Escolar Documentos

Profissional Documentos

Cultura Documentos

NanoSHIELD™ Hollow Fiber Filter Cartridge Series - (529.4 K)

Enviado por

singlethienDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

NanoSHIELD™ Hollow Fiber Filter Cartridge Series - (529.4 K)

Enviado por

singlethienDireitos autorais:

Formatos disponíveis

NanoSHIELD Hollow Fiber Series

Polypropylene Filter Cartridges

High Flow Rates, Low Pressure Drop, and Longer Filter Lifetime

NanoSHIELD hollow fiber series polypropylene filter cartridges have been engineered to combine the highest level of particle retention with superior flow rates and minimal pressure drop for demanding applications at the 45 nm node.

Peak Performance Provided by Hollow Fiber Technology (HFT)

NanoSHIELD hollow fiber series filter cartridges with HFT provide up to 2 times more surface area and up to 5 times higher flow rates at the same pressure drop when compared to pleated membrane cartridges. This increase to flow and decrease to pressure drop allows a typical 10 NanoSHIELD hollow fiber series filter cartridge to perform similarly to a 20 pleated filter cartridge. This significant advantage allows for the use of smaller and less costly filter housings which reduce hold-up volume, filter change-out times, and total cost-of-ownership for the life of the process. In addition, 3M Purification Inc.s HFT produces a membrane that is up to 2 times thicker than other technologies which in turn maximizes the depth of filtration and particle removal efficiency.

NanoSHIELD Hollow Fiber Series Cartridge Construction

The hollow fiber polypropylene membrane in an all polyethylene construction provides low metallic/ionic contamination and excellent resistance to most chemicals. Metallic or ionic contaminants can extract from surface modified and or improperly manufactured filters, which may reduce shelf life and or change the photo-speed, viscosity, or molecular weight of advanced chemicals. For this reason, all NanoSHIELD hollow fiber series filters are critically cleaned and integrity tested to provide low extractables and process repeatability out of the box. The compact design of NanoSHIELD hollow fiber series polypropylene filter cartridges make them ideally suited for critical applications requiring low hold-up volume with superior flow rates and high particle retention at 0.01, 0.02, 0.05, and 0.1 m

Applications

ARC, BARC, TARC 193 nm Photoresists Polyimide Solvents Alcohols Bases Developers Etchants / Strippers

Features &Benefits

Hollow Fiber Technology. n Up to 2 times more surface area as compared to equivalent sized pleated filters. n Increased depth (2x thicker) of filtration results in improved particle retention. Large Surface Area n Up to 5 times higher flow rates as compared to other pleated cartridges. n 10 NanoSHIELD hollow fiber series cartridges flow similar to 20 pleated cartridges n Increased lifetime, throughput, and overall equipment effectiveness (OEE). Compact Design. n Allows for smaller, less costly filter housings. n Reduces hold-up volume, exposure, and waste of expensive chemicals. 0.01 m and 0.02 m Retention Ratings. n Superior removal of particles, gels, and micro-bubbles. n Reduced micro-bridge and wafer level defects for 193 nm photoresists. Quality Manufacturing. n Manufactured in a cleanroom to reduce particle adders and extractables. n Filters are critically cleaned and tested for process repeatability.

NanoSHIELD Hollow Fiber Series Polypropylene Filter Cartridge

Typical Cartridge Flow vs. Differential Pressure (1cps @ 25C) Graph 1: 5 NanoSHIELD Hollow Graph 2: 10 NanoSHIELD Hollow Graph 3: 20 NanoSHIELD Hollow Fiber SeriesCartridge Cartridge Graph 1: 5 NanoSHIELD

1

02

Series Cartridge Graph 2: 10 Fiber NanoSHIELD Cartridge

10

NS P0 02

Series Cartridge Graph 3: 20 Fiber NanoSHIELD Cartridge

10

NS P0 01 NS P0 02

10 Differential Pressure (psid) 8 6 4

NS P0 05 NS P0 10

NSP00

Differential Pressure (psid)

Differential Pressure (psid)

Differential Pressure (bar)

8 6 4 2 0 0 1.0

Differential Pressure (bar)

0.4 0.2

05 P0 0 NS P01 S N

8 6 4

0.4 0.2

NS P01 NS

0 P0

5

0

0.4 0.2

2 0 0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0

2 0 0 2.0 4.0 6.0 8.0 10.0 12.0

2.0 3.0

4.0

5.0

6.0

7.0

8.0

Fluid Flow Rate (GPM) 0 5 10 15 20 Fluid Flow Rate (LPM) 25 30 0 5

Fluid Flow Rate (GPM) 10 15 20 Fluid Flow Rate (LPM) 25 30 0

Fluid Flow Rate (GPM) 10 20 30 Fluid Flow Rate (LPM) 40

NanoSHIELD Hollow Fiber Series Cartridge Specifications NanoSHIELD Cartridge Specifications

Membrane Material Cage and End Caps Potting Material Hydrophobic Polyproylene Polyethylene Polyethylene 5 Cartridge 10.8 ft2 (10,000 cm2) 10 Cartridge 23.7 ft2 (22,000 cm2) 20 Cartridge 47.3 ft2 (44,000 cm2) 2.75 (7 cm) nominal Nominal 5, 10, and 20 (12.7, 25.4, and 50.8 cm) 58 psig @ 77F (4 bar @ 25C) 28 psid @ 77F (1.9 bar @ 25C) 104F (40C) 0.01, 0.02, 0.05, and 0.1 100% Tested

Ordering Guide

Media

NSP 001 - 0.01 m 002 - 0.02 m 005 - 0.05 m 010 - 0.1 m 50 - 5* 01 - 10** 02 - 20

Removal Rating

Configuration

Length

Fitting Connection

B - 226 O-Ring & Spear C - 222 O-Ring & Spear F - 222 O-Ring & Flat Cap J - 226 O-Ring & Flat Cap

O-ring Material

Filtration Surface Area

Cartridge Outside Diameter Length Maximum Operating Pressure Maximum Differential Pressure Maximum Operating Temperature Absolute Removal Ratings (m) Filter Capsule Integrity

C - EPDM K - Fluorocarbon Encapsulated PTFE (FEP)

* Available in F end modification only. ** Available in F and J end modifications only. Consult factory for pre-wet options.

Important Notice 3M Purification Inc. MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Since a variety of factors can affect the use and performance of a 3M Purification Inc. product in a particular application, some of which are uniquely within the users knowledge and control, user is responsible for determining whether or not the 3M Purification Inc. product is fit for a particular purpose and suitable for users method of application. Limitation of Remedies and Liability If the 3M Purification Inc. product is proved to be defective, THE EXCLUSIVE REMEDY, AT 3M Purification Inc.S OPTION, SHALL BE TO REFUND THE PURCHASE PRICE OR TO REPAIR OR REPLACE THE DEFECTIVE PRODUCT. 3M Purification Inc. shall not otherwise be liable for loss or damages, whether direct, indirect, special, incidental or consequential, regardless of the legal theory asserted, including, but not limited to, contract, negligence, warranty or strict liability. Warranty Seller warrants its equipment against defects in workmanship and material for a period of 12 months from date of shipment from the factory under normal use and service and otherwise when such equipment is used in accordance with instructions furnished by Seller and for purposes disclosed in writing at the time of purchase, if any. Any unauthorized alteration of modification of the equipment by Buyer will void this warranty. Sellers liability under this warranty shall be limited to the replacement or repair, F.O.B., point of manufacture, of any defective equipment or part which, having been returned to the factory, transportation charges prepaid, has been inspected and determined by Seller to be defective. THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, EITHER EXPRESSED OR IMPLIED, AS TO DESCRIPTION, QUALITY, MERCHANTABILITY, FITNESS FOR ANY PARTICULAR PURPOSE OR USE, OR ANY OTHER MATTER. Under no circumstances shall Seller be liable to Buyer or any third party for any loss of profits or other direct or indirect costs, expenses, losses or consequential damages arising out of or as a result of any defects in or failure of its products or any part or parts thereof or arising out of or as a result of parts or components incorporated in Sellers equipment but not supplied by the Seller.

Your Local Distributor:

3M Purification Inc.

400 Research Parkway Meriden, CT 06450 U.S.A. Phone (800) 243-6894 (203) 237-5541 Fax (203) 630-4530 www.3Mpurification.com

Please recycle. Printed in U.S.A. NanoSHIELD is a trademark of 3M Company. 3M 2011. All rights reserved. 70-0201-8778-0 REV 1011b

Differential Pressure (bar)

NSP 0

0.6

NSP 001

0.6

0.6

Você também pode gostar

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Words and PhrasesDocumento604 páginasWords and Phrasessinglethien100% (2)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Chapter 4.2 Chemical HazardsDocumento32 páginasChapter 4.2 Chemical HazardsFarid Nasri100% (1)

- Alacc Guide 2008Documento18 páginasAlacc Guide 2008Karen Kawanishi100% (1)

- 8189473158Documento326 páginas8189473158sharan100% (6)

- PHD Thesis Samuel CarraraDocumento259 páginasPHD Thesis Samuel CarraraCostas MoraitisAinda não há avaliações

- Complying With ISO 17025 A Practical GuidebookDocumento122 páginasComplying With ISO 17025 A Practical Guidebookyes17025100% (8)

- BOD ProcedureDocumento14 páginasBOD ProcedureSajith Ranatunga100% (1)

- BOD ProcedureDocumento14 páginasBOD ProcedureSajith Ranatunga100% (1)

- WI-INSP-01 R2 Work Instruction-Pressure Vessel InspDocumento8 páginasWI-INSP-01 R2 Work Instruction-Pressure Vessel InspRakesh Mishra100% (1)

- Laboratory ManagementDocumento33 páginasLaboratory ManagementsinglethienAinda não há avaliações

- Interconection Pipe RackDocumento16 páginasInterconection Pipe RackPhucChuVanAinda não há avaliações

- Blasting and PaintingDocumento64 páginasBlasting and PaintingSyahril Aizal Ahmad75% (4)

- Process GuidelinesDocumento87 páginasProcess Guidelinesjvatsan100% (5)

- 0819492485Documento405 páginas0819492485arulmurugu100% (1)

- Rate of Exhaustion Compatibility of DyesDocumento16 páginasRate of Exhaustion Compatibility of Dyesadali2020100% (2)

- RFCC FinalDocumento61 páginasRFCC Finalsem100% (5)

- European Biochar Certificate V4.8 IBI Biochar Standards V2.0 IBI Test MethodDocumento5 páginasEuropean Biochar Certificate V4.8 IBI Biochar Standards V2.0 IBI Test MethodMohd SAinda não há avaliações

- Prudent Practices in The LaboratoryDocumento8 páginasPrudent Practices in The LaboratorysinglethienAinda não há avaliações

- Action Plan TemplateDocumento4 páginasAction Plan TemplateJanith DushyanthaAinda não há avaliações

- 9373 0 How To Use Social Media For Your BusinessDocumento35 páginas9373 0 How To Use Social Media For Your BusinessJawad Ahmed Siddiqui100% (1)

- Accreditation For Microbiological Laboratories: Second Edition 2013Documento32 páginasAccreditation For Microbiological Laboratories: Second Edition 2013Tammy McdanielAinda não há avaliações

- Accreditation For Microbiological Laboratories: Second Edition 2013Documento32 páginasAccreditation For Microbiological Laboratories: Second Edition 2013Tammy McdanielAinda não há avaliações

- Bang Gia ThuocDocumento2 páginasBang Gia ThuocsinglethienAinda não há avaliações

- HFM Lab ProcedureDocumento3 páginasHFM Lab ProcedureWong Foo SengAinda não há avaliações

- CV - Doan Tuan KietDocumento3 páginasCV - Doan Tuan KietsinglethienAinda não há avaliações

- Executive Summary: Exposure To DEHPDocumento6 páginasExecutive Summary: Exposure To DEHPsinglethienAinda não há avaliações

- ChlorineDocumento3 páginasChlorinesinglethienAinda não há avaliações

- IrDocumento4 páginasIrsinglethienAinda não há avaliações

- 3-6-Thermodynamic Vs Kinetic ControlDocumento3 páginas3-6-Thermodynamic Vs Kinetic ControlsinglethienAinda não há avaliações

- Applying Total Quality Management To Educational InstructionDocumento21 páginasApplying Total Quality Management To Educational InstructionsinglethienAinda não há avaliações

- Higher Algebra - Hall & KnightDocumento593 páginasHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Technical Information No. 12 Vermicular Graphite Cast Iron: MicrostructureDocumento1 páginaTechnical Information No. 12 Vermicular Graphite Cast Iron: MicrostructureVelina MilevaAinda não há avaliações

- Pilot Product Catalogue 18Documento28 páginasPilot Product Catalogue 18veerraju tvAinda não há avaliações

- Physics ProjectDocumento13 páginasPhysics ProjectsherineAinda não há avaliações

- FMV Spreadsheets-Master-FMVIDocumento15 páginasFMV Spreadsheets-Master-FMVIadrianaortizv100% (1)

- Ethylbenzene DehydrogenationDocumento12 páginasEthylbenzene DehydrogenationCeciAinda não há avaliações

- Chee3005: Experiment 1 1. Aim and Objectives of The ExperimentDocumento13 páginasChee3005: Experiment 1 1. Aim and Objectives of The ExperimentRafael HassanAinda não há avaliações

- CharacteristicsSelectedDisinfectants PDFDocumento1 páginaCharacteristicsSelectedDisinfectants PDFMadmanMSUAinda não há avaliações

- ITA 2012 Sir Alan Muir Wood LectureDocumento10 páginasITA 2012 Sir Alan Muir Wood LectureFlaviaAinda não há avaliações

- SIKA - Tunnel Segments Production With SIKA Rapid-1Documento4 páginasSIKA - Tunnel Segments Production With SIKA Rapid-1gianniorlatiAinda não há avaliações

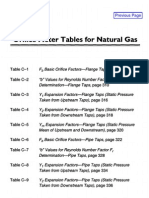

- Aga TableDocumento35 páginasAga TableilublessingAinda não há avaliações

- EQMS Consulting Limited (Testing Laboratory)Documento2 páginasEQMS Consulting Limited (Testing Laboratory)Afrin NadiaAinda não há avaliações

- Yin Yang PrimerDocumento66 páginasYin Yang PrimerAnais100% (2)

- Anti TpoDocumento28 páginasAnti TpoFlorea RodicaAinda não há avaliações

- Basic Nuclear Physics: Day 1-Lecture 1Documento35 páginasBasic Nuclear Physics: Day 1-Lecture 1jody9090Ainda não há avaliações

- Co-Crystal and Eutatic MixtureDocumento11 páginasCo-Crystal and Eutatic MixtureQA Dhq OkaraAinda não há avaliações

- Risk Profile Chelidonium MajusDocumento6 páginasRisk Profile Chelidonium Majusroze60Ainda não há avaliações

- NDT PDFDocumento0 páginaNDT PDFAnthony CyrilAinda não há avaliações

- Over The Counter (OTC) Product List: Aetna Better Health®Documento5 páginasOver The Counter (OTC) Product List: Aetna Better Health®sarath chandraAinda não há avaliações

- LectureEKC216 CH7Documento38 páginasLectureEKC216 CH7Siva SangaryAinda não há avaliações

- Masterflex FGTUDocumento1 páginaMasterflex FGTUprabakaranAinda não há avaliações