Escolar Documentos

Profissional Documentos

Cultura Documentos

OptiML WLO PDF

Enviado por

paulmazziottaTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

OptiML WLO PDF

Enviado por

paulmazziottaDireitos autorais:

Formatos disponíveis

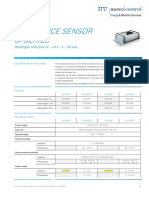

OptiML Wafer-Level Optics

Reduce Form Factors, Cut Costs and Boost Performance with Wafer-Level Optics

Analysts forecast that in 2013 approximately 525 million VGA camera modules will be manufactured for cell phone applications. Manufacturers of todays camera modules are constantly challenged to find more efficient and costeffective ways to meet market demands for smaller devices with greater capabilities. Tesseras OptiML Wafer-Level Optics technology solves these challenges by enabling manufacturers to significantly advance the integration of miniaturized cameras in cell phones, personal computers, security cameras and other portable devices. Based on advanced semiconductor manufacturing techniques, OptiML Wafer-Level Optics technology makes it possible to manufacture camera modules at the wafer level, dramatically reducing the size and total materials cost of camera modules while maintaining camera performance. This innovative approach enables manufacturers to simultaneously build thousands of lenses on a single wafer. The number of lens wafers required to build the optical module is based upon the optical requirements of the camera module. The lens wafers are aligned and bonded at the wafer level and diced into individual, integrated optical stacks that are mounted on top of a wafer-level packaged image sensor. The accuracy of the wafer stacking process optimizes the performance of integrated optics and packaged image sensors and eliminates the need for costly manual focusing. OptiML Wafer-Level Optics technology can be used for a wide range of camera resolutions, from VGA to multi-megapixel. Auto-focus and zoom capabilities can also be easily integrated with the OptiML solution.

Optical Communication Solutions

Benefits

Enables higher yield and significantly reduces costs Minimizes the camera form factor without sacrificing performance Reduces part count and cycle time Utilizes standard reflow processes Sustains high-temperature soldering Enables camera module assembly directly on the phone board Lowers overall cost Reduces components

Specifications

Pixel Size Cover Glass F/# Relative Illumination (y=1.32mm) Chief Ray Angle (Max.) Diagonal FOV Optical Distortion TV Distortion TTL Min MTF @ Nyquist/4 On-axis 0.8 Field 1.0 Field Min MTF @ Nyquist/2 On-axis 0.8 Field Die Size 30% 10% 2.3x2.3mm 65% 30% 15% 2.2m 400m 2.8 >50% 28 60 <1% <2% 2.25mm

OptiML Wafer-Level Optics technology is scalable, from a single-element CIF/VGA lens to a multi-element megapixel lens structure, where the lens wafers are precision aligned, bonded together and diced to form multi-element lens stacks. Tight alignment tolerances can be achieved to enable higher yield.

OptiML Single-Element VGA Lenses

The OptiML single-element VGA lens is an innovative camera solution for cell phones, PCs, gaming consoles, security cameras and web cams. The reflow-compatible two-surface lens is designed to work with 2.2m or 1.75m pixel size VGA image sensors. The lens offers several cost and performance advantages and its reflow compatibility enables camera modules to sustain high temperature soldering during the manufacturing process without damage. The lens, which incorporates an infra-red filter to reduce the number of components required by the camera module, can be customized.

Contact a Tessera sales representative for more information about OptiML Wafer-Level Optics.

3025 Orchard Parkway | San Jose, CA 95134 |

DS0026, 8-2010

+1.408.321.6000 |

+1.408.321.8257 | www.tessera.com

Tessera, the Tessera logo, OptiML, PILR, Tessera Compliant Chip, Z and BGA are trademarks or registered trademarks of Tessera Inc. or its afliated companies in the United States and other countries.

Você também pode gostar

- UmboCV IntroductionDocumento6 páginasUmboCV IntroductionAlexander LewisAinda não há avaliações

- AV4655DN A&E Spec 01 - 05 - 17 v8 - 0Documento5 páginasAV4655DN A&E Spec 01 - 05 - 17 v8 - 0Horacio Rasgado PosadaAinda não há avaliações

- Dualis Contour Brochure UKDocumento24 páginasDualis Contour Brochure UKifm electronicAinda não há avaliações

- 10reasons For IPDocumento7 páginas10reasons For IPpetrovickvAinda não há avaliações

- Surveillance System DesignDocumento24 páginasSurveillance System Designmostafa HusseinAinda não há avaliações

- Mantis Vision F5Documento4 páginasMantis Vision F5Sivananthaa MurtheeAinda não há avaliações

- Case StudyDocumento12 páginasCase Studygargashish11Ainda não há avaliações

- Basler's Camera Modules For Embedded Vision Systems: Operation - Integration - Image QualityDocumento2 páginasBasler's Camera Modules For Embedded Vision Systems: Operation - Integration - Image Qualitywassim becheikhAinda não há avaliações

- BC Netcams 45129 en 1111 LoDocumento8 páginasBC Netcams 45129 en 1111 LoteiniaAinda não há avaliações

- Control Design 06 10 Smart Cameras PDFDocumento3 páginasControl Design 06 10 Smart Cameras PDFElafanAinda não há avaliações

- Fisheye Network Camera: Technical SpecificationsDocumento2 páginasFisheye Network Camera: Technical SpecificationsnavijacobsAinda não há avaliações

- Camera Overview ReportDocumento5 páginasCamera Overview ReportRose GhamariAinda não há avaliações

- 2012 VisionSolutions Bro WebDocumento24 páginas2012 VisionSolutions Bro WebVarthini RajaAinda não há avaliações

- Simplify Industrial Vision ApplicationsDocumento20 páginasSimplify Industrial Vision ApplicationsJose Gabriel Aguirre AndradeAinda não há avaliações

- Top 10 Machine VisionDocumento6 páginasTop 10 Machine VisionkaicyemAinda não há avaliações

- Mayflex - WhitePaper - Six Steps To Successfully Designing and Planning An IP CCTV SystemDocumento6 páginasMayflex - WhitePaper - Six Steps To Successfully Designing and Planning An IP CCTV Systemme1111Ainda não há avaliações

- Teledyne Dalsa - Eguide2 FinalDocumento19 páginasTeledyne Dalsa - Eguide2 Finalkhaled azzamAinda não há avaliações

- Optera IMM Series KintronicsDocumento6 páginasOptera IMM Series KintronicsElvis Richard Barrera RomanAinda não há avaliações

- Axis Q1941-E Thermal Network Camera With 35mm Fixed Lens India - TanotisDocumento6 páginasAxis Q1941-E Thermal Network Camera With 35mm Fixed Lens India - TanotisRamalingam Rathinasabapathy EllappanAinda não há avaliações

- Mobotix M15Documento144 páginasMobotix M15cr0testAinda não há avaliações

- Rotakin White Paper-File064826Documento12 páginasRotakin White Paper-File064826karvizAinda não há avaliações

- 5digital CameraDocumento7 páginas5digital Camera516 AnushkaAinda não há avaliações

- Solutions Provider: Imagepilot Aero DRDocumento8 páginasSolutions Provider: Imagepilot Aero DRTaha ObedAinda não há avaliações

- 360 Degree Camera - ArticleDocumento3 páginas360 Degree Camera - ArticlePRATEEK BOHRAAinda não há avaliações

- 360 Degree Camera - ArticleDocumento3 páginas360 Degree Camera - ArticlePRATEEK BOHRAAinda não há avaliações

- Mic 550 IrDocumento16 páginasMic 550 IrYosi DarmawansyahAinda não há avaliações

- Flir Ats BrochureDocumento8 páginasFlir Ats BrochureShadab KhanAinda não há avaliações

- Cam Ip Serie 5600Documento6 páginasCam Ip Serie 5600Julio Cesar LarraAinda não há avaliações

- MX CS Cal Gary School en 120110Documento4 páginasMX CS Cal Gary School en 120110ravierahulAinda não há avaliações

- COGNEX In-Sight Product GuideDocumento16 páginasCOGNEX In-Sight Product GuidedollareAinda não há avaliações

- The Right Optics For Your Application: Compact and Highly EfficientDocumento4 páginasThe Right Optics For Your Application: Compact and Highly EfficientMikro IndiaAinda não há avaliações

- Network Bullet Camera: Technical SpecificationsDocumento2 páginasNetwork Bullet Camera: Technical SpecificationsnavijacobsAinda não há avaliações

- CBC Computar Ganz 2012Documento24 páginasCBC Computar Ganz 2012Selo ChristoAinda não há avaliações

- BLins1209 PDFDocumento100 páginasBLins1209 PDFJigisha VasaAinda não há avaliações

- MosesDocumento34 páginasMosesBUKENYA BEEE-2026Ainda não há avaliações

- Phase One Aerial Cameras 1.1-2cb4Documento9 páginasPhase One Aerial Cameras 1.1-2cb4jckworldAinda não há avaliações

- Machine Vision Generic 4Documento14 páginasMachine Vision Generic 4khaled azzamAinda não há avaliações

- Auto Farming Case StudyDocumento4 páginasAuto Farming Case StudyYADU MUNTHAAinda não há avaliações

- Video - FLEXIDOME IP Indoor 5000iDocumento7 páginasVideo - FLEXIDOME IP Indoor 5000iGlobal Titan PratamaAinda não há avaliações

- Datasheet CamcubeDocumento4 páginasDatasheet CamcubeAdrian BallAinda não há avaliações

- Siemen - VideoSurveillance en WebDocumento20 páginasSiemen - VideoSurveillance en Webscm balikpapanAinda não há avaliações

- Vision System PlatformDocumento4 páginasVision System PlatformtnchsgAinda não há avaliações

- Datenblatt Optisches Mikrometer 8400kDocumento4 páginasDatenblatt Optisches Mikrometer 8400kzvezdan bilanovicAinda não há avaliações

- Moticam 10 SpecDocumento16 páginasMoticam 10 SpecCarlos MatallanaAinda não há avaliações

- Vitsat-1 Payload Report.: DescriptionDocumento12 páginasVitsat-1 Payload Report.: DescriptionVarun ReddyAinda não há avaliações

- BVS SC Balluff Vision Solutions SmartCamera Flyer 944547 - EN - G19Documento4 páginasBVS SC Balluff Vision Solutions SmartCamera Flyer 944547 - EN - G19AngelAinda não há avaliações

- A Guide To MegaView Wall2Documento6 páginasA Guide To MegaView Wall2Diana Josephine MarthariaAinda não há avaliações

- CCTVDocumento9 páginasCCTVAruna ShanthaAinda não há avaliações

- Bticino CCTV GuideDocumento58 páginasBticino CCTV GuideH_REZAPANAAinda não há avaliações

- VB6555 - Videoteknika Bullet Camera - Data SheetDocumento3 páginasVB6555 - Videoteknika Bullet Camera - Data SheetNamburu SomanadhAinda não há avaliações

- Wireless Mesh For Video SurveillanceDocumento20 páginasWireless Mesh For Video SurveillanceRochmad HidayatAinda não há avaliações

- Fo Optral CatalogoDocumento20 páginasFo Optral CatalogoSergio SanchezAinda não há avaliações

- FLIR Optical SystemDocumento8 páginasFLIR Optical System조용준Ainda não há avaliações

- Machine Vision System Overview PDFDocumento32 páginasMachine Vision System Overview PDFkfathi55Ainda não há avaliações

- Acti Cam 6630Documento7 páginasActi Cam 6630e2uartAinda não há avaliações

- Visiorock, An Integrated Vision Technology For Advanced Control of Aggregate CircuitsDocumento11 páginasVisiorock, An Integrated Vision Technology For Advanced Control of Aggregate CircuitsOscar MonttelongoAinda não há avaliações

- Mobotix RobotikDocumento96 páginasMobotix RobotikZenulla FidaAinda não há avaliações

- Digitare eDocumento14 páginasDigitare eGuyIncognito314Ainda não há avaliações

- Introduction to N.C.M., a Non Contact Measurement ToolNo EverandIntroduction to N.C.M., a Non Contact Measurement ToolAinda não há avaliações

- SSW4 How Do You Do Maritime ArchaeologyDocumento2 páginasSSW4 How Do You Do Maritime ArchaeologypaulmazziottaAinda não há avaliações

- EMG Supplies and Electrodes - CloudEMGDocumento8 páginasEMG Supplies and Electrodes - CloudEMGpaulmazziottaAinda não há avaliações

- Neuromuscular Physical Therapy Course by NTC - Welcome To NASDocumento2 páginasNeuromuscular Physical Therapy Course by NTC - Welcome To NASpaulmazziottaAinda não há avaliações

- Intro To ElectronicsDocumento52 páginasIntro To ElectronicspaulmazziottaAinda não há avaliações

- Badlands Owners Manual PDFDocumento40 páginasBadlands Owners Manual PDFKaryllongAinda não há avaliações

- Persistence HuntingDocumento3 páginasPersistence HuntingpaulmazziottaAinda não há avaliações

- SSW4 Welcome To Week 4Documento1 páginaSSW4 Welcome To Week 4paulmazziottaAinda não há avaliações

- Titan Post AnchorsDocumento4 páginasTitan Post AnchorspaulmazziottaAinda não há avaliações

- New Developments For Paul Ekman Courses at EIA For 2012Documento3 páginasNew Developments For Paul Ekman Courses at EIA For 2012paulmazziottaAinda não há avaliações

- Miller Hostage NegDocumento22 páginasMiller Hostage NegpaulmazziottaAinda não há avaliações

- Kalamazoo Art of Pizza AdDocumento1 páginaKalamazoo Art of Pizza AdpaulmazziottaAinda não há avaliações

- Kalamazoo Beauty Beast AdDocumento1 páginaKalamazoo Beauty Beast AdpaulmazziottaAinda não há avaliações

- Bring Bluetooth Wireless Cellular Communications Capability To Your Existing Hostage/Crisis Response Throw Phone System!Documento1 páginaBring Bluetooth Wireless Cellular Communications Capability To Your Existing Hostage/Crisis Response Throw Phone System!paulmazziottaAinda não há avaliações

- Poseidon: Product Range 2014Documento36 páginasPoseidon: Product Range 2014paulmazziottaAinda não há avaliações

- Kzoo Industries Cat 2013 SMDocumento24 páginasKzoo Industries Cat 2013 SMpaulmazziottaAinda não há avaliações

- Proxxon Pd400cnc EnglishDocumento2 páginasProxxon Pd400cnc EnglishpaulmazziottaAinda não há avaliações

- Catalogo MailgraphDocumento10 páginasCatalogo MailgraphpaulmazziottaAinda não há avaliações

- Operational Studies: Convoy Security in Semi-Permissive War Zones (Iraq & Afghanistan)Documento14 páginasOperational Studies: Convoy Security in Semi-Permissive War Zones (Iraq & Afghanistan)paulmazziottaAinda não há avaliações

- More en A Ginge LearningDocumento12 páginasMore en A Ginge LearningpaulmazziottaAinda não há avaliações

- Leave No Marks - Enhanced Interrogation TechniquesDocumento57 páginasLeave No Marks - Enhanced Interrogation Techniquesda5id665100% (2)

- Iraq Afghan TerrorismDocumento19 páginasIraq Afghan TerrorismpaulmazziottaAinda não há avaliações

- Spiricom Tech ManualDocumento98 páginasSpiricom Tech Manualetendard100% (1)

- Alternative InterrogationDocumento97 páginasAlternative InterrogationpaulmazziottaAinda não há avaliações

- European Attacks PaperDocumento11 páginasEuropean Attacks PaperpaulmazziottaAinda não há avaliações

- HICCS05Documento8 páginasHICCS05paulmazziottaAinda não há avaliações

- Proxy Behaviours For ViolenceDocumento17 páginasProxy Behaviours For ViolencepaulmazziottaAinda não há avaliações

- Detainee 063 Interrogation LogDocumento83 páginasDetainee 063 Interrogation LogTerrance HeathAinda não há avaliações

- European Attacks PaperDocumento11 páginasEuropean Attacks PaperpaulmazziottaAinda não há avaliações

- Attacks On The British Royal FamilyDocumento9 páginasAttacks On The British Royal FamilypaulmazziottaAinda não há avaliações

- 20080158Documento9 páginas20080158paulmazziottaAinda não há avaliações

- Dot 57406 DS1Documento172 páginasDot 57406 DS1Carlos FernandezAinda não há avaliações

- Triboelectric Nanogenerators As New Energy Technology For Self-Powered Systems and As Active Mechanical and Chemical SensorsDocumento25 páginasTriboelectric Nanogenerators As New Energy Technology For Self-Powered Systems and As Active Mechanical and Chemical SensorsAnonymous AEicha08AF100% (1)

- Comparative Analysis of Public and Private Educational Institutions: A Case Study of District Vehari-PakistanDocumento10 páginasComparative Analysis of Public and Private Educational Institutions: A Case Study of District Vehari-PakistannithyaAinda não há avaliações

- Tutorial On SchedulingDocumento14 páginasTutorial On Schedulingrktiwary256034Ainda não há avaliações

- Av02 2516enDocumento13 páginasAv02 2516enpagol_23_smhAinda não há avaliações

- Sci Problem SolutionsDocumento10 páginasSci Problem SolutionsVS PUBLIC SCHOOL BangaloreAinda não há avaliações

- DDR3 and LPDDR3 Measurement and Analysis: 6 Series MSO Opt. 6-CMDDR3 and Opt. 6-DBDDR3 Application DatasheetDocumento14 páginasDDR3 and LPDDR3 Measurement and Analysis: 6 Series MSO Opt. 6-CMDDR3 and Opt. 6-DBDDR3 Application DatasheetNaveenAinda não há avaliações

- FireEdge FE400 PLC Interface Tech NoteDocumento2 páginasFireEdge FE400 PLC Interface Tech NoteTuyên VũAinda não há avaliações

- Statistics Fall2013 - Final Sample Test 01Documento7 páginasStatistics Fall2013 - Final Sample Test 01Thanh VyAinda não há avaliações

- Solar Radiation, Heat Balance and Temperature Chapter 8 - Class 11 Geography NCERT - Class Notes - Samagra Book Series Batch (Hinglish)Documento30 páginasSolar Radiation, Heat Balance and Temperature Chapter 8 - Class 11 Geography NCERT - Class Notes - Samagra Book Series Batch (Hinglish)avnish.k.verma.2014Ainda não há avaliações

- Slip TestDocumento2 páginasSlip TestkrctmechAinda não há avaliações

- 2 Parameter Circular (61-80)Documento6 páginas2 Parameter Circular (61-80)Papan SarkarAinda não há avaliações

- Irhlf77214 250V Radhard N MosfetDocumento9 páginasIrhlf77214 250V Radhard N MosfetarsebiscuitsAinda não há avaliações

- Quiz Sectiunea 7Documento5 páginasQuiz Sectiunea 7Bogdan BrkicAinda não há avaliações

- Sakshi: 7.coordinate GeometryDocumento3 páginasSakshi: 7.coordinate GeometryMartyn MartynAinda não há avaliações

- Chapter 4 - Production TheoryDocumento10 páginasChapter 4 - Production TheorypkashyAinda não há avaliações

- DB Irradiance Sensor Si-Series en 20171016Documento3 páginasDB Irradiance Sensor Si-Series en 20171016Solar ProjectsAinda não há avaliações

- Notes 240105 063345 933Documento6 páginasNotes 240105 063345 933Rachel MaharaniAinda não há avaliações

- Emulsions: - Part 1 Preparation Methods (Some) PropertiesDocumento52 páginasEmulsions: - Part 1 Preparation Methods (Some) PropertieschandramohanAinda não há avaliações

- CapacitanceDocumento71 páginasCapacitanceTharaj ThajAinda não há avaliações

- Activity Sheets Grade 8 Geometry CDocumento15 páginasActivity Sheets Grade 8 Geometry CLeopold Laset33% (3)

- In The: CavityDocumento9 páginasIn The: Cavitybrowar444Ainda não há avaliações

- Power System Analysis and Design 6Th Edition Glover Solutions Manual Full Chapter PDFDocumento58 páginasPower System Analysis and Design 6Th Edition Glover Solutions Manual Full Chapter PDFDanielleNelsonxfiq100% (10)

- Automatic Bug BountyDocumento80 páginasAutomatic Bug BountyAlbert Luzx100% (1)

- CHAPTER 31 Faraday S LawDocumento27 páginasCHAPTER 31 Faraday S LawSattishZeeAinda não há avaliações

- B.A GeographyDocumento8 páginasB.A GeographyShravani SalunkheAinda não há avaliações

- Ondemand: Key SpecificationsDocumento2 páginasOndemand: Key SpecificationsNUBIA DIAZAinda não há avaliações

- Percentiles (Measures of Positions)Documento4 páginasPercentiles (Measures of Positions)Leidel Claude TolentinoAinda não há avaliações

- Traffic Accidents - Balai Polis Trafik Jalan Tun H.SDocumento3 páginasTraffic Accidents - Balai Polis Trafik Jalan Tun H.SsimoniaAinda não há avaliações

- Brake Disc ProposalDocumento12 páginasBrake Disc ProposalNiko KoAinda não há avaliações