Escolar Documentos

Profissional Documentos

Cultura Documentos

Air Handling Units With Coils - Rev

Enviado por

Luis Gabriel BautistaTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Air Handling Units With Coils - Rev

Enviado por

Luis Gabriel BautistaDireitos autorais:

Formatos disponíveis

Document Name: Specifications (Mechanical) Date: March 7, 2009 Rev. Rev.

0 Project: AL RAJHI STEEL (CUT & BEND PROCESSING BLDG) - JEDDAH Owner: AL RAJHI STEEL CO.

SECTION 15763 AIR HANDLING UNIT WITH COILS

PART 1 GENERAL 1.01 WORK INCLUDED: A. This section covers the furnishing, installing testing and placing in satisfactory operating condition of the air handling units, accessories, controls and related work as shown on the drawings, described in the Schedules and as specified herein.

1.02

RELATED WORK A. B. C. D. E. F. G. H. I. J. K. L. M. N. Section 01710 : Section 15060 : Section 15210 : Section 15160 : Section 15258 : Section 15680 : Section 15750 : Section 15820 : Section 15840 : Section 15880 : Section 15900 : Section 16150 : Section 16155 : Section 16913 : Cleaning Pipe and Pipe Fittings Vibration Isolation Expansion Compensation Duct Insulation Air Cooled Water Chiller Coils Air Distribution Equipment (Fans) Ductwork Air Treatment Equipment (Filters) Controls and Instrumentation Motors Motor Starters Mechanical Equipment Controls

1.03

REFERENCE STANDARDS A. B. Deutsche Industrie Norm (DIN) American National Standards Institute (ANSI). G33.54-1972 C. Safety Standard for Electric Fans.

Air Conditioning and Refrigerating Institute (ARI). Standard 410-64 Forced Circulation Air Cooling and Air Heating Coils.

D.

Air Moving and Conditioning Association (AMCA). 210 Methods of Testing Fans for Rating Purposes.

Page 1 of 6

(SDEC) SECTION 15763

Document Name: Specifications (Mechanical) Date: March 7, 2009 Rev. Rev. 0 Project: AL RAJHI STEEL (CUT & BEND PROCESSING BLDG) - JEDDAH Owner: AL RAJHI STEEL CO.

300 201 E.

Air Moving Devices. Test Code for Sound Rating. Fans and Systems.

American Society of Heating, Refrigeration and Air Conditioning Engineers (ASHRAE). 33-64 Method of Testing for Rating Forced Circulation Air Cooling and Heating Coils.

E.

National Fire Protection Association (NFPA) 90A-1985 Installation of Air Conditioning and Ventilation Systems.

F.

Under Writers Laboratories (UL). 465 507 Air Conditioners, Central Cooling Fans, Electric

1.04

SUBMITTALS A. B. Submit shop drawings and product data in accordance with Section 01340. Submit fan curves showing fan performance with system operating point plotted on curves. Submit Manufacturer's installation instructions. Manufacturer's recommended spare parts and tools list. Operating and maintenance data in accordance with Section 01730. Certificate of compliance for materials and operation. Field tests.

C. D.

E. F. 1.05

QUALITY ASSURANCE A. B. Provide fans bearing AMCA certified rating seal. Provide filter media with UL Class I or Class II ratings as specified respectively EUROVENT - DIN 24185.

PART 2 PRODUCTS 2.01 ACCEPTABLE MANUFACTURERS A. The Contractor shall submit to the Supervising Engineer the names of three manufacturers and their products which will be acceptable under this Section. Approval of the manufacturer or product must be obtained before proceeding with associated work. Units shall be the product of a Manufacturer regularly engaged in the production of these units issuing complete catalog data for same. Items of same function and performance are acceptable in conformance with Section 01630.

Page 2 of 6

B.

C.

(SDEC) SECTION 15763

Document Name: Specifications (Mechanical) Date: March 7, 2009 Rev. Rev. 0 Project: AL RAJHI STEEL (CUT & BEND PROCESSING BLDG) - JEDDAH Owner: AL RAJHI STEEL CO.

2.02

TYPE AND PERFORMANCE A. Provide the air handling units suitable for indoor or outdoor application including accessories having the performances and duties as indicated in the Equipment Schedules and as shown on the drawing. Air handling units shall be draw-thru type of modular design suitable for low, medium or high pressure operation as indicated. Components shall consist of, but not limited to fan section plus accessories, mixing box section, filter section, cooling coil section, heating coil section, and fan discharge damper. Select size, NBS test efficiency, initial and final resistance of filters to agree with types specified. Provide number of tube rows, air and water pressure drops, and features such as cleanability, drainability, same or opposite end connections, support, and venting of coils to match type specified.

