Escolar Documentos

Profissional Documentos

Cultura Documentos

Lathe Cutter Height Gage

Enviado por

kokiskoDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Lathe Cutter Height Gage

Enviado por

kokiskoDireitos autorais:

Formatos disponíveis

Lathe Cutter Height Gage, version 1

By R. G. Sparber

Copyleft protects this document.1

One common procedure on a lathe is setting the cutter at the same height as the center of rotation. There are many ways to do this that work just fine. Well, here is another one. This height gage has two subtle features. First, it beeps when the cutter contacts the underside of the puck. That is certainly nothing all that new.

You are free to copy and distribute this document but not change it. March 22, 2012 Page 1 of 12

R. G. Sparber

The other feature is that the underside of the puck is not flat. It has a taper. This taper lets me quickly detect if the cutter has been set right. What you see here is an exaggerated taper. The real one rises only a few thou from center to perimeter. To use the height gage, I first move the tip of the cutter about half way between the post and the perimeter of the puck. Then I raise or lower the cutter until the beeping just starts to cut out. I then slide the gage away from the cutter. Since this underside is tapered, the distance from cutter tip to the tapered surface increases. If the tool has been set correctly, a small movement of the gage stops the beeping. If it was set too high, the beeping will not stop until the cutter clears the puck. This is a prototype so I made the puck out of aluminum. A better choice for a final design would be to use at least mild steel. Ideally, the puck would be hardened so the cutter would not dig into it.

R. G. Sparber

March 22, 2012

Page 2 of 12

The puck slides on a aluminum rod. A flat has been cut in the side of the rod so burrs generated by the set screw do not jam the movement.

R. G. Sparber

March 22, 2012

Page 3 of 12

The beeper is contained in an old Altoids box.

R. G. Sparber

March 22, 2012

Page 4 of 12

Inside the box is a 9 volt battery and a piezoelectric beeper from Radio Shack.

R. G. Sparber

March 22, 2012

Page 5 of 12

The black wire from the beeper connects to the metal of the base. The red wire goes to the positive terminal of the battery. The negative terminal of the battery connects to the insulated bolt that anchors the post. Note the insulating washer under the -20 bolt. There is no need for a power switch. The beeper only sounds when a circuit is completed between the puck and the cutter by way of the tool post, lathe apron, and lathe ways.

R. G. Sparber

March 22, 2012

Page 6 of 12

Here you see the other insulating washers. They isolate the puck and post from the base.

R. G. Sparber

March 22, 2012

Page 7 of 12

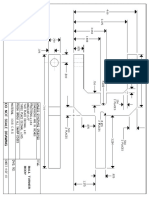

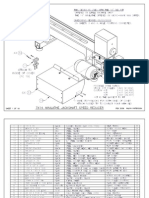

Shop Drawings

R. G. Sparber

March 22, 2012

Page 8 of 12

R. G. Sparber

March 22, 2012

Page 9 of 12

R. G. Sparber

March 22, 2012

Page 10 of 12

R. G. Sparber

March 22, 2012

Page 11 of 12

You will also need one -20 set screw, a -20 x 1 bolt, and a 6-32 x screw.

I welcome your comments and questions. Rick Sparber Rgsparber@aol.com Rick.Sparber.org

R. G. Sparber

March 22, 2012

Page 12 of 12

Você também pode gostar

- Ball Turner PrintsDocumento10 páginasBall Turner PrintskokiskoAinda não há avaliações

- Quantum Wave of Life Evolution: Written by DR Kiril Chukanov, June 2009, Calgary, CanadaDocumento32 páginasQuantum Wave of Life Evolution: Written by DR Kiril Chukanov, June 2009, Calgary, CanadakokiskoAinda não há avaliações

- Ball Turner Prints PDFDocumento10 páginasBall Turner Prints PDFkokiskoAinda não há avaliações

- UFODocumento2 páginasUFOkokiskoAinda não há avaliações

- Evading Thermal Imaging and Radar Detection-1Documento8 páginasEvading Thermal Imaging and Radar Detection-1kokiskoAinda não há avaliações

- Cross Slide Nut ModificationDocumento3 páginasCross Slide Nut ModificationkokiskoAinda não há avaliações

- Ralph Patterson Speed Reducer 2Documento27 páginasRalph Patterson Speed Reducer 2kokiskoAinda não há avaliações

- Metal Spinning TutorialDocumento15 páginasMetal Spinning TutorialMike SullivanAinda não há avaliações

- Morse Taper Dimensions and Drill Chuck ArborsDocumento4 páginasMorse Taper Dimensions and Drill Chuck ArborskokiskoAinda não há avaliações

- Change Gears Charts For Metric Threading On The 7x MiniDocumento2 páginasChange Gears Charts For Metric Threading On The 7x MinikokiskoAinda não há avaliações

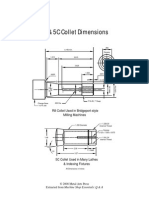

- r8 5c Collet DimensionsDocumento2 páginasr8 5c Collet Dimensionskokisko100% (1)

- Drilling SpeedsDocumento3 páginasDrilling SpeedskokiskoAinda não há avaliações

- Perreault, Bruce A. U.S. Patent Application Filed May 04, 2007Documento9 páginasPerreault, Bruce A. U.S. Patent Application Filed May 04, 2007kokiskoAinda não há avaliações

- APL 2013catalog 06-2013 WebDocumento9 páginasAPL 2013catalog 06-2013 WebkokiskoAinda não há avaliações

- Hammer MillsDocumento56 páginasHammer MillskokiskoAinda não há avaliações

- Learjet 85 enDocumento2 páginasLearjet 85 enkokiskoAinda não há avaliações

- Lear 45 XRDocumento2 páginasLear 45 XRkokisko100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- MV SWGR & CGR - Inspn & Test Procedure IECDocumento9 páginasMV SWGR & CGR - Inspn & Test Procedure IECMohammed Madi100% (2)

- 2088B PAM加药机说明书 中英文Documento16 páginas2088B PAM加药机说明书 中英文Jairo Andrés FAAinda não há avaliações

- GAC - Application Note Cummins PT Fuel Systems PIB1006Documento12 páginasGAC - Application Note Cummins PT Fuel Systems PIB1006gilizaniniAinda não há avaliações

- Biomedical Instrumentation: COURSE CODE: 15EC1148Documento2 páginasBiomedical Instrumentation: COURSE CODE: 15EC1148hema maliniAinda não há avaliações

- Dura-Lift Maintenance Program EMDocumento5 páginasDura-Lift Maintenance Program EMSalim Ben AmorAinda não há avaliações

- Rp6s - Master For Idc - 8-Oct-2021 Printed PDFDocumento25 páginasRp6s - Master For Idc - 8-Oct-2021 Printed PDFItz GyyyAinda não há avaliações

- 2002 Kx125 Parts Diagram: Cylinder Head/CylinderDocumento3 páginas2002 Kx125 Parts Diagram: Cylinder Head/CylinderZach NewellAinda não há avaliações

- Ceiling Diffuser (CD) : Product DescriptionDocumento24 páginasCeiling Diffuser (CD) : Product DescriptionahmedAinda não há avaliações

- Mission Critical: Series 6, 8 & 9Documento8 páginasMission Critical: Series 6, 8 & 9Luis VeraAinda não há avaliações

- Rsti-L Screened, Separable Connection System 630 A Up To 24 KVDocumento4 páginasRsti-L Screened, Separable Connection System 630 A Up To 24 KVdeepu_er100% (1)

- Motor - Suction Side - 20230308 - 075344Documento3 páginasMotor - Suction Side - 20230308 - 075344Mohammad AlmafarjehAinda não há avaliações

- Ql700 PL Verb1Documento22 páginasQl700 PL Verb1heardcAinda não há avaliações

- Tutorial QuestionsDocumento2 páginasTutorial QuestionsAmber MomentAinda não há avaliações

- Digital User ManualDocumento23 páginasDigital User ManualkahandawalaAinda não há avaliações

- Instruction Manual For LS PDFDocumento104 páginasInstruction Manual For LS PDFRM HaroonAinda não há avaliações

- KVM Usb Switch 2 Port - Google SearchDocumento1 páginaKVM Usb Switch 2 Port - Google SearchNaveen Gowdru ChannappaAinda não há avaliações

- HaDocumento2 páginasHamonica_lelisAinda não há avaliações

- Analyser - Schematic (As of 2021-01-21)Documento11 páginasAnalyser - Schematic (As of 2021-01-21)aryo ganda pakpahanAinda não há avaliações

- Klinger KGS/VD: The First Infinitely Adjustable GasketDocumento4 páginasKlinger KGS/VD: The First Infinitely Adjustable Gasketperdhana2000Ainda não há avaliações

- SBP2DI48524: Dupline Carpark Display InterfaceDocumento7 páginasSBP2DI48524: Dupline Carpark Display Interfaceimadz853Ainda não há avaliações

- T-7-List of Supporting DocumentsDocumento24 páginasT-7-List of Supporting DocumentsductaiutcAinda não há avaliações

- 福建马尾MMC887PSV完工图 PDFDocumento48 páginas福建马尾MMC887PSV完工图 PDFcarlos100% (1)

- Plumbing Contractor Scope of Work Item DescriptionDocumento1 páginaPlumbing Contractor Scope of Work Item DescriptionParthiban SobanaAinda não há avaliações

- Bird Photography: Staying Sharp and Focused: PhotzyDocumento24 páginasBird Photography: Staying Sharp and Focused: PhotzymrpiracyAinda não há avaliações

- 16mb1a0 InstalacionDocumento2 páginas16mb1a0 InstalacionAntonio MurrietaAinda não há avaliações

- DP 460 330L Parts Ver2Documento149 páginasDP 460 330L Parts Ver2Ivan WengerAinda não há avaliações

- Rasb10n3kv2 Series PDFDocumento10 páginasRasb10n3kv2 Series PDFSomadbsiAinda não há avaliações

- Adam Tech Product Catalog2022Documento357 páginasAdam Tech Product Catalog2022nue_helmutAinda não há avaliações

- Lab ReportDocumento7 páginasLab ReportRehanNasirAinda não há avaliações

- Superior Belt Scale 1Documento61 páginasSuperior Belt Scale 1jack doffAinda não há avaliações