Escolar Documentos

Profissional Documentos

Cultura Documentos

CAMS1V6P (Old Style) Swing and Spin Stopper Settings

Enviado por

joecentroneDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

CAMS1V6P (Old Style) Swing and Spin Stopper Settings

Enviado por

joecentroneDireitos autorais:

Formatos disponíveis

How to adjust spin stoppers to get a straight Line

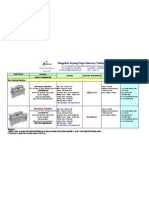

Figure 1.

Name of each part of CAMS1V6P

1. Timing belt tension adjustment

Check timing belt tension of X axis and Y axis first. If it is too loose, it is difficult to get a good result as shown on the PC monitor. If the tension is too high, Motor shaft and timing belt can get damage easily. I recommend to adjust it as much as the tension of Classic Guitar string (No.6 E note). Use X axis (Y axis) tension bolt shown in Figure 1.

stopper setting for swing & spin module

- 1 -

YongNam Engineering < 2003, 12.18 >

PDF created with FinePrint pdfFactory Pro trial version www.pdffactory.com

2. Prepare Line data using GemMaster

Draw Lines using GemMaster as shown in Figure 2. This is for making it easy to see how the machine set stones on XY table. I recommend to use SS10 rhinestone and set the distance to 1mm.

Figure 2

Lines for Adjusting spin stoppers

After selecting stone, draw line using Icon ( see Figure 2 ) Draw one line first like and copy it to draw lines like .

stopper setting for swing & spin module

- 2 -

YongNam Engineering < 2003, 12.18 >

PDF created with FinePrint pdfFactory Pro trial version www.pdffactory.com

3. setting spin-stopper 1 & spin-stopper 2

In other to get a good result, the distance between stones like 'A,B,C,D,E,F,G' in Figure 3 should be exactly same when making a line in X axis direction. The distance between stones is controlled by the stop position of LSET and RSET. In case when you can not get a same distance between stones located next to each other while making line( see Figure 3 Wrong line ), you have to fix it by adjusting spin stopper 1 and spin stopper 2. (see Figure 5, Figure 6)

Figure 3.

Correct Line & Wrong Line

When the stop position of LSET and RSET is not correctly set up, it shows bad result in X direction like (see Figure 3) or like , (see Figure 4) and in Y direction like (see Figure 4). And also, you can't make a good circle as you can see (see Figure 4). When you correctly set spin stopper 1 and spin stopper 2, you can get a same distance between stones for X direction line, straight line for Y direction line, and perfect circle.

stopper setting for swing & spin module

- 3 -

YongNam Engineering < 2003, 12.18 >

PDF created with FinePrint pdfFactory Pro trial version www.pdffactory.com

Figure 4.

bad result

3.1

to set RSET stop position by spin stopper 1

When the distance between stones is not same while making line in X direction like Figure 5, stop machine by pressing SET button at the moment before setter is stretched(see Figure 5). <Step 1> In Figure 5, RSET is located at XY table. RSET stop position is controlled by spin stopper 1. When you screw the spin stopper 1 to clock wise direction, it moves to direction, and RSET moves to direction. and vice versa. To make RSET put stone on XY table correctly, adjust spin stopper 1 so that the distance 'E' becomes same with half of the value of 'C + D'. ( see Figure 5 )

stopper setting for swing & spin module

- 4 -

YongNam Engineering < 2003, 12.18 >

PDF created with FinePrint pdfFactory Pro trial version www.pdffactory.com

Figure 5.

in case RSET is located on XY table

< Step 2 > In Figure 6, LSET is located at XY table. LSET stop position is controlled by spin stopper 2. When you screw the spin stopper 2 to counter clock wise direction, it moves to direction, and LSET moves to direction. and vice versa. To make LSET put stone on XY table correctly, adjust spin stopper 2 so that the distance 'E' becomes same with half of the value of 'C + D'. ( see Figure 6 )

stopper setting for swing & spin module

- 5 -

YongNam Engineering < 2003, 12.18 >

PDF created with FinePrint pdfFactory Pro trial version www.pdffactory.com

Figure 6.