B.

C.

D.

E.

2.03

GENERAL A. Construct all apparatus of materials suitable for the conditions encountered during operation. Where an indoor air handling unit is shown on the drawings, the unit shall be of heavy gauge G-90 construction, galvanized or bonderized and all joints are welded. Where corrosion can occur, appropriate corrosion resistant materials and assembly methods must be used including isolation of dissimilar metal against galvanic interaction. Locate and arrange motors, and other components and accessories so that they are accessible for repair, maintenance and replacement. Mount grease fittings directly on bearing unless the latter are not readily accessible. Where equipment bearings are not visible or are inaccessible, provide easily accessible extensions to bearing lubrication fitting. Thoroughly clean the entire system before installing filters or operating the fans in conformance with applicable sections.

B.

C.

D.

E.

2.04

CASING GENERAL: All Air Handling Units and Fan Coil Units shall be of single skinned construction. No exposed insulation shall be accepted. A. Mount equipment and support exterior steel panels from structural steel frame. Reinforce panels. Provide hinged access doors or removable panels for access to sections and components requiring servicing. Minimum size 600mm x 600mm. Provide fasteners and gasket seals.

B.

(SDEC) SECTION 15763

Page 3 of 6

Document Name: Specifications (Mechanical) Date: March 7, 2009 Rev. Rev. 0 Project: AL RAJHI STEEL (CUT & BEND PROCESSING BLDG) - JEDDAH Owner: AL RAJHI STEEL CO.

C.

Steel finished in baked enamel primer followed by exterior application of enamel. Construct indoor units of heavy gauge G-90 galvanized steel. Weld or bolt and seal seams. Fabricate drain pans from piece of single galvanized steel with welded corners. Provide insulated drain pans under coils. Condensate drain pans shall be continuos under the entire coil section.

D.

2.05

INSULATION A. Insulate unit panels with min. 25mm thick glass fiber insulation, "K" value at 42 C maximum 0.037 Watts/meter degree K or as per detailed bill of quantity. Insulate the fan section, filter section, mixing section and coil sections as per detailed bill of quantity.

B.

2.06

FAN A. Centrifugal type with forward curved blades for pressures up to 1.5 KPa or backward inclined blades for pressures up to 2.0 KPa, double width, double inlet, with multi-blade wheel statically and dynamically balanced. Provide self-aligning ball bearings. Extend lubrication fittings to exterior of fan casing or as per detailed bill of quantity. Provide variable sheaves for motors to give plus (+) or minus (-) 10% rated performance. On all units mount fan motors within casing. Fan motors shall be heavy duty, open drip-proof type with relubricative ball bearing & class B insulation 40C max. environment rated standard and as per detailed bill of quantity. The entire fan assembly shall be completely isolated from the unit bulkhead with neoprene gasketing and mounted on spring isolators or as specified in bill of quantity.

B.

C.

D. E.

F.

2.07

FILTERS A. Filter section shall consist of primary and secondary filters. Primary filter shall be washable and secondary filter shall be high efficiency bag filters as indicated in the schedules. Final filter class shall be EU 9 or as per detailed bill of quantity. Filters to conform to applicable sections.

B.

2.08

MIXING BOX: A. Casing box with two sets of opposed blade steel dampers mounted on steel shafts supported in nylon bearings. Arrange dampers for mixing of air stream with damper blades positioned across the short air opening dimension.

2.09

COILS A. B. Enclose coils in coil section with headers and U-bends fully contained within the casing. Coil sections shall be in accordance with Section 15750 and have the capacities indicated in Equipment Schedules in the Engineering Calculation Sheets.

Page 4 of 6

(SDEC) SECTION 15763

Document Name: Specifications (Mechanical) Date: March 7, 2009 Rev. Rev. 0 Project: AL RAJHI STEEL (CUT & BEND PROCESSING BLDG) - JEDDAH Owner: AL RAJHI STEEL CO.

2.10

VIBRATION ISOLATORS A. Spring type or neoprene pad vibration isolators shall be provided for each unit or whichever is specified or recommended by the manufacturer. Selection shall be made with proper consideration of the prevailing machine frequencies to prevent transmission of noise to the building structure. Refer to applicable sections.

B.

