Escolar Documentos

Profissional Documentos

Cultura Documentos

Borepile Statment

Enviado por

mmanueqDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Borepile Statment

Enviado por

mmanueqDireitos autorais:

Formatos disponíveis

Monday, April 7, 2008

Method Statement For Bored Piling Works

WORKS METHOD STATEMENT BORED PILING WORKS APPROVAL TABLE OF CONTENTS

1.0 INTRODUCTION 2.0 DESIGN CONSTRAINTS AND COORDINATION 3.0 CONTRACTING METHODS 4.0 PROCUREMENT METHODS 5.0 RESOURCE PROVISIONS 6.0 LOGISTICS PROVISIONS 7.0 MATERIAL MANAGEMENT SYSTEMS 8.0 CONSTRUCTION METHODS AND TECHNOLOGY 9.0 CONSTRUCTION PHASING AND WORKFLOW 10.0 TRAFFIC MANAGEMENT AND MONITORING 11.0 SAFETY PROGRAMME 12.0 QUALITY ASSURANCE AND CONTROL PROGRAMMES 13.0 INDUSTRIAL RELATIONS POLICIES 14.0 ENVIRONMENTAL MONITORING PROGRAMMES 15.0 APPENDICES

1.0 INTRODUCTION This Work Method Statement outlines the method of which the bored piling works are installed for the project.

2.0 DESIGN CONSTRAINTS AND COORDINATION Not Applicable

3.0 CONTRACTING METHODS The Conditions of Contract have been reviewed by PCSB and particularly those conditions in respect of Sub-contractors. The conditions are bespoke for this project and therefore be required to be reflected in any form of Sub-contract utilized on the project. Please refer to PHOS-CN-010 to PHOS-CN-030 for the Contract Procedures.

4.0 PROCUREMENT METHODS Since PCSB is liable for the performance of any Sub-contractor, it is vital that only companies with proven track records in the relevant activity will be engaged as Sub contractors. It is acknowledged that before any part of the works can be sublet, the approval of the Employers Representative is required. Please refer to PHOS-PR-010 to PHOS-PR-030 for the procurement procedures.

5.0 RESOURCE PROVISIONS 5.1 Manpower/Labour The number of manpower/labour to be used during the earthworks activities have been identified in the Manpower Histogram. 5.2 Plant Equipment Hydraulic bored piling plant shall be used. The piling plants consist of a telescopic kelly bar and the lower of the kelly bar is an adaptable to other drilling tools. 6.0 LOGISTICS PROVISIONS The logistic control shall be in accordance with the approved Site Logistic Plan.

7.0 MATERIAL MANAGEMENT SYSTEMS Please refers to PHOS-CP-040 for the Material Control Procedure.

8.0 CONSTRUCTION METHODS AND TECHNOLOGY 8.1 Piling On completion of the temporary platform, the piling rigs shall be moved in assembled and ready for work on the installation of the 800 mm and 1050 mm diameter bored piles. A test pile for vertical pile shall be carried out to verify the designed load carrying capacity of the piles, the installation of which shall be determined jointly with Employers Representative. 8.2 Bored Piles Bored piles are cast-in-situ piles formed by excavating a hole of the specified size (diameter), to the required depth and casting the excavated hole with concrete of specified strength after the reinforcement is lowered into the hole.

