Escolar Documentos

Profissional Documentos

Cultura Documentos

Desalting of Crude Oil in Refinery

Enviado por

Kmt_AeDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Desalting of Crude Oil in Refinery

Enviado por

Kmt_AeDireitos autorais:

Formatos disponíveis

e nggcyclo pe dia.

co m

http://www.enggcyclo pedia.co m/2012/06/desalting-crude-o il-refinery/

Desalting of crude oil in refinery

Purpose of crude oil desalt ing

Crude oil introduced to ref inery processing contains many undesirable impurities, such as sand, inorganic salts, drilling mud, polymer, corrosion byproduct, etc. T he salt content in the crude oil varies depending on source of the crude oil. When a mixture f rom many crude oil sources is processed in ref inery, the salt content can vary greatly. T he purpose of desalting is to remove these undesirable impurities, especially salts and water, f rom the crude oil prior to distillation. T he most concerns of the impurities in crude oil: T he Inorganic salts can be decomposed in the crude oil pre-heat exchangers and heaters. As a result, hydrogen chloride gas is f ormed which condenses to liquid hydrochloric acid at overhead system of distillation column, that may causes serious corrosion of equipment. To avoid corrosion due to salts in the crude oil, corrosion control can be used. But the byproduct f rom the corrosion control of oil f ield equipment consists of particulate iron sulf ide and oxide. Precipitation of these materials can cause plugging of heat exchanger trains, tower trays, heater tubes, etc. In addition, these materials can cause corrosion to any surf ace they are precipitated on. T he sand or silt can cause signif icant damage due to abrasion or erosion to pumps, pipelines, etc. T he calcium naphthanate compound in the crude unit residue stream, if not removed can result in the production of lower grade coke and deactivation of catalyst of FCC unit

Benef it s of Crude Oil Desalt ing

Increase crude throughput Less plugging, scaling, coking of heat exchanger and f urnace tubes Less corrosion in exchanger, f ractionators, pipelines, etc. Better corrosion control in CDU overhead Less erosion by solids in control valves, exchanger, f urnace, pumps Saving of oil f rom slops f rom waste oil

Desalt ing process

T he desalting process is completed in f ollowing steps: Dillution water injection and dispersion Emusif ication of diluted water in oil Distribution of the emulsion in the electrostatic f ield Electrostatic coalescence Water droplet settling Crude oil passes through the cold preheat train and is then pumped to the Desalters by crude charge pumps. T he recycled water f rom the desalters is injected in the crude oil containing sediments and produced salty water. T his f luid enters in the static mixer which is a crude/water disperser, maximizing the interf acial surf ace area f or optimal contact between both liquids. T he wash water shall be injected as near as possible emulsif ying device to avoid a f irst separation with crude oil. Wash water can come f rom various sources including relatively high salt sea water, stripping water, etc. T he static mixers are installed upstream the emulsif ying devices to improve the contact between the salt in the crude oil and the wash water injected in the line. T he oil/water mixture is homogenously emulsif ied in the emulsif ying device. T he emulsif ying device (as a valve) is used to emulsif y the dilution water injected upstream in the oil. T he emulsif ication is important f or contact between the salty production water contained in the oil and the wash water. T hen the emulsion enters the Desalters where it separates into two phases by electrostatic coalescence. T he electrostatic coalescence is induced by the polarization ef f ect resulting f rom an external electric source. Polarization of water droplets pulls them out f rom oil-water emulsion phase. Salt being dissolved in these water droplets, is also separated along the way. T he produced water is discharged to the water treatment system (ef f luent water). It can also be used as wash water f or mud washing process during operation. A desalting unit can be designed with single stage or two stages. In the ref ineries, the two stages desalting system is normally applied, that consists of 2 electrostatic Coalescers (Desalter).

