Escolar Documentos

Profissional Documentos

Cultura Documentos

Z-Ball Brochure PBM2011 PDF

Enviado por

Amir Hooshang Ghadymi MahaniTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Z-Ball Brochure PBM2011 PDF

Enviado por

Amir Hooshang Ghadymi MahaniDireitos autorais:

Formatos disponíveis

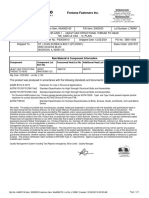

PBMs Z-Ball - Zero Dead

Leg Ball Valve Design

Features:

n Eliminates dead-legs in puried water systems and clean steam

systems

n Compact size - short branch geometry n 316L wrought low-ferrite stainless steel, other alloys available n Manual or pneumatic operation with optional device net n Mechanical and electro-polished surfaces n Fully drainable n Adjustable seats (Adjust-O-Seal) resulting in both upstream

and downstream seal. n Optional purge porting available

PBMs Z-Ball, zero dead leg ball valve replaces traditional diaphragm valve coupled with a ball valve design used as a sterile barrier for puried water system loops and clean gas utilities. For clean steam header sterilization, the PBM valve is opened to introduce clean steam into the process loop. In a closed position, to prevent condensate from accumulating, the purge port in the valve body removes condensate through trap to drain. This design offers PBM the ability to provide an ultra-sanitary process isolation valve which seals on both upstream and downstream seats resulting in signicant savings compared to traditional methods of using a combination diaphragm valve coupled with a ball valve.

NUMBER(S) IN PARENTHESES INDICATE VALVE CONFIGURATION PART NUMBER POSITION

PRODUCT (1-2) MATERIAL (3-4) HL 316L Stainless Steel Cast HF 316L Stainless Steel Forged C- Hastelloy C-276 P- AL6XN Y- Hastelloy C-22 C 1/2 inch D 3/4 inch E 1 inch 9 PBM Series 9, Igenix Sanitary Cast < 2% ferrite G 1-1/2 inch H 2 inch 8 PBM Series 8, Igenix Sanitary Forged < 1% ferrite VALVE SIZE (5) VALVE SERIES (6) MANIFOLD END CONNECTION BY VALVE END CONNECTION (7-8) FF FX FS Butt weld for Tube (Manifold) X Ext. Buttweld for Tube (Valve) Butt weld for Tube (Manifold) X Hygenic Clamp (Valve) Butt weld for Tube (Manifold) X Compression End (1" Max. Valve) Hygenic Clamp (Manifold) X Ext. Buttweld for Tube (Valve) Hygenic Clamp (Manifold) X Hygenic Clamp (Valve) SEAT \ FILLER O-RING (9) G TFM seats (ZG series) TFM seats, O-rings (ZS series)

ZG Sanitary True-bore 2-way (Gas Service) ZS Sanitary Clean Steam True-bore 2-way

XF PURGE PORTS (10) - no purge ports required A (1) 1/2" clamp on center, 90 degrees from stem B (1) 1/2" clamp on center, opposite stem C (1) 1/2" clamp upstream, 90 degrees from stem D (1) 1/2" clamp downstream opposite stem E (2) 1/2" clamps on center 90 deg from & opposite stem F (2) 1/2" clamps upstream 90 deg from & downstream opp stem G (1) 1/2" stub on center, 90 degrees from stem H (1) 1/2" stub on center, opposite stem I (1) 1/2" stub upstream, 90 degrees from stem J (1) 1/2" stub downstream opposite stem K (2) 1/2" stubs on center 90 deg from & opposite stem L (2) 1/2" stubs upstream 90 deg from & downstream opp stem