in case RSET is located on XY table

< Step 3 > After finishing Step 1, Step 2, it is necessary to adjust swing stopper 2. (see Figure 7) 'Swing module stop position' is controlled by swing stopper 2. When you screw the spin stopper 2 to clock wise direction, it moves to direction. and vice versa. - Stop machine by pressing SET button when GUN module is located at the right side.(see Figure 7) - Adjust swing stopper 2 to meet the center of RSET, LSET. After finishing Step 1, Step 2, Step 3, continue working by pressing 'SET' button when the cursor is on 'CONTINUE'. And look carefully whether the machine is making the line correctly or not. Maybe, you need to repeat from Step 1 to Step 3 several times. By doing these steps, you can find out the correct points of 'RSET stop position', 'LSET stop position', 'Swing module stop position'. direction, and GUN nozzle moves to

* Stopper nuts have to be fasten firmly. *

stopper setting for swing & spin module

- 6 -

YongNam Engineering < 2003, 12.18 >

PDF created with FinePrint pdfFactory Pro trial version www.pdffactory.com

Figure 7

Swing module stop position

stopper setting for swing & spin module

- 7 -

YongNam Engineering < 2003, 12.18 >

PDF created with FinePrint pdfFactory Pro trial version www.pdffactory.com

Você também pode gostar

- Gun Up Down Sensor 1V2PDocumento4 páginasGun Up Down Sensor 1V2Pjoecentrone100% (1)

- How To Input From USB Flash Drive With Your CAMS1V2PDocumento5 páginasHow To Input From USB Flash Drive With Your CAMS1V2PjoecentroneAinda não há avaliações

- Gun Nozzle Tip Maintenance and ReplacementDocumento2 páginasGun Nozzle Tip Maintenance and ReplacementjoecentroneAinda não há avaliações

- Doing Multiple Stone Sizes and Colors 1V2PDocumento4 páginasDoing Multiple Stone Sizes and Colors 1V2PjoecentroneAinda não há avaliações

- Gun Rod Replacement 1V2PDocumento5 páginasGun Rod Replacement 1V2PjoecentroneAinda não há avaliações

- CAMS Training AssuranceDocumento1 páginaCAMS Training Assurancejoecentrone100% (1)

- Gun Up Down Sensors 1V6PDocumento5 páginasGun Up Down Sensors 1V6PjoecentroneAinda não há avaliações

- Replacing The Double Acting Solenoid 1V2P and 1V6P MachinesDocumento2 páginasReplacing The Double Acting Solenoid 1V2P and 1V6P MachinesjoecentroneAinda não há avaliações

- Setter Gun Nozzle Tip ReplacementDocumento1 páginaSetter Gun Nozzle Tip ReplacementjoecentroneAinda não há avaliações

- Diagnosing The Causes of Stones Throwing Mini CamsDocumento11 páginasDiagnosing The Causes of Stones Throwing Mini CamsjoecentroneAinda não há avaliações

- Solenoid Replacement 1V2P (CAMC2E001-A)Documento3 páginasSolenoid Replacement 1V2P (CAMC2E001-A)joecentroneAinda não há avaliações

- New 1v6p Cams PartsDocumento25 páginasNew 1v6p Cams PartsjoecentroneAinda não há avaliações

- Cams 1v-2p Parts BookDocumento12 páginasCams 1v-2p Parts BookjoecentroneAinda não há avaliações

- Old 1v6p Cams PartsDocumento18 páginasOld 1v6p Cams PartsjoecentroneAinda não há avaliações

- Model LM410 Manual PDFDocumento31 páginasModel LM410 Manual PDFJahir GolbemAinda não há avaliações

- WinCNC - V1.12 - V8 Operating Manual PDFDocumento48 páginasWinCNC - V1.12 - V8 Operating Manual PDFMilko Migneco100% (1)

- Cams 1v-2p ManualDocumento48 páginasCams 1v-2p Manualjoecentrone100% (2)

- Technical Data Press MaintenanceDocumento6 páginasTechnical Data Press MaintenanceKaran VirbhadreAinda não há avaliações

- G Shock Manual GA-201Documento6 páginasG Shock Manual GA-201Steven TjiputraAinda não há avaliações

- Fanuc 6M Alarm CodesDocumento7 páginasFanuc 6M Alarm CodesKrassi GlogovskiAinda não há avaliações

- Fog Lamps Install (Mazda5)Documento9 páginasFog Lamps Install (Mazda5)Joshby BimmerAinda não há avaliações

- Ultimaker 2+ - Repair Manual - Heater CartridgeDocumento15 páginasUltimaker 2+ - Repair Manual - Heater Cartridgemiruna apostolAinda não há avaliações

- s6 Seed Manual UkDocumento40 páginass6 Seed Manual UkCorliiAinda não há avaliações

- Nomenclatures of Single Point Cutting Tool Using Tool Makers MicroscopeDocumento7 páginasNomenclatures of Single Point Cutting Tool Using Tool Makers Microscopeविशाल पुडासैनीAinda não há avaliações

- Eumig Projector P8 User Manual TextDocumento9 páginasEumig Projector P8 User Manual Textazeaze.1245Ainda não há avaliações

- Automatic BANDSAW: Instruction ManualDocumento29 páginasAutomatic BANDSAW: Instruction ManualArvian Sandhika PratamaAinda não há avaliações

- JIH 455 Part3Documento61 páginasJIH 455 Part3Michał JabłońskiAinda não há avaliações

- Ultimaker 2+ - Repair Manual - Model Cooling FansDocumento13 páginasUltimaker 2+ - Repair Manual - Model Cooling Fansmiruna apostolAinda não há avaliações

- Eba ManualDocumento46 páginasEba Manualddrak1964Ainda não há avaliações

- Ultimaker 2+ - Repair Manual - Hot End IsolatorDocumento11 páginasUltimaker 2+ - Repair Manual - Hot End Isolatormiruna apostolAinda não há avaliações

- Metal Matic P 200 ManualDocumento13 páginasMetal Matic P 200 ManualRon BoeserAinda não há avaliações

- VaraDocumento8 páginasVaraCesar Alfonso Saldivar MontoyaAinda não há avaliações

- SteelDocumento5 páginasSteelSarah PerezAinda não há avaliações

- DMY3dp-001 Automatic Leveling Debug Guide V2Documento5 páginasDMY3dp-001 Automatic Leveling Debug Guide V2Saed CattywampusAinda não há avaliações

- DiskWizard - Three - User Guide FAQ - INSTRUCTION MANUALDocumento8 páginasDiskWizard - Three - User Guide FAQ - INSTRUCTION MANUALundisclosed.undisclosedAinda não há avaliações

- Hybrid Racing 8th Gen CAI Install GuideDocumento19 páginasHybrid Racing 8th Gen CAI Install GuideHybrid Racing100% (2)

- Cellsecure E6 Product User ManualDocumento35 páginasCellsecure E6 Product User ManualCellSecure IndonesiaAinda não há avaliações

- Autodesk Fusion 360: CAMDocumento39 páginasAutodesk Fusion 360: CAMSapril ArikanoshikiAinda não há avaliações

- Redsail Cutting Plotter TroubleDocumento6 páginasRedsail Cutting Plotter TroublezaharimanAinda não há avaliações

- Uselessbox Manual v13 Gm3 Oct122011Documento16 páginasUselessbox Manual v13 Gm3 Oct122011pqr1100% (1)

- Whyte - 146-T-120-E-120 Supplementary Service Manual Edn1Documento16 páginasWhyte - 146-T-120-E-120 Supplementary Service Manual Edn1Jamie WatsonAinda não há avaliações

- JET Surface Grinder Operating Manual Parts List M-414519 JPSG-618M1Documento40 páginasJET Surface Grinder Operating Manual Parts List M-414519 JPSG-618M1Roberto PalaciosAinda não há avaliações

- Jih 20 24 英文說明書 標準機+護罩 (Auto)Documento28 páginasJih 20 24 英文說明書 標準機+護罩 (Auto)Michał JabłońskiAinda não há avaliações

- DTM122 Manual ServiceDocumento30 páginasDTM122 Manual ServicejopejiAinda não há avaliações

- Light Object DSP Controller Setup GuideDocumento20 páginasLight Object DSP Controller Setup Guideblondu0070% (1)

- Hegner Manual PDFDocumento19 páginasHegner Manual PDFOsairManassan0% (3)

- Shaping MachineDocumento10 páginasShaping MachinesifuszAinda não há avaliações

- Gorilla Mighty Ladder ManualDocumento6 páginasGorilla Mighty Ladder ManualFrank MatzkaAinda não há avaliações

- DC Circuit Breaker WiringDocumento7 páginasDC Circuit Breaker WiringboltgingerkoppyAinda não há avaliações

- Testing The AFM's Air Temperature SensorDocumento1 páginaTesting The AFM's Air Temperature SensorporkfaceAinda não há avaliações

- LP-500 Manual PDFDocumento10 páginasLP-500 Manual PDFRico GonzalezAinda não há avaliações

- 3.24 980MD EnglishDocumento348 páginas3.24 980MD EnglishAbraham Tellez Flores100% (1)

- Android App Tinycam Monitor Setup Manual: by Apexis IP Camera at Good PricesDocumento5 páginasAndroid App Tinycam Monitor Setup Manual: by Apexis IP Camera at Good PricesBobbylenAinda não há avaliações

- Remote Meter MT 50 ManualDocumento36 páginasRemote Meter MT 50 ManualNaiIanAinda não há avaliações

- 9.4 Process AdjustmentDocumento11 páginas9.4 Process AdjustmentHugo Luis Escalante100% (1)

- Rish em 3490 Ss Manual Rev-C 1phDocumento7 páginasRish em 3490 Ss Manual Rev-C 1phpitambervermaAinda não há avaliações

- Manual El Dyn1440g 2017Documento51 páginasManual El Dyn1440g 2017ppalomino171Ainda não há avaliações

- Cat EyeDocumento2 páginasCat EyejaklaudiuszAinda não há avaliações

- MaestroJack enDocumento11 páginasMaestroJack enAymen OmariAinda não há avaliações

- Binder Clips SetDocumento1 páginaBinder Clips SetjoecentroneAinda não há avaliações

- Reciprocator Compact Single and MultiheadDocumento14 páginasReciprocator Compact Single and MultiheadjoecentroneAinda não há avaliações

- Buckle SetDocumento1 páginaBuckle SetjoecentroneAinda não há avaliações

- Presser Foot Stopper Roller-C SeriesDocumento8 páginasPresser Foot Stopper Roller-C SeriesjoecentroneAinda não há avaliações

- Installation Directions For The Presser Foot (Compact)Documento6 páginasInstallation Directions For The Presser Foot (Compact)joecentroneAinda não há avaliações

- Picker and Picker BaseDocumento4 páginasPicker and Picker BasejoecentroneAinda não há avaliações

- Installation Directions For The Presser Foot (Compact)Documento6 páginasInstallation Directions For The Presser Foot (Compact)joecentroneAinda não há avaliações

- Installation Directions For The Rotary HookDocumento5 páginasInstallation Directions For The Rotary HookjoecentroneAinda não há avaliações

- Upper Thread Catcher-WiperDocumento3 páginasUpper Thread Catcher-WiperjoecentroneAinda não há avaliações

- Take Up Lever Gray.Documento6 páginasTake Up Lever Gray.joecentroneAinda não há avaliações

- Part Direction - Tension Adjusting Bolt.Documento2 páginasPart Direction - Tension Adjusting Bolt.joecentroneAinda não há avaliações

- Replacing The Double Acting Solenoid 1V2P and 1V6P MachinesDocumento2 páginasReplacing The Double Acting Solenoid 1V2P and 1V6P MachinesjoecentroneAinda não há avaliações

- Part Direction - Thread Take Up SpringDocumento4 páginasPart Direction - Thread Take Up SpringjoecentroneAinda não há avaliações

- CAMS Training AssuranceDocumento1 páginaCAMS Training Assurancejoecentrone100% (1)

- ProSpangle User Manual v2.4Documento60 páginasProSpangle User Manual v2.4joecentroneAinda não há avaliações

- Instalation Directions For The Round Frame HoldersDocumento3 páginasInstalation Directions For The Round Frame HoldersjoecentroneAinda não há avaliações

- Installation Directions For The Presser Foot (Compact)Documento5 páginasInstallation Directions For The Presser Foot (Compact)joecentroneAinda não há avaliações

- ProSpangle Customer Training Assurance FormDocumento1 páginaProSpangle Customer Training Assurance FormjoecentroneAinda não há avaliações

- DTG Training AssuranceDocumento1 páginaDTG Training AssurancejoecentroneAinda não há avaliações

- How To Replace The Shock Absorbers On An Old Style 1V6P MachineDocumento3 páginasHow To Replace The Shock Absorbers On An Old Style 1V6P MachinejoecentroneAinda não há avaliações

- Replacing The X Belt 1V6P MachineDocumento6 páginasReplacing The X Belt 1V6P MachinejoecentroneAinda não há avaliações

- Replacing The Y Belt 1V6P MachineDocumento3 páginasReplacing The Y Belt 1V6P MachinejoecentroneAinda não há avaliações

- Part Direction - Tension Adjusting Bolt.Documento2 páginasPart Direction - Tension Adjusting Bolt.joecentroneAinda não há avaliações

- Replacing The Centering Screw 1V2P and 1V6PDocumento1 páginaReplacing The Centering Screw 1V2P and 1V6PjoecentroneAinda não há avaliações

- Solenoid Replacement For Old Style 1V6PDocumento3 páginasSolenoid Replacement For Old Style 1V6PjoecentroneAinda não há avaliações

- Part Direction - Thread Take Up SpringDocumento4 páginasPart Direction - Thread Take Up SpringjoecentroneAinda não há avaliações

- Error 400Documento11 páginasError 400joecentrone100% (1)

- Solenoid Replacement 1V6P (CAMC2E001-A)Documento2 páginasSolenoid Replacement 1V6P (CAMC2E001-A)joecentroneAinda não há avaliações

- Gun Up Down Sensors 1V6PDocumento5 páginasGun Up Down Sensors 1V6PjoecentroneAinda não há avaliações

- Poster SIL PDFDocumento1 páginaPoster SIL PDFvgogulakrishnanAinda não há avaliações

- Dacell Dn-10w, Dn-15w, Dn-20w SpecDocumento1 páginaDacell Dn-10w, Dn-15w, Dn-20w SpecmegacobAinda não há avaliações

- Quotation For Blue Star Printek From Boway2010 (1) .09.04Documento1 páginaQuotation For Blue Star Printek From Boway2010 (1) .09.04Arvin Kumar GargAinda não há avaliações

- How To Restring An Acoustic Guitar Nicholas OngkowijayaDocumento9 páginasHow To Restring An Acoustic Guitar Nicholas Ongkowijayaplebeius31Ainda não há avaliações

- Blinx01's Ultimate DVD Subbing GuideDocumento12 páginasBlinx01's Ultimate DVD Subbing GuideloscanAinda não há avaliações

- 20 Advanced Processor DesignsDocumento28 páginas20 Advanced Processor DesignsHaileab YohannesAinda não há avaliações

- XDM-100 IOM SDH A00 4-5 enDocumento334 páginasXDM-100 IOM SDH A00 4-5 endilipgulatiAinda não há avaliações

- Photometric Design White PaperDocumento5 páginasPhotometric Design White PaperScott VokeyAinda não há avaliações

- 2016 HSC Engineering StudiesDocumento40 páginas2016 HSC Engineering StudiesR MathewAinda não há avaliações

- Bank Statement - Feb.2020Documento5 páginasBank Statement - Feb.2020TRIVEDI ANILAinda não há avaliações

- Mmro C 053 MD 0357 Interior PL DrawingsDocumento82 páginasMmro C 053 MD 0357 Interior PL DrawingsAnonymous 4Ts8UBFwzAinda não há avaliações

- Capitulo 9 - Flujo de DatosDocumento24 páginasCapitulo 9 - Flujo de DatosOrlando Espinoza ZevallosAinda não há avaliações

- Experiment No.7 Study of Disc Pelletizer: ObjectivesDocumento4 páginasExperiment No.7 Study of Disc Pelletizer: ObjectivesPrafulla Subhash SarodeAinda não há avaliações

- ITP For Pipeline (Sampel)Documento5 páginasITP For Pipeline (Sampel)Reza RkndAinda não há avaliações

- CM29, 03-16-17Documento3 páginasCM29, 03-16-17Louie PascuaAinda não há avaliações

- Lector: Aleksandar Karamfilov Skype: Sanders - Kar E-Mail: Aleksandar - Karamfilov@Pragmatic - BG Linkedin: 2013 - 2014Documento19 páginasLector: Aleksandar Karamfilov Skype: Sanders - Kar E-Mail: Aleksandar - Karamfilov@Pragmatic - BG Linkedin: 2013 - 2014Diana DikovaAinda não há avaliações

- Transition SignalsDocumento10 páginasTransition Signalshana nixmaAinda não há avaliações

- Abbbaileyinfi 90Documento17 páginasAbbbaileyinfi 90Vipper80Ainda não há avaliações

- Why Rife Was Right and Hoyland Was Wrong and What To Do About ItDocumento4 páginasWhy Rife Was Right and Hoyland Was Wrong and What To Do About ItHayley As Allegedly-Called Yendell100% (1)

- Roxtec CatalogDocumento41 páginasRoxtec Catalogvux004Ainda não há avaliações

- Engg Prospect1usDocumento20 páginasEngg Prospect1usArun KumarAinda não há avaliações

- Android VersionsDocumento7 páginasAndroid VersionsEdna Mae Salas GarciaAinda não há avaliações

- Omni III User's Manual Va.1.0-20140124Documento130 páginasOmni III User's Manual Va.1.0-20140124Reuel TacayAinda não há avaliações

- Report On Siddartha Bank LimitedDocumento24 páginasReport On Siddartha Bank LimitedSanim AmatyaAinda não há avaliações

- Basement Masonry Wall Design Based On TMS 402-16/13: Input Data & Design SummaryDocumento2 páginasBasement Masonry Wall Design Based On TMS 402-16/13: Input Data & Design SummaryRidho ZiskaAinda não há avaliações

- ICT Css NotesDocumento11 páginasICT Css NotesWinnie OoiAinda não há avaliações

- Weg CFW500 Enc PDFDocumento32 páginasWeg CFW500 Enc PDFFabio Pedroso de Morais100% (1)

- PROSIS Part Information: Date: Image Id: Catalogue: ModelDocumento2 páginasPROSIS Part Information: Date: Image Id: Catalogue: ModelAMIT SINGHAinda não há avaliações

- View/Update Profile Apply For STC: Upload Sponsorship STC Applied Download Certificate Change PasswordDocumento2 páginasView/Update Profile Apply For STC: Upload Sponsorship STC Applied Download Certificate Change PasswordlakshmilavanyaAinda não há avaliações

- A330 Tire Inspn PDFDocumento21 páginasA330 Tire Inspn PDFRithesh Ram NambiarAinda não há avaliações