Você também pode gostar

- Corrosion Control in Refining IndustryDocumento8 páginasCorrosion Control in Refining IndustryKmt_Ae0% (1)

- API 510 Inspector CourseDocumento6 páginasAPI 510 Inspector CourseKmt_AeAinda não há avaliações

- API 570 Piping InspectorDocumento6 páginasAPI 570 Piping InspectorBuddharaju KiranAinda não há avaliações

- Cold Backup and Recovery From Archivelog - OrACLE-HELPDocumento4 páginasCold Backup and Recovery From Archivelog - OrACLE-HELPadelarduarteAinda não há avaliações

- Cec 103. - Workshop Technology 1Documento128 páginasCec 103. - Workshop Technology 1VietHungCao92% (13)

- Dynamic model of manipulatorsDocumento20 páginasDynamic model of manipulatorsbalkyderAinda não há avaliações

- Desalting Crude OilDocumento13 páginasDesalting Crude Oilpardise4000Ainda não há avaliações

- Pressure ReliefDocumento207 páginasPressure ReliefAH100% (1)

- World Class ShutdownDocumento6 páginasWorld Class ShutdownKmt_AeAinda não há avaliações

- Crude Oil Desalting Process Removes SaltsDocumento2 páginasCrude Oil Desalting Process Removes Saltshassan zakwanAinda não há avaliações

- De SaltersDocumento15 páginasDe SaltersMuhammad Arslaan100% (2)

- Sixty Years of Research On Ship Rudders Effects of Design Choices On Rudder Performance PDFDocumento19 páginasSixty Years of Research On Ship Rudders Effects of Design Choices On Rudder Performance PDFSunil100% (1)

- ASME VIII Pressure Vessel MasterclassDocumento6 páginasASME VIII Pressure Vessel MasterclassKmt_AeAinda não há avaliações

- Desalting of Crude OilDocumento14 páginasDesalting of Crude OilHammad Hashmi100% (4)

- PRPP 2013 Crude Oil CompositionDocumento18 páginasPRPP 2013 Crude Oil CompositionEnvyousCustomsAinda não há avaliações

- DesalterDocumento2 páginasDesalterHimanshu SharmaAinda não há avaliações

- Crude Oil Refining - 2018Documento35 páginasCrude Oil Refining - 2018Matthew SantawAinda não há avaliações

- Crude DistillationDocumento35 páginasCrude DistillationraisAinda não há avaliações

- API 653 - Storage Tank Inspector Certification Examination Preparatory CourseDocumento5 páginasAPI 653 - Storage Tank Inspector Certification Examination Preparatory CourseKmt_AeAinda não há avaliações

- API 653 - Storage Tank Inspector Certification Examination Preparatory CourseDocumento5 páginasAPI 653 - Storage Tank Inspector Certification Examination Preparatory CourseKmt_AeAinda não há avaliações

- Rochor Station Pile Design CalculationsDocumento15 páginasRochor Station Pile Design CalculationsDifa LiuAinda não há avaliações

- Debottlenecking Refineries Through Comprehensive Feedstock PretreatmentDocumento20 páginasDebottlenecking Refineries Through Comprehensive Feedstock PretreatmentAnonymous msVFzaAinda não há avaliações

- Desalter PresentationDocumento17 páginasDesalter PresentationGeorge J Alukkal100% (3)

- A Quick Look at DesaltingDocumento12 páginasA Quick Look at Desaltingananth2012Ainda não há avaliações

- Crude Oil Distillation: Course: Chemical Technology (Organic) Module VIDocumento10 páginasCrude Oil Distillation: Course: Chemical Technology (Organic) Module VIapi-256504985Ainda não há avaliações

- Lecture 1 Chemistry of Crude-FinalDocumento39 páginasLecture 1 Chemistry of Crude-FinalNaval Koralkar Chemical Engg. Dept.Ainda não há avaliações

- Crude Oil Desalting ProcessDocumento24 páginasCrude Oil Desalting ProcessamirejazAinda não há avaliações

- Dewatering and Desalting Crude OilDocumento2 páginasDewatering and Desalting Crude OilRichard ObinnaAinda não há avaliações

- Acoustic and Flow Induced VibrationDocumento5 páginasAcoustic and Flow Induced VibrationKmt_AeAinda não há avaliações

- Desalting Part 2 May 2009Documento51 páginasDesalting Part 2 May 2009ermusatAinda não há avaliações

- Desalting Part 1 May 2009Documento104 páginasDesalting Part 1 May 2009ermusatAinda não há avaliações

- Desalter Operation OptimizationDocumento3 páginasDesalter Operation OptimizationRexx MexxAinda não há avaliações

- API 580 and 581risk Based InspectionDocumento5 páginasAPI 580 and 581risk Based InspectionKmt_Ae100% (1)