C. 2.11

MOTORS AND MOTOR STARTERS A. Provide fan motors. Motor speed unless otherwise indicated shall not exceed 1800 r.p.m. and shall have totally enclosed enclosure. Motors shall be in accordance with Section 16150 and as per detailed bill of quantity. Motor starters shall be provided as part of electrical works and shall be in accordance with applicable sections.

B.

2.12

AUTOMATIC CONTROLS A. Motor starters will be individually mounted and installed in the motor control centers as part of electrical work. Motor control center individual starters and all associated work shall be covered under electrical section in accordance with applicable sections. Unit controls and instrumentation shall be as indicated on the drawings and in accordance with applicable sections. Mechanical equipment controls shall be in accordance with applicable sections.

B.

C.

D.

PART 3 EXECUTION 3.01 ASSEMBLY A. Assemble low and medium pressure units by bolting sections together to make single unit. Assemble high pressure units by bolting sections together except for fan section. Isolate fan section with flexible duct connections.

B.

3.02

INSTALLATION A. B. C. Install unit on vibration isolators. Install items in accordance with Manufacturer's instructions. Ensure there is adequate space in mechanical rooms for removal of filters, coils and for section. Replace all filters used during testing and balancing. Provide one complete set of spare filters.

D.

3.03

TESTING AND BALANCING A. Testing, and balancing shall conform to Section 15990.

Page 5 of 6

(SDEC) SECTION 15763

Document Name: Specifications (Mechanical) Date: March 7, 2009 Rev. Rev. 0 Project: AL RAJHI STEEL (CUT & BEND PROCESSING BLDG) - JEDDAH Owner: AL RAJHI STEEL CO.

3.04

PAINTING A. Painting shall be in accordance with applicable sections or as per detailed bill of quantity or manufacturers specification.

3.05

CLEANING A. All cleaning shall conform to applicable sections.

3.06

OPERATING AND MAINTENANCE DATA A. Operating and maintenance data shall be supplied in conformance with applicable sections. ***** END OF SECTION *****

(SDEC) SECTION 15763

Page 6 of 6

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- Armaflex 520 MSDSDocumento1 páginaArmaflex 520 MSDSLuis Gabriel BautistaAinda não há avaliações

- BoilersDocumento69 páginasBoilersSantosh C0% (1)

- Ceiling Diffusers (Halton)Documento7 páginasCeiling Diffusers (Halton)Luis Gabriel BautistaAinda não há avaliações

- Arm A Flex Duct Work Manual UkDocumento16 páginasArm A Flex Duct Work Manual UkLuis Gabriel BautistaAinda não há avaliações

- Circular Elbow No Media StSiDocumento2 páginasCircular Elbow No Media StSiLuis Gabriel BautistaAinda não há avaliações

- Rectang & Circ Low Press Drop SiDocumento2 páginasRectang & Circ Low Press Drop SiLuis Gabriel BautistaAinda não há avaliações

- Short Rectang Dissipative SiDocumento2 páginasShort Rectang Dissipative SiLuis Gabriel BautistaAinda não há avaliações

- Acoustical Plenum SiDocumento2 páginasAcoustical Plenum SiLuis Gabriel BautistaAinda não há avaliações

- External Media SiDocumento2 páginasExternal Media SiLuis Gabriel BautistaAinda não há avaliações

- High Transmission Loss Si & DuctworkDocumento2 páginasHigh Transmission Loss Si & DuctworkLuis Gabriel BautistaAinda não há avaliações

- Boq-Arch - (Rev-1) (Cut & Bend Rajhi Steel)Documento3 páginasBoq-Arch - (Rev-1) (Cut & Bend Rajhi Steel)Luis Gabriel BautistaAinda não há avaliações

- RFL & CFL Film Line StsiDocumento2 páginasRFL & CFL Film Line StsiLuis Gabriel BautistaAinda não há avaliações

- Open Burner Heavy Duty Gas Range PDFDocumento2 páginasOpen Burner Heavy Duty Gas Range PDFLuis Gabriel BautistaAinda não há avaliações

- Ice Cube Machine PDFDocumento2 páginasIce Cube Machine PDFLuis Gabriel BautistaAinda não há avaliações

- SR42G Super Runner Gas Fryer PDFDocumento2 páginasSR42G Super Runner Gas Fryer PDFLuis Gabriel BautistaAinda não há avaliações

- Boq-Civil-Struct - (Rev-1) (Cut & Bend Rajhi Steel)Documento3 páginasBoq-Civil-Struct - (Rev-1) (Cut & Bend Rajhi Steel)Luis Gabriel BautistaAinda não há avaliações

