Escolar Documentos

Profissional Documentos

Cultura Documentos

Distillery Wastewater Treatment and Disposal: LT Col Mantha Nagaraj, DR Arvind Kumar

Enviado por

Amol DeshmukhTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Distillery Wastewater Treatment and Disposal: LT Col Mantha Nagaraj, DR Arvind Kumar

Enviado por

Amol DeshmukhDireitos autorais:

Formatos disponíveis

DISTILLERY WASTEWATER TREATMENT AND DISPOSAL

Lt Col Mantha Nagaraj*, Dr Arvind K !ar** *PhD Scholar, Environmental Engineering Civil Engineering Department, Indian Institute of Technology (IIT), oor!ee " #$% &&%' District (arid)ar, *ttaranchal, India' (e-mail: manthanagaraj@yahoo.com) **Professor + (ead of Civil Engineering Department Indian Institute of Technology (IIT) oor!ee " #$% &&%' District (arid)ar, *ttaranchal, India' (e-mail: prof_ak04@yahoo.com) A"STRACT

,' -ne of the most important environmental pro.lems faced .y the )orld is management of )astes' Industrial processes create a variety of )aste)ater pollutants/ )hich are difficult and costly to treat' 0aste)ater characteristics and levels of pollutants vary significantly from industry to industry' 1o)2a2days emphasis is laid on )aste minimi3ation and revenue generation through .yproduct recovery' Pollution prevention focuses on preventing the generation of )astes, )hile )aste minimi3ation refers to reducing the volume or to4icity of ha3ardous )astes .y )ater recycling and reuse, and process modifications and the .yproduct recovery as a fall out of manufacturing process creates ample scope for revenue generation there.y offsetting the costs su.stantially' #' Production of ethyl alcohol in distilleries .ased on cane sugar molasses constitutes a ma5or industry in 6sia and South 6merica' The )orld7s total production of alcohol from cane molasses is more than,8 million m89annum' The a:ueous distillery effluent stream !no)n as spent )ash is a dar! .ro)n highly organic effluent and is appro4imately ,#2,; times .y volume of the product alcohol' It is one of the most comple4, trou.lesome and strongest organic industrial effluents, having e4tremely high C-D and <-D values' <ecause of the high concentration of organic load, distillery spent )ash is a potential source of rene)a.le energy' The paper revie)s the status and appropriate treatment alternatives for disposal of the distillery )aste)ater'

KEYWORDS

Distillery Spent)ash, evenue =eneration, <yproduct ecovery'

INTROD#CTION

,' Production of ethyl alcohol in distilleries .ased on cane sugar molasses constitutes a ma5or industry in 6sia and South 6merica' The )orld7s total production of alcohol from cane molasses is more than,8 million m89annum' The a:ueous distillery effluent stream !no)n as spent )ash is a dar! .ro)n highly organic effluent and is appro4imately ,#2,; times .y volume of the product alcohol' It is one of the most comple4, trou.lesome and strongest organic industrial effluents, having e4tremely high C-D and <-D values' <ecause of the high concentration of organic load, distillery spent )ash is a potential source of rene)a.le energy' #' The #>; distilleries in India produce #'% .illion litres of alcohol and generating $? .illion litres of )aste)ater annually' The enormous distillery )aste)ater has potential to produce ,,?? million cu.ic meters of .iogas' The population e:uivalent of distillery )aste)ater .ased on <-D has .een reported to .e as high as &'# .illion )hich means that contri.ution of distillery )aste in India to organic pollution is

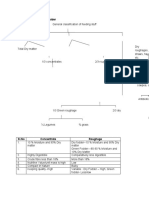

appro4imately seven times more than the entire Indian population' The )aste)ater from distilleries, ma5or portion of )hich is spent)ash, is nearly ,; times the total alcohol production' This massive :uantity, appro4imately $? .illion litres of effluent, if disposed untreated can cause considera.le stress on the )ater courses leading to )idespread damage to a:uatic life' MOLASSES WATER DILUTER YEAST PROPAGATION FERMENTER FERMENTER SLUDGE

ANALYSER

RECTIFIER

ALCOHOL

SPENT WASH

SPIRIT RECEIVER

EFFLUENT TREATMENT

ALCO$OL MAN#%ACT#RIN& PROCESS AND NAT#RE O% DISTILLERY WASTEWATER

8' In India .ul! of the alcohol is .eing produced from sugar cane molasses' @olasses is a thic! viscous .yproduct of the sugar industry )hich is acidic in nature, rich in salts, dar! .ro)n in colour and it also contains sugar )hich could not .e crystalli3ed' Aor manufacturing alcohol, the @olasses is diluted )ith )ater into a solution containing ,;2,& B of sugars' This solution is then inoculated )ith yeast strain and is allo)ed to ferment at room temperature' The fermented )ash is distilled in a series of distillation columns to o.tain alcohol of ade:uate9 re:uisite strength and :uality9specification' This alcohol is used for various purposes including pota.le and industrial' Aor manufacture of alcoholic .everages, the alcohol is, if re:uired, matured and .lended )ith malt alcohol (for manufacture of )his!y) and diluted to re:uisite strength to o.tain the desired type of li:uor9 Indian @ade Aoreign Ci:uor (I@AC)' This is .ottled in .ottles of various si3es for the convenience of consumers'

S'No'

,' #' 8' $' ;'

Para!(t(r

p( Total Suspended Solids Total Dissolved Solids <'-'D', #? ?C, ; days C'-'D'

Rang(

$'82;'8 ,#,???2,$,??? $;,???2%;,??? $?,???2;?,??? D?,???2,,??,???

"IO)ENER&Y POTENTIAL %ROM DISTILLERY E%%L#ENTS

$' In India there are #>; distilleries producing 8'#? .illion litres of alcohol generating $; .illion litres of )aste)ater annually' The enormous distillery )aste)ater has potential to produce ,#?? million cu.ic meters of .iogas' The post methanation )aste)ater if used carefully for irrigation of agricultural crops can produce more than D;??? tonne of .iomass annually' This .iogas normally contains &?B methane gas, )hich is a )ell2recogni3ed fuel gas )ith minimum air pollution potential' If this source of energy is tapped, it )ill fetch additional energy units )orth ; trillion2!ilo calories annually' <esides, the Post @ethanation Effluent (P@E) can provide #$;??? tones of potassium, ,#;?? tones of nitrogen and #,?? tones of phosphorus annually' Thus the manorial potential of effluent can .e measured .y the fact that one year7s effluent can meet the potassium re:uirement of ,';; million hectare land, nitrogen re:uirement of ?',8 million hectare land and phosphorus re:uirement of ?'?#; million hectare land if t)o crops are ta!en in a year' Annual Bio energy Potential of Distillery Effluent in Various States of India Stat( 6P 6ssam <ihar =oa =u5arat Earnata!a @P @aharashtra Pun5a. Tamilnadu *P 0< a5asthan Eerala Pondicherry Si!!im 1agaland F+E (P (aryana Total #nit* #$ , ,8 & ,? #D #, &; D ,> $8 & % D 8 , , % # ; #D; Ca+a,it.M Ltr/Yr0 ,#8 # DD ,; ,#D ,D% $&> &#; DD #,# &,% #$ ,$ #8 ,, % # #$ 8 $, #%?8 E11l (nt .M Ltr/Yr0 ,D;# #$ ,8#8 #,D ,>,> #%>> %?8& >8&% ,8,% 8,%D >#;# 8%, #?# 8$8 ,&; >D #$ 8&& 8> &,; $?,;?D "ioga* .M !20 ;? ?'% 8;'% & ;,'D %;'& ,>? #;8 8;'& D& #;? ,?', 8 >'8 $'; ;'; ?'% ,, , ,&'& ,?>&', Total N .ton(*0 ;&& % 8>% &; ;%& D$? #,,, #D,? 8>; >;8 #%%& ,,, &, ,?8 ;? #> % ,,? ,# ,D; ,#,,;$ Total Ka .ton(*0 ,,,,; ,$$ %>$? ,8?$ ,,;,, ,&%>$ $##,> ;&#,% %>?# ,>%, ;;;,# ####8 ,#,; #?&$ >>? ;D; ,$$ #,>& #8$ 8&>? #&8,?%? "io!a** .ton(*0 8%?$ $D #&$& $8& 8D8D ;;>D ,$?%# ,D%8$ #&8$ &8;& ,D;?$ %$# $?$ &D& 88? ,>& $D %8# %D ,#8? D,?,&

PRESENT STAT#S O% TREATMENT AND DISPOSAL

;' Spent )ash treatment is proposed .y three different routes currently vi3/ (a) Concentration follo)ed .y incineration, (.) 6naero.ic digestion )ith .iogas recovery follo)ed .y aero.ic polishing and (c) Direct )et o4idation of stillage .y air at high temperature )ith generation of steam follo)ed .y aero.ic polishing' 6ll of these processes are capital intensive' The incineration process involves an investment of the order of $??B of the distillery cost, )hereas the other t)o processes along )ith the secondary treatment re:uire an investment of #??28??B of the distillery cost' The unfavoura.le economics ma!e it difficult to implement these treatment processes on the plant scale' <ecause anaero.ic digestion and )et o4idation are less e4pensive, these alternatives are more attractive' (o)ever, there is a need for development of a suita.le process )ith lo)er investments and higher energy recovery' @any distilleries in India are allo)ing their effluent for application on land as direct irrigation )ater, spent )ash ca!e and spent )ash2 press mud compost' The advances manifesting the possi.ilities of energy conservation are also discerni.le in the case of distilleries' The methane gas generated in the digesters is used as a fuel to compensate the

energy needs of the industry' 6 general estimate suggests that the cost of an anaero.ic .iological digester is recovered )ithin #28 years of installation .ecause of su.stantial saving of coal and other fuels'

COST RECO3ERY MET$ODS %ROM T$E DISTILLERY E%%L#ENTS

&' The )aste)aters generated during the distillery and .re)ery operations contain high organic loads' It has a <-D from 8?,??? to &?,??? mg9,' So due to this high organic contents, the )aste)aters can .e su.5ected to treatment for the production of .iogas, composting, a:uaculture and potash recovery' .a0 "IO&AS' Aor the production of .iogas from distillery effluent, anaero.ic .iomethanation of the effluent is adopted, generally' (igh rate anaero.ic technologies are utili3ed for .iogas generation' Aluidised <ed eactors and *p flo) 6naero.ic Sludge <lan!et (*6S<) eactors are mostly utili3ed for the production of .iogas from the effluents' Some of the .iogas production processes .eing commercial,y esta.lished in India at present areG2 "IOT$ANE PROCESSG This process uses the *6S< reactor for the production of .iogas' This is a sta.le and automatic process )ith lo) operational costs' "IO"ED PROCESSG It is similar to <io thane process' It uses *A< reactors' It needs less installation area and its construction cost is lo)er compared to any other system' "IOPA4 PROCESSG In this process anaero.ic .acteria are used to treat the distillery effluents for the production of .iogas' *6S< process is utili3ed here' The separated sludge in this process ma!es e4cellent manure' The generated .iogas is used to produce steam for the distillation of alcohol and thus it replaces ;?2&?B of the total re:uired energy in the process of distillation' Aor a plant having $?2$;,??? !g C-D9day %;2D?B of C-D can .e reduced and nearly s' #;';? la!hs can .e saved annually for a distillery having 8?? )or!ing days in a year' The generated .iogas from *6S< reactor of <ioPa: process can .e collected and .e used as a fuel in gas9dual engine' Through suita.le coupling the engine can .e coupled )ith the 69C generator for generation of electricity from .iogas' Aor a $; !lpd distillery ,, EH of po)er is generated )hich is then utili3ed in the distillery thus cutting do)n the po)er consumption' S#L5ER6 S PROCESSG The technology of this type of .iogas plant is provided .y Sul3er <rothers Cimited, S)it3erland' It is specifically made for Indian conditions' 6 .iogas plant at the distillery of Padmashri Dr' Hitthalrao Hi!he Patil S'S'E' Ctd', Pravaranagar, 6hmednagar District, @aharashtra is .ased on Sul3erIs technology' The capacity of this distillery is &,??? lpd )hich generates >?? m8 of spent )ash per day' The .iogas production is in the range of ,&,;;? to #,,D%? m8 per day' The savings in the cost of fuel is in the range of s' 8,# la!hs to s' &;# la!hs per year' o ECONOMICS O% T$E "IO&AS PLANT O% S#L5ER7S DESI&N

These calculations are made for a distillery producing 8?,??? litres of alcohol per day' The effluent characteristics are for conventional .atch type fermentation process'

o E%%L#ENT C$ARACTERISTICS

Alo) m89day p( <-D mg9l C-D mg9l

<efore Treatment 6fter Treatment $;? $;? $'? to $'; %'? to %'D $;,??? to ;?,??? &,??? to D,??? D?,??? to ,???,??? #;,??? to 8;,???

PER%ORMANCE

eduction of <-D B eduction of C-D B <iogas Production 1m89day Specific <iogas Production 1m89!g of C-D degraded B of methane in .iogas

o ECONOMICS

D? to D; B &; to %? B ,#,8?? ?'$ to ?'; &? to &; B &??? Ecal9 1m8 $??? Ecal9Eg ,D'$; tonnes s 88,#,? pd s >>'&8 lacs s #8? lacs s #&,%8,%;? s #,??,??? s ,,;?,??? s ;,%&,??? s 8&,??,??? s >>'8& " 8& J s &8'&8 lacs J #8? 9 &8'&8 J 8 to $ years'

Calorific value of .iogas Calorific Halue of Coal Coal e:uivalent of <iogas per day Cost of Coal at s ,D?? per tonne 6nnual fuel savings Capital cost of plant Interest at ,; B on %; B of the capital cost** @aintenance costs Staff Salary Po)er $? E0 at s #92 per unit Total 6nnual Cost 1et Savings per year Total Pay .ac! period

.80 COMPOSTIN& In this process, press mud generated from sugar mill is utilised to produce compost .y mi4ing distillery effluent' <oth anaero.ic and aero.ic composting systems are practiced' In some plants composting )ith treated effluent treated through .io2methanation plant is also practiced' This system can achieve 3ero effluent if the press mud :uantity matches )ith the effluent generated'

ECONOMICS O% "IOEART$ COMPOSTIN&

Capacity of the Distillery 1um.er of )or!ing days in a year In the Distillery In the Composting Plant =enerated spent)ash Solid content in spent)ash Spent)ash to Press mud atio @an Po)er e:uired Culture e:uirement Press mud re:uirement Cost of Culture Cost of Press mud @an Po)er cost Capital Cost Cand e:uirement <io Earth Production 6nnual @aintenance Costs B Costs of Aunds

;? ECPD 8?? #%; 8;? ECPD (<iostil Plant) ,% B #'; EC G , @T ;? 8,'; @T9annum $8,??? @T9 annum s ,'%; la!hs per @T s ,# per @T s ;? per day s ,%; la!hs (e4cluding land) #; acres 8D,??? @T per year ,'; B of e:uipment costs #? B per annum

OPERATION COSTS

Cost of Culture

;;',8 la!hs

6verage Cost of Aunds Cost of Diesel Cost of Press mud Cost of Transportation of Press mud 6nnual @an Po)er Cost Depreciation (K ,? B) @aintenance 6nnual -perational Cost of Compost Plant Cost of -ne @etric Tonne of <ioearth

,%'; la!hs ,,'8# la!hs ;',& la!hs ?'?? &'DD la!hs ,;'?? la!hs #'#; la!hs ,,8'#$ la!hs J6nnual -perational cost of plant Compost Produced in @T J J ,,8#$??? 8D??? s #>D'?? per @T

NET COST/"ENE%IT %OR DI%%ERENT SELLIN& PRICES O% COMPOST

SP o1 "io(arth in R* ? ,??'?? #??'?? #>D'?? 8;?'?? $??'?? ;??'?? 1et annual cost9.enefit of Compost

N(t Co*t / "(n(1it in R* 2,,8#$???'?? 2%;#$???'?? 28%#$???'?? ?'?? ,>%&???'?? 8D%&???'?? %&%&???'?? J Sales value of 8D??? @T of compost less annual operating costs

COMP#TATION O% PAY "ACK PERIOD

,'

SP of <ioearth Initial cash outflo) 1et annual cash inflo) Pay <ac! Period SP of <ioearth Initial cash outflo) 1et annual cash inflo) Pay <ac! Period SP of <ioearth Initial cash outflo) 1et annual cash inflo) Pay <ac! Period

2 2 2 2 2 2 2 2 2 2 2 2

s #;?'?? s ,%;?????'?? s ,%8D???'?? ,?'?& Lears (,%;?????9,%8D???'??) s 8;?'?? s ,%;?????'?? s ;##&???'?? 8'8$ Lears (,%;?????'??9;##&???'??) s ;??'?? s ,%;?????'?? s ,?>#&???'?? ,'& Lears (,%;?????'??9,?>#&???'??)

#'

8'

.,0 POTAS$ RECO3ERY It is done .y incinerating the distillery spent )ash' In this process, the ra) distillery spent )ash is first neutrali3ed )ith lime and filtered' This is further concentrated to a.out &?B solids in multiple2effect forcer circulation evaporators' 1o) this thic! li:uor from the evaporator is .urnt in an incinerator and is converted into ash' The dry solids of

the spent )ash in the form of co!e in the incinerator has an average calorific value of # Ecal9!g, )hich is sufficient for supporting self2com.ustion of the thic! li:uor in the incinerator' The resulting ash is found to contain a.out 8%B of potash as potassium o4ide on an average' This ash is further leached )ith )ater to dissolve the potassium salts' Then it is neutrali3ed )ith sulphuric acid and is evaporated' The potassium salts are crystalli3ed in a crystal,i3er' The crystalli3ed mi4ed potassium salt contains %8';B of potassium sulphate (E #S-$) ,&';B potassium chloride (ECl) and ;B of sodium salts' It is estimated that a distillery discharging a.out 8?? m8 of spent )ash per day could recover 8 tonnes of Potassium as Potassium o4ide or a.out ;'8$ tonnes of Potassium sulphate and ,'# tonnes of Potassium chloride per day' This potassium is used as a fertili3er'

.d0

DISTILLERY WASTEWATER #TILISATION IN A&RIC#LT#RE <eing very rich in organic matters, the utilisation of distillery effluents in agricultural fields creates organic fertili3ation in the soil )hich raises the p( of the soil, increases availa.ility of certain nutrients and capa.ility to retain )ater and also improves the physical structure of soil' @ostly the distillery )aste)aters are used for pre2so)ing irrigation' The post2harvest fields are filled )ith distillery effluents' 6fter ,;2#? days, )hen the surface is almost dried, the fields are tilled and the crops are so)n and su.se:uent irrigation is given )ith fresh )ater' (o)ever, the effluent is diluted #28 times .efore application on crops' 6pparently, the irrigation )ith distillery )aste)ater seems to .e an attractive agricultural practice )hich not only augments crop yield .ut also provides a plausi.le solution for the land disposal of the effluents' -ne cu.ic metre of methanated effluent contains nearly ; !g of potassium, 8?? grams of nitrogen and #? grams of phosphorus' If one centimetre of post methanation effluent is applied on one hectare of agricultural land annually, it )ill yield nearly &?? !g of potassium, 8&? !g of calcium, ,?? !g of sulphates, #D !g of nitrogen and # !g of phosphates' The distillery effluent contains ?'& to #,'; percent potash as E - , ?', to ,'? percent phosphorus as P- and ?'?, to ,'; percent 1itrogen as 1#' The irrigational and manorial potential of distillery )aste)aters is given .elo)G i) ii) Total Holume availa.le in @illion m8 9annum 1utrients Contri.ution Potential (tonnes9annum) G G1 PE&'D% 2 2 2 &>8D? ,,88; #%$D?

ECONOMICAL ASPECTS 0hen the distillery effluents are used for i r ri ga t i on in fallo) lands, the micro.es present in it transform the lands into fertile ones, giving high yields of paddy and sugarcane' Aarmers could save nitrogenous fertilisers )orth s ,88; crores per annum if at least #?? distilleries of out country recycled their )astes to the agricultural fields' (o)ever, it is predicted that the utilisation of distillery effluent for irrigation of land )ould ma!e a v a i l 2 a.le nitrogen, phosphorous and potash valued at a.out s ;?? crores each year' The added advantage of this application )ould .e that these fertilisers )ould .e a va i l a. l e to s o i l in organic form' 6s the secondary and tertiary systems for the treatment of distillery effluent are highly energy intensive and according to the estimates of the *nion @inistry of Energy a total connected load of #?? @'0' )ould .e re:uired to energising these systems if #$& distilleries endeavour to reduce the <-D level of effluent to the e4tent possi.le' The generation of the desired energy )ould need an installed load of 8;? @'0' )hich )ould re:uire capital investment of the order of a.out s ,$?? crores' So it )ill .e an attractive practice to utilise the distillery effluents for ferti2irrigation of land after primary treatment, as land is availa.le in a.undance around the distilleries )hich are located in the sugarcane .elts'

RECOMMENDATIONS

%' evie)ing the magnitude of pollution potential of distillery )aste)aters and the e4periences gained over years on recovery of residues and treatment of )aste)ater the follo)ing recommendations are made G2

In2plant control measures for conservation and reuse of )ater and good house2!eeping for prevention of spillage and lea!ages should .e the prere:uisite' Aor recovery from the treatment of distillery spent)ash, depending on the availa.ility and cost of land in a particular area, simple treatment in anaero.ic lagoon to generate .iogas follo)ed .y treatment in aerated lagoon or o4idation ditch may .e considered' 0here the availa.ility and cost of land are the main constraints, activated sludge type of aeration treatment in a deep o4idation ditch )ould .e more economical than the conventional or e4tended aeration sludge process' Aor the treatment of distillery spent )ash, removal and9or recovery of yeast should .e prere:uisite to reduce the load and eliminate certain undue pro.lems in the )aste treatment9recovery plants' This recovered yeast can .e utilised as a good cattle feed' ecovery of spent grains and yeast and their utilisation as animal feed and feed supplement might .e encouraged not only for reducing the pollution load form the )aste)aters .ut also in providing for a reasona.le return on their capital investment of the industry' 0here the availa.ility of land is a severe constraint, evaporation and incineration of distillery spent )ash to recover potash )ould appear to .e the only choice' In spite of high capital investment re:uired for such type of plants, heat recovery )ould defray significantly the organisation and maintenance costs and contri.ute to)ards conservation of energy' In the countries li!e ours, )here indigenous sources of potash are scarce or not availa.le, recovery of potash from crude ash .y evaporation and incineration of spent )ash )ould appear to .e an economically attractive alternative' If heat recovery is simultaneously used, the pay .ac! period of the plant can .e su.stantially reduced' 6naero.ic digestion of spent )ash in a closed digester follo)ed .y its treatment under an activated sludge process, especially in an o4idation ditch to reduce costs, might .e adopted as the most cost2 effective system for the distilleries )hich are located a)ay from sugar factories' @oreover, the treated effluent can .e conveniently used for irrigation of cane fields or other crop lands, su.se:uently' <iogas generated from the distillery effluents, can .e effectively utili3ed in production plant .oilers thus saving a.out ;? to &? percent fuel9steam' The treated effluent having almost all the potash retained in it may .e utilised for irrigation purposes' The utilisation of the distillery effluent in agricultural fields )ill not only enrich these further )ith essential plant nutrients li!e nitrogen, phosphorous and potash .ut also compensate the e4penditure on fertili3ers for crop gro)th' This practice )ill result in revenue generation and further lead to offsetting the costs su.stantially' Similarly spent)ash utili3ation in .ioearth composting, )here ade:uate land is availa.le, .eing a simple process and not involving any heavy machinery is also one of the cost effective methods of disposal' @oreover it is feasi.le alternative for utili3ation of treated effluent/ as the same generates revenue thus offsetting the costs and further leading to reduction in pay .ac! period'

CONCL#SION

D' -ne of the most important environmental pro.lems faced .y the )orld is management of )astes' 1o)2a2days emphasis is laid on )aste minimi3ation and revenue generation through .yproduct recovery' Pollution prevention focuses on preventing the generation of )astes, )hile )aste minimi3ation refers to reducing the volume or to4icity of ha3ardous )astes .y )ater recycling and reuse, and process modifications and the .yproduct recovery as a fall out of manufacturing process creates ample scope for revenue generation there.y offsetting the costs su.stantially'

>' The cost of effluent treatment in distilleries is li!ely to .e compensated su.stantially .y availa.ility of methane gas' Effluent application )ill reduce the nutrient re:uirement through fertilisers' (o)ever, high salt load, mainly potassium and sulphur, into the soil system may hamper the sustained crop yields due to continued long2term application of effluents' Therefore the effect on crop productivity has to .e visualised on long2term and sustaina.le .asis' 6pplication of post methanation effluent suita.ly diluted according to crop re:uirements and soil conditions seems to .e via.le alternative' If all the distilleries present in India resort to .iomethanation, then appro4imately #'? million cu.ic metres of .iogas shall .e generated per day, )ith a calorific value of appro4imately ;??? Ecal9m' This is e:uivalent to saving of ##$? tonnes of coal per day, in turn avoiding C- of a.out 8,?? tonnes per day' ,?' The present study coupled )ith the corresponding techno mar!et survey has .een aimed at revie)ing the e4isting technological status of treatment and disposal of distillery spent)ash in our country and comparing )ith that of the contemporary international technologies, thus identifying the gaps in the technologies and suggesting an action plan for overcoming these' Some relative issues in the areas of :uality criteria )ith respect to gaps in technologies and financial implication in implementing the technological options, has .een highlighted in this study' It has to .e stressed that recovery from the distillery effluents is a .etter )ay to reduce the cost of )aste)ater treatment for decreasing its pollution level )hich is actually a very costly affair' So this is a matter great importance for the Indian distilleries and .re)eries' Harious recommendations are given for the esta.lishment of recovery plants in India' It has also .een elucidated during the study that several technological options that are availa.le in our country need to .e e4ploited to the ma4imum so that, this )ill help to control the pollution created .y the distillery )aste)aters and also ena.le to derive .y2products )hich are commercially .eneficial'

RE%ERENCES

CPC< Parivesh 1e)s Cetters' Hen!ites)aran, S'C' (,>D%) Effluents from Distilleries' Chemical 0ee!ly 6nnual 1um.er, &;' Cha!ra.arty, '1', M @anagement of Sugar and 6lcohol Industry 0astes 2 Pollution Control and Conservation of Energy and Aertili3erM, Proc' Symp' Disposal of Sugar and Distillery 0astes, *'P' 0ater Pollution Control <oard, Cuc!no) , 6pril ,>D?' Directory of Indian Distilleries, 6ll India DistillersI 6ssociation, 1e) Delhi' Cha!ra.arty, '1' and <has!aran, T' ', M ecovery of Potassium Salts form Spent 0ash of @olasses DistilleryM, For' Institute of Engineers (India), Hol' NCHI, 1o',?, Pt C(8' Falgaon!ar, 6'D', MPo)er =eneration Arom Distillery Spent 0ashM, Chemical Industry Digest, $th Ouarter I>8 (Decem.er)' a5u, H'S', His)anathan, C',MDistillery Effluent Treatment 0ith Energy ecoveryM, Chemical Industry Digest, $th Ouarter I>8 (Decem.er)' Cha!ra.arty, '1' and <has!aran, T' ', M*tilisation of Ci:uid 0astes from @olasses Distillery for ecovery of Potassium SaltsM, Special eport Series 1o' $>, Indian Council of @edical esearch, 1e) Delhi, ,>&$' MComposting of Distillery Effluent *sing <agasse CilloM, Tech @onitor, Fanuary2Ae.ruary, ,>>$' Cha!ra.arty, '1', Sen, <'P', Trivedi, 'C' and <has!aran, T' ', MPilot Plant for Treatment of Distillery 0astes at =olago!arnathMt eport of 6ll India Inst' (yg' and Pu.' (ealth, Calcutta, ,>&$' <asu, <'S'E', @eshram, S'E' and Hen!atesh, E'H', M6nalysis of Performance of I ED6 Sponsored <io2@ethanation Pro5ects and Their Impact 6ssessmentM, I ED6 1e)s, Hol' ;, 1o' $, ,>>$' MThe =uide for Treatment of Distillery EffluentsM, Indian Standards 8?8#2,>%&, I'S'I'

ao, P'E', MSugarcane @icro.es can ma!e Aallo)s AertileM Ainancial E4press, Tuesday, -cto.er ,;,,>>,'

Você também pode gostar

- Biogas Plant: Biogas Digester Design, Gas Production and PurificationNo EverandBiogas Plant: Biogas Digester Design, Gas Production and PurificationNota: 3 de 5 estrelas3/5 (1)

- Hazardous WastesDocumento11 páginasHazardous WastesKavi MaranAinda não há avaliações

- Waste Management in the Chemical and Petroleum IndustriesNo EverandWaste Management in the Chemical and Petroleum IndustriesAinda não há avaliações

- 08ijbas PDFDocumento7 páginas08ijbas PDFAndrew FaguhAinda não há avaliações

- Abstract Kuat Yogiristanto UnpadDocumento2 páginasAbstract Kuat Yogiristanto UnpadMenur Mandriati SudrajatAinda não há avaliações

- The Carbon Dioxide Revolution: Challenges and Perspectives for a Global SocietyNo EverandThe Carbon Dioxide Revolution: Challenges and Perspectives for a Global SocietyAinda não há avaliações

- Final Report of Thermal Power PlantDocumento92 páginasFinal Report of Thermal Power Plantfunkisanju1Ainda não há avaliações

- Environmental Scenario in Indian Mining Industry - an OverviewNo EverandEnvironmental Scenario in Indian Mining Industry - an OverviewAinda não há avaliações

- Activated CarbonDocumento34 páginasActivated CarbonSanjeeva YedavalliAinda não há avaliações

- Ethanol From Cellulose: A General ReviewDocumento5 páginasEthanol From Cellulose: A General ReviewRahmat YousdarAinda não há avaliações

- Ministry of Micro - Small & Medium EnterprisesDocumento4 páginasMinistry of Micro - Small & Medium EnterprisescbhattAinda não há avaliações

- Comparative Analysis of Scrap Car Recycling Management PoliciesDocumento7 páginasComparative Analysis of Scrap Car Recycling Management PoliciesPiranha TourniquetAinda não há avaliações

- Icoseat (2022)Documento8 páginasIcoseat (2022)Maulana ArifAinda não há avaliações

- Technology For Waste Management in DistilleryDocumento4 páginasTechnology For Waste Management in DistilleryIOSRjournalAinda não há avaliações

- Ascorbic AcidDocumento17 páginasAscorbic AcidNURUL SYAHIRAH BINTI ABDUL HALIMAinda não há avaliações

- Effluent Treatment of Pharmaceutical Industry by Using Subsurface Flow Wetland SystemDocumento6 páginasEffluent Treatment of Pharmaceutical Industry by Using Subsurface Flow Wetland SystemBrowniepieAinda não há avaliações

- Acetic AnhydrideDocumento117 páginasAcetic AnhydrideEr Bali Pandhare87% (15)

- A Novel Method For Recovery of Acidic Sludge of Used-Motor Oil Reprocessing Industries To Bitumen Using Bentonite and SBSDocumento6 páginasA Novel Method For Recovery of Acidic Sludge of Used-Motor Oil Reprocessing Industries To Bitumen Using Bentonite and SBSrahmanqasemAinda não há avaliações

- Recycle of Lead Acid Battery (Lead Refining Process) (CODE NO.3822)Documento7 páginasRecycle of Lead Acid Battery (Lead Refining Process) (CODE NO.3822)ayaanAinda não há avaliações

- Production of Activated CarbonDocumento11 páginasProduction of Activated CarbonShii Bautista100% (1)

- Difference Between Industrial Wastewater and Municipal WastewaterDocumento11 páginasDifference Between Industrial Wastewater and Municipal Wastewatertawsifamin19896% (25)

- Kim Dan DaleDocumento29 páginasKim Dan DaleRahmat YousdarAinda não há avaliações

- Treatment and Injection of Produced WaterDocumento8 páginasTreatment and Injection of Produced WaterLaura Alejandra Arevalo SanchezAinda não há avaliações

- Eia StudyDocumento10 páginasEia StudycandhareAinda não há avaliações

- EMAIL: Gopikrishna (Tkrcet) ANUSHA (Tkrcet) : E-Wastage: Challenges and OpportunitiesDocumento9 páginasEMAIL: Gopikrishna (Tkrcet) ANUSHA (Tkrcet) : E-Wastage: Challenges and Opportunitiesyuviraj0810Ainda não há avaliações

- Water Purification Production ManagmentDocumento31 páginasWater Purification Production ManagmentNitin SakpalAinda não há avaliações

- GIA Industries White Paper How To Profit From Biogas Market DevelopmentsDocumento69 páginasGIA Industries White Paper How To Profit From Biogas Market DevelopmentszetseatAinda não há avaliações

- Industrial Crops and ProductsDocumento9 páginasIndustrial Crops and ProductsVISHNU P SRIVASTAVAAinda não há avaliações

- Bio Gas From Distillery Spent WashDocumento40 páginasBio Gas From Distillery Spent WashGerlane Paiva100% (4)

- Transparency Market ResearchDocumento11 páginasTransparency Market Researchapi-259683748Ainda não há avaliações

- Project Report On Ethanol From Broken RiceDocumento7 páginasProject Report On Ethanol From Broken RiceEIRI Board of Consultants and PublishersAinda não há avaliações

- Brewery Effluent Treatment Plant (ETP) PerformanceDocumento7 páginasBrewery Effluent Treatment Plant (ETP) PerformanceMohan P100% (1)

- CT Course Project - Grpno.15Documento23 páginasCT Course Project - Grpno.15Sanika TalathiAinda não há avaliações

- Qiang Hu - Scripps Inst Talk-V1 For PublicDocumento27 páginasQiang Hu - Scripps Inst Talk-V1 For PublicJohny KurubilaAinda não há avaliações

- Production of Ethanol From Cassava and Yam Peels Using Acid HydrolysisDocumento12 páginasProduction of Ethanol From Cassava and Yam Peels Using Acid HydrolysisChinwuba Samuel EbukaAinda não há avaliações

- I Taconic AcidDocumento32 páginasI Taconic AcidAgustin CantilloAinda não há avaliações

- Brij 5Documento20 páginasBrij 5u10ch019Ainda não há avaliações

- A Feasibility Study Analysing Various Process Routes of The Production of Ethyl AcetateDocumento17 páginasA Feasibility Study Analysing Various Process Routes of The Production of Ethyl AcetateNastase DamianAinda não há avaliações

- Chapter 1Documento79 páginasChapter 1Siyadarakkalmajeed ArakkalmajeedAinda não há avaliações

- Comparison of Treatment Potential of Electrocoagulation of Distillery Effluent With and Without Activated Areca Catechu Nut CarbonDocumento7 páginasComparison of Treatment Potential of Electrocoagulation of Distillery Effluent With and Without Activated Areca Catechu Nut CarbonSteven ClarkAinda não há avaliações

- Economic Feasibility Studies 5.1 Sulphuric Acid Business in The Global MarketDocumento8 páginasEconomic Feasibility Studies 5.1 Sulphuric Acid Business in The Global MarketAkpan Anthonia AthanasiusAinda não há avaliações

- October 2012 Hi Tech MagazineDocumento37 páginasOctober 2012 Hi Tech MagazineeiribooksAinda não há avaliações

- HPCL Project ReportDocumento56 páginasHPCL Project ReportLln Vamsi Krishna100% (1)

- Building Services AssignmentDocumento42 páginasBuilding Services AssignmentSamantha Lim Ai PeiAinda não há avaliações

- Acetic AnhydrideDocumento117 páginasAcetic AnhydrideEsquivel EmilioAinda não há avaliações

- Production of Ethanol From BagasseDocumento64 páginasProduction of Ethanol From Bagasseajali1957Ainda não há avaliações

- JournalNX - Water TreatmentDocumento5 páginasJournalNX - Water TreatmentJournalNX - a Multidisciplinary Peer Reviewed JournalAinda não há avaliações

- Evaluating Water Quality in The Oil and Gas Exploitation Regions Within The Excravos River CatchmentDocumento12 páginasEvaluating Water Quality in The Oil and Gas Exploitation Regions Within The Excravos River CatchmentEditor IJTSRDAinda não há avaliações

- Green BuildingDocumento14 páginasGreen BuildingbabudevanandAinda não há avaliações

- Water Award Questionnaire 2012 - Wthin The FenceDocumento14 páginasWater Award Questionnaire 2012 - Wthin The FenceSendhilKumarAinda não há avaliações

- Integrated Enology - Utilization of Winery By-Products Into High Added Value ProductsDocumento12 páginasIntegrated Enology - Utilization of Winery By-Products Into High Added Value ProductsAngelito PerezAinda não há avaliações

- Sweet BrothersDocumento33 páginasSweet BrothersMozam MushtaqAinda não há avaliações

- Waste As A Renewable Energy Source Savu Laura IM2Documento4 páginasWaste As A Renewable Energy Source Savu Laura IM2Savu LauraAinda não há avaliações

- PreparationOfAlternativeFuels TextDocumento35 páginasPreparationOfAlternativeFuels TextMKPashaPashaAinda não há avaliações

- Design, Construction and Testing of A Biogas Reactor For Production of Biogas Using Cassava Peel and Cow Dung As BiomassDocumento11 páginasDesign, Construction and Testing of A Biogas Reactor For Production of Biogas Using Cassava Peel and Cow Dung As BiomassAZOJETEAinda não há avaliações

- Value-In-Use Model From Iron Ore Through Direct-Reduced Iron and Electric Arc FurnaceDocumento11 páginasValue-In-Use Model From Iron Ore Through Direct-Reduced Iron and Electric Arc FurnaceGladman MundingiAinda não há avaliações

- Water Management STDocumento10 páginasWater Management STMubarik AliAinda não há avaliações

- MS-AGS32F20 Muhammad AminDocumento6 páginasMS-AGS32F20 Muhammad AminUsama HassanAinda não há avaliações

- Basics of Gas and OilDocumento6 páginasBasics of Gas and OilPrathmesh GujaratiAinda não há avaliações

- Address Proof For BankDocumento1 páginaAddress Proof For BankAmol DeshmukhAinda não há avaliações

- Address Proof Letter For Employee: To Whomsoever It May ConcernDocumento27 páginasAddress Proof Letter For Employee: To Whomsoever It May ConcernAmol DeshmukhAinda não há avaliações

- Project: Gangapur Dam View N.A. Residential Plots Near Fravashi AcadamyDocumento2 páginasProject: Gangapur Dam View N.A. Residential Plots Near Fravashi AcadamyAmol DeshmukhAinda não há avaliações

- Annexre-13 Photographs of Faunas Found in Study AreaDocumento4 páginasAnnexre-13 Photographs of Faunas Found in Study AreaAmol DeshmukhAinda não há avaliações

- Research PublicationsDocumento22 páginasResearch PublicationsAmol DeshmukhAinda não há avaliações

- Add To Favorites: Pimpalgaon (Behed)Documento2 páginasAdd To Favorites: Pimpalgaon (Behed)Amol DeshmukhAinda não há avaliações

- To, Shree Saptashrung Nivasini Devi Trust At/Post-Saptashrung Gad, Tal - Kalwan Dist-Nashik Maharashtra-423501Documento1 páginaTo, Shree Saptashrung Nivasini Devi Trust At/Post-Saptashrung Gad, Tal - Kalwan Dist-Nashik Maharashtra-423501Amol DeshmukhAinda não há avaliações

- Surface AeratorDocumento1 páginaSurface AeratorAmol DeshmukhAinda não há avaliações

- Rajhans ETPDocumento39 páginasRajhans ETPAmol DeshmukhAinda não há avaliações

- STP Scheme New2Documento14 páginasSTP Scheme New2Amol DeshmukhAinda não há avaliações

- Small Dairy & Chilling Centre Effluent Treatment PlantDocumento8 páginasSmall Dairy & Chilling Centre Effluent Treatment PlantAmol DeshmukhAinda não há avaliações

- CSTR (Completely Stirred Tank Reactor) Technology:: AdvantagesDocumento1 páginaCSTR (Completely Stirred Tank Reactor) Technology:: AdvantagesAmol DeshmukhAinda não há avaliações

- Chapter - 3: Baseline EnvironmentDocumento9 páginasChapter - 3: Baseline EnvironmentAmol DeshmukhAinda não há avaliações

- Major Refurbishment of Dairy Effluent Treatment PlantDocumento6 páginasMajor Refurbishment of Dairy Effluent Treatment PlantAmol DeshmukhAinda não há avaliações

- Ex Sum DCRathore English PDFDocumento33 páginasEx Sum DCRathore English PDFAmol DeshmukhAinda não há avaliações

- Technicalreport Alcoholtechnology PDFDocumento0 páginaTechnicalreport Alcoholtechnology PDFAmol DeshmukhAinda não há avaliações

- Exe - Sumbabasaheb SSKL - Jan2013 PDFDocumento26 páginasExe - Sumbabasaheb SSKL - Jan2013 PDFAmol DeshmukhAinda não há avaliações

- LamellaDocumento5 páginasLamellaKhoa Nguyen DangAinda não há avaliações

- 35MoM SEAC PDFDocumento27 páginas35MoM SEAC PDFAmol DeshmukhAinda não há avaliações

- M/S. Empee Sugars and Chemicals Limited: Proposed Distillery PlantDocumento16 páginasM/S. Empee Sugars and Chemicals Limited: Proposed Distillery PlantAmol DeshmukhAinda não há avaliações

- Sai Solutions-IntroductionDocumento2 páginasSai Solutions-IntroductionAmol DeshmukhAinda não há avaliações

- Revised Distillery Tender PDFDocumento218 páginasRevised Distillery Tender PDFAmol DeshmukhAinda não há avaliações

- HVT Substation Equipment - Product List PDFDocumento2 páginasHVT Substation Equipment - Product List PDFAmol DeshmukhAinda não há avaliações

- Tea and Lentil Export Potential of NepalDocumento23 páginasTea and Lentil Export Potential of NepalChandan SapkotaAinda não há avaliações

- Induced+spawning 2Documento11 páginasInduced+spawning 2Balaji Prasanna KumarAinda não há avaliações

- Unit-13 Agrarian Classes and Categories PDFDocumento16 páginasUnit-13 Agrarian Classes and Categories PDFramsharannitAinda não há avaliações

- This Space-Savvy Integrated Farming Unit Lets You Grow Fish, Poultry & Vegetables OrganicallyDocumento9 páginasThis Space-Savvy Integrated Farming Unit Lets You Grow Fish, Poultry & Vegetables OrganicallyVicente SalanapAinda não há avaliações

- Pulp & PaperDocumento42 páginasPulp & PaperGautam SharmaAinda não há avaliações

- Farm Show Complex MapDocumento1 páginaFarm Show Complex MapCBS21 NEWSAinda não há avaliações

- Methods of AgricultureDocumento13 páginasMethods of AgricultureEsha HafeezAinda não há avaliações

- FijiTimes - Nov 23 2012pdfDocumento48 páginasFijiTimes - Nov 23 2012pdffijitimescanadaAinda não há avaliações

- Antimicrobial Effects of Spices and HerbsDocumento4 páginasAntimicrobial Effects of Spices and HerbsGrace Jeba Rani CAinda não há avaliações

- Animal Husbandry, Dairy, Fisheries DeptDocumento205 páginasAnimal Husbandry, Dairy, Fisheries DeptksbbsAinda não há avaliações

- Antagonistic Effects of Plant Growth Promoting Bacteria Against Bacterial Diseases of Black GramDocumento5 páginasAntagonistic Effects of Plant Growth Promoting Bacteria Against Bacterial Diseases of Black GramAcademic JournalAinda não há avaliações

- GR No 170220 - Digest - LBP Vs LubricaDocumento1 páginaGR No 170220 - Digest - LBP Vs LubricaRae Manar0% (1)

- Detection of Formalin in Fish Samples Collected From Dhaka City, BangladeshDocumento4 páginasDetection of Formalin in Fish Samples Collected From Dhaka City, BangladeshFaisal AhmedAinda não há avaliações

- PesticidesDocumento241 páginasPesticidesKiran ChokshiAinda não há avaliações

- Cultivation, Collection and PreparationDocumento9 páginasCultivation, Collection and PreparationHarish Kakrani100% (1)

- Farm ImplementsDocumento34 páginasFarm ImplementsJelyn Mae BoholAinda não há avaliações

- Traning Manual NREGA June 2009Documento230 páginasTraning Manual NREGA June 2009Rama KrishnaAinda não há avaliações

- Genbio2 ReviewerDocumento5 páginasGenbio2 ReviewerLeandre Jasmine ReyesAinda não há avaliações

- Compositional Analysis of Foods - Food Analysis - S.S. Nielsen PDFDocumento130 páginasCompositional Analysis of Foods - Food Analysis - S.S. Nielsen PDFMary Jane ColomaAinda não há avaliações

- Eriophyidae PDFDocumento2 páginasEriophyidae PDFJulieAinda não há avaliações

- 15 Eco TourismDocumento8 páginas15 Eco TourismManoj SatheAinda não há avaliações

- Capiz NGO/PO Network For Enterprise Development (CapizNED), Inc.Documento56 páginasCapiz NGO/PO Network For Enterprise Development (CapizNED), Inc.Capizned Capizned CapiznedAinda não há avaliações

- Tax System SriLankaDocumento44 páginasTax System SriLankamandarak7146Ainda não há avaliações

- Debt, Time and Extravagance Prathama BanerjeeDocumento20 páginasDebt, Time and Extravagance Prathama BanerjeeNupur MittalAinda não há avaliações

- Agricultural Injuries Risk Factors and Severity by Affected Body Part Among US Midwest FarmersDocumento11 páginasAgricultural Injuries Risk Factors and Severity by Affected Body Part Among US Midwest FarmersSabrina ajaAinda não há avaliações

- Classification Feed and FodderDocumento4 páginasClassification Feed and FoddermathiAinda não há avaliações

- Class 3 April AssignmentDocumento4 páginasClass 3 April AssignmenttttAinda não há avaliações

- UPSSSC Chackbandi Lekhpal (30 Sept 2019 Shift 2) EnglishDocumento29 páginasUPSSSC Chackbandi Lekhpal (30 Sept 2019 Shift 2) EnglishSHUBHAM PATELAinda não há avaliações

- Environmental ScienceDocumento5 páginasEnvironmental Sciencearijit_ghosh_18Ainda não há avaliações

- Ancient CivilizationDocumento9 páginasAncient CivilizationEl KatchAinda não há avaliações

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactNo EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactNota: 5 de 5 estrelas5/5 (5)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincNo EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincNota: 3.5 de 5 estrelas3.5/5 (137)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeNo EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeNota: 4 de 5 estrelas4/5 (1)

- AP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeNo EverandAP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeNota: 5 de 5 estrelas5/5 (1)

- It's Elemental: The Hidden Chemistry in EverythingNo EverandIt's Elemental: The Hidden Chemistry in EverythingNota: 4 de 5 estrelas4/5 (10)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeNo EverandChemistry for Breakfast: The Amazing Science of Everyday LifeNota: 4.5 de 5 estrelas4.5/5 (90)

- Taste: Surprising Stories and Science About Why Food Tastes GoodNo EverandTaste: Surprising Stories and Science About Why Food Tastes GoodNota: 3 de 5 estrelas3/5 (20)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeNo EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeNota: 5 de 5 estrelas5/5 (4)

- Guidelines for Defining Process Safety Competency RequirementsNo EverandGuidelines for Defining Process Safety Competency RequirementsNota: 3 de 5 estrelas3/5 (1)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeNo EverandChemistry for Breakfast: The Amazing Science of Everyday LifeNota: 4.5 de 5 estrelas4.5/5 (14)

- Formulating, Packaging, and Marketing of Natural Cosmetic ProductsNo EverandFormulating, Packaging, and Marketing of Natural Cosmetic ProductsAinda não há avaliações

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolNo EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolAinda não há avaliações

- Handbook of Formulating Dermal Applications: A Definitive Practical GuideNo EverandHandbook of Formulating Dermