Escolar Documentos

Profissional Documentos

Cultura Documentos

Material Control Gates

Enviado por

Mohamed ShehataDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Material Control Gates

Enviado por

Mohamed ShehataDireitos autorais:

Formatos disponíveis

Application

Material control gates are used in the cement industry at all levels of production for redirecting, damming or dividing flows of material. FLS have designed gates for all types of raw materials, clinker, and finished cement; dusttight gates and gates equipped with wearplates are also available. FLS Material Control Gates come in standard series for application together with FLS screw conveyors, drag chains, Fluxoslides, and silos. Gates are available for both transversal and longitudinal installation below screw conveyors and drag chains. The opening, resetting, and closing of FLS material control gates may be effected by remote control, automatically by means of RACO motor-operated actuators, hydraulically or pneumatically. Manual operation is also possible for smaller size gates. In each case a signal is automatically sent to a central control panel showing the gate position.

Design and operation

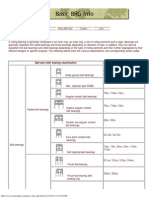

Air-tight change-over gates have individual motors for each chute, thus enabling one gate to be opened in the event of a blockage in the other passage. The use of dividing gates makes it possible to direct the flow of material towards two subsequent mechanical conveyors in any preselected proportion. For extrernely sticky materials a special design of control gate has been developed which permits fast cleaning by water flushing. In certain cases electric heating elements are incorporated to prevent clogging. The type designations are as follows : D, S, P , PL, R, or UK One or two figures (mm or cm) L or T

Slide gate for drag chain, transversal Slide gate for drag chain longitudnal Slide gate for screw conveyor, transversal Slide gate for screw conveyor, longitudinal Change-over gate for pulverulent or bulk material Change-over gate for ulverulent material (air-tight) Dividing gate Flap gate for hot clinker Hoisting gate for UK hammer mill

2 3 4

5 6 7 8 9

Machinery or Dimension(s) Longitudinal material or Transversal installation.

Dimensioning

Data in this brochure series is only intended for preliminary project planning. Manufacturer reserves the right to modify equipment details and/or specifications without notice. DENMARK: F. L. Smidth & Co. A/S. Vigerslev All 77, DK-2500 Valby Copenhagen UNITED KINGDOM: F. L. Smidth & Co., Ltd. 17, Lansdowne Road, Croydon, GB-CR9 2JT FRANCE: F. L. Smidth & Cie - France, 55, Rue Ampre, F-75017 Paris FEDERAL REPUBLIC OF GERMANY: F. L. Smidth & Co. GmbH, D-2400 Lbeck, Geniner Strasse 133-135 ITALY: F. L. Smidth & C. Italiana, S.r.l., Via Lucilio, 25,1-00136 Rome SPAIN: F. L. Smidth & Cia. Espaola, S.A., Calle de Jorge Juan, 46, Madrid 1 CANADA: F. L. Smidth & Co. of Canada, Limited, 1500 De Mainsonneuve Blvd. West, Montreal, Quebec, Canada H3G 1H1 U.S.A.: F. L. Smidth & Co., 300 Knickerbocker Road, Cresskill, New Jersey 07626 MEXICO: F. L. Smidth & Cia., S.A. de C.V., Ave, Campos Eliseos, 385, 5 piso, Torre B, Polanco. Mexico City 5, D.F. BRAZIL: F. L. Smidth, S.A. Comrcio e indstria, Rua Nebraska, 459, Brooklin Paulista - CEP-04560, Caixa Postal 3506, 01000 Sao Paulo - SP JAPAN: F. L. Smidth & Co. (Japan) Ltd., Togeki Building 1-1, Tsukiji 4-chome, Kyobashi P.O. Box 78, Chuo-ku, Tokyo 104.

Você também pode gostar

- Shaft AlignmentDocumento8 páginasShaft AlignmentTarek MohamedAinda não há avaliações

- Dial Indicator Alignment Procedure PDFDocumento4 páginasDial Indicator Alignment Procedure PDFMohamed ShehataAinda não há avaliações

- FNL Flanged Bearing HousingDocumento11 páginasFNL Flanged Bearing HousingMohamed ShehataAinda não há avaliações

- Basic BRG InfoDocumento5 páginasBasic BRG InfoMohamed ShehataAinda não há avaliações

- Dynamic Movement White Paper: Vibralign, Inc. 530G Southlake BLVD Richmond, Va 232326 804.379.2250Documento0 páginaDynamic Movement White Paper: Vibralign, Inc. 530G Southlake BLVD Richmond, Va 232326 804.379.2250SreenivasAinda não há avaliações

- Gears and PinionsDocumento5 páginasGears and Pinionsmahreza189Ainda não há avaliações

- Dial Indicator Alignment ProcedureDocumento4 páginasDial Indicator Alignment ProcedureMohamed ShehataAinda não há avaliações

- Example by Microsoft Project PDFDocumento1 páginaExample by Microsoft Project PDFMohamed ShehataAinda não há avaliações

- Example by Microsoft Project PDFDocumento1 páginaExample by Microsoft Project PDFMohamed ShehataAinda não há avaliações

- YbearingsDocumento227 páginasYbearingsmasmuinAinda não há avaliações

- Bearing Basics ExplainedDocumento6 páginasBearing Basics ExplainedMohamed ShehataAinda não há avaliações

- CarbDocumento84 páginasCarbJurun_BidanshiAinda não há avaliações

- 1582 GBDocumento7 páginas1582 GBMohamed Shehata100% (1)

- Pages 9-66 From Complete Idler Roller CatalogDocumento59 páginasPages 9-66 From Complete Idler Roller CatalogjashmithAinda não há avaliações

- CP Pci TechnikDocumento8 páginasCP Pci TechnikMohamed ShehataAinda não há avaliações

- CP Profile - English 0106Documento16 páginasCP Profile - English 0106Mohamed ShehataAinda não há avaliações

- CP Dry Mortar & MixDocumento12 páginasCP Dry Mortar & MixMohamed ShehataAinda não há avaliações

- 5aese Yang ImproDocumento6 páginas5aese Yang ImproMohamed ShehataAinda não há avaliações

- WisdomDocumento6 páginasWisdomMohamed ShehataAinda não há avaliações

- Plant 2000tpdDocumento9 páginasPlant 2000tpdMohamed ShehataAinda não há avaliações

- Unax InternalsDocumento4 páginasUnax InternalsMohamed ShehataAinda não há avaliações

- Europe Largest KilnDocumento11 páginasEurope Largest KilnMohamed ShehataAinda não há avaliações

- Mech Kiln InspectionDocumento2 páginasMech Kiln InspectionMohamed ShehataAinda não há avaliações

- 100,000t ExpansionDocumento8 páginas100,000t ExpansionMohamed ShehataAinda não há avaliações

- Laboratory ServicesDocumento6 páginasLaboratory ServicesMohamed ShehataAinda não há avaliações

- Laboratory ServicesDocumento6 páginasLaboratory ServicesMohamed ShehataAinda não há avaliações

- Water Cooling For Cement Mill PDFDocumento2 páginasWater Cooling For Cement Mill PDFjagrutAinda não há avaliações

- Heat correction of kiln cranks is cost effectiveDocumento4 páginasHeat correction of kiln cranks is cost effectiveMohamed Shehata100% (2)

- After Sales ServiceDocumento10 páginasAfter Sales ServiceSamehibrahemAinda não há avaliações

- Mech Kiln InspectionDocumento2 páginasMech Kiln InspectionMohamed ShehataAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- CH - 3Documento3 páginasCH - 3Phantom GamingAinda não há avaliações

- Mesopotamia CivilizationDocumento56 páginasMesopotamia CivilizationYashika TharwaniAinda não há avaliações

- Brochure - Truemax Concrete Pump Truck Mounted TP25M4Documento16 páginasBrochure - Truemax Concrete Pump Truck Mounted TP25M4RizkiRamadhanAinda não há avaliações

- Application Programming InterfaceDocumento12 páginasApplication Programming InterfacesorinproiecteAinda não há avaliações

- Migration (LIN 19/051: Specification of Occupations and Assessing Authorities) Instrument 2019Documento28 páginasMigration (LIN 19/051: Specification of Occupations and Assessing Authorities) Instrument 2019Ajay palAinda não há avaliações

- Mechanical Questions & AnswersDocumento161 páginasMechanical Questions & AnswersTobaAinda não há avaliações

- Manju Philip CVDocumento2 páginasManju Philip CVManju PhilipAinda não há avaliações

- Center of Gravity and Shear Center of Thin-Walled Open-Section Composite BeamsDocumento6 páginasCenter of Gravity and Shear Center of Thin-Walled Open-Section Composite Beamsredz00100% (1)

- EcohistDocumento3 páginasEcohistRkmv EconAinda não há avaliações

- RestrukturisasiDocumento17 páginasRestrukturisasimuhammad hayel wallaAinda não há avaliações

- Biomechanics of Advanced Tennis: January 2003Documento7 páginasBiomechanics of Advanced Tennis: January 2003Katrien BalAinda não há avaliações

- W1inse6220 PDFDocumento11 páginasW1inse6220 PDFpicalaAinda não há avaliações

- WA Beretta M92FS Parts ListDocumento2 páginasWA Beretta M92FS Parts ListDenis Deki NehezAinda não há avaliações

- Medical filter performance specificationsDocumento1 páginaMedical filter performance specificationsPT.Intidaya Dinamika SejatiAinda não há avaliações

- Legal Research MethodsDocumento10 páginasLegal Research MethodsCol Amit KumarAinda não há avaliações

- Indian Institute OF Management, BangaloreDocumento20 páginasIndian Institute OF Management, BangaloreGagandeep SinghAinda não há avaliações

- Week 6Documento7 páginasWeek 6Nguyễn HoàngAinda não há avaliações

- K Series Parts List - 091228Documento25 páginasK Series Parts List - 091228AstraluxAinda não há avaliações

- 256267a1Documento5.083 páginas256267a1Елизавета ШепелеваAinda não há avaliações

- FINAL - Plastic Small Grants NOFO DocumentDocumento23 páginasFINAL - Plastic Small Grants NOFO DocumentCarlos Del CastilloAinda não há avaliações

- Nature and Scope of Marketing Marketing ManagementDocumento51 páginasNature and Scope of Marketing Marketing ManagementFeker H. MariamAinda não há avaliações

- Basic Calculus: Performance TaskDocumento6 páginasBasic Calculus: Performance TasksammyAinda não há avaliações

- OROLO & W. D. GannDocumento56 páginasOROLO & W. D. GannGaurav Garg100% (1)

- DMS-2017A Engine Room Simulator Part 1Documento22 páginasDMS-2017A Engine Room Simulator Part 1ammarAinda não há avaliações

- Mama Leone's Profitability AnalysisDocumento6 páginasMama Leone's Profitability AnalysisLuc TranAinda não há avaliações

- R4 User GuideDocumento48 páginasR4 User GuideAaron SmithAinda não há avaliações

- Palgrave Handbook of Research in Historical Culture and EducationDocumento847 páginasPalgrave Handbook of Research in Historical Culture and EducationGonzalo Garcia100% (1)

- Chapter 1 - IntroductionDocumento42 páginasChapter 1 - IntroductionShola ayipAinda não há avaliações

- EMMS SpecificationsDocumento18 páginasEMMS SpecificationsAnonymous dJtVwACc100% (2)

- PM - Network Analysis CasesDocumento20 páginasPM - Network Analysis CasesImransk401Ainda não há avaliações