number/location c. Terminal type d. Terminal size e. Area factor f. Design velocity g. Design air flow h. Test (final) velocity i. Test (final) air flow j. Percent of design air flow Sound Level Report: a. Location b. Octave bands - equipment off c. Octave bands - equipment on d. RC level equipment on Vibration Test: a. Location of points: 1) Fan bearing, drive end 2) Fan bearing, opposite end 3) Motor bearing, center (when applicable) 4) Motor bearing, drive end 5) Motor bearing, opposite end 6) Casing (bottom or top) 7) Casing (side) 8) Duct after flexible connection (discharge) 9) Duct after flexible connection (suction) b. Test readings: 1) Horizontal, velocity and displacement 2) Vertical, velocity and displacement 15950/9

Rev.0 March.2012

16.

17.

18.

Cleopatra Plaza Tower (Nasr City) Specifications

Crown Home Consultants

3) Axial, velocity and displacement Normally acceptable readings, velocity and acceleration Unusual conditions at time of test Vibration source (when non-complying)

c. d. e.

END OF SECTION 15950

Cleopatra Plaza Tower (Nasr City) Specifications

15950/10

Rev.0 March.2012

Você também pode gostar

- Electrical Estimating Pal The Professionals Choice Pal Pocket Reference SeriesDocumento4 páginasElectrical Estimating Pal The Professionals Choice Pal Pocket Reference SeriesWaleed Abd El-HamiedAinda não há avaliações

- Getting Started PDFDocumento14 páginasGetting Started PDFCeliz MedinaAinda não há avaliações

- Getting Started PDFDocumento14 páginasGetting Started PDFCeliz MedinaAinda não há avaliações

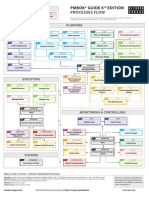

- Ricardo Vargas Simplified Pmbok Flow 6ed Color En-A3Documento1 páginaRicardo Vargas Simplified Pmbok Flow 6ed Color En-A3Hero Sa Mac100% (1)

- MemTest86 Report 20191206 094746.htmlDocumento2 páginasMemTest86 Report 20191206 094746.htmlWaleed Abd El-HamiedAinda não há avaliações

- 20178311513285639Documento10 páginas20178311513285639Waleed Abd El-HamiedAinda não há avaliações

- Electrical Spec.'S Identification 16195-1Documento2 páginasElectrical Spec.'S Identification 16195-1Waleed Abd El-HamiedAinda não há avaliações

- Building TYPE - BDocumento1 páginaBuilding TYPE - BWaleed Abd El-HamiedAinda não há avaliações

- Visio-F (7) PDFDocumento1 páginaVisio-F (7) PDFWaleed Abd El-HamiedAinda não há avaliações

- Electrical Spec.'S CCTV System 16782-1Documento12 páginasElectrical Spec.'S CCTV System 16782-1Waleed Abd El-HamiedAinda não há avaliações

- Description Qty Unit Rate Amount LE LE 16 Electrical 1 MV Ring Main UnitDocumento5 páginasDescription Qty Unit Rate Amount LE LE 16 Electrical 1 MV Ring Main UnitWaleed Abd El-HamiedAinda não há avaliações

- SECTION - 16465 Bus-Way & Power FeedersDocumento7 páginasSECTION - 16465 Bus-Way & Power FeedersWaleed Abd El-HamiedAinda não há avaliações

- Building TYPE - BDocumento1 páginaBuilding TYPE - BWaleed Abd El-HamiedAinda não há avaliações

- Electrical Spec.'S Wiring Devices & Methods of Installation 16130-1Documento9 páginasElectrical Spec.'S Wiring Devices & Methods of Installation 16130-1Waleed Abd El-HamiedAinda não há avaliações

- Lighting FixturesDocumento10 páginasLighting FixturesWaleed Abd El-HamiedAinda não há avaliações

- Elecrical Spec'S General Lighting Installation 16500-1Documento6 páginasElecrical Spec'S General Lighting Installation 16500-1Waleed Abd El-HamiedAinda não há avaliações

- Electrical Spec'S Panel Boards 16470-1Documento13 páginasElectrical Spec'S Panel Boards 16470-1Waleed Abd El-HamiedAinda não há avaliações

- Electrical Spec'S Panel Boards 16470-1Documento13 páginasElectrical Spec'S Panel Boards 16470-1Waleed Abd El-HamiedAinda não há avaliações

- Electrical Spec.'S Cables, Wires & Color Codes. 16120 - 1Documento6 páginasElectrical Spec.'S Cables, Wires & Color Codes. 16120 - 1Waleed Abd El-HamiedAinda não há avaliações

- Electrical Spec.'S CCTV System 16782-1Documento12 páginasElectrical Spec.'S CCTV System 16782-1Waleed Abd El-HamiedAinda não há avaliações

- Low Voltage Networks Bus Bar System Bus Bar System: Bill. 1Documento2 páginasLow Voltage Networks Bus Bar System Bus Bar System: Bill. 1Waleed Abd El-HamiedAinda não há avaliações

- Section - 16010 Basic Electrical RequirmentsDocumento17 páginasSection - 16010 Basic Electrical RequirmentsWaleed Abd El-HamiedAinda não há avaliações

- Division 16 Electrical SpecificationsDocumento3 páginasDivision 16 Electrical SpecificationsWaleed Abd El-HamiedAinda não há avaliações

- SECTION - 16465 Bus-Way & Power FeedersDocumento7 páginasSECTION - 16465 Bus-Way & Power FeedersWaleed Abd El-HamiedAinda não há avaliações

- Item Description QTY Unit Rate Amount L.E L.E: Bill. 1Documento15 páginasItem Description QTY Unit Rate Amount L.E L.E: Bill. 1Waleed Abd El-HamiedAinda não há avaliações

- Hanger All Mass V.S FostatDocumento10 páginasHanger All Mass V.S FostatWaleed Abd El-HamiedAinda não há avaliações

- W0119NNX Course Details ENUDocumento1 páginaW0119NNX Course Details ENUWaleed Abd El-HamiedAinda não há avaliações

- 00-Elec Vendor List CoverDocumento1 página00-Elec Vendor List CoverWaleed Abd El-HamiedAinda não há avaliações

- ورقة مقاولDocumento1 páginaورقة مقاولWaleed Abd El-HamiedAinda não há avaliações

- Car Parking Control System: BILL.8Documento1 páginaCar Parking Control System: BILL.8Waleed Abd El-HamiedAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)

- Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesDocumento8 páginasHot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesradziAinda não há avaliações

- iSYS Company Profile QSIDocumento9 páginasiSYS Company Profile QSIAshwin0% (1)

- PTX 510 and PTX 510/IS: Industrial Pressure TransmitterDocumento2 páginasPTX 510 and PTX 510/IS: Industrial Pressure Transmittermelad yousefAinda não há avaliações

- Gradsko Osvetljenje TownGuideDocumento24 páginasGradsko Osvetljenje TownGuidePustinjak SaharicAinda não há avaliações

- DPS Calculation SheetDocumento133 páginasDPS Calculation SheetKraiwan AranyawatAinda não há avaliações

- JWT Magazine December 2023Documento130 páginasJWT Magazine December 2023Arbab AlamAinda não há avaliações

- Basf Bed Bug GuideDocumento8 páginasBasf Bed Bug Guideapi-214441294Ainda não há avaliações

- PCB Design RuleDocumento43 páginasPCB Design RuletrinhdieuhvktqsAinda não há avaliações

- Norma VDI 2230 Estimación Tornillos (Inglés)Documento15 páginasNorma VDI 2230 Estimación Tornillos (Inglés)jupimadAinda não há avaliações

- Internship ReportDocumento9 páginasInternship ReportSyrah MichaelAinda não há avaliações

- (BS 1715-2.2 - 1989) - Analysis of Soaps. Quantitative Test Methods. Method For Determination of Total Free Alkali ContentDocumento10 páginas(BS 1715-2.2 - 1989) - Analysis of Soaps. Quantitative Test Methods. Method For Determination of Total Free Alkali ContentamazondayAinda não há avaliações

- 100 40 Gbps Ethernet Wall ChartDocumento1 página100 40 Gbps Ethernet Wall ChartgliranAinda não há avaliações

- Suruhanjaya TenagaDocumento43 páginasSuruhanjaya Tenagaavenged sevenfold6989% (9)

- Data Type For Word Documents Handling: WorddocumentDocumento9 páginasData Type For Word Documents Handling: WorddocumentciganoAinda não há avaliações

- SSD Support Solutions - Bizhub 601Documento127 páginasSSD Support Solutions - Bizhub 601Adrian Moisiu50% (4)

- Countersunk Screw With Hexagon Socket Head ISO 10642 Steel 10.9Documento10 páginasCountersunk Screw With Hexagon Socket Head ISO 10642 Steel 10.9Alex DeschevogAinda não há avaliações

- BS en 22768-2 1993Documento16 páginasBS en 22768-2 1993Hüseyin BuğdaycıAinda não há avaliações

- Terminal Manager Truck Transportation in Denver CO Resume Dan LoganDocumento2 páginasTerminal Manager Truck Transportation in Denver CO Resume Dan LoganDanLoganAinda não há avaliações

- Correlation Matrices Between ISO 9001:2015, ISO 14001:2015, ISO DIS2 45001:2017 & Xyz Integrated Management SystemDocumento5 páginasCorrelation Matrices Between ISO 9001:2015, ISO 14001:2015, ISO DIS2 45001:2017 & Xyz Integrated Management SystemrichypatAinda não há avaliações

- Flaw Detector Sonic1200 PlusDocumento2 páginasFlaw Detector Sonic1200 PlusvrapciudorianAinda não há avaliações

- Af302 Major Assignment Sem 1 2016Documento3 páginasAf302 Major Assignment Sem 1 2016StingrayAinda não há avaliações

- AcknowledgementDocumento15 páginasAcknowledgementNoman khanAinda não há avaliações

- ITB-KEOC-2013-009 - Section VIII C - Mechanical SpecificationsDocumento151 páginasITB-KEOC-2013-009 - Section VIII C - Mechanical SpecificationsMACOYAinda não há avaliações

- Vol39No7 Full PDFDocumento68 páginasVol39No7 Full PDFdeviationzAinda não há avaliações

- Traffic SymbolDocumento27 páginasTraffic SymbolraviAinda não há avaliações

- Temp Mapping Protocol For Reefer TrucksDocumento15 páginasTemp Mapping Protocol For Reefer TrucksJewel HernandezAinda não há avaliações

- Detector 70-02 - Photo Smoke Detector Model CPD-7157 - 2010Documento4 páginasDetector 70-02 - Photo Smoke Detector Model CPD-7157 - 2010DM2Ainda não há avaliações

- QS Evinrude JohnsonDocumento4 páginasQS Evinrude JohnsonmohamedalibctAinda não há avaliações

- Webdispatcher TimeoutsDocumento9 páginasWebdispatcher Timeoutsowl meadowAinda não há avaliações

- Inkscape Tutorial - Seamless Patterns - VectorsDocumento17 páginasInkscape Tutorial - Seamless Patterns - VectorskmcoulibAinda não há avaliações