CONSULT FACTORY FOR SPECIFIC AUTOMATION OPTIONS CONSULT FACTORY FOR OTHER CONFIGURATIONS OR OPTIONS

BALL FLATS/PURGE HOLES (11) no ball flats or ball purge holes required

MANIFOLD SIZE BY VALVE SIZE OPTIONS (12) A Manifold and Valve Same Size B 3/4 inch Manifold X 1/2 inch Valve C 1 inch Manifold X 1/2 inch Valve D 1 inch Manifold X 3/4 inch Valve E 1-1/2 inch Manifold X 1/2 inch Valve F

1-1/2 inch Manifold X 3/4 inch Valve

OPERATOR (13-14) - - with lever handle operator 04 lever handle w/ locking device 18 4" extended locking lever handle 71 2" extended locking lever handle 20 80 PSIG Double Acting Actuator 21 80 PSIG Double Acting Actuator w/ Nema 4 Limit Switch 24 80 PSIG Double Acting Actuator w/ Nema 7 Limit Switch 27 60 PSIG Double Acting Actuator 28 60 PSIG Double Acting Actuator w/ Nema 4 Limit Switch 31 60 PSIG Double Acting Actuator w/ Nema 7 Limit Switch 34 80 PSIG Spring Return Actuator 35 80 PSIG Spring Return Actuator w/ Nema 4 Limit Switch 38 80 PSIG Spring Return Actuator w/ Nema 7 Limit Switch 41 60 PSIG Spring Return Actuator 42 60 PSIG Spring Return Actuator w/ Nema 4 Limit Switch 45 60 PSIG Spring Return Actuator w/ Nema 7 Limit Switch XX

A ball flats facing downstream in ball-closed position B ball flats facing upstream in ball-closed position C ball flats facing upstream in ball-open position D ball flats facing downstream in ball-open position E ball flats up & downstream in ball-open position F ball holes facing downstream in ball-closed position G ball holes facing upstream in ball-closed positon H ball holes facing upstream in ball open positon I

ball holes facing downstream in ball open position

Hygenic Clamp (Manifold) X XS Compression End (1" Max. Valve)

POLISH (15)

No additional polish (30 Ra ID Standard)

LOX CLEANING(16) L

LOX cleaning per PBM procedure

G 1-1/2 inch Manifold X 1 inch Valve H 2 inch Manifold X 1/2 inch Valve J L

2 inch Manifold X 3/4 inch Valve

A 20 RA ID polish D 15 RA ID polish E 10 RA ID polish F 20 RA ID polish after electropolish G 15 RA ID polish after electropolish H 10 RA ID polish after electropolish

K 2 inch Manifold X 1 inch Valve

2 inch Manifold X 1-1/2 inch Valve

J ball holes up & downsteam in ball in ball open position

M 3 inch Manifold X 1/2 inch Valve N 3 inch Manifold X 3/4 inch Valve P 3 inch Manifold X 1 inch Valve Q 3 inch Manifold X 1-1/2 inch Valve R 3 inch Manifold X 2 inch Valve

copyright PBM, Inc. LT-39 10/11

Você também pode gostar

- Carry Heat Away From Power Modules PCBsDocumento8 páginasCarry Heat Away From Power Modules PCBsAmir Hooshang Ghadymi MahaniAinda não há avaliações

- BISCO Material Selection Guide PDFDocumento9 páginasBISCO Material Selection Guide PDFAmir Hooshang Ghadymi MahaniAinda não há avaliações

- SolidWorks PlasticsDocumento60 páginasSolidWorks PlasticsAmir Hooshang Ghadymi MahaniAinda não há avaliações

- OTR Installation Instruction - EngDocumento14 páginasOTR Installation Instruction - EngAmir Hooshang Ghadymi MahaniAinda não há avaliações

- Jaguar E PACE Brochure 1X5401810000BCAEN01P Tcm131 413875Documento80 páginasJaguar E PACE Brochure 1X5401810000BCAEN01P Tcm131 413875Amir Hooshang Ghadymi MahaniAinda não há avaliações

- Critical Examination of A Common Assumption in System Availability ComputationsDocumento24 páginasCritical Examination of A Common Assumption in System Availability ComputationsAmir Hooshang Ghadymi MahaniAinda não há avaliações

- Iron Horse PM DCDocumento6 páginasIron Horse PM DCAmir Hooshang Ghadymi MahaniAinda não há avaliações

- Sapa STNDRD Extr Cat 8-10Documento138 páginasSapa STNDRD Extr Cat 8-10Amir Hooshang Ghadymi MahaniAinda não há avaliações

- Daewoo Nubira Manual InglesDocumento1.032 páginasDaewoo Nubira Manual Inglesivan_georgiev34793% (15)

- Daewoo Lanos Service Manual Full EngDocumento2.038 páginasDaewoo Lanos Service Manual Full EngRafael Hernandez90% (30)

- Designing Foundations With Piles For Vibrating Machinery: M. Gohnert, I. Luker and C. MorrisDocumento7 páginasDesigning Foundations With Piles For Vibrating Machinery: M. Gohnert, I. Luker and C. MorrisAmir Hooshang Ghadymi MahaniAinda não há avaliações

- GHGHFDocumento35 páginasGHGHFMetin BlackshotAinda não há avaliações

- Diamondback Brochure2013Documento10 páginasDiamondback Brochure2013Amir Hooshang Ghadymi MahaniAinda não há avaliações

- Fatigue and Fracture Mechanics Analysis of Threaded ConnectionsDocumento402 páginasFatigue and Fracture Mechanics Analysis of Threaded ConnectionsAmir Hooshang Ghadymi MahaniAinda não há avaliações

- PART4Documento92 páginasPART4Amir Hooshang Ghadymi MahaniAinda não há avaliações

- 550 0013-SureGripCatalog PDFDocumento21 páginas550 0013-SureGripCatalog PDFAmir Hooshang Ghadymi MahaniAinda não há avaliações

- 550.0029-Diode Pack Info PDFDocumento0 página550.0029-Diode Pack Info PDFAmir Hooshang Ghadymi MahaniAinda não há avaliações

- Concepts of Model Verification and Validation: LA-14167-MSDocumento41 páginasConcepts of Model Verification and Validation: LA-14167-MSAmir Hooshang Ghadymi MahaniAinda não há avaliações

- Nu-Calgon Application Bulletin: A Complete Family of Gas Leak Detectors From The Leaders in Gas Leak Detection TechnologyDocumento4 páginasNu-Calgon Application Bulletin: A Complete Family of Gas Leak Detectors From The Leaders in Gas Leak Detection TechnologyAmir Hooshang Ghadymi MahaniAinda não há avaliações

- 15 - Hot Stamped Bumper Design PDFDocumento16 páginas15 - Hot Stamped Bumper Design PDFAmir Hooshang Ghadymi MahaniAinda não há avaliações

- Apex150 16/18 AWG Female Terminal On 18AWG M1L123A Wire: ESR# AM-030127A Test Request #05-003Documento20 páginasApex150 16/18 AWG Female Terminal On 18AWG M1L123A Wire: ESR# AM-030127A Test Request #05-003Amir Hooshang Ghadymi MahaniAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Urban Design Studio Final NotesDocumento174 páginasUrban Design Studio Final NotesDaniella SobrevillaAinda não há avaliações

- Other Building Material McqsDocumento30 páginasOther Building Material McqsZeeshan AhmadAinda não há avaliações

- Design of Trail Bridges: Sag Calculation D TypeDocumento4 páginasDesign of Trail Bridges: Sag Calculation D TypePramod RijalAinda não há avaliações

- Estimation and CostingDocumento44 páginasEstimation and CostingSuhasini Pranay100% (2)

- SAGAG Haffir Dam Works Final BOQ1Documento14 páginasSAGAG Haffir Dam Works Final BOQ1Maulid100% (2)

- Lifts and Escalators 2.0Documento38 páginasLifts and Escalators 2.0Joseph KaranjaAinda não há avaliações

- Analysis of The Relationships Between Causes of Delay in Construction Projects in BangladeshDocumento10 páginasAnalysis of The Relationships Between Causes of Delay in Construction Projects in Bangladeshtm7Ainda não há avaliações

- 10 GS-08 - Air Conditioning - Ventilation SystemDocumento111 páginas10 GS-08 - Air Conditioning - Ventilation SystemshivvaramAinda não há avaliações

- Dex Stainless Steel Undermount Kitchen Sinks: Installation ManualDocumento18 páginasDex Stainless Steel Undermount Kitchen Sinks: Installation ManualRrsc RamsAinda não há avaliações

- Demolition of Existing StructuresDocumento7 páginasDemolition of Existing StructuresRayGaintAinda não há avaliações

- Cert Perno Hex A325 5.8 (11) X 1-1.2Documento4 páginasCert Perno Hex A325 5.8 (11) X 1-1.2Abril SalinasAinda não há avaliações

- Sesión 3 - Metso Outotec Filtros PFDocumento82 páginasSesión 3 - Metso Outotec Filtros PFEyner GonzalesAinda não há avaliações

- Technical Information Sheet: Harris 15 Low Fuming BronzeDocumento1 páginaTechnical Information Sheet: Harris 15 Low Fuming BronzeMarcelino Navarrete EvaristoAinda não há avaliações

- Chapter 1 Soils InvestigationDocumento45 páginasChapter 1 Soils InvestigationAdron LimAinda não há avaliações

- Central Park in Manhattan - New York City: (Atoz)Documento2 páginasCentral Park in Manhattan - New York City: (Atoz)Shariful IslamAinda não há avaliações

- Technical-Manual AGS-CW150CurtainWall Capral 2020 06 01Documento87 páginasTechnical-Manual AGS-CW150CurtainWall Capral 2020 06 01LEONARDOAinda não há avaliações

- About Sink AdvantagesDocumento2 páginasAbout Sink AdvantagesGrandMet EducationAinda não há avaliações

- 2022 Quoted Jobs NO. Company AmountDocumento6 páginas2022 Quoted Jobs NO. Company AmountRichard KankamAinda não há avaliações

- Mughal or Moorish Architecture: The Origins of Malaysian Mosques During Colonial PeriodsDocumento17 páginasMughal or Moorish Architecture: The Origins of Malaysian Mosques During Colonial PeriodsSyiqin HamediAinda não há avaliações

- Electrical Estimator ManualDocumento48 páginasElectrical Estimator Manualjanmczeal100% (3)

- Rosa Maria AguadoDocumento12 páginasRosa Maria Aguadoapi-507049229Ainda não há avaliações

- Tabelat Thermal Comfort IndexDocumento17 páginasTabelat Thermal Comfort IndexoutmatchAinda não há avaliações

- Pemp 5C 82Documento22 páginasPemp 5C 82Yogaraja MathialaganAinda não há avaliações

- Shell & Tube Heat Exchanger - PresentationDocumento17 páginasShell & Tube Heat Exchanger - Presentationtantri.hellyantiAinda não há avaliações

- IJSDR190491Documento21 páginasIJSDR190491RohimAinda não há avaliações

- Saju ResumeDocumento5 páginasSaju Resumeyoga jaiAinda não há avaliações

- Nathan My CM1Documento3 páginasNathan My CM1Deviga SharmaniAinda não há avaliações

- Technical Manual LU 8047 TMDocumento6 páginasTechnical Manual LU 8047 TMArif ZuhairiAinda não há avaliações

- Greeks (Made)Documento3 páginasGreeks (Made)Mohimarnob Paul MithunAinda não há avaliações

- PalDuct PIR Datasheet ME EN 04 15Documento2 páginasPalDuct PIR Datasheet ME EN 04 15Leonardo PimentelAinda não há avaliações