Escolar Documentos

Profissional Documentos

Cultura Documentos

Bardenpho Process

Enviado por

Anonymous 8ooQmMoNs1Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Bardenpho Process

Enviado por

Anonymous 8ooQmMoNs1Direitos autorais:

Formatos disponíveis

Bardenpho Process

Biological Nutrient Removal System

A GLV COMPANY

Biological Nutrient Removal System

Operating Principle Bardenpho Biological Systems represent an advance modification of the activated sludge process consisting of a multi-stage biological reactor. High levels of BOD, suspended solids, nitrogen, and phosphorus removal are consistently achieved without the use of chemicals. Influent is mixed with activated sludge, returned from the final clarifier, in the fermentation stage. After contact, liquid is transported to an anoxic zone where it is mixed with nitrates from the nitrification zone. Oxygen, which is added in the nitrification zone, converts BOD to carbon dioxide, and ammonia to nitrate. In the second anoxic zone, nitrate is reduced to nitrogen gas. The final stage of the Bardenpho Process is a reaeration zone where the dissolved oxygen concentration is the mixed liquor is increased to prevent phosphorus from being released in the final clarifier.

Process Description Fermentation Stage Activated sludge, consisting of a broad spectrum of organisms, is returned from the clarifier to the fermentation stage. This sludge is contacted with the plant influent to produce the appropriate stress condition that allows large quantities of phosphorus to be removed from the wastewater biologically in subsequent aerobic stages. Organism stress occurs in the absence of dissolved oxygen (DO) and nitrates (NO3).

The Bardenpho Process

First Anoxic Stage Mixed liquor containing nitrates from the third stage is recycled to the first anoxic stage. Here it is mixed with conditioned sludge from the fermentation stage in the absence of oxygen. Bacteria utilize BOD in the influent, reducing the nitrates to gaseous nitrogen. Approximately two-thirds of the influent nitrogen is removed in the first anoxic stage. Nitrification Stage Oxygen is introduced in the nitrification stage to oxidize BOD and ammonia. BOD is converted to new cell mass and carbon dioxide. Ammonia is converted to nitrate. Mixed liquor, containing the nitrates, is recycled back to the first anoxic stage. Luxury phosphorus uptake by the organisms occurs in this stage. Second Anoxic Stage Nitrate, no recycled to the first anoxic stage, is introduced to the second anoxic stage where it is reduced (in the absence of oxygen) to nitrogen gas. This produces a low effluent nitrate concentration Reaeration Stage When maintained in an aerobic environment, the Bardenpho system mixed liquor contains 5% to 6% phosphorus. If the sludge is permitted to become septic, phosphorus could be released in the final clarifier. Subjecting the sludge to reaeration introduces additional oxygen to the mixed liquor, insuring that it remains aerobic, thus retaining phosphorus.

The Bardenpho Process

The overall Bardenpho Process is similar to a conventional activated sludge flowsheet. Raw or settled sewage (waste) enters the biological reactor and is mixed with return settled sludge. Mixed liquor from the reactor flows to a clarifier where biological solids are removed from the treated wastewater and are recycled to a reactor basin. A portion of the sludge is wasted, removing excess cell material generated during processing. Sludge wasting also removes phosphorus from the system.

Removal of Nutrients, Nitrogen and Phosphorus

No Expensive Chemical Required Low effluent concentrations of BOD, nitrogen and phosphorus are achieved using the Bardenpho Process with little or no costly chemical additives. Reliability has been demonstrated at installations obtaining an AWT 5-5-3-1 effluent (BOD, SS, N, P). Operating costs are lower than conventional nutrient removal processes. Also, the stable sludge can be disposed of directly, not like voluminous hard to handle chemical sludges. Simple and Stable Operation Bardenpho Systems are similar to conventional activated sludge plants, and personnel do not require retraining. The flowsheet is simple, with few control parameters to measure and adjust. Compatible with the Carrousel Biological Oxidation Systems Typically, a Carrousel System is used as the nitrification stage in the Bardenpho Process. Many advantages associated with the Carrousel System therefore are inherently obtained. These advantages include lower construction and energy costs, while improving control and performance. Existing Carrousel Systems can be upgraded to a Bardenpho Process when regulations change, requiring strict control of nitrogen and phosphorus.

Low Cost System By eliminating chemicals from the process, Bardenpho Systems can reduce operating costs as much as $400,000 per MGD over an estimated 20 year life. Other operating costs are similarly reduced. Construction costs for a Bardenpho System are comparable to conventional activated sludge plants designed for secondary treatment, and only one-third to one-half that of other AWT plants.

Complete Process Design and Technical Support Services Our company provides complete Bardenpho design and technical support services for Bardenpho Process treatment facilities. Our engineers have applied this proprietary technology* in designing over forty installations for the world's most sensitive and closely regulated watersheds. Perhaps the most telling tribute to the flexibility and effectiveness of the Bardenpho Process is the fact that every one of these facilities operates in full compliance with its discharge permit.

*Bardenpho systems include the wastewater treatment processes covered by Eimco Water Technologies U.S. patent number 3,964,998 and Bardenpho design, licensing, technical and start-up assistance services for treatment basins utilizing these processes.

Typical Operating Installations - Bardenpho Process

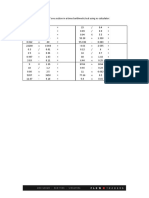

Palmetto, Florida Operation of the Palmetto, Florida advanced secondary treatment system began in October 1979. It is the first Bardenpho Process treatment facility in North America and is rated at 1.4 MGD. Performance results for six months of 1983, which are shown below, are typical of the outstanding performance achieved since start-up. Note the wide variation of influent conditions - flow from .89 MGD to 1.6 MGD; BOD5 from 156 to 76; SS from 136 to 62. This demonstrates the ability of the Bardenpho Process to adapt to variations in flow and wastewater concentration. Influent TKN was typically about 35 mg/l and phosphorous about 6 mg/l. Effluent quality for each constituent is below State and Federal requirements.

PALMETTO, FLORIDA WWTP PERFORMANCE RESULTS Monthly Averages - 1983 Influent Q, MGD BOD,mg.1 SS, mg/1 Effluent BOD, mg/1 SS, mg/1 Total N, mg/1 NO, N, mg/1 NH, N, mg/1 Total N, mg/1 June 0.89 156 136 1.6 2 2.4 1.3 0.4 *1.7 July 0.95 127 122 1.5 1 2 1.3 0.2 *1.2 August 1.58 76 62 2.2 1.2 2.5 1.6 0.4 0.6 September 1.6 81 65 1.5 1.4 2.5 1.7 0.4 0.5 October 1.14 92 128 1.7 1.4 2.4 1.7 0.3 *1.0 November 1.1 132 133 1.8 1.6 2.8 1.8 0.3 0.4

* Alum was not being added for phosphorus removal during the indicated months. Alum was added during the months without asterisks for removal of P. A minimal dosage of alum is typical added immediately upstream of final clarification.

Typical Operating Installations - Bardenpho Process

Orange County Florida Easterly Sub-regional WWTP The Easterly Orange County Wastewater Treatment Plant began operation as a 6 MGD facility in early 1984. It consists of a full 5-stage Bardenpho Process with Carrousel aeration used in the nitrification stage. The Easterly Orange County Bardenpho flowsheet is designed for Overland Flow / Wetlands effluent disposal. This requires a very high quality effluent which is consistently as good as the receiving water for protection of Wetland wildlife. Thus alum polishing is used to trim effluent phosphorus values to well below 1mg/l. Other facilities worldwide currently have operating Bardenpho Systems and more are in design and construction phases. These plants range in size from about 1 MGD to over 40 MGD with various climatic and influent conditions.

EASTERLY ORANGE COUNTY, FLORIDA PERFORMANCE RESULTS Monthly Average - 1985 Effluent January February March April May June July August September October November December Bod 2 2 2 2 2 2 2 2 2 1 2 2 TSS 2 1 1 2 2 1 2 2 2 2 2 1 TN 1.9 1.5 1.3 1.6 2.3 1 2.9 2.9 2.5 1.7 2.1 2.5 TP 0.2 0.2 0.2 0.4 2 1.7 1.9 1.9 0.4 0.2 0.3 0.7

Advantages and Benefits of the Bardenpho Process

Benefits No Chemicals Simple and Stable to Operate Stable Sludge Lower operating costs No chemical sludge to dispose Comparable to conventional waste treatment plants Biological nitrogen and phosphorus removal without costly chemical feed systems Simple design minimizes construction Few controls to monitor and adjust Operation similar to conventional activated sludge plants, requiring no operator retraining Long SRT provides process stability Accommodates Carrousel Biological Oxidation System Additional sludge digestion may not be required, allowing direct disposal Low operating cost Nitrate removal credit More than half a century commitment to waste treatment Experience Recognize technological leadership Reputable, long-term equipment supplier

Low Capital Cost

Energy Efficient

You Deal with Us

Copyright 2007 GLV. All rights reserved. ETE036

For more information visit us at www.glv.com

Você também pode gostar

- Solving Operation Problems For Wastewater Treatment Plants in Cold ClimateDocumento3 páginasSolving Operation Problems For Wastewater Treatment Plants in Cold ClimateShakeel ShahAinda não há avaliações

- Conventional FiltrationDocumento102 páginasConventional FiltrationKanchanAinda não há avaliações

- dw-25 Hypochlorite WB Jan2006 PDFDocumento53 páginasdw-25 Hypochlorite WB Jan2006 PDFSong Nguyen NguyenAinda não há avaliações

- Conversion Table For Wastewater TreatmentDocumento5 páginasConversion Table For Wastewater TreatmentAG-Metal /Tretman Otpadnih Voda/Wastewater TreatmentAinda não há avaliações

- AOPs A Critical Review PDFDocumento54 páginasAOPs A Critical Review PDFM S MahtabAinda não há avaliações

- Aerated Lagoon: Types of Aerated Lagoons or BasinsDocumento4 páginasAerated Lagoon: Types of Aerated Lagoons or BasinsRaajiv MenonAinda não há avaliações

- STP Secondary Treatment Sept 27 2018Documento26 páginasSTP Secondary Treatment Sept 27 2018Mulberry PlaceAinda não há avaliações

- Mohammed Saleh - STOAT ASM - Simulation Model of Wastewater Treatment ProcessesDocumento104 páginasMohammed Saleh - STOAT ASM - Simulation Model of Wastewater Treatment ProcessesAnish Ghimire100% (1)

- Pulsator sludge blanket clarifier optimized performanceDocumento2 páginasPulsator sludge blanket clarifier optimized performancepjrapanutAinda não há avaliações

- Journal of Water Process Engineering: SciencedirectDocumento8 páginasJournal of Water Process Engineering: SciencedirectOmar GameelAinda não há avaliações

- GPSX - Techref 01Documento372 páginasGPSX - Techref 01felixAinda não há avaliações

- Managing Food Industry Waste EffluentsDocumento5 páginasManaging Food Industry Waste EffluentsAbiodun GbengaAinda não há avaliações

- Module 25: Hypochlorite TrainingDocumento53 páginasModule 25: Hypochlorite Traininggiu-story100% (1)

- Modeling Oxidation Ditches Wastewater TreatmentDocumento19 páginasModeling Oxidation Ditches Wastewater Treatmentashok100% (1)

- Ammonium Feedback Control in Wastewater Treatment Plants PDFDocumento258 páginasAmmonium Feedback Control in Wastewater Treatment Plants PDFalae1970Ainda não há avaliações

- CAP 15 - 3 Design of Water Resource Recovery Facilities, Sixth Edition Nitrogen-Removal-Sidestream-Process-DesignDocumento4 páginasCAP 15 - 3 Design of Water Resource Recovery Facilities, Sixth Edition Nitrogen-Removal-Sidestream-Process-DesignNICOLAS SANCHEZ GOMEZAinda não há avaliações

- NUTR1R06w PDFDocumento110 páginasNUTR1R06w PDFAli Rıza Üreten100% (1)

- Activated Sludge Process Calculations and Design ParametersDocumento3 páginasActivated Sludge Process Calculations and Design ParametersCamille LeiAinda não há avaliações

- DBDocumento25 páginasDBAbhijit MondalAinda não há avaliações

- AnoxKaldnesBrochure2016Documento6 páginasAnoxKaldnesBrochure2016n_zeinounAinda não há avaliações

- 4333Documento282 páginas4333alcava219151Ainda não há avaliações

- WWTP Mardan 1st PhaseDocumento41 páginasWWTP Mardan 1st Phasemohammad armaghan100% (1)

- Design Aspects Drinking Water Treatment.Documento32 páginasDesign Aspects Drinking Water Treatment.Milton Alexander Rivera TorresAinda não há avaliações

- Active Sludge PDFDocumento8 páginasActive Sludge PDFDark_KiroAinda não há avaliações

- Fundamentals of Wastewater TreatmentDocumento72 páginasFundamentals of Wastewater Treatmentanikamanal100% (3)

- Main CatalogueDocumento10 páginasMain CatalogueMohamed SalahAinda não há avaliações

- DisinfectionDocumento82 páginasDisinfectionJoby AbrahamAinda não há avaliações

- Water Measurement ManualDocumento317 páginasWater Measurement ManualJean BattellAinda não há avaliações

- 21810, Ultrapure Water Breakpoint CL andDocumento5 páginas21810, Ultrapure Water Breakpoint CL andWaleed EmaraAinda não há avaliações

- German Atv Standards: Advisory Leaflet ATV-M 269EDocumento32 páginasGerman Atv Standards: Advisory Leaflet ATV-M 269EMehmet Emre Bastopcu100% (2)

- Project Semester ReportDocumento60 páginasProject Semester ReportPrabhjot Singh TinnaAinda não há avaliações

- Solving Activated Sludge Math ProblemsDocumento5 páginasSolving Activated Sludge Math ProblemsArashAinda não há avaliações

- Introduction To Activated Sludge Study Guide: Wisconsin Department of Natural Resources Wastewater Operator CertificationDocumento33 páginasIntroduction To Activated Sludge Study Guide: Wisconsin Department of Natural Resources Wastewater Operator CertificationAgus WitonoAinda não há avaliações

- Chapter 17 - MathematicsDocumento13 páginasChapter 17 - MathematicsLivingston JosephAinda não há avaliações

- Why floating solids in secondary clarifiersDocumento6 páginasWhy floating solids in secondary clarifiersIsaac FernándezAinda não há avaliações

- Aeration System in WWTPDocumento10 páginasAeration System in WWTPashokAinda não há avaliações

- Teza Namol EpurareDocumento267 páginasTeza Namol EpurareMarcel BurlacuAinda não há avaliações

- Activated Carbon Treatment of Drinking WaterDocumento6 páginasActivated Carbon Treatment of Drinking WaterHaimwant DhanieAinda não há avaliações

- BAT Study Wastewater FINAL REPORT PDFDocumento183 páginasBAT Study Wastewater FINAL REPORT PDFKhang TrầnAinda não há avaliações

- Hazardous Areas For Water & Wastewater Facilities PDFDocumento9 páginasHazardous Areas For Water & Wastewater Facilities PDFKVRamananAinda não há avaliações

- Upflow Anaerobic Sludge Blanket Process UASB GuideDocumento18 páginasUpflow Anaerobic Sludge Blanket Process UASB GuideKhang TrầnAinda não há avaliações

- All About WastewatertreatmentDocumento383 páginasAll About WastewatertreatmentLucian Apostu100% (1)

- For Standard Bidding Document (SPD) For Works and Operation ServicesDocumento121 páginasFor Standard Bidding Document (SPD) For Works and Operation Servicespls_79Ainda não há avaliações

- Trickling Filter and Trickling Filter-Suspended Growth Process Design and OperationDocumento19 páginasTrickling Filter and Trickling Filter-Suspended Growth Process Design and OperationMichał KisielewskiAinda não há avaliações

- Lec4 Water and Wastewater TreatmentDocumento54 páginasLec4 Water and Wastewater TreatmentKent Harry CumpioAinda não há avaliações

- Waste Water Treatment PlantsDocumento5 páginasWaste Water Treatment Plantssharath100% (1)

- 04 Sec. 3 Sewage Characteristics and Effluent Discharge Requirements PDFDocumento8 páginas04 Sec. 3 Sewage Characteristics and Effluent Discharge Requirements PDFVic KeyAinda não há avaliações

- Rotating Biological ContactorsDocumento18 páginasRotating Biological Contactorsjjiménez_142046Ainda não há avaliações

- Wastewater IrrigationDocumento28 páginasWastewater IrrigationZindai WazirAinda não há avaliações

- Systematic Methods of Water Quality Parameters Analysis: Analytical MethodsNo EverandSystematic Methods of Water Quality Parameters Analysis: Analytical MethodsAinda não há avaliações

- Municipal Wastewater Treatment: Evaluating Improvements in National Water QualityNo EverandMunicipal Wastewater Treatment: Evaluating Improvements in National Water QualityAinda não há avaliações

- Water Treatment Plant Performance Evaluations and OperationsNo EverandWater Treatment Plant Performance Evaluations and OperationsAinda não há avaliações

- Sanitary Engineer II: Passbooks Study GuideNo EverandSanitary Engineer II: Passbooks Study GuideAinda não há avaliações

- Applications of New Concepts of Physical-Chemical Wastewater Treatment: Vanderbilt University, Nashville, Tennessee September 18-22, 1972No EverandApplications of New Concepts of Physical-Chemical Wastewater Treatment: Vanderbilt University, Nashville, Tennessee September 18-22, 1972Nota: 5 de 5 estrelas5/5 (1)

- L8 - Human Resource ManagementDocumento6 páginasL8 - Human Resource ManagementAnonymous 8ooQmMoNs1Ainda não há avaliações

- L9 - Dynamics of Behaviour in OrganisationsDocumento5 páginasL9 - Dynamics of Behaviour in OrganisationsAnonymous 8ooQmMoNs1Ainda não há avaliações

- L6 - LeadershipDocumento11 páginasL6 - LeadershipAnonymous 8ooQmMoNs1Ainda não há avaliações

- Portelli Massacre at Fosse ArdeatineDocumento9 páginasPortelli Massacre at Fosse ArdeatineAnonymous 8ooQmMoNs1Ainda não há avaliações

- Sontag Collective MemoryDocumento7 páginasSontag Collective MemoryAnonymous 8ooQmMoNs1Ainda não há avaliações

- L7 - Managing DiversityDocumento5 páginasL7 - Managing DiversityAnonymous 8ooQmMoNs1Ainda não há avaliações

- L4 - Managerial Decision MakingDocumento9 páginasL4 - Managerial Decision MakingAnonymous 8ooQmMoNs1Ainda não há avaliações

- Bill Niven War MemorialsDocumento7 páginasBill Niven War MemorialsAnonymous 8ooQmMoNs1Ainda não há avaliações

- L5 - OrganisingDocumento13 páginasL5 - OrganisingAnonymous 8ooQmMoNs1Ainda não há avaliações

- L3 - Planning and GoalsDocumento9 páginasL3 - Planning and GoalsAnonymous 8ooQmMoNs1Ainda não há avaliações

- L1 - The Changing Paradigm of ManagementDocumento8 páginasL1 - The Changing Paradigm of ManagementAnonymous 8ooQmMoNs1Ainda não há avaliações

- Bill Niven War MemorialsDocumento7 páginasBill Niven War MemorialsAnonymous 8ooQmMoNs1Ainda não há avaliações

- Fit Interview 071712 PDFDocumento14 páginasFit Interview 071712 PDFAnonymous 9W8HM1nqXBAinda não há avaliações

- Ginsborg History of ItalyDocumento8 páginasGinsborg History of ItalyAnonymous 8ooQmMoNs10% (1)

- Richard Osborne - MythDocumento3 páginasRichard Osborne - MythAnonymous 8ooQmMoNs1Ainda não há avaliações

- 06 AnsDocumento4 páginas06 AnsAnonymous 8ooQmMoNs1Ainda não há avaliações

- Philip Taylor PropagandaDocumento3 páginasPhilip Taylor PropagandaAnonymous 8ooQmMoNs1Ainda não há avaliações

- Harry HearderDocumento15 páginasHarry HearderAnonymous 8ooQmMoNs1Ainda não há avaliações

- TJX Forecast ChangesDocumento13 páginasTJX Forecast ChangesAnonymous 8ooQmMoNs1Ainda não há avaliações

- Jock Reynolds J LT RookiesDocumento14 páginasJock Reynolds J LT RookiesAnonymous 8ooQmMoNs1Ainda não há avaliações

- 2006 Stanford Consulting Case Interview PreparationDocumento62 páginas2006 Stanford Consulting Case Interview Preparationr_oko100% (3)

- Weak & Strong FormsDocumento77 páginasWeak & Strong FormsAnonymous 8ooQmMoNs1Ainda não há avaliações

- Lectures 1-3 COLOURDocumento45 páginasLectures 1-3 COLOURAnonymous 8ooQmMoNs1Ainda não há avaliações

- 07 AnsDocumento5 páginas07 AnsAnonymous 8ooQmMoNs10% (1)

- Arithmetic Test Example PDFDocumento1 páginaArithmetic Test Example PDFAnonymous 8ooQmMoNs1Ainda não há avaliações

- 04 AnsDocumento20 páginas04 AnsAnonymous 8ooQmMoNs1Ainda não há avaliações

- Grammar Guide 2018Documento56 páginasGrammar Guide 2018Tony NguerezaAinda não há avaliações

- 02 AnsDocumento10 páginas02 AnsAnonymous 8ooQmMoNs1Ainda não há avaliações

- 05 AnsDocumento8 páginas05 AnsAnonymous 8ooQmMoNs1Ainda não há avaliações

- Chapter 01 Solutions PalepuDocumento3 páginasChapter 01 Solutions Palepuilhamuh67% (6)

- Tan DeltaDocumento8 páginasTan DeltaManiVinoAinda não há avaliações

- Colacor 93Documento1 páginaColacor 93mndmattAinda não há avaliações

- Program of NEWCA Workshop (V27-04)Documento2 páginasProgram of NEWCA Workshop (V27-04)Queiroz PortorrealAinda não há avaliações

- IKEA PG Godmorgon 2010 Great Britian - EnglishDocumento5 páginasIKEA PG Godmorgon 2010 Great Britian - Englishkarisma_bsAinda não há avaliações

- Excavation Removal-PlanDocumento34 páginasExcavation Removal-PlanABDELKADER BENABDALLAHAinda não há avaliações

- SSPC PA1 2016 - Part1Documento1 páginaSSPC PA1 2016 - Part1Jagannath SahuAinda não há avaliações

- Bensultap 464Documento6 páginasBensultap 464jessica montielAinda não há avaliações

- AWG Catalog PDFDocumento424 páginasAWG Catalog PDFJSEMSAinda não há avaliações

- 4516 PDFDocumento10 páginas4516 PDFRajesh BabuAinda não há avaliações

- Sand Casting Guide: Gating Systems & RisersDocumento31 páginasSand Casting Guide: Gating Systems & RisersAmruta Rane100% (1)

- Stainless Steel For Potable Water Treatment Plants PWTP Guidelines PDFDocumento8 páginasStainless Steel For Potable Water Treatment Plants PWTP Guidelines PDFAsgard SanchezAinda não há avaliações

- Effect of Case Depth On Fatigue Performance of AISI 8620 Carburized SteelDocumento7 páginasEffect of Case Depth On Fatigue Performance of AISI 8620 Carburized SteelthisisjineshAinda não há avaliações

- td1437-01 TAD750VE Operaters ManualDocumento73 páginastd1437-01 TAD750VE Operaters ManualArtur Daneshwar100% (1)

- TG-500M CRANE SPECIFICATIONSDocumento16 páginasTG-500M CRANE SPECIFICATIONSnamduong368Ainda não há avaliações

- API - 510-Open - Book - Mock UpDocumento13 páginasAPI - 510-Open - Book - Mock Upprashanth-967782Ainda não há avaliações

- ANSI C29.17-2002 Composite-Line Post TypeDocumento22 páginasANSI C29.17-2002 Composite-Line Post Typesoc_unfvAinda não há avaliações

- C2 Metallic Bonding Answers (Rocket Sheets)Documento1 páginaC2 Metallic Bonding Answers (Rocket Sheets)Maria CamilleriAinda não há avaliações

- Technical Bulletin: 3M VHB DurabilityDocumento6 páginasTechnical Bulletin: 3M VHB DurabilityAlvin Dela CruzAinda não há avaliações

- Organic Syntheses, Coll. Vol. 2, p.219 (1943) Vol. 16, p.25Documento3 páginasOrganic Syntheses, Coll. Vol. 2, p.219 (1943) Vol. 16, p.25ariesterAinda não há avaliações

- SSP Nfra BDT1 Jind MST 00032Documento42 páginasSSP Nfra BDT1 Jind MST 00032Zulhazmi ZulkafliAinda não há avaliações

- Chapter 9 - Electron Beam WeldingDocumento14 páginasChapter 9 - Electron Beam WeldingrafikdmeAinda não há avaliações

- Winsurf QX-9: Tech Data SheetDocumento16 páginasWinsurf QX-9: Tech Data SheetFloraAinda não há avaliações

- Building Envelope Compliance FormsDocumento9 páginasBuilding Envelope Compliance FormsJWAinda não há avaliações

- Machine Tools Design and Numerical Control by M. K. Mehta PDFDocumento560 páginasMachine Tools Design and Numerical Control by M. K. Mehta PDFPranav Thorat100% (3)

- Metal Reinforcement - Term PaperDocumento35 páginasMetal Reinforcement - Term PaperDrei ServitoAinda não há avaliações

- Chemical HazardousDocumento31 páginasChemical HazardousGummie Akalal SugalaAinda não há avaliações

- Tech Data Sheet 6600Documento1 páginaTech Data Sheet 6600Shubhankar MenonAinda não há avaliações

- IO - 20190107 - ABB MV Switchgear 36kV - Installation and Operating Instructions - V20 - ENDocumento24 páginasIO - 20190107 - ABB MV Switchgear 36kV - Installation and Operating Instructions - V20 - ENFranco MolinaAinda não há avaliações

- Variables For Welding 11-3-2016 - 264B1DF6 PDFDocumento2 páginasVariables For Welding 11-3-2016 - 264B1DF6 PDFSameh AminAinda não há avaliações

- Bosch A-Si PDFDocumento2 páginasBosch A-Si PDFKirsten HernandezAinda não há avaliações