8.3 Positioning of Boring Plant The hydraulic pile points setting out shall be provided by a qualified Surveyor. The boring plant will be moved to the pile point intended for excavation. The kelly bar mounted with an auger is placed just above the pile point. The vertically of the kelly bar should be checked by means of a spirit level. Adjustment should be made so as to enable the kelly bar to be as vertical as possible. Then the position of the auger is checked against the pile point. Adjustment should be made so that the centre of the auger is nearest to the pile point. The auger is then lowered and boring operating commenced. Reasonable care should be taken so that the pile position and vertically are constructed within the specified tolerance i.e. 75mm and 1 in 150 respectively. 8.4 Boring Boring commerce after the positions of the boring plant is checked. Usually, an auger of the required size is used to excavate hole is collapsible; a temporary casing of the same size should be installed to prevent collapse. Excavation of the hole continued until the required depth. At the point of encountering the rock head level where soil drilling tools are unable to penetrate the strata any further, boring shall cease in order that the Employers Representative to verify the occurrence and confirm the rock head reduced level. Rock drilling tools shall be used for drilling into and through rock. After reaching the required depth, a cleaning bucket will be used to clean up the bottom of the borehole. A joint measurement of the depth should be made before lowering of reinforcement and concreting. 8.5 Reinforcement Reinforcement to bored piles will be fabricated in the reinforcement yard and transported to the borehole for placing. After fabrication by the bar benders, the helical links will be tack welded to the main reinforcement Laps are also to be welded sufficiently so that they are intact during transportation. 100 mm diameter round spacers will be welded to the reinforcement to provide the cover to the reinforcement against the soil during concreting. The reinforcement will be lowered to the completed bore hole, prior to concreting, by means of a service crane arid to be adjusted to the correct level. 8.6 Concreting Concreting conforming to the specification will be delivered to the site by Ready Mixed supplier. If bore hole are dry, the concrete shall be discharges through a short funnel at the top of the bored hole to prevent free falling concrete hitting the sides of the bore. If bored holes contain

either water or bentonite drilling mud the concrete shall be placed by the tremie method. (i) Dry Hole Mix This mix shall be designed to give works cube strength of 35 Mpa at 28days with a slump of 100 25mm. (ii) Tremie Mix This mix shall be designed to give minimum works cube strength of 35 Mpa at 28 days with a slump of 175 25mm. The method of placing shall be such as to ensure that the concrete in its final positions shall be dense and homogeneous.

The piles shall be concrete in one continuous operation immediately after the excavation has been completed and inspected where inspection is required by the Specification. If the continuity of placing the concrete is interrupted, no further concrete shall be placed without the prior approval of the Engineer. 8.7 Extraction Of Temporary Casing All temporary casings are to be extracted immediately after completion of concreting. A vibro-Hammer will be used to extract the casing. Reasonable care should be taken to ensure that the concrete level is above the cut-off level after extracting of casing point.

9.0 CONSTRUCTION PHASING AND WORKFLOW Please refer to Appendix 15.3 for the bored piling works phasing and workflow.

10.0 TRAFFIC MANAGEMENT AND MONITORING The Logistic Manager and the traffic management contractor shall be responsible for the management and control of the traffic in and out from the construction site.

11.0 SAFETY PROGRAMME Please refer to PHOS-HS-010 Health and Safety Plan.

12.0 QUALITY ASSURANCE AND CONTROL PROGRAMMES Please refer to Appendix 15.1 for the Inspection and Test Plan and Appendix 15.2 for the Piling Checklist.

13.0 INDUSTRIAL RELATIONS POLICIES Not Applicable

14.0 ENVIRONMENTAL MONITORING PROGRAMMES Please refer to PHOS-EMP-001 Environmental Management Plan 15.0 APPENDICES 15.1 Inspection and Test Plan Bored Piling 15.2 Inspection Form Bored Piling 15.3 Construction phases and workflow for bored piling works Project file to be check with current

Você também pode gostar

- Micropile Mechine PDFDocumento2 páginasMicropile Mechine PDFmmanueqAinda não há avaliações

- User Guideline RenewalDocumento10 páginasUser Guideline RenewalmmanueqAinda não há avaliações

- KamasutraDocumento149 páginasKamasutrakumanqatar67% (9)

- Pre-concreting inspection checklist for Tropicana Grande projectDocumento1 páginaPre-concreting inspection checklist for Tropicana Grande projectmmanueqAinda não há avaliações

- SoilDocumento32 páginasSoilmmanueqAinda não há avaliações

- Borepile FormDocumento7 páginasBorepile FormmmanueqAinda não há avaliações

- SlopeDocumento60 páginasSlopemmanueqAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Alexander Lee ResumeDocumento2 páginasAlexander Lee Resumeapi-352375940Ainda não há avaliações

- Kunci Jawaban Creative English 3BDocumento14 páginasKunci Jawaban Creative English 3BLedjab Fatima67% (3)

- A Dream Takes FlightDocumento3 páginasA Dream Takes FlightHafiq AmsyarAinda não há avaliações