- Boq-Compressed Air (Rev1) (Cut & Bend Rajhi Steel)Documento3 páginasBoq-Compressed Air (Rev1) (Cut & Bend Rajhi Steel)Luis Gabriel BautistaAinda não há avaliações

- Construction Specifications: Sect. /div. No. TitleDocumento2 páginasConstruction Specifications: Sect. /div. No. TitleLuis Gabriel BautistaAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- A Geoscientist's Guide To PetrophysicsDocumento363 páginasA Geoscientist's Guide To PetrophysicsGunturAinda não há avaliações

- All Area Equipment ListDocumento16 páginasAll Area Equipment ListMOHSIN HASNAINAinda não há avaliações

- Safety Data Sheet: 1. IdentificationDocumento8 páginasSafety Data Sheet: 1. IdentificationNurafindaAinda não há avaliações

- At The End of The Lesson, Students Should Be Able ToDocumento4 páginasAt The End of The Lesson, Students Should Be Able ToAlfredo Jr VergaraAinda não há avaliações

- BioFlo 3000 ManualDocumento28 páginasBioFlo 3000 ManualAndres Puc SosaAinda não há avaliações

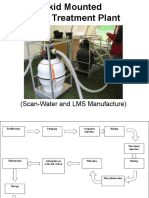

- Scan-Water and LMS ManufactureDocumento19 páginasScan-Water and LMS Manufactureshivani guptaAinda não há avaliações

- Site Instruction FormatDocumento26 páginasSite Instruction FormatMesfin100% (3)

- Brochure Busse GTDocumento8 páginasBrochure Busse GTLTE002Ainda não há avaliações

- D1348Documento6 páginasD1348Ненад КнежевићAinda não há avaliações

- Boiler OperationDocumento97 páginasBoiler Operationdeeli1100% (2)

- Geomembranes For Canal LiningDocumento11 páginasGeomembranes For Canal Lininggalca_stefanAinda não há avaliações

- Sustainable Business Survey QuestionnaireDocumento9 páginasSustainable Business Survey QuestionnairedeniseflimAinda não há avaliações

- ASCOM HiPer Sand Removal CycloneDocumento1 páginaASCOM HiPer Sand Removal CycloneShawn AngAinda não há avaliações

- Clean Kitchen Premises and Equipment SITHKOP001 - PowerpointDocumento57 páginasClean Kitchen Premises and Equipment SITHKOP001 - PowerpointJuan Diego Pulgarín Henao0% (2)

- Segmented WormsDocumento6 páginasSegmented WormsDavid WuAinda não há avaliações

- Penntreat 6536.Documento2 páginasPenntreat 6536.sushantAinda não há avaliações

- Mock Test 907Documento4 páginasMock Test 907KIMTHOAAinda não há avaliações

- FGD by BHELDocumento20 páginasFGD by BHELVibhas Kumar100% (1)

- Doon Survey CompanyDocumento17 páginasDoon Survey CompanyTarik AliAinda não há avaliações

- MSDS Strata Bond W S Comp A 2020-09-03 enDocumento7 páginasMSDS Strata Bond W S Comp A 2020-09-03 encarlos_salas80Ainda não há avaliações

- Brilube ULTRA 2Documento1 páginaBrilube ULTRA 2Rodrigo PorcaroAinda não há avaliações

- Test Report 179 - Copper Tape B Bond Clamp - BB32BDocumento18 páginasTest Report 179 - Copper Tape B Bond Clamp - BB32BannamalaiAinda não há avaliações

- Env Health Pool Hydraulic Analysis FormDocumento5 páginasEnv Health Pool Hydraulic Analysis Formhabib shuaibAinda não há avaliações

- 2 HPS PlusDocumento2 páginas2 HPS PlusAhmed MamdouhAinda não há avaliações

- Introduction:-: UnitsDocumento8 páginasIntroduction:-: UnitsSANJAYAinda não há avaliações

- Design of Movable Weirs WG26Documento10 páginasDesign of Movable Weirs WG26zmogoAinda não há avaliações

- Using HHO Gas To Reduce Fuel Consumption and Emissions in Internal Combustion Engines - En.esDocumento86 páginasUsing HHO Gas To Reduce Fuel Consumption and Emissions in Internal Combustion Engines - En.esSergio Ballestas100% (1)

- Sedimentary RocksDocumento8 páginasSedimentary Rocksmostafa haibaAinda não há avaliações

- Shiraj Baral - Cleanup of River Thames...Documento2 páginasShiraj Baral - Cleanup of River Thames...Samita sharmaAinda não há avaliações