- Drager Fabius Gs Technical Service ManualDocumento350 páginasDrager Fabius Gs Technical Service ManualLeonardo Chirinos100% (3)

- Desalter OperationDocumento19 páginasDesalter OperationmohammedAinda não há avaliações

- Section 3: Desalters: Reduced Crude Unit Corrosion. at The High Temperatures Found in Crude UnitDocumento48 páginasSection 3: Desalters: Reduced Crude Unit Corrosion. at The High Temperatures Found in Crude Unitrvkumar61Ainda não há avaliações

- Crude Oil DesaltingDocumento5 páginasCrude Oil DesaltingAhmed Mohamed Khalil0% (1)

- ADU Desalting PDFDocumento100 páginasADU Desalting PDFHARSHA DEEPTHI GUNANA (N150434)Ainda não há avaliações

- Desalter PDFDocumento132 páginasDesalter PDFAlzahraa Alhaj AliAinda não há avaliações

- Facilities Assignment 1-2-2015Documento2 páginasFacilities Assignment 1-2-2015Xnort G. Xwest0% (1)

- A Working Guide To Process Equipments Upto 22062016Documento37 páginasA Working Guide To Process Equipments Upto 22062016DPKRSTGIAinda não há avaliações

- Crude Oil DesaltingDocumento25 páginasCrude Oil DesaltingNaumanAinda não há avaliações

- Birendra KumarDocumento50 páginasBirendra KumarAhmed YousryAinda não há avaliações

- Refinery Definitions - FAQDocumento7 páginasRefinery Definitions - FAQbalajiupesAinda não há avaliações

- CDU Training Powerpoint PDFDocumento144 páginasCDU Training Powerpoint PDFnefoussi100% (1)

- Managing Crude Slate ChangesDocumento23 páginasManaging Crude Slate Changeskishoreprithika100% (1)

- Nādatanumanisham Shankaram Namami Me Manasa ShirasaDocumento12 páginasNādatanumanisham Shankaram Namami Me Manasa Shirasaveena murthyAinda não há avaliações

- Desalter EfficiencyDocumento3 páginasDesalter Efficiencykronos39zeusAinda não há avaliações

- Eletrochemicaldesalter 191231094907Documento6 páginasEletrochemicaldesalter 191231094907ShakerMahmoodAinda não há avaliações

- DesaltDocumento8 páginasDesalt7awyAinda não há avaliações

- Pre-Treatment of Crude OilDocumento25 páginasPre-Treatment of Crude OilAbhisek AgarwalAinda não há avaliações

- Refining ProcessDocumento22 páginasRefining Processramadoss_alwar7307Ainda não há avaliações

- Use and Importance of Furnaces in Oil RefineriesDocumento6 páginasUse and Importance of Furnaces in Oil RefineriesMusa KaleemAinda não há avaliações

- Optimize Crude Oil Desalting with Membrane FiltrationDocumento14 páginasOptimize Crude Oil Desalting with Membrane FiltrationDucViking100% (1)

- Electrostatic Coalescer (Laminar Flow)Documento3 páginasElectrostatic Coalescer (Laminar Flow)Yusof SundangAinda não há avaliações

- Desalter Control PDFDocumento2 páginasDesalter Control PDFmotalebyAinda não há avaliações

- Treatment Processes in Petroleum RefiningDocumento6 páginasTreatment Processes in Petroleum RefiningtalhaAinda não há avaliações

- Packed Column Design GuideDocumento32 páginasPacked Column Design GuideAnaBelenMedranoBarrientosAinda não há avaliações

- FMDS0129Documento49 páginasFMDS0129hhAinda não há avaliações

- NG Engineering by Engr DR CIC AnyadiegwuDocumento31 páginasNG Engineering by Engr DR CIC Anyadiegwudavidchinedu008Ainda não há avaliações

- Crude Oil DesalterDocumento3 páginasCrude Oil DesalterStaherAinda não há avaliações

- What Is DistillationDocumento25 páginasWhat Is DistillationashirAinda não há avaliações

- API 579 Fitness For ServiceDocumento5 páginasAPI 579 Fitness For ServiceKmt_Ae100% (1)

- API 579 Fitness For ServiceDocumento5 páginasAPI 579 Fitness For ServiceKmt_Ae100% (1)

- Summer Training Presentation: ON Distillation Unit OF Mathura RefineryDocumento14 páginasSummer Training Presentation: ON Distillation Unit OF Mathura RefineryGovindPatelAinda não há avaliações

- Suez University Faculty of Petroleum andDocumento14 páginasSuez University Faculty of Petroleum andAsh BuzAinda não há avaliações

- Desalting Paper Musleh1Documento18 páginasDesalting Paper Musleh1Ahmed Mohamed KhalilAinda não há avaliações

- ETI Electrostatic BrochureDocumento6 páginasETI Electrostatic BrochureHector RodriguezAinda não há avaliações

- Crude Oil Desalting-Barcelona, Spain 2005Documento2 páginasCrude Oil Desalting-Barcelona, Spain 2005Mohamed Sayed AbdoAinda não há avaliações

- 1 DesalterDocumento20 páginas1 Desaltershyam_anupAinda não há avaliações

- التلوث النفطي واثره على البيئةDocumento16 páginasالتلوث النفطي واثره على البيئةMurtezAinda não há avaliações

- Baker Hughes DesalterDocumento5 páginasBaker Hughes DesalteralexHuy88Ainda não há avaliações

- Desalter Salt Balance - 1 PDFDocumento1 páginaDesalter Salt Balance - 1 PDFengr.shahid041Ainda não há avaliações

- Amine Treatment/ Regeneration UnitDocumento17 páginasAmine Treatment/ Regeneration UnitSyed Abdul RehmanAinda não há avaliações

- Types and Design of Tower TraysDocumento11 páginasTypes and Design of Tower TraysHeet PatelAinda não há avaliações

- SRU Start-Up Considerations - Shrikant Koli - Black & Veatch PDFDocumento26 páginasSRU Start-Up Considerations - Shrikant Koli - Black & Veatch PDFJunghietu DorinAinda não há avaliações

- Distillation Application in PetroleumDocumento46 páginasDistillation Application in Petroleumamirthalingam_b671Ainda não há avaliações

- API Oil Separator Removes 90% Oil from WastewaterDocumento2 páginasAPI Oil Separator Removes 90% Oil from Wastewaterbesant vargheesAinda não há avaliações

- 08 HydroprocessingDocumento52 páginas08 HydroprocessingThaiyalNayakiAinda não há avaliações

- FN Flare Tips DatasheetDocumento2 páginasFN Flare Tips DatasheetHector RodriguezAinda não há avaliações

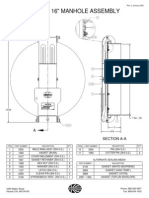

- Ld3310 16" Manhole Assembly: Rev. 0, January 2003Documento1 páginaLd3310 16" Manhole Assembly: Rev. 0, January 2003Kmt_AeAinda não há avaliações

- Catalog 2001Documento10 páginasCatalog 2001Kmt_AeAinda não há avaliações

- Pipe Stess Static and Dynamic AnalysisDocumento5 páginasPipe Stess Static and Dynamic AnalysisKmt_AeAinda não há avaliações

- Heat Exchanger Fouling Mitigation TechnologyDocumento5 páginasHeat Exchanger Fouling Mitigation TechnologyKmt_AeAinda não há avaliações

- Aerosol Adhesives LitDocumento18 páginasAerosol Adhesives LitKmt_AeAinda não há avaliações

- Corrosion Control in E&PDocumento7 páginasCorrosion Control in E&PKmt_AeAinda não há avaliações

- API 571 Damage Mechanism Affecting Fixed Refining EquipmentsDocumento4 páginasAPI 571 Damage Mechanism Affecting Fixed Refining EquipmentsKmt_AeAinda não há avaliações

- z4 Coupe Roadster DatasheetDocumento8 páginasz4 Coupe Roadster DatasheetStephenAinda não há avaliações

- Heat Exchanger Fouling Mitigation TechnologyDocumento5 páginasHeat Exchanger Fouling Mitigation TechnologyKmt_AeAinda não há avaliações

- z4 Coupe Roadster CatalogueDocumento19 páginasz4 Coupe Roadster CatalogueKmt_AeAinda não há avaliações

- z4 Coupe Roadster CatalogueDocumento19 páginasz4 Coupe Roadster CatalogueKmt_AeAinda não há avaliações

- Tema & HtriDocumento5 páginasTema & HtriKmt_AeAinda não há avaliações

- Aboveground Storage Tank Design Masterclass (M'Sia) - LynnDocumento5 páginasAboveground Storage Tank Design Masterclass (M'Sia) - LynnKmt_AeAinda não há avaliações

- FC Catalogue PDFDocumento36 páginasFC Catalogue PDFIndra FandyAinda não há avaliações

- Advanced Pressure Vessels and Other Pressure EquipmentsDocumento6 páginasAdvanced Pressure Vessels and Other Pressure EquipmentsKmt_AeAinda não há avaliações

- x5 DatasheetDocumento7 páginasx5 DatasheetKmt_AeAinda não há avaliações

- x3 DatasheetDocumento7 páginasx3 DatasheetKmt_AeAinda não há avaliações

- x5 CatalogueDocumento18 páginasx5 CatalogueKmt_AeAinda não há avaliações

- Propeller forces and typesDocumento2 páginasPropeller forces and typesEdison Gutierrez CapunoAinda não há avaliações

- PF-CIS-Fall 2022 LABDocumento4 páginasPF-CIS-Fall 2022 LABMuhammad FaisalAinda não há avaliações

- Recommended Procedures For Internet-Based Connections Between Rths and Nmcs (VPN, Ipsec)Documento38 páginasRecommended Procedures For Internet-Based Connections Between Rths and Nmcs (VPN, Ipsec)Crismaruc Maria-madalinaAinda não há avaliações

- Ain 2016 Pilot Report m600Documento4 páginasAin 2016 Pilot Report m600Antonio Cesar de Sa LeitaoAinda não há avaliações

- Superconductivity in RH S and PD Se: A Comparative StudyDocumento5 páginasSuperconductivity in RH S and PD Se: A Comparative StudyChithra ArulmozhiAinda não há avaliações

- Camshaft Test SheetDocumento4 páginasCamshaft Test SheetsughieantoAinda não há avaliações

- Sample Question Paper Provides Practice for Class 9 Science ExamDocumento5 páginasSample Question Paper Provides Practice for Class 9 Science ExamViswak BalajiAinda não há avaliações

- Uncompacted Void Content of Fine Aggregate (As Influenced by Particle Shape, Surface Texture, and Grading)Documento5 páginasUncompacted Void Content of Fine Aggregate (As Influenced by Particle Shape, Surface Texture, and Grading)ROBERTO MIRANDAAinda não há avaliações

- DS Ac0801 GBDocumento20 páginasDS Ac0801 GBHossein Jalali MoghaddamAinda não há avaliações

- Introduction To Curve FittingDocumento10 páginasIntroduction To Curve FittingscjofyWFawlroa2r06YFVabfbajAinda não há avaliações

- PEE3-M Lec 1Documento19 páginasPEE3-M Lec 1Ena Leanica DelgadoAinda não há avaliações

- Network Layer: Computer Networking: A Top Down ApproachDocumento83 páginasNetwork Layer: Computer Networking: A Top Down ApproachMuhammad Bin ShehzadAinda não há avaliações

- Leveling Limits For Stationary Reciprocating Compressors: Engineering ReferenceDocumento2 páginasLeveling Limits For Stationary Reciprocating Compressors: Engineering ReferencealtruismAinda não há avaliações

- EET422 EMC Intro-Banana Skins 2011-2012 MSWDocumento6 páginasEET422 EMC Intro-Banana Skins 2011-2012 MSWVeeradasan PerumalAinda não há avaliações

- ChamSys Touchscreen SupportDocumento2 páginasChamSys Touchscreen SupportKayla PadillaAinda não há avaliações

- UniversulDocumento56 páginasUniversulGabriel DutuAinda não há avaliações

- Manual de Operacion de Bomba BlackmerDocumento20 páginasManual de Operacion de Bomba BlackmerMorales EduardoAinda não há avaliações

- Unit 10Documento18 páginasUnit 10ChaithraMalluAinda não há avaliações

- Matlab programs to fit common curves using least squares methodDocumento5 páginasMatlab programs to fit common curves using least squares methodRavi ParkheAinda não há avaliações

- Numeri OrdinaliDocumento2 páginasNumeri OrdinaliClaudioAinda não há avaliações

- Digital Logic Design - Switch Logic & Basic GatesDocumento27 páginasDigital Logic Design - Switch Logic & Basic GatesTroon SoonAinda não há avaliações