Escolar Documentos

Profissional Documentos

Cultura Documentos

Alignment Procedure

Enviado por

bulentbulutDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Alignment Procedure

Enviado por

bulentbulutDireitos autorais:

Formatos disponíveis

Alignment Procedure Typical alignment procedures from screw compressor manufactures are posted in Technical Information-Alignment section.

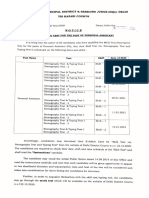

(These procedures are reference use only. Contact manufacturer for updated procedure.) Typical alignment procedures from screw compressor manufactures are posted in Technical Information-Alignment section. (These procedures are reference use only. Contact manufacturer for updated procedure.) Saving Energy Cost by Precision Alignment It has been reported that precision alignment can save power consumption by 1% to 3%. There is also a conflicting study report that finds no significant correlation between misalignment and machine efficiency. As well, there has been no study done indicating the energy savings for screw compressors used in refrigeration and process gas that have utilized precision alignment. However, it is not an overstatement that precision alignment can save energy consumption by reducing mechanical inefficiency. Below is a calculation for the annual dollar savings of a compressor with 350HP motor. Yearly Savings = (Motor H.P. x 0.746) x (1/Efficiency) x Power Cost x Average Annual Operating hour x % saving. For 350 HP motor running 6000 annual operating hours in San Antonio, TX, yearly savings will be calculated as below. Yearly Savings = (350 x 0.746) x (1/0.95) x $0.0613/kwh x 6000 x 0.02=$2,021/yearly savings. High vibration due to misalignment and machine life Estimated time a machine will fail due to misalignment. Misalignment (Mil/Inch) Estimated time to failure 0.2 1 5 10 50 100 250 months 60 months 10 months 6 months 2 months 0.6 months

Note Misalignment is mil/Inch (Milradian.) 6" of distance between shafts and 0.2 mil/Inch tolerance is equal to 1.2/1000" of offset at the center of the shafts. Shaft Seal Failure and Misalignment

There is no proven study as to the relationship between shaft seal failure and misalignment for screw compressors. However, a majority of screw compressors with vibration caused by misalignment will vibrate more in axial direction. This may cause the shaft seal to fail prematurely. It is reported that more than 5/1000" in T.I.R of misalignment will cause more frequent shaft seal failure in screw compressors. Motor Bearing Failure due to misalignment Bearing Life (L10 life) for deep grooved single row spherical ball bearing used in the motor can be calculated as follow. L10 life= (Bearing Rating/Bearing Load)3 Therefore, if the bearing load increases due to mechanical stress by misalignment, it will reduce bearing life by factor powered by 3. e.g. 10% increase in bearing load=75.1% of bearing life left than normal load. 20% increase in bearing load=57.8% of bearing life left than normal load. 50% increase in bearing load=29.6% of bearing life left than normal load. This calculation is based on zero internal clearance in the bearing. If the internal clearance increases due to mechanical stress, it will further reduce bearing life in accordance with the actual clearance.

Você também pode gostar

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionNo EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionNota: 4 de 5 estrelas4/5 (1)

- Dynamic Movement White Paper: Vibralign, Inc. 530G Southlake BLVD Richmond, Va 232326 804.379.2250Documento0 páginaDynamic Movement White Paper: Vibralign, Inc. 530G Southlake BLVD Richmond, Va 232326 804.379.2250SreenivasAinda não há avaliações

- VW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)No EverandVW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Ainda não há avaliações

- Shaft Alignment White PaperDocumento14 páginasShaft Alignment White PaperHamed HamedAinda não há avaliações

- All About Shaft AlignmentDocumento3 páginasAll About Shaft AlignmentMahmoud Abd El LateefAinda não há avaliações

- Diesel Common Rail Injection Electronic Components ExplainedNo EverandDiesel Common Rail Injection Electronic Components ExplainedNota: 3.5 de 5 estrelas3.5/5 (7)

- Manual D398 CAT Ajustes EspecificacionesDocumento259 páginasManual D398 CAT Ajustes Especificacionescristian100% (5)

- Benefits Shaft AlignmentDocumento4 páginasBenefits Shaft AlignmentCarolina PBAinda não há avaliações

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceAinda não há avaliações

- Alignment Basics - Part OneDocumento2 páginasAlignment Basics - Part Oneamigoeres7337Ainda não há avaliações

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallNo EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallNota: 4 de 5 estrelas4/5 (8)

- Potentials For Efficiency Improvement Out of The Synchronizer - enDocumento13 páginasPotentials For Efficiency Improvement Out of The Synchronizer - enR KathirasanAinda não há avaliações

- The Power of Wear RingsDocumento18 páginasThe Power of Wear RingsVinh Do ThanhAinda não há avaliações

- Ing 64 (CV) Carburetor Part 3 (Idle Circuit)Documento4 páginasIng 64 (CV) Carburetor Part 3 (Idle Circuit)Moto CrewAinda não há avaliações

- Motor Solved Written Question AnswerDocumento64 páginasMotor Solved Written Question Answerkum512Ainda não há avaliações

- 21 toleranciasAcoplesAlineacionVsTablasTolerables-12Oct10Documento3 páginas21 toleranciasAcoplesAlineacionVsTablasTolerables-12Oct10Wilson GarciaAinda não há avaliações

- How Unbalance Affects Bearing LifeDocumento8 páginasHow Unbalance Affects Bearing Lifeagrocel_bhv5591Ainda não há avaliações

- Blow by Breather SystemsDocumento19 páginasBlow by Breather SystemsekumaranAinda não há avaliações

- Pump AlignmentDocumento69 páginasPump AlignmentJ.SIVIRA100% (1)

- Advanced SyTech EnginDocumento21 páginasAdvanced SyTech EnginShreepal ChilaAinda não há avaliações

- Engine Crankshaft Deflection Measurement Guide - IIMSDocumento9 páginasEngine Crankshaft Deflection Measurement Guide - IIMSNyan ThutaAinda não há avaliações

- Choosing The Perfect Performance CamshaftDocumento9 páginasChoosing The Perfect Performance CamshaftDesotoJoe100% (1)

- Clamping ForceDocumento3 páginasClamping ForceabcAinda não há avaliações

- ICEF2006-1566 PistonFriction Mahle-Brasil 2006Documento7 páginasICEF2006-1566 PistonFriction Mahle-Brasil 2006Bogdan NeagoeAinda não há avaliações

- 44 42 56.03 - Vertical Turbine Pumps - Engineers Comments & SPCO Responses APPROVEDDocumento306 páginas44 42 56.03 - Vertical Turbine Pumps - Engineers Comments & SPCO Responses APPROVEDspcoaustinAinda não há avaliações

- Mistry 2014Documento10 páginasMistry 2014tgrlAinda não há avaliações

- 7 DD 0031Documento3 páginas7 DD 0031fstaday6624Ainda não há avaliações

- The Power Wear RingDocumento16 páginasThe Power Wear Ringpaola hernandezAinda não há avaliações

- Nadella - Needle BearingsDocumento230 páginasNadella - Needle Bearingsג'ון ירוקAinda não há avaliações

- Considerations For Impeller Trimming - Empowering Pumps and EquipmentDocumento8 páginasConsiderations For Impeller Trimming - Empowering Pumps and Equipment김기준Ainda não há avaliações

- Machine Installation - Shaft AlignmentDocumento17 páginasMachine Installation - Shaft AlignmentD.b. Tampubolon100% (1)

- Basics of AlignmentDocumento18 páginasBasics of Alignmentbtdoss72Ainda não há avaliações

- 3300 Engine Timing Measurement For Reduced Emissions and Improved Engine Performance/Life CaterpillarDocumento3 páginas3300 Engine Timing Measurement For Reduced Emissions and Improved Engine Performance/Life CaterpillarfrgmanAinda não há avaliações

- March 11, 2016 News Hound: Engine Crankshaft Deflection MeasurementDocumento11 páginasMarch 11, 2016 News Hound: Engine Crankshaft Deflection Measurementiwan ridwanAinda não há avaliações

- Crankshaft Failure in CompressorDocumento12 páginasCrankshaft Failure in CompressorKristomiDerMarine-IngenieurAinda não há avaliações

- FPS Wind Turbine Rotor Balance Article PublishCDocumento12 páginasFPS Wind Turbine Rotor Balance Article PublishCmlenzAinda não há avaliações

- Bodine Selecting FHP GearmotorsDocumento2 páginasBodine Selecting FHP GearmotorsJesus N RodriguezAinda não há avaliações

- C. Kalavrytinos - Dynamics Analysis of A Three Cylinder EngineDocumento24 páginasC. Kalavrytinos - Dynamics Analysis of A Three Cylinder EngineChristos Kalavrytinos100% (4)

- Mot29 07 1399Documento14 páginasMot29 07 1399Mobin GhariAinda não há avaliações

- mbd-02 Multi Body Dynamic Mahindra2wheelers PDFDocumento6 páginasmbd-02 Multi Body Dynamic Mahindra2wheelers PDFManicharanAinda não há avaliações

- Couplings: Section Page #Documento48 páginasCouplings: Section Page #Sadashiw PatilAinda não há avaliações

- Sleeve Bearing Specification For MotorDocumento45 páginasSleeve Bearing Specification For MotorThiMinhKhuyen100% (2)

- Recesion de Valvulas.Documento3 páginasRecesion de Valvulas.omaira vegaAinda não há avaliações

- Vibration Versus Bearing Life HandoutDocumento11 páginasVibration Versus Bearing Life Handoutscribdtaker12345Ainda não há avaliações

- Design Factors When Using Small Bearings: Part 1: Bearing GeometryDocumento7 páginasDesign Factors When Using Small Bearings: Part 1: Bearing Geometryhittaf_05Ainda não há avaliações

- How Green Is Your GearboxDocumento10 páginasHow Green Is Your GearboxDhairyasheel BhutkarAinda não há avaliações

- Bearing Tech PDFDocumento6 páginasBearing Tech PDFmurali036Ainda não há avaliações

- ShaftingDocumento3 páginasShafting41vaibhavAinda não há avaliações

- Radial Thrust BRG Case StudiesDocumento14 páginasRadial Thrust BRG Case StudiesRajagopal100% (1)

- Timing Belt Drives and Their Advantages Regarding Engine Efficiency and NVH CharacteristicsDocumento3 páginasTiming Belt Drives and Their Advantages Regarding Engine Efficiency and NVH Characteristicsu.rghu.kAinda não há avaliações

- 1999-01-1259 Kluger SWRIDocumento8 páginas1999-01-1259 Kluger SWRIManish Kulkarni100% (1)

- Undetected Bearing Wear Leads To Catastrophic Compressor FailureDocumento5 páginasUndetected Bearing Wear Leads To Catastrophic Compressor FailureMuhammad ImranAinda não há avaliações

- Chemical ProcessingDocumento13 páginasChemical ProcessingTaha ZiaAinda não há avaliações

- X2 5 g4 1800 RPMDocumento4 páginasX2 5 g4 1800 RPMCarlos SolisAinda não há avaliações

- Effect of Energy Flow and Transmitted Power in The Degrading Wet FrictionDocumento5 páginasEffect of Energy Flow and Transmitted Power in The Degrading Wet FrictionIPASJAinda não há avaliações

- VTEC Cams Specs Comparison For Bseries EnginesDocumento30 páginasVTEC Cams Specs Comparison For Bseries EnginesChristopher RusliAinda não há avaliações

- Brake GuideDocumento63 páginasBrake GuideainginerAinda não há avaliações

- Shaft Alignment Is A Profitable Form of Preventative MaintenanceDocumento1 páginaShaft Alignment Is A Profitable Form of Preventative MaintenancebelenyeriruelAinda não há avaliações

- Pump AuditDocumento1 páginaPump AuditbulentbulutAinda não há avaliações

- Fertilizer Guide 170418 508Documento162 páginasFertilizer Guide 170418 508Job MateusAinda não há avaliações

- SUPERTHERM To Replace HouseWrapDocumento1 páginaSUPERTHERM To Replace HouseWrapbulentbulutAinda não há avaliações

- Flo Way PresentationDocumento33 páginasFlo Way PresentationbbulutmmAinda não há avaliações

- Light Bulb CalculatorDocumento7 páginasLight Bulb CalculatorbulentbulutAinda não há avaliações

- SUPERTHERM To Replace HouseWrapDocumento1 páginaSUPERTHERM To Replace HouseWrapbulentbulutAinda não há avaliações

- Open Gears: Lubrication + Maintenance + ServiceDocumento16 páginasOpen Gears: Lubrication + Maintenance + ServicebulentbulutAinda não há avaliações

- SS20 All Films CarliDocumento4 páginasSS20 All Films CarlibulentbulutAinda não há avaliações

- Brochure - Mecontrol AirDocumento2 páginasBrochure - Mecontrol AirKenny RuizAinda não há avaliações

- Bu Coalpsa en v011Documento2 páginasBu Coalpsa en v011bulentbulutAinda não há avaliações

- Dustex Turkey - Cement Industry 11-27-13Documento37 páginasDustex Turkey - Cement Industry 11-27-13bulentbulutAinda não há avaliações

- SS20 All Films CarliDocumento4 páginasSS20 All Films CarlibulentbulutAinda não há avaliações

- Nansulate For Energy Efficient WindowsDocumento5 páginasNansulate For Energy Efficient WindowsbulentbulutAinda não há avaliações

- SUPERTHERM Over Tanks JapanDocumento2 páginasSUPERTHERM Over Tanks JapanbulentbulutAinda não há avaliações

- Loesche Classifiers Modification Report at MCLDocumento42 páginasLoesche Classifiers Modification Report at MCLnsprasad88Ainda não há avaliações

- EN21004243A Roller StationsDocumento51 páginasEN21004243A Roller StationsbulentbulutAinda não há avaliações

- SUPERTHERM Over Tanks JapanDocumento2 páginasSUPERTHERM Over Tanks JapanbulentbulutAinda não há avaliações

- WEBBH009 - Baghouse Maintenance GuideDocumento1 páginaWEBBH009 - Baghouse Maintenance GuidebulentbulutAinda não há avaliações

- Çap3668 X L 1777-ModelDocumento1 páginaÇap3668 X L 1777-ModelbulentbulutAinda não há avaliações

- Dustex Overview For DustexTurkey TrainingDocumento69 páginasDustex Overview For DustexTurkey TrainingbulentbulutAinda não há avaliações

- Filter Media Selection GuideDocumento29 páginasFilter Media Selection GuidebulentbulutAinda não há avaliações

- Dustex Turkey - Power Industry 12-16-13Documento37 páginasDustex Turkey - Power Industry 12-16-13bulentbulutAinda não há avaliações

- WEBBH009 - Baghouse Maintenance GuideDocumento1 páginaWEBBH009 - Baghouse Maintenance GuidebulentbulutAinda não há avaliações

- Nansulate Translucent PT DataSheetDocumento2 páginasNansulate Translucent PT DataSheetbulentbulutAinda não há avaliações

- CompAir L23 - L29 - RS Compressor Brochure PDFDocumento8 páginasCompAir L23 - L29 - RS Compressor Brochure PDFbulentbulutAinda não há avaliações

- Stroboskop RT LED TR PDFDocumento2 páginasStroboskop RT LED TR PDFbulentbulutAinda não há avaliações

- Chap 2 3 PDFDocumento56 páginasChap 2 3 PDFbulentbulut100% (1)

- High-Pressure Grinding 2MB PDFDocumento0 páginaHigh-Pressure Grinding 2MB PDFbulentbulutAinda não há avaliações

- Without ATEX Permission: LED-cap Lamp With 2-Step Illumination (Emergency Light, Main Light)Documento29 páginasWithout ATEX Permission: LED-cap Lamp With 2-Step Illumination (Emergency Light, Main Light)bulentbulutAinda não há avaliações

- Lab Nov 2013Documento35 páginasLab Nov 2013balajigandhirajanAinda não há avaliações

- Fluid FrictionDocumento10 páginasFluid FrictionUmesh PatilAinda não há avaliações

- TqemDocumento3 páginasTqemJudith D'SouzaAinda não há avaliações

- Fine Focus 450Documento70 páginasFine Focus 450Guilherme Altenbernd100% (3)

- Thermal Modeling and Design Considerations of Lithium-Ion BatteriesDocumento8 páginasThermal Modeling and Design Considerations of Lithium-Ion BatteriesVarun Gupta100% (1)

- Gmail - CAMPUS DRIVE NOTIFICATION - Himadri Speciality Chemical LTDDocumento2 páginasGmail - CAMPUS DRIVE NOTIFICATION - Himadri Speciality Chemical LTDShresth SanskarAinda não há avaliações

- Vi Quick ReferenceDocumento1 páginaVi Quick ReferenceSneetsher Crispy100% (6)

- 2015 Jicable - Risk On Failure Based On PD Measurements in Actual MV PILC and XLPE Cables.Documento3 páginas2015 Jicable - Risk On Failure Based On PD Measurements in Actual MV PILC and XLPE Cables.des1982Ainda não há avaliações

- Simulation Exercise Manual HandbookDocumento44 páginasSimulation Exercise Manual HandbookMayte Gz100% (1)

- 07.4 111 FW ML PF WPS 20mm ENGDocumento1 página07.4 111 FW ML PF WPS 20mm ENGViktorAinda não há avaliações

- How Bangalore Gets ElectricityDocumento1 páginaHow Bangalore Gets ElectricityNabeel AhmedAinda não há avaliações

- English Core 2005Documento5 páginasEnglish Core 2005thiripura sundariAinda não há avaliações

- 00 Its A OrderDocumento5 páginas00 Its A OrderJunky FoolAinda não há avaliações

- DPC6HG Aa00 G0000 ZS001 - 001 - 01Documento6 páginasDPC6HG Aa00 G0000 ZS001 - 001 - 01rajitkumar.3005Ainda não há avaliações

- Muhammad ALI Azmi: Contact +62 812 1944 5086 Komplek Poin Mas Blok F-2 No. 20B, Depok, Jawa BaratDocumento1 páginaMuhammad ALI Azmi: Contact +62 812 1944 5086 Komplek Poin Mas Blok F-2 No. 20B, Depok, Jawa BaratanggaraAinda não há avaliações

- Brakel Eura Excellent: Highly Insulated Louvred VentilatorDocumento4 páginasBrakel Eura Excellent: Highly Insulated Louvred VentilatorhjduarteAinda não há avaliações

- Unit: Pltu Bolok Area: UNIT #1 Equipment Standard Measurement Point Unit Minggu 1 Minggu 2 Minggu 3 Minggu 4 StatusDocumento18 páginasUnit: Pltu Bolok Area: UNIT #1 Equipment Standard Measurement Point Unit Minggu 1 Minggu 2 Minggu 3 Minggu 4 StatusAchmad Zaki MubarokAinda não há avaliações

- Finite State Machine Based Vending Machine Controller With Auto-Billing FeaturesDocumento5 páginasFinite State Machine Based Vending Machine Controller With Auto-Billing FeaturesSubbuNaiduAinda não há avaliações

- Rattan Pole BendingDocumento21 páginasRattan Pole Bendingcintamore_jos355Ainda não há avaliações

- M180: Data Structure and Algorithms in Java Arab Open UniversityDocumento18 páginasM180: Data Structure and Algorithms in Java Arab Open Universityamr201020Ainda não há avaliações

- GET OA Doc - Batch 2Documento3 páginasGET OA Doc - Batch 2Ganesh Sai VelidiAinda não há avaliações

- GE Custom 8000 Horizontal Induction Motor - GEEP-124-I (1998)Documento41 páginasGE Custom 8000 Horizontal Induction Motor - GEEP-124-I (1998)Edson França Rodrigues100% (1)

- 4 Leed Open SpaceDocumento6 páginas4 Leed Open SpaceswapnilupgadeAinda não há avaliações

- VCSEL Technology v1Documento17 páginasVCSEL Technology v1Vaibhav MathurAinda não há avaliações

- Brother Service Manual 7440NDocumento64 páginasBrother Service Manual 7440NAlicia Smith100% (1)

- Reading and Writing Writing An EmailDocumento1 páginaReading and Writing Writing An EmailferfonsegonAinda não há avaliações

- Athena Huongdan Hoc Hacker Mu Trang AehDocumento1 páginaAthena Huongdan Hoc Hacker Mu Trang AehNguyen Ba HoangAinda não há avaliações

- UTDEC 2020: Sub: Skill Test/Typing Test For The Post of Personal AssistantDocumento2 páginasUTDEC 2020: Sub: Skill Test/Typing Test For The Post of Personal Assistantneekuj malikAinda não há avaliações

- MHDDocumento33 páginasMHDkashyapAinda não há avaliações

- Practical Reservoir Engineering and CharacterizationNo EverandPractical Reservoir Engineering and CharacterizationNota: 4.5 de 5 estrelas4.5/5 (3)

- Enhanced Oil Recovery Handout: A Focus on WaterfloodingNo EverandEnhanced Oil Recovery Handout: A Focus on WaterfloodingAinda não há avaliações

- Pocket Guide to Flanges, Fittings, and Piping DataNo EverandPocket Guide to Flanges, Fittings, and Piping DataNota: 3.5 de 5 estrelas3.5/5 (22)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesNo EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesAinda não há avaliações

- Well Testing Project Management: Onshore and Offshore OperationsNo EverandWell Testing Project Management: Onshore and Offshore OperationsAinda não há avaliações

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsNo EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsNota: 4 de 5 estrelas4/5 (4)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideNo EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideNota: 2 de 5 estrelas2/5 (1)

- Fundamentals and Applications of Bionic Drilling FluidsNo EverandFundamentals and Applications of Bionic Drilling FluidsAinda não há avaliações

- Well Control for Completions and InterventionsNo EverandWell Control for Completions and InterventionsNota: 4 de 5 estrelas4/5 (10)

- Heavy and Extra-heavy Oil Upgrading TechnologiesNo EverandHeavy and Extra-heavy Oil Upgrading TechnologiesNota: 4 de 5 estrelas4/5 (2)

- Essentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesNo EverandEssentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesNota: 5 de 5 estrelas5/5 (5)

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityNo EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityNota: 3 de 5 estrelas3/5 (2)

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsNo EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsNota: 4 de 5 estrelas4/5 (6)

- Asset Integrity Management for Offshore and Onshore StructuresNo EverandAsset Integrity Management for Offshore and Onshore StructuresAinda não há avaliações

- Advanced Production Decline Analysis and ApplicationNo EverandAdvanced Production Decline Analysis and ApplicationNota: 3.5 de 5 estrelas3.5/5 (4)

- Gas and Oil Reliability Engineering: Modeling and AnalysisNo EverandGas and Oil Reliability Engineering: Modeling and AnalysisNota: 4.5 de 5 estrelas4.5/5 (6)

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANo EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AAinda não há avaliações

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryNo EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryNota: 5 de 5 estrelas5/5 (3)