- Gigahertz company background and store locationsDocumento1 páginaGigahertz company background and store locationsjay BearAinda não há avaliações

- JWCh06 PDFDocumento23 páginasJWCh06 PDF007featherAinda não há avaliações

- Examination: Subject CT5 - Contingencies Core TechnicalDocumento7 páginasExamination: Subject CT5 - Contingencies Core TechnicalMadonnaAinda não há avaliações

- Factory Hygiene ProcedureDocumento5 páginasFactory Hygiene ProcedureGsr MurthyAinda não há avaliações

- FZ16 9B 1KD2 (Patada) PDFDocumento62 páginasFZ16 9B 1KD2 (Patada) PDFPanthukalathil Ram100% (1)

- MT R 108 000 0 000000-0 DHHS B eDocumento68 páginasMT R 108 000 0 000000-0 DHHS B eRafal WojciechowskiAinda não há avaliações

- Road Safety GOs & CircularsDocumento39 páginasRoad Safety GOs & CircularsVizag Roads100% (1)

- ECED Lab ReportDocumento18 páginasECED Lab ReportAvni GuptaAinda não há avaliações

- Market Participants in Securities MarketDocumento11 páginasMarket Participants in Securities MarketSandra PhilipAinda não há avaliações

- Movie Review TemplateDocumento9 páginasMovie Review Templatehimanshu shuklaAinda não há avaliações

- Tutorial Manual Safi PDFDocumento53 páginasTutorial Manual Safi PDFrustamriyadiAinda não há avaliações

- Characteristics: Wheels Alloy Aluminium Magnesium Heat ConductionDocumento4 páginasCharacteristics: Wheels Alloy Aluminium Magnesium Heat ConductionJv CruzeAinda não há avaliações

- DS 20230629 SG3300UD-MV SG4400UD-MV Datasheet V16 ENDocumento2 páginasDS 20230629 SG3300UD-MV SG4400UD-MV Datasheet V16 ENDragana SkipinaAinda não há avaliações

- High Uric CidDocumento3 páginasHigh Uric Cidsarup007Ainda não há avaliações

- ASM Architecture ASM Disk Group AdministrationDocumento135 páginasASM Architecture ASM Disk Group AdministrationVamsi ChowdaryAinda não há avaliações

- Ethical Leadership Karen May P. UrlandaDocumento8 páginasEthical Leadership Karen May P. UrlandaKaren May UrlandaAinda não há avaliações

- Memento Mori: March/April 2020Documento109 páginasMemento Mori: March/April 2020ICCFA StaffAinda não há avaliações

- Broschuere Unternehmen Screen PDFDocumento16 páginasBroschuere Unternehmen Screen PDFAnonymous rAFSAGDAEJAinda não há avaliações

- PHASE 2 - Chapter 6 Object ModellingDocumento28 páginasPHASE 2 - Chapter 6 Object Modellingscm39Ainda não há avaliações

- cp2021 Inf03p02Documento242 páginascp2021 Inf03p02bahbaguruAinda não há avaliações

- Discount & Percentage Word Problems SolutionsDocumento4 páginasDiscount & Percentage Word Problems SolutionsrheAinda não há avaliações

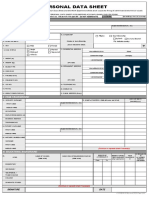

- PDS-1st PageDocumento1 páginaPDS-1st PageElmer LucreciaAinda não há avaliações

- Scenemaster3 ManualDocumento79 páginasScenemaster3 ManualSeba Gomez LAinda não há avaliações

- Hillingdon Health Visiting ServiceDocumento12 páginasHillingdon Health Visiting ServiceAnnikaAinda não há avaliações

- DSP Lab Record Convolution ExperimentsDocumento25 páginasDSP Lab Record Convolution ExperimentsVishwanand ThombareAinda não há avaliações

- HPE Alletra 6000-PSN1013540188USENDocumento4 páginasHPE Alletra 6000-PSN1013540188USENMauricio Pérez CortésAinda não há avaliações

- 16 BPI V FernandezDocumento1 página16 BPI V FernandezAngelica Joyce BelenAinda não há avaliações