Escolar Documentos

Profissional Documentos

Cultura Documentos

Demag Standard Cranes

Enviado por

Eldio KlenDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Demag Standard Cranes

Enviado por

Eldio KlenDireitos autorais:

Formatos disponíveis

Demag Standard Cranes

Performance and ef ciency at the highest level

Demag sets crane standards for the future

Standard solutions made by Demag offer outstanding quality, ef ciency, and reliability at the highest level. Every crane and every crane component re ects decades of crane expertise and reliability as a partner for the industry. Innovation for greater ef ciency to bene t our customers With the new DR rope hoist, Demag Cranes & Components has introduced a state-of-the-art standard for crane applications with loads weighing up to 50 mt and, at the same time, an entirely new crane philosophy. The C shape of the Demag DR rope hoist design is ideally suited to crane applications. Thanks to the many bene ts offered by the new DR rope hoist, the entire crane operates much more ef ciently. Proven crane geometry guarantees high design rigidity, optimum travel characteristics and minimum wear Raised crane girders, designs tailored to match the roof structure, and compact trolleys with minimum approach dimensions facilitate larger hook paths as well as better utilization of the available space and reduce initial construction and subsequent costs Ergonomic pushbutton stations and interactive radio controls with load range display ensure highly convenient operation and safe load handling. The display provides complete transparency of the system controls

38926-2

In nitely variable speed control in all motion axes, via frequency inverter-fed drives, reduces load sway, facilitates exact and gentle positioning, and lowers the mechanical load on the crane installation High lifting and cross travel speeds provide faster handling rates and greater ef ciency Standard overload devices prevent unsafe overload conditions

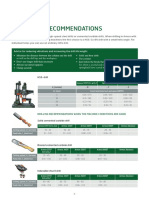

Crane type Capacity* up to Span* up to Bridge travel speed* up to Trolley travel speeds* up to Hoist lifting speed* up to Stepless motions * Other speci cations on request

Under running single girder cranes 10 mt 60' (18m)

Top running single girder cranes 12.5 mt

Top running double girder cranes 50 mt

98' (30m) 160 fpm 100 fpm 41 fpm 3 axes 82 fpm

39343-2

In nitely variable speed control facilitates particularly gentle handling of the load

Top running single girder crane with beam girder

Under running single girder crane

Top running single girder crane with box-section girders

Top running double girder crane

Attention to detail for total quality

39559

37371-1

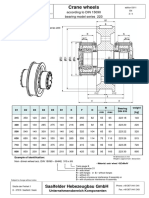

End truck Maximum strength by using a rigid box-section design with reinforced connection areas as well as machined tolerances in the crane girder connection system guarantee superior structural integrity and optimum travel characteristics with minimum wear The precise travel wheel alignment and exact adaptation of the crane span dimension via interchangeable spacer elements ensure optimum travel characteristics and high adaptability End trucks con gured with proprietary structural design programs

Power supply line Demag DCL compact conductor line for 4 to 7 poles; connections ensure long-term power supply and minimize unplanned downtime Pre-assembled building blocks for simple assembly or replacement of current collector trolleys or complete straight sections provide optimum serviceability IP 23 or IP 24 high protection against accidental contact with sealing lip and integral expansion joints for optimum safety

Travel unit Maintenance-free drives with anti-friction bearings lubricated for life, maximum bearing centers to accommodate horizontal forces, and travel wheels made of spheroidal graphite nodular iron provide for favorable travel characteristics and minimum crane runway wear In nitely stepless variable travel speeds via frequency inverters with speeds up to 240 fpm guarantee travel with minimum load-sway as well as precise positioning

37427-4

38972-2-1

39589-4

39030-1

39330-1

Hoist trolleys State-of-the-art Demag DR rope hoist of C-shaped design optimized for crane applications with higher hoist and cross travel speeds provides higher handling rates and ef ciency for cranes with capacities up to 50 m t Compact designs with minimum approach dimensions and larger hook path guarantee optimum utilization of the available space and height and reduce initial construction and subsequent costs In nitely variable hoist and travel motions guarantee low-sway handling. Precise, gentle positioning provides for greater safety and convenient operation CAN Bus technology to meet tomorrows demands for high data transmission reliability, corresponding to safety class 3 to DIN / EN 954, ensures optimum monitoring for greater ef ciency thanks to preventive maintenance

Control system Ergonomically designed control units for safe, fatigue-free handling. The display provides complete transparency for control of the installation. The CAN Bus control system corresponds to safety category 3 to DIN / EN 954. Demag DSE pushbutton control pendant suspended for separate travel on the crane girder Handheld or belly box CAN Bus radios for wireless control allow operator exibility

Bottom block Enhanced bottom block design with standard load hook for ease of load connection Rope lead-in guard eliminates the risk of being caught between the rope and sheave Handle recesses on both sides simplify handling of the bottom block and increase operating safety

38962

Top running single girder cranes

EKKE top running single girder cranes provide you with Demag technology at a particularly attractive price. They feature maximum rigidity for a minimum deadweight. This keeps the load on the crane runway low, and a cost-effective design can be selected for the building. They also offer the bene ts of outstanding crane geometry, resulting in exceptional travel characteristics. The Demag EKDR rope hoist is the optimum design for crane applications, enabling the crane to meet your requirements for greater ef ciency. Bene ts and features Computer-optimized box section for the crane girder End truck of torsionally rigid, welded box girder construction Travel wheels of highly wear-resistant GGG 70 spheroidal nodular iron with self-lubricating properties

Connections between the girder and end trucks manufactured to precise machined tolerances for minimum wear Trolley of low-headroom design with rope hoist, offering particularly favorable hook approach dimensions to serve the largest possible area Power supply to the trolley via high- exibility at cable with protective ground conductor Control pendant suspended for separate travel on the crane girder, with display for system monitoring Optional: radio remote control Pre-treatment of steel components for optimum anti-corrosion protection of all parts Paint nish in golden yellow. Travel drives in azure blue. Trolley powder-coated in azure blue and silver grey

EKKE single girder crane

Technical data Capacity Span Bridge travel speed Trolley travel speed Hoist speed Other speci cations on request to 12.5 mt to 98' to 160 fpm to 100 fpm to 41 fpm

Optimum adaptation to the building design

Type 1

Type 2

Options See accessories, page 14 Technical data sheet Ident. no. 900 435 49

Type 3 Type 4/5

38972-1-1

Your bene ts with the Demag DR rope hoist optimized for crane applications Minimum operating cost thanks to extended FEM 2m+ service life (1900-hour full load service life) which exceeds the duty requirements of H4 rating per ASTM B30.16 Improved load handling due to increased lifting and cross travel speed

Minimum load-sway thanks to in nitely variable cross travel speeds System monitoring for improved operational transparency Improved utilization of your production area thanks to minimum approach dimensions

Top running single girder cranes with beam girder

EKKE top running single girder cranes with beam girders offer outstanding value for the money. The use of rolled steel sections for the crane girder and traveling rope hoists optimized for crane applications make these cranes the optimum solution for lighter loads and shorter spans. EKKE standard cranes ensure ef cient and fatigue-free load handling thanks to the higher cross travel speed and optimized ergonomic control pendants. When tted with features such as in nitely variable speed cross travel drives, they also make it possible to achieve low-sway travel motions for gentle handling and precise positioning of loads.

In addition, they also offer high reliability and safety as well as a long service life combined with high levels of operating ef ciency by all components. Bene ts and features Rolled section crane girder Optimum adaptation to the building design (page 6)

EKKE single girder crane

Technical data Capacity Span Bridge travel speed Trolley travel speed Hoist speed Other speci cations on request to 10 mt to 59' to 160 fpm to 100 fpm to 41 fpm

Options See accessories, page 14 Technical data sheet Ident. no. 900 435 49

The standard display in the control pendant provides complete transparency for control of the crane system

Under running single girder cranes the column-free alternative

Simply attached to the existing roof structure, Demag under running cranes eliminate the need for runway support columns. This way, the entire building oor area is available for production. Peripheral areas of the workshop can be served by using the girder overhangs to extend the travel range of the hoist trolley beyond the runways. Optional latching devices make it possible to transfer the hoist trolley from the crane girder to a branch track and back without having to deposit the load.

Bene ts and features Consistent quality with overhead traveling crane bene ts End truck of optimized structural design Rigid beam girders or welded box girders for optimum load distribution Loads can be handled immediately adjacent to the building wall by means of girder ends tailored to the application requirements

EDKE under running single girder crane

Technical data Capacity Span Bridge travel speed Trolley travel speed Hoist speed Other speci cations on request to 10 mt to 60' to 160 fpm to 100 fpm to 41 fpm

Options See accessories, page 14 Technical data sheet Ident. no. 900 436 49

10

Radio control systems enable cranes to be controlled from any operator position

11

Top running double girder overhead cranes high load capacities combined with long spans

Demag double girder overhead traveling cranes offer you a virtually unmatched deadweight/load capacity ratio. They are also characterized by their outstanding crane geometry, ensuring extremely favorable travel characteristics and therefore minimizing wear. The particularly large lifting height is derived from the fact that the load hook can be raised between the two crane girders. Depending on requirements, our double girder overhead traveling cranes can also be tted with radio or operator cab controls. Optional maintenance platforms and trolley platforms not only facilitate crane maintenance but also ensure that your hall ttings such as lamps, heating elements or supply lines can be quickly and easily reached.

Bene ts and features Consistent quality with overhead traveling crane bene ts Performance oriented double girder bridge design for high speeds in all axes Optimized structural design using proprietary software to meet crane duty class requirements per speci ed standards Low deadweight reduces initial runway structure investment Options - Maintenance platform - Full length walkway on one or both girders - Trolley maintenance platform

ZKKE double girder crane

Technical data Capacity Span Bridge travel speed Trolley travel speed Hoist speed Other speci cations on request to 50 mt to 114' to 160 fpm to 82 fpm to 41 fpm

Optimum adaptation to the building design

Type 1

Options See accessories, page 14 Technical data sheet Ident. no. 900 463 49

Type 2

12

The double girder design provides for particularly high load capacities and sensitive load handling thanks to in nitely variable speed control 13

Demag crane accessories and auxiliary equipment

39343-3

39294-2

39008-2

With our wide range of accessories and auxiliary equipment, we are able to adapt our standard cranes to the individual requirements of your application. Control by means of a pendant switch or, if desired, interactive radio control Variable speed motors with frequency inverters help to avoid load sway Cranes equipped with two trolleys make it easy to handle long and awkward loads A comprehensive range of load handling attachments satis es the most varied requirements

For applications that are not suitable for the digital CAN Bus control technology, Demag offers the exibility to provide any DR hoist with conventional, non-digital controls Planners and plant designers can use our online Automated Quotation System (AQS), which allows for quick and easy con guration of standard cranes, complete with dimensional Auto CAD drawings of the cranes. http://aqs.demag-us.com

14

Double girder overhead traveling crane with tandem end trucks for transporting and turning engine blocks

15

Crane system data can be displayed for preventative and scheduled maintenance

Sales and Service Centers in North America

California 5435 Industrial Parkway San Bernardino, California 92407 Telephone (909) 880-8800 Fax (909) 880-4469 Georgia 254 Lake Ruby Drive Suwanee, Georgia 30024 Telephone (678) 546-0593 Fax (678) 482-7653 Illinois 11261 Kiley Drive Huntley, Illinois 60142 Telephone (847) 515-7030 Fax (847) 515-7040 Michigan 46545 Continental Drive Chestereld, Michigan 48047 Telephone (586) 949-6035 Fax (586) 949-6038 Missouri 3375 Hwy 185 Washington, Missouri 63090 Telephone (314) 401-9517 Fax (636)239-4217 South BTC 560, Suite 150, 454 S. Anderson Road Rock Hill, SC 29730 Carolina Telephone (803) 909-9000 Fax (803) 909-9001 Ohio 29201 Aurora Road Cleveland, Ohio 44139 Telephone (440) 248-2400 Fax (440) 248-3874 Ontario 1155 North Service Road West, Unit 1 Oakville, Ontario L6M 3E3 Telephone (905) 825-5900 Fax (905) 825-5901 Quebec 3524, Rue Ashby St-Laurent, Quebec H4R 2C1 Telephone (514) 336-5556 Fax (514) 336-4349 Texas 16430 Aldine-Westeld Road Houston, Texas 77032 Telephone (281) 443-7331 Fax (281) 443-7308 Washington 704 - 228th Avenue NE Sammamish, Washington 98074 Telephone (425) 883-4668 Fax (425) 883-4828

Demag Cranes & Components Corp.

29201 Aurora Road Cleveland, Ohio 44139 Telephone (440) 248-2400 Fax (440) 248-3874 www.demag-us.com

06/09 US/EN

229 996 49

701 IS 100

Not liable for errors or omissions. Subject to change. Printed in the U.S.A.

Você também pode gostar

- Manual Crane CalculationDocumento98 páginasManual Crane CalculationLarry Bea67% (15)

- Crane Tips: Overhead Crane Vibration, Natural FrequencyDocumento3 páginasCrane Tips: Overhead Crane Vibration, Natural FrequencySACHINAinda não há avaliações

- Crane Runway Beam Design Using CSA S16-14 CodeDocumento3 páginasCrane Runway Beam Design Using CSA S16-14 CodesergiooiAinda não há avaliações

- Crane BeamDocumento8 páginasCrane BeamastorAinda não há avaliações

- List of FEM Documents 2015Documento6 páginasList of FEM Documents 2015jmpateiro1985Ainda não há avaliações

- FEM9.751 Engl PDFDocumento52 páginasFEM9.751 Engl PDFserkanAinda não há avaliações

- Van Leusden Catalogue 2008Documento66 páginasVan Leusden Catalogue 2008Marcel VanAinda não há avaliações

- Rigging FittingsDocumento52 páginasRigging FittingsbhaskarjalanAinda não há avaliações

- Cranes DEMAG CatalogueDocumento160 páginasCranes DEMAG Cataloguelcorao100% (1)

- Conventional Ammunition Unit Operations - FM 9-38Documento101 páginasConventional Ammunition Unit Operations - FM 9-38Robert SuteuAinda não há avaliações

- Demag Crane BrochureDocumento20 páginasDemag Crane BrochureSugiarto SaptomoAinda não há avaliações

- KBK Brochure PDFDocumento12 páginasKBK Brochure PDFMahendran KuppusamyAinda não há avaliações

- Eot Crane During SeismicDocumento12 páginasEot Crane During SeismicboyzesAinda não há avaliações

- Non-Driven Wheel DIN15090 Series 223 EN PDFDocumento1 páginaNon-Driven Wheel DIN15090 Series 223 EN PDFayavuzbvsAinda não há avaliações

- FEM9.311 EnglDocumento6 páginasFEM9.311 EnglPınar SunAinda não há avaliações

- ETN ESN ETL KerékszekrenyDocumento66 páginasETN ESN ETL KerékszekrenyKovács EndreAinda não há avaliações

- End Carriage DFW S E AssmeblyDocumento52 páginasEnd Carriage DFW S E AssmeblycutenganAinda não há avaliações

- Slewing Jib Cranes - Vetter KrantechnikDocumento18 páginasSlewing Jib Cranes - Vetter KrantechnikSamuel OchoaAinda não há avaliações

- CSA Bolted Connection FatigueDocumento3 páginasCSA Bolted Connection FatiguejurieskAinda não há avaliações

- Demag CataloqueDocumento204 páginasDemag CataloqueEu100% (1)

- Free Standing Hoist CraneDocumento16 páginasFree Standing Hoist CranecadsultanAinda não há avaliações

- Catálogo Guindaste de Coluna DemagDocumento72 páginasCatálogo Guindaste de Coluna Demag0842500% (1)

- 40 Ton PayloadDocumento1 página40 Ton PayloadSabra A.S.Ainda não há avaliações

- Crane Beam Design: AISC Design Guide 7 Example 18.1.2 LRFD Aisc CSD 3/25/2005Documento38 páginasCrane Beam Design: AISC Design Guide 7 Example 18.1.2 LRFD Aisc CSD 3/25/2005yercAinda não há avaliações

- Demag Vinç BilgileriDocumento28 páginasDemag Vinç BilgileriZahid ArıcıAinda não há avaliações

- Brugg Catalog enDocumento28 páginasBrugg Catalog enSinoj V AntonyAinda não há avaliações

- C HookDocumento11 páginasC HookPradip SitaparaAinda não há avaliações

- Wheel Load Data PDFDocumento54 páginasWheel Load Data PDFDinesh PatilAinda não há avaliações

- Crane Guide Chap-1Documento1 páginaCrane Guide Chap-1Jayadev PalaiAinda não há avaliações

- Cross Travel Motor Power CalculationsDocumento1 páginaCross Travel Motor Power Calculationssmarika_16Ainda não há avaliações

- Design of Crane Runway Beam With ChannelDocumento9 páginasDesign of Crane Runway Beam With Channellatyrniang100% (3)

- KranDocumento7 páginasKranMarioAinda não há avaliações

- Overhead Crane DesignDocumento50 páginasOverhead Crane DesignjuanAinda não há avaliações

- Tong HookDocumento8 páginasTong HookEricAinda não há avaliações

- Crane Runway Beam Design - Crane Load CalculationDocumento6 páginasCrane Runway Beam Design - Crane Load CalculationMuhammed ShamseerAinda não há avaliações

- SteelBook UpdateDocumento450 páginasSteelBook UpdateJorge Varela100% (1)

- Loads Acting On Crane Structure During TravelDocumento11 páginasLoads Acting On Crane Structure During Travelaiyubi2Ainda não há avaliações

- Component Parts: DZW Position Measuring SystemDocumento12 páginasComponent Parts: DZW Position Measuring SystemBang OchimAinda não há avaliações

- STAHL Crane PDFDocumento18 páginasSTAHL Crane PDFJustin AlwarAinda não há avaliações

- 10 - The Rail Book Issue3 - WIPDocumento41 páginas10 - The Rail Book Issue3 - WIPTT100% (1)

- Eurobloc VT 9 10 11 12 GBDocumento6 páginasEurobloc VT 9 10 11 12 GBToni RenedoAinda não há avaliações

- CMAA 70 2000 Structure DesignDocumento19 páginasCMAA 70 2000 Structure DesignmishikhanAinda não há avaliações

- Fine Boring ToolsDocumento39 páginasFine Boring Toolsm_najmanAinda não há avaliações

- ASME B30.13-2011 IngDocumento4 páginasASME B30.13-2011 IngEmmanuel NahasAinda não há avaliações

- Sheave Design 10tDocumento1 páginaSheave Design 10tSubratAinda não há avaliações

- Transfer Chute For Bulk Materi PDFDocumento131 páginasTransfer Chute For Bulk Materi PDFAkhilprasad SadigeAinda não há avaliações

- Chain RollerANSIDocumento35 páginasChain RollerANSICallao JimmyAinda não há avaliações

- EOT Crane Mechanical Equipment Calculation 1Documento17 páginasEOT Crane Mechanical Equipment Calculation 1satendra sharmaAinda não há avaliações

- Crane CalcsDocumento13 páginasCrane Calcslenganji simwandaAinda não há avaliações

- Crane BeamDocumento20 páginasCrane BeamPreyash Shah100% (1)

- 01 Top Running Double Girder Crane DataDocumento8 páginas01 Top Running Double Girder Crane Dataevelyn_inocenci6140Ainda não há avaliações

- Heaviest Loads On Modular Axle Lines: Powered byDocumento28 páginasHeaviest Loads On Modular Axle Lines: Powered byTcristomoradoAinda não há avaliações

- Demag Standard Cranes PDFDocumento16 páginasDemag Standard Cranes PDFSikasep TeaAinda não há avaliações

- Brochure DemagDocumento16 páginasBrochure DemagaghussrAinda não há avaliações

- ES 200 HD - CatalogueDocumento17 páginasES 200 HD - CatalogueAyman HammodehAinda não há avaliações

- DEMAG Universal CranesDocumento20 páginasDEMAG Universal CranesIgnacio Moratinos CastañedaAinda não há avaliações

- 110730Documento20 páginas110730Hebert CcahuanaAinda não há avaliações

- Standard CraneDocumento20 páginasStandard CranecehaiguAinda não há avaliações

- Demag Standard Crane (Brochure)Documento20 páginasDemag Standard Crane (Brochure)MadhaneAinda não há avaliações

- EKKE Single-Girder Overhead Travelling Cranes Up To 12.5 Tonnes - DemagcranesDocumento1 páginaEKKE Single-Girder Overhead Travelling Cranes Up To 12.5 Tonnes - Demagcranesadik andi rahmat hanafiAinda não há avaliações

- Demag Crane Sets: Tailored Component Sets For Suspension and Single and Double-Girder Overhead Travelling CranesDocumento8 páginasDemag Crane Sets: Tailored Component Sets For Suspension and Single and Double-Girder Overhead Travelling CranesAmazonas ManutençãoAinda não há avaliações

- Interview QuestionDocumento2 páginasInterview Questionmarikarthi100% (1)

- DICA - List of Restricted Investment ActivitiesDocumento18 páginasDICA - List of Restricted Investment ActivitiesYe Tun AungAinda não há avaliações

- HF Drilling Rig InstructionDocumento146 páginasHF Drilling Rig InstructionLuis Alberto Moscoso AranedaAinda não há avaliações

- Machining Recommendations: Advice For Reducing Vibrations and Increasing The Drill Life LengthDocumento3 páginasMachining Recommendations: Advice For Reducing Vibrations and Increasing The Drill Life LengthbasaricaAinda não há avaliações

- Vocabulary of HolidayDocumento3 páginasVocabulary of Holidaydoctor_carmonaAinda não há avaliações

- Hydrometallurgy in Codelco Norte: Division Production KT Copper Net Cost US$/lbDocumento12 páginasHydrometallurgy in Codelco Norte: Division Production KT Copper Net Cost US$/lbLuis Paulo Medina ArévaloAinda não há avaliações

- Civil Aviation Act 2006Documento6 páginasCivil Aviation Act 2006Iludiran KolaAinda não há avaliações

- Purchasing Manufacturing Tooling Manager in Racine WI Resume William GustinDocumento2 páginasPurchasing Manufacturing Tooling Manager in Racine WI Resume William GustinWilliamGustinAinda não há avaliações

- 4 - Agenda 6 REACDocumento7 páginas4 - Agenda 6 REACSumit TutejaAinda não há avaliações

- Prod Pitot Static Adapters 18821 4 PDFDocumento8 páginasProd Pitot Static Adapters 18821 4 PDFIvo SilvaAinda não há avaliações

- Fiche cfm56-5c Ang1Documento2 páginasFiche cfm56-5c Ang1hamidrezachamaniAinda não há avaliações

- Inventory Management Technique Used in Retail IndustryDocumento64 páginasInventory Management Technique Used in Retail IndustryChangoGhosteryAinda não há avaliações

- Project Document11Documento10 páginasProject Document11shouri12aAinda não há avaliações

- Coal Handling PLantDocumento8 páginasCoal Handling PLantPrasanna kumar subudhiAinda não há avaliações

- Impact of GST On Indian SCMDocumento9 páginasImpact of GST On Indian SCMVinodh Kumar Perumal100% (2)

- 23.249 DWTDocumento4 páginas23.249 DWTCornel N. ŞeitanAinda não há avaliações

- Flanges and Pipe Fitting ManufacturerDocumento12 páginasFlanges and Pipe Fitting Manufacturer9823458877Ainda não há avaliações

- Methods of Tube Expansion in Tube To TubDocumento19 páginasMethods of Tube Expansion in Tube To Tubkurcek100% (1)

- PHELPS DODGE Superflex Pdic01214Documento5 páginasPHELPS DODGE Superflex Pdic01214unividenteAinda não há avaliações

- 1019spm S7000re L03Documento12 páginas1019spm S7000re L03Farid TataAinda não há avaliações

- Daftar Obat PharmacyDocumento7 páginasDaftar Obat PharmacyparulianoAinda não há avaliações

- Thin-Wall Injection Molding.Documento2 páginasThin-Wall Injection Molding.Werner SchrammelAinda não há avaliações

- OrmglasDocumento24 páginasOrmglasdanielep1Ainda não há avaliações

- Design of Jigs and FixturesDocumento7 páginasDesign of Jigs and FixturesOnkar KakadAinda não há avaliações

- CottonDocumento92 páginasCottonANILAinda não há avaliações

- FHY AnchorDocumento2 páginasFHY Anchorlbhnsw5930Ainda não há avaliações

- Samsung Washing Machine (WA80U3) ManualDocumento12 páginasSamsung Washing Machine (WA80U3) ManualRalph Montejo0% (1)

- Reflection 1Documento10 páginasReflection 1api-287545754Ainda não há avaliações

- Astm F 568M-04Documento9 páginasAstm F 568M-04JORGE ARTURO TORIBIO HUERTAAinda não há avaliações