Escolar Documentos

Profissional Documentos

Cultura Documentos

Central Boiler Board updates Indian boiler regulations

Enviado por

Gajanan JagtapDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Central Boiler Board updates Indian boiler regulations

Enviado por

Gajanan JagtapDireitos autorais:

Formatos disponíveis

Message From Chairman Indian Boiler Regulations are the standards in respect of materials, design and construction, inspection

and testing of boilers and boiler components for compliance by the manufacturer's and users of boilers in the country. These regulations are being updated regularly by amending them in line with fast changes in boiler technology by the Central Boilers Board. With the globalisation of Indian economy and the competition it is facing with the foreign companies, it is prudent to impart the latest information about the international standards and technology without loss of time. It gives me great pleasure to say that users across the Industry would now be able to download information related to the standards for materials, design, construction as well as for registration and inspection of boilers. In fact such a move was indeed required as accessing information through hard copies is time taking and also inconvenient. With the uploading of the Indian Boiler regulations - 1950, the standards would now be readily available at the click of the mouse.

Chairman Central Boilers Board

Message from Chairman of Central Boilers Board About

Central Boiler Board History of Indian Boiler Regulations Foreword Contents Chapter Wise

Contents Regulation Wise List of Amendments Indian Boilers Act 1923 Ibr Forms Home Help

Contact Us About Central Boilers Board

The Central Boilers Board, constituted under Section 27A of the Indian Boilers Act 1923 ( 5 of 1923) is responsible for making regulations for lying down the standards for materials, design, construction as well as for registration and inspection of boilers. The Board comprises of the represntatives of the Central and State Governments, Union Territories, Bureau of Indian Standards, Coal Industry, Boiler Manufacturing Industry, Boiler Ancillaries Industry, Steel Manufacturers, users of Boilers and other interests connected with the Boiler Industry. The Secretary, Department of Industrial Policy and Promotion is the ex-officio Chairman and Technical Adviser ( Boilers) is the ex-officio Member-Secretary of the Board. The Board deals with the problems of both the users and manufacturers and takes policy decisions for the proper growth of the boiler manufacturing units in the country. The Board formulates the Indian Boiler Regulations incorporating the latest developments taking place in the Boiler Industry all over the world. CBB Gazette Notification Beginning of Boiler Legislation in India Steam Boilers are of very ancient origin. The introduction of famous James Watt's improved steam engine from 1769 to 1775 onwards resulted in great improvement in steam plants. In the year 1863, a very serious boiler explosion occurred in Calcutta which caused the loss of several lives. As a result of this explosion, the necessity of inspection of boilers was widely recognised and a bill was introduced in the Bengal Council to provide for the inspection of steam boilers. In the year 1864, the Bengal Act VI of 1864 was passed which provided for the inspection of steam boilers and prime movers in the town and suburbs of Calcutta. This is the beginning of boiler legislation in India. Following the Bengal Act of 1864, each of the other provinces framed legislation. At that time there were seven different Acts and seven different sets of rules and regulations. Those Acts and rules & regulations were inconsistent with one another. As the differences in the Acts and rules and regulations among the various provinces in India gave rise to many difficulties and hampered the development of industries, the Central Government appointed a committee called "The Boiler Law Committee" in 1920 to examine and report on the general question of boiler legislation in India. The Boiler Laws Committee, 1920-21, the first to review the boiler laws on a national scale reported in March, 1921. The report criticised the differences in the Acts, rules and regulations. The report also pointed out that in the inspection of boilers the personal element was a weighty factor, and the difference in regulations resulted in what was termed as "provincial jealousy". The report stressed that all provinces should be subject to the same regulations and work done in one province should be accepted as correct in another province. The Committee recommended that regulations to cover the standard conditions for material, design and construction of boilers should be framed by Government of India and make applicable to all the provinces. The report

also pointed out that regulations were entirely of technical nature and there was no reason for which these regulations would be affected by local conditions. The Committee prepared a draft Act on the lines of which, the basic All-India Act was passed in 1923. The Boiler Laws Committee also prepared a uniform set of technical regulations and a model set of administrative rules. A sharp distinction was drawn between the regulations and the rules. The regulations referred entirely to technical matters where as the rules referred to questions concerning the administration of the Act. Indian Boiler act, 1923 provides for the safety of life and property of persons from the danger of explosion of boilers. The Government of India Act, 1935 assigned the subject 'Boilers' to the concurrent field. The provision for constituting Central Boilers Board having the authority to make regulations consistent with the Act was made in the Indian Boilers (Amendment) Act, 1937. A Board called the Central Boilers Board was accordingly constituted in the year 1937. The Central Boilers Board in exercise of the powers conferred under section 28 of the said Act, formulated regulations on boilers. The current version of these regulations is known as the Indian Boiler Regulations, 1950 with amendments up to 22nd February, 2005. Reg. 1 Short Title, Extent, Application and Commencement: 1) 2) These Regulations may be called the Indian Boiler Regulations, 1950. They extend to the whole of India, except the State of Jammu and Kashmir.

2a) These Regulations generally apply to:(i) all boilers, including those working on the principles of natural circulation, forced circulation and forced flow with no fixed steam water line, and (ii) to steam pipes. 3) They shall come into force at once

Reg. 2 Definitions In these Regulations, unless the context otherwise requires a) b) the Act means the Indian Boilers Act, 1923: Accident means an explosion of a boiler or steam-pipe or any damage of a boiler or steam-pipe, which is calculated to weaken the strength thereof so as to render it liable to explode: Boiler means any closed vessel exceeding 22.75 litres (five gallons) in capacity which is used expressly for generating steam under pressure and includes any mounting or other fitting

c)

attached to such vessel, which is wholly or partly under pressure when steam is shut off: cc) Calculation Pressure, in relation to a boiler, means the design pressure of any part adjusted to take into account the pressure drops corresponding to the most severe conditions of pressure drop and hydraulic head; Chief Inspector and Inspector means, respectively, a person appointed to be a Chief Inspector and an Inspector under the Act: Competent Authority means an authority recognised by the Central Boilers Board in the manner as laid down in regulation 4A to 4H, as competent to issue certificates to welders for the purposes of regulation 4(b)(ii) and regulation 605; "Design Pressure" means:(i) in relation to a natural or assisted circulation boiler, the maximum allowable working pressure in the steam drum of the boiler; (ii) in relation to a once through forced-circulation boiler, the maximum allowable working pressure at the final superheater steam outlet; e) Economiser means any part of a feed-pipe that is wholly or partly exposed to the action of flue gases for the purpose of recovery of waste heat: Evaluation Committee means a committee constituted by the Central Government consisting of :(a) Technical Adviser (Boilers) (b) Chief Inspector (Boilers) of the State where the unit is located : Chairman : Member

d)

dd)

ddd)

ee)

c) A representative of the manufacturers of boilers/ancillaries in public sector. : Member f) feed-pipe (i) means any pipe or connected fitting wholly or partly under pressure through which feed-water passes directly to a boiler. (ii) every reference to a steam-pipe or steam-pipes shall be deemed to include also a reference to feed-pipe or feed-pipes respectively. Inspecting Authority means an authority recognised by the Central Boilers Board in the manner as laid down in regulation 4A to 4H, as competent to grant a certificate in Form-II, II-A or

g)

II-B. h) Inspecting Officer means :(i) in respect of material manufactured or boilers constructed in any State an officer appointed by the Inspecting Authority in that State; in respect of material manufactured or boilers constructed outside the States an officer acting on behalf of the Inspecting Authority: in respect of : (a) Approval of drawings of boilers or parts thereto with minor changes, where necessary, except for the drawings of the first set of boilers or parts thereto; Inspection at stages of manufacture including examination of repairs;

(ii)

(iii)

(b) hh)

Liaison Sub-Committee means a committee constituted by the Central Boilers Board under bye-law 3 (i)(e) of the Bye-Laws of the Central Boilers Board. owner includes any person using a boiler as agent of the owner thereof and any person using a boiler which he has hired or obtained on loan from the owner thereof : prescribed means prescribed by regulations or rules made under the Act: Steam-pipe means any pipe through which steam passes from a boiler to a prime-mover or other user or both if :(i) the pressure at which steam passes through such pipe exceeds 3.5 Kilograms per square centimetre above atmospheric pressure; or such pipe exceeds 254 millimetres in internal diameter; and includes in either case any connected fitting of a steam-pipe.

i)

j) k)

(ii)

l) m)

State or States means a State or the States to which these regulations extend. Structural alteration, addition or renewal shall not be deemed to include any renewal or replacement, of a petty nature when the part or fitting used for replacement is not inferior in strength, efficiency or otherwise to the replaced part or fitting

n)

Technical Adviser (Boilers) means Technical Adviser (Boilers) to the Government of India in the Ministry of Industry (Department of Industrial Development).

Reg. 3 GENERAL REQUIREMENTS, APPLICATION OF STANDARD CONDITIONS AND EXCEPTIONS THERETO: 3(1) A boiler shall not be registered under sub-section (4) of Section 7 of the Act and a certificate shall not be issued under sub-section (5) of that section with reference to a boiler, unless the standard conditions in respect of material, design and construction, which are specified in the subsequent Chapters of these Regulations, are satisfied in respect of such a boiler. (2) Notwithstanding anything contained in sub-regulation (1), the Chief Inspector may, subject to the provisions of regulation 7 and 8, register a boiler and order the issue of a certificate authorising the use thereof, under any of the following circumstances, namely (i) when the material used in the construction of a boiler, steam-pipe, economiser or superheater is not in conformity with the Indian Boiler Regulations but is known to be commonly used in other countries as being suitable for use in the construction of boilers and steam-pipes, provided that such material is not specifically prohibited by the Regulation and that the methods of manufacture, fabrication and heat treatment conform to the specified Codes or Standards; when the constructional features of a boiler, steam-pipe, economiser or superheater are not in conformity with the Regulations but are not considered by the Chief Inspector to be inferior in strength to those prescribed in the Regulations and form part of the usual manufacturing practice of boilers and steam-pipes in other countries;

(ii)

(iii) when a boiler, steam-pipe, economiser or superheater has obviously been built in conformity with the regulations but no certificate as required under the regulations is forthcoming. (3) No structural part of a boiler, which is subject to pressure, shall be made of Bessemer process steel or of Cast or Malleable Cast Iron. (4) Where no specific provision is made in these regulations for design or manufacture of any pressure part, the Inspecting Authority may permit the design, manufacture, stage inspections and certification of such pressure parts including the valves, mountings and fittings conforming to the Codes or Standards like BS, ASME Boiler and pressure vessels code, TEMA, TRD, GOST and JIS which are known to be commonly used in industrially advanced countries. The decision of Inspecting Authorities shall be binding on all Registering authorities. (4A) The tubes of boilers and heat exchangers made of Titanium and other exotic metals

may be approved as per international codes, including ASME, BS, DIN, TEMA with the minimum thickness specified in those codes of manufacture.

Reg. 3A Inspection of boiler to comply into any foreign code: Notwithstanding anything contained in these regulations, the Inspecting Authority may inspect any boiler meant for export during the various stages of its construction so as to comply with the requirements of any foreign code and may grant a certificate in Form-II-A. Reg. 4 STANDARD REQUIREMENTS (a) Material.-All plates, rivets and bars used in the construction of boilers shall be tested and found to conform with the Regulations hereinafter contained. (b) Construction.(i) All boilers during construction shall be under the supervision of an Inspecting Officer and shall be inspected at all stages of construction prescribed in Appendix J. Tubes and steampipes shall also be inspected at the makers works at the stages prescribed in Appendix J, and the tests conducted by the makers shall also be witnessed by the Inspecting Officer.

(ii) Welders engaged in site welding of boilers, steam-pipes, economisers and superheaters shall possess and produce to the satisfaction of the Chief Inspector the Welders Performance Qualification Certificate issued by a Competent Authority. (c) Certificates, etc. under section 14(1)(c) of the Act.-In advance of or along with an application for registration of a boiler the following certificates and drawings or specifications shall be furnished to the Chief Inspector, namely:(i) A certificate in Form-II.- from an Inspecting Authority certifying that the material was tested and the boiler was built under their supervision. Together with such certificate the Inspecting Authority may furnish a Memorandum of Inspection Book in Form-I prepared in the manner prescribed by Regulation 386 in respect of the Inspection of the boiler during construction and the hydraulic test applied on completion. In case of a boiler which is to be assembled only at site, requirement of the hydraulic test on a completely assembled boiler by the Inspecting Authority shall not apply provided that the individual parts of such boiler have been hydraulically tested and certified by the Inspecting Authority separately as required under these Regulations.

NOTE.-In lieu of Form-II, a certificate in Form-II-B may be granted by the Inspecting Authority for boilers for which variations from the standard conditions in respect of material, design and construction features have been permitted by the Board or the Inspection Authority under sub-regulation (5) or sub-regulation (6) of regulation 3. (ii) A certificate in Form-III of manufacture and test signed by the maker or by a responsible representative of the maker of the boiler containing a description of the boiler, its principle dimensions, particulars of the kind of material used in its construction, the thickness of all plates, the diameter of and method of forming the rivet holes in the shell plates, particulars of any departure from ordinary practice in making the shell such as solid rolling or welding, the hydraulic test to which the boiler was subjected, the intended working pressure, the area of heating surface, the maximum continuous evaporative capacity, the year and place of make, and the works number of the boiler. NOTE.-The Chief Inspector may, however, approve a modified form of certificate wherein items which do not pertain to a particular boiler may be omitted. (iii) A drawing or print to a scale, in the case of large boilers of not less than inch to the foot and, in the case of small boilers of not less than 1 inches to the foot, showing the principal dimensions and a longitudinal section and end view of the boiler, and bearing the works number of the boiler and Makers office stamp. The drawing shall show details of riveting of longitudinal and circumferential seams with pitch of rivets, cross spacing of dished end plates, fillets and flanges and corners of bent plates, and where gusset stays are fitted the number and diameter of rivet holes in each gusset stay. In the case of water tube boilers, the foregoing scales shall apply to the main boiler drums only, but in addition a general arrangement drawing of the boiler to a scale of not less than inch to the foot shall be provided. (iv) A certificate in Form-IV from the steel maker and a certificate from the maker of the plates, rivets or bars, shall show the charge numbers, the plate or bar numbers and the number and dimensions of the various plates etc. tested, their chemical analysis, their ultimate tensile breaking strength in tons per square inch of section, the percentage of elongation and the length on which measured, the number, kind and result of bend or other tests made and the date of tests: Provided that where an Inspecting Authority furnished a certificate in Form-II together with a Memorandum of Inspection Book in Form-I in accordance with sub-regulation (c)(i) the certificates prescribed under clauses (ii) and (iv) need not be furnished to the Chief Inspector when application is made for registration of the boiler. But should any question arise in respect of the fitness of the boilers for the working pressure approved by the Inspecting Authority within a period of three years from the date of their registration, the owner shall if requested by the Chief Inspector obtain and furnish the original documents specified in the said clauses. Provided further that in respect of the steel made and tested by Well-known Steel Makers

recognised by the Central Boilers Board in the manner laid down in regulations 4A to 4H, a certificate of Well-known Steel Maker in Form-IV-A shall be accepted in lieu of a certificate from an Inspecting Authority: Provided also that in respect of the tubes/pipes made and tested by Well-known tube/pipe maker recognised by the Central Boilers Board in the manner as laid down in regulations 4A to 4H, a certificate of manufacture and test of Well-known tube/pipe maker in Form-III-D or III-E, as the case may be, shall be accepted in lieu of a certificate from an Inspecting Authority. In case where certificate in Form-IV is not producible owing to such certificate containing details of plates used for other purpose, also, all the relevant information in respect of the boiler furnished in Form IV-A duly signed by the Makers of the boiler and countersigned by the Inspecting Authority, shall be acceptable in lieu of the certificate in Form-IV. Original steel makers certificate or manufacture and results of tests shall be produced to the Chief Inspector on demand. In the case of fusion welded drums the diagram of welded repairs and temperature charts of heattreatment shall also be furnished. In addition, certificates in respect of yield point at service temperature (0.2 per cent proof stress), the average stress to produce elongation of 1 per cent (creep) in 100,000 hours and the average and the lowest stresses to produce rupture in 100,000 hours in the material, wherever is applicable, are to be furnished. (vi) For tubes and pipes subjected to internal pressure, a certificate giving results of tests regarding chemical analysis, warm yield point (0.2 per cent proof stress), the average stress to produce an elongation of 1 per cent (creep) in 100,000 hours and the average and the lowest stresses to produce rupture in 100,000 hours in the material wherever applicable, shall be furnished. NOTE:- Until 33,000 hours tests are carried out by National Metallurgical Laboratory or Corporate Research and Development Laboratory of Bharat Heavy Electricals Limited for collecting elevated temperature data of alloy steel produced indigenously against ASME or BS or EN Code, these grades of steel may be accepted and long time elevated temperature properties/maximum allowable stress values given in ASME or BS or EN Code, as the case may be, may be used for the purpose of design. Provided that (I) a certificate is furnished by the producer of the steel to the effect that the steel has been manufactured strictly in accordance with the technical requirements of the ASME or BS or EN Code to assure that the creep rupture requirements are complied with. (II) the Steel maker furnishes the necessary certificate that the steel conforms to the chemical analysis, room and elevated temperature mechanical properties

given in ASME or BS or EN Code as the case may be. (III) the short-term stress-rupture tests for 1000 hours as described below are carried out by NML/Steel Plants for the purpose of checking whether the steel is up to the specification and also to ensure that the Steel is capable of meeting the long-term rupture stress values/ maximum allowable stress values given in ASME or BS or EN Code, as the case may be, and a certificate is given by NML/Steel plant to this effect. (IV) two numbers of 1000 hour creep rupture tests shall be carried out at a temperature 50C above the service temperature for each grade of steel for tubing or piping or castings or plates grades; when in furnace and/or in superheater zone. However, the forging to be used in valves should be tested at 550C for 1000 hours. The stress to cause rupture in 1000 hours at above temperatures may be taken from the master curve corresponding to 20% line. At this stress, a minimum rupture life of 1000 hours is expected. Both the samples should pass 1000 hour tests at the above stress and temperature. These samples may be selected at random by the Chief Inspector of Boilers of the respective State. The samples could be in the form of semi-finished products, say, forged bars of about 25mm2 which will undergo heat treatment as prescribed by the relevant specifications. (d) Makers Stamp.- The boiler shall have stamped upon its front plate in a conspicuous position the following particulars:MAKERS NAME Works Number_____________________________________ Year of make__________________ Tested to __________________________ Lbs.________________________ on _______________ W.P.________________________________________________ Lbs._____________ Inspecting Officers or Inspecting Authoritys Official Stamp ___________________________________ (e) Certificates for steam-pipes A certificate of manufacture and test in Form III-A, signed by the maker and the Inspecting Authority shall be furnished. (f) Certificates for tubes A certificate of manufacture and test in Form III-B, signed by the maker and the Inspecting Authority shall be furnished. Note: In case of tubes made by Well-known Tube Makers recognised by the Central Boilers Board in the manner as laid down in regulations 4A to 4H in India or other countries, material

testing including mechanical tests may be carried out by them and the particulars regarding testing of material including mechanical tests as certified by them shall be noted in the appropriate column or paragraphs in the certificate in Form III-B. In case, certificate from the Well-known Tube Makers as aforesaid, is produced, such certificate may be accepted in lieu of the certificate from the Inspecting Authority in so far as it relates to testing of material including mechanical tests specified in this form. (g) Certificates for mountings and fittings:- A certificate of Manufacture and Test in Form IIIC signed by the Maker and the Inspecting Authority in respect of boiler mountings and steampipe fittings during manufacture, shall be furnished. Note-1: For the purpose of this clause certificates issued by an authority empowered in this behalf by or under the law in force or the national code in a foreign country, in respect of mountings and fittings in that country and containing the particulars required to be specified in this certificate, may be accepted. Where, however, the material used, is in conformity with the code of the country of manufacture and is covered by those Regulations, the permissible stress figures specified in the Code at different temperatures may be accepted in lieu of figures computed from the data required to be furnished under Regulation 271 in any of the following cases, namely:(i) Where a certificate is furnished from an Inspecting Authority to the effect that the steel complies with the requirements of the grade steel (to be specified) and the permissible stress for the working conditions as allowed for in the Code of the country of manufacture falls within the limit permissible under this Regulation.

(ii) Where the basis upon which these stresses have been arrived at is made available and such basis is not found to be such as to give rise to stresses higher than those permissible under the Regulations. Note-2: For the purpose of clause (c), (e), (f) and (g) of this regulation, certificates issued by an authority empowered in this behalf by or under the law in force or national Code or Standard of any foreign country in respect of plates, bars, tubes, pipes, forgings and castings manufactured in that country and containing the particulars required to be specified in the steel makers certificates referred to in the above mentioned clauses of regulation 4 may be accepted provided such certificates contain a statement duly signed by the Inspecting Authority to the effect that these materials comply with the requirements of the law or the Code or Standard of the foreign country. Note-3: Photostat copy of the certificate in Form III-C shall be accepted provided it is endorsed by the manufacturer or the Inspecting Authority. (h) Certificates of inspection during construction of pipes for which variation from standard conditions have been permitted.- A certificate of manufacture and test in Form IIIA(I), signed by the maker and the Inspecting Authority shall be furnished. (i) Certificate of Inspection during construction of tubes for which variation from standard conditions have been permitted.- A certificate of manufacture and test in Form III-B(i), signed

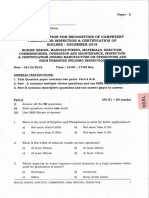

by the maker and the Inspecting Authority shall be furnished. Reg. 4 A PROCEDURE FOR RECOGNITION OF COMPETENT AUTHORITY, INSPECTING AUTHORITY, WELL-KNOWN MATERIAL TESTING LABORATORY, WELLKNOWN STEEL MAKER, WELL-KNOWN FOUNDRY/FORGE AND WELL-KNOWN TUBE/PIPE MAKER AND WELL-KNOWN REMNANT LIFE ASSESSMENT ORGANISATION:-

Application for recognition:(1) An application for recognition as Competent Authority, Inspecting Authority, Wellknown Material Testing Laboratory, Well-known Steel maker, Well-known Foundry/Forge and Well-known tube and pipe Maker and Well-known Remnant Life Assessment Organisation shall be made by a firm to the Secretary, Central Boilers Board, Ministry of Industry (Department of Industrial Development), New Delhi, for recognition as one of the aforementioned areas of activity in which that firm is engaged. On receipt of applications under sub-regulation (1), the Secretary, Central Boilers Board shall send a questionnaire in any of the Form (Form XV-A to XV-G) applicable to the area of activity to the applicant who shall send the same after duly completed, to the Secretary, Central Boilers Board. Any firm applying for recognition under sub-regulation (1) shall have a minimum experience of two years in the area of activity for which recognition is applied for. In case of firms in foreign countries seeking recognition as Well known Steel Maker, Well known Pipe/Tube maker, Well known Foundry or Well known Forge, a fee of US$ 10,000/- (Ten Thousand US Dollars) to meet the expenses of the visit of the Evaluation Committee shall be deposited along with the completed Questionnaire form. Provided that where the firm has more than one manufacturing unit in the same country, an additional fee at the rate of US$ 2000/- (Two Thousand US Dollars) per additional unit shall be deposited. The Evaluation Committee shall carry out the evaluation of the manufacturing works of the firm within 120 days of receipt of the fees.

(2)

(3) (4)

Você também pode gostar

- Chlorine: International Thermodynamic Tables of the Fluid StateNo EverandChlorine: International Thermodynamic Tables of the Fluid StateAinda não há avaliações

- EA in Biscuit MFG With Photo PDFDocumento8 páginasEA in Biscuit MFG With Photo PDFSivakumar SelvarajAinda não há avaliações

- Energy Audit and Energy Efficient Recommendations With Payback Period For Industrial BoilerDocumento7 páginasEnergy Audit and Energy Efficient Recommendations With Payback Period For Industrial BoilerInternational Journal of Innovative Science and Research TechnologyAinda não há avaliações

- Company ProfileDocumento4 páginasCompany ProfileLOGIN ANIMOAinda não há avaliações

- E Series RO 2000 LPH - Final NRP 27092021Documento10 páginasE Series RO 2000 LPH - Final NRP 27092021Anand_HvacAinda não há avaliações

- Softener Plant-2Documento2 páginasSoftener Plant-2Md. Suruz Zaman100% (1)

- Hexamide Agrotech CatalogueDocumento13 páginasHexamide Agrotech CatalogueHexamide Agrotech Inc100% (3)

- Chandra Agro TechDocumento17 páginasChandra Agro TechVinothkumar NamakkalAinda não há avaliações

- E Kranti RO 1000 LPHDocumento23 páginasE Kranti RO 1000 LPHdigitalindian newsAinda não há avaliações

- Report FY 2017-18Documento20 páginasReport FY 2017-18Tarachand PatidarAinda não há avaliações

- Introduction Letter: Subject: Company ProfileDocumento21 páginasIntroduction Letter: Subject: Company ProfilePritam JadhavAinda não há avaliações

- Training Report MC 1-1Documento60 páginasTraining Report MC 1-1Raj KumarAinda não há avaliações

- Thermax Evaporative Condenser Product Range GuideDocumento2 páginasThermax Evaporative Condenser Product Range GuideShubham VermaAinda não há avaliações

- Ppppu: Pressure Powered Pump Package Unit With IJ and CRM485RDocumento4 páginasPpppu: Pressure Powered Pump Package Unit With IJ and CRM485Rnemi90Ainda não há avaliações

- Powermax Catalogue (Thermax)Documento5 páginasPowermax Catalogue (Thermax)tydusgaravaeaAinda não há avaliações

- Steam Boiler ProjectDocumento32 páginasSteam Boiler ProjectSwastik BhokareAinda não há avaliações

- Etp LatestDocumento13 páginasEtp LatestRashid FarooquiAinda não há avaliações

- The Power of An Atom.: High Performance, Low Emissions, Real Energy Optimization and Trouble-Free PerformanceDocumento12 páginasThe Power of An Atom.: High Performance, Low Emissions, Real Energy Optimization and Trouble-Free PerformanceCarlos LehmanAinda não há avaliações

- Sa 423Documento6 páginasSa 423Widya widyaAinda não há avaliações

- Boilers Basic Components (Att. VIII)Documento28 páginasBoilers Basic Components (Att. VIII)Vijay RajAinda não há avaliações

- Research Study Diesel To BiomassDocumento9 páginasResearch Study Diesel To BiomassDarrel MagnoAinda não há avaliações

- Books on Refractories, Boilers, Pumps and Heat TransferDocumento12 páginasBooks on Refractories, Boilers, Pumps and Heat TransferSikander GirgoukarAinda não há avaliações

- Request Letter: Sub:Requesting Experience Certificate For Applying BOE ExamDocumento3 páginasRequest Letter: Sub:Requesting Experience Certificate For Applying BOE ExammaheshAinda não há avaliações

- Double Effect Steam Driven Vapour Absorption Machine: 310 1 Shalina Laboratories PVT LTDDocumento31 páginasDouble Effect Steam Driven Vapour Absorption Machine: 310 1 Shalina Laboratories PVT LTDBashir AliAinda não há avaliações

- l6ll2l20L8: Fifth 2018Documento16 páginasl6ll2l20L8: Fifth 2018dileepAinda não há avaliações

- CWC TrainingDocumento58 páginasCWC Trainingbalaji3110Ainda não há avaliações

- Seminar Report (L&T)Documento27 páginasSeminar Report (L&T)Pushpendu SinghAinda não há avaliações

- TB1-022 Energy Loss Vs Scale ThicknessDocumento1 páginaTB1-022 Energy Loss Vs Scale Thicknessjesus_manrique2753Ainda não há avaliações

- Soot Deposits and Fires in Exhaust Gas BoilerDocumento21 páginasSoot Deposits and Fires in Exhaust Gas BoilerJose G. CastilloAinda não há avaliações

- Blowdown Economizer CalculationDocumento2 páginasBlowdown Economizer CalculationSajjad AhmedAinda não há avaliações

- JBC Common Boiler FormulasDocumento12 páginasJBC Common Boiler Formulasnesrine10Ainda não há avaliações

- Boiler Water Treatment FormulaDocumento5 páginasBoiler Water Treatment Formulasaif asqalanyAinda não há avaliações

- Tugas BoilerDocumento33 páginasTugas BoilerAgus Dwi Nurcahyo JemberAinda não há avaliações

- pp57-65 MS06Documento9 páginaspp57-65 MS06vikaskatheriaAinda não há avaliações

- Reverse Osmosis Chemical BrochureDocumento4 páginasReverse Osmosis Chemical BrochuredavidnpsAinda não há avaliações

- DZL 4-1.25-AiiDocumento10 páginasDZL 4-1.25-AiiSamulaAinda não há avaliações

- Organic - New - 2019 Product ProfileDocumento15 páginasOrganic - New - 2019 Product Profilevaibhav khodakeAinda não há avaliações

- Calculate True Steam Costs in 40 CharactersDocumento2 páginasCalculate True Steam Costs in 40 CharactersBuddhi Raj SharmaAinda não há avaliações

- 2ND CLASS Boilers in Lahore CircleDocumento14 páginas2ND CLASS Boilers in Lahore CircleGoldenshakehandAinda não há avaliações

- KM Industrial Trades Quotation DocumentDocumento9 páginasKM Industrial Trades Quotation DocumentFatima Anwar100% (1)

- Design Calculations: Flash Mixing TankDocumento4 páginasDesign Calculations: Flash Mixing TankRamkiAinda não há avaliações

- Control InstrumentsDocumento36 páginasControl Instrumentsvivek1119Ainda não há avaliações

- 11.water Level ControlDocumento43 páginas11.water Level Controlsandeep kumarAinda não há avaliações

- Water Treatment Chemicals ListDocumento1 páginaWater Treatment Chemicals ListPrashanth JeerAinda não há avaliações

- DLT 5054-1996Documento245 páginasDLT 5054-1996ecsuperalAinda não há avaliações

- Corex GyanDocumento104 páginasCorex Gyanrohitbhat2345Ainda não há avaliações

- Technical Comparision - BoilerDocumento2 páginasTechnical Comparision - Boilermpcd07Ainda não há avaliações

- Project On Conservation of Steam in Electroplating in Hero CyclesDocumento7 páginasProject On Conservation of Steam in Electroplating in Hero Cyclessharanjeet4uAinda não há avaliações

- Comparison of Price For Water Treatment Chemicals by The Following 3 VendorDocumento1 páginaComparison of Price For Water Treatment Chemicals by The Following 3 VendorAK TRIPATHIAinda não há avaliações

- Radico Khaitan Summer Training Report on Working Capital ManagementDocumento94 páginasRadico Khaitan Summer Training Report on Working Capital ManagementAbhishek AgarwalAinda não há avaliações

- Asme Iso IbrDocumento63 páginasAsme Iso IbrdhaneshquilonAinda não há avaliações

- CRS Manual - PPPU PumpDocumento27 páginasCRS Manual - PPPU PumpRishabh VermaAinda não há avaliações

- Husk Fired Boiler Designed for SavingsDocumento4 páginasHusk Fired Boiler Designed for SavingssebinAinda não há avaliações

- Industrial Waste Fuel Options and Steam Generator Design ConsiderationsDocumento21 páginasIndustrial Waste Fuel Options and Steam Generator Design ConsiderationsSathish PaulAinda não há avaliações

- Bill of Quantities of M. S. Pipe Fittings (O-14027)Documento4 páginasBill of Quantities of M. S. Pipe Fittings (O-14027)Tanmoy DuttaAinda não há avaliações

- Ibr ContentsDocumento29 páginasIbr ContentssunitbhaumikAinda não há avaliações

- Microsoft Word - IBRDocumento5 páginasMicrosoft Word - IBRsujit05Ainda não há avaliações

- Ibr 1950Documento5 páginasIbr 1950sebinAinda não há avaliações

- The Indian Boilers Act, 1923Documento17 páginasThe Indian Boilers Act, 1923Jitendra GandhiAinda não há avaliações

- Indian Boiler Regulations SummaryDocumento15 páginasIndian Boiler Regulations SummarySivi NallamothuAinda não há avaliações

- Chandrapur Super Thermal Power Station, Chandrapur Auxiliary Failure Event Analysis Report Unit No-1 DATE-02.05.2012 Auxiliary FailedDocumento1 páginaChandrapur Super Thermal Power Station, Chandrapur Auxiliary Failure Event Analysis Report Unit No-1 DATE-02.05.2012 Auxiliary FailedGajanan JagtapAinda não há avaliações

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocumento2 páginasEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapAinda não há avaliações

- 02 06 12Documento1 página02 06 12Gajanan JagtapAinda não há avaliações

- Chandrapur Super Thermal Power Station, Chandrapur Auxiliary Failure Event Analysis Report Unit No-1 DATE-02.05.2012 Auxiliary FailedDocumento1 páginaChandrapur Super Thermal Power Station, Chandrapur Auxiliary Failure Event Analysis Report Unit No-1 DATE-02.05.2012 Auxiliary FailedGajanan JagtapAinda não há avaliações

- Turbine Tripped on Condenser Vacuum Low ProtectionDocumento31 páginasTurbine Tripped on Condenser Vacuum Low ProtectionGajanan JagtapAinda não há avaliações

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocumento1 páginaEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapAinda não há avaliações

- CSTPS Unit 3 boiler tube leakageDocumento1 páginaCSTPS Unit 3 boiler tube leakageGajanan JagtapAinda não há avaliações

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocumento1 páginaEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapAinda não há avaliações

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocumento1 páginaEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapAinda não há avaliações

- Unit-1 Tripping 28-3-2009Documento1 páginaUnit-1 Tripping 28-3-2009Gajanan JagtapAinda não há avaliações

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocumento1 páginaEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapAinda não há avaliações

- Event Ana U#6-2006Documento32 páginasEvent Ana U#6-2006Gajanan JagtapAinda não há avaliações

- Unit-2 Tripping 28 - 03 - 2009Documento1 páginaUnit-2 Tripping 28 - 03 - 2009Gajanan JagtapAinda não há avaliações

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocumento1 páginaEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapAinda não há avaliações

- Unit-1 Tripping 28-3-2009Documento1 páginaUnit-1 Tripping 28-3-2009Gajanan JagtapAinda não há avaliações

- Unit-1 Tripping 19-3-2009 - ADocumento1 páginaUnit-1 Tripping 19-3-2009 - AGajanan JagtapAinda não há avaliações

- OS-II Stage-III Event Analysis CardDocumento2 páginasOS-II Stage-III Event Analysis CardGajanan JagtapAinda não há avaliações

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocumento1 páginaEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapAinda não há avaliações

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocumento1 páginaEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapAinda não há avaliações

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocumento1 páginaEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapAinda não há avaliações

- Event Ana U#7,2005Documento24 páginasEvent Ana U#7,2005Gajanan JagtapAinda não há avaliações

- Event Ana U#7,2005Documento24 páginasEvent Ana U#7,2005Gajanan JagtapAinda não há avaliações

- Event Ana U#6,2005Documento27 páginasEvent Ana U#6,2005Gajanan JagtapAinda não há avaliações

- U3 Tripping 12 - 02 - 2009 - ADocumento2 páginasU3 Tripping 12 - 02 - 2009 - AGajanan JagtapAinda não há avaliações

- CSTPS UNIT 3 TRIP DUE TO WET COALDocumento1 páginaCSTPS UNIT 3 TRIP DUE TO WET COALGajanan JagtapAinda não há avaliações

- Event Analysis Report: 198 A, B, D, E, F NILDocumento1 páginaEvent Analysis Report: 198 A, B, D, E, F NILGajanan JagtapAinda não há avaliações

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocumento1 páginaEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapAinda não há avaliações

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocumento1 páginaEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapAinda não há avaliações

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocumento1 páginaEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapAinda não há avaliações

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocumento1 páginaEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapAinda não há avaliações

- Method Statement For Project Signages Rev 0 AfcDocumento16 páginasMethod Statement For Project Signages Rev 0 AfcEchik Kici0% (1)

- HS220 Specification V1.0Documento4 páginasHS220 Specification V1.0Malm n FeelAinda não há avaliações

- ARFCNDocumento2 páginasARFCNAnonymous i3gPuCAinda não há avaliações

- Eds460-490 D00085 M XxenDocumento100 páginasEds460-490 D00085 M XxencostelchelariuAinda não há avaliações

- f2403 Wcdma Ip Modem Technical SpecificationDocumento3 páginasf2403 Wcdma Ip Modem Technical SpecificationCocofourfaithAinda não há avaliações

- Operating Instructions CS 3000 - Pausch LLCDocumento33 páginasOperating Instructions CS 3000 - Pausch LLCEdgar DauzonAinda não há avaliações

- Source ChangeoverDocumento116 páginasSource ChangeoverDiana ConsstantinAinda não há avaliações

- Table of Design Properties For Metric Steel Bolts M5 To M39 - Eurocode 3Documento10 páginasTable of Design Properties For Metric Steel Bolts M5 To M39 - Eurocode 3anon_295574042Ainda não há avaliações

- 119 Vol25 ATR72-212A600 MP Version1.50 1nov2017Documento179 páginas119 Vol25 ATR72-212A600 MP Version1.50 1nov2017Jnr Rastah MarksmahnAinda não há avaliações

- Battle of The Bands PDFDocumento4 páginasBattle of The Bands PDFMarty DelimaAinda não há avaliações

- BSNL Summer TrainingDocumento258 páginasBSNL Summer TrainingTarun SamaAinda não há avaliações

- OMG Standards: Common Object Request Broker ArchitectureDocumento3 páginasOMG Standards: Common Object Request Broker ArchitecturejayanthikrishnanAinda não há avaliações

- Development of Vietnamese Codes and Standards in Construction - Ws2006-Nbnguyen-PDocumento20 páginasDevelopment of Vietnamese Codes and Standards in Construction - Ws2006-Nbnguyen-PSen HuAinda não há avaliações

- Kershaw CatalogDocumento68 páginasKershaw CatalogjoeAinda não há avaliações

- Madras Fertilizers TAT LAT ApplicationDocumento10 páginasMadras Fertilizers TAT LAT ApplicationSagar MalothAinda não há avaliações

- Section 5 - Drawings Design Calculations & Specifications ControlDocumento5 páginasSection 5 - Drawings Design Calculations & Specifications ControlYasser Hammad MohamedAinda não há avaliações

- Proceq Operating Instructions Dyna EDocumento35 páginasProceq Operating Instructions Dyna Ecristina_romanescuAinda não há avaliações

- 434 HW 2 SolDocumento5 páginas434 HW 2 SolAnhTuan NguyenHuuAinda não há avaliações

- Dinesh Op. Mgmt.Documento26 páginasDinesh Op. Mgmt.Nino Dinesh TaringAinda não há avaliações

- HSPA - Network Optimization & Trouble Shooting v1.2Documento15 páginasHSPA - Network Optimization & Trouble Shooting v1.2Ch_L_N_Murthy_273Ainda não há avaliações

- GXW Series Extending Analog LinesDocumento4 páginasGXW Series Extending Analog LinesSR DTAinda não há avaliações

- Interface Qos: Security LevelDocumento6 páginasInterface Qos: Security Levelmafasa_2005Ainda não há avaliações

- Putty For Windows, Linux and Mac - Install SSH in PuTTYDocumento10 páginasPutty For Windows, Linux and Mac - Install SSH in PuTTYRiris Sigit PramonoAinda não há avaliações

- 54810A Service GuideDocumento202 páginas54810A Service GuideSeoolasAinda não há avaliações

- CC65 ManualDocumento4 páginasCC65 ManualWalter ChavezAinda não há avaliações

- HydroGate PDFDocumento12 páginasHydroGate PDFecocadecAinda não há avaliações

- Ping TCU and NWI 2GDocumento9 páginasPing TCU and NWI 2G3GSEROAinda não há avaliações

- ARM 54 Look Inside The Book PDFDocumento6 páginasARM 54 Look Inside The Book PDFJha NizAinda não há avaliações

- SB 150Documento4 páginasSB 150AnilAinda não há avaliações

- 37222090-Huawei-WCDMA-HSDPA-Parameters Huawei)Documento68 páginas37222090-Huawei-WCDMA-HSDPA-Parameters Huawei)Faizal Jamaludeen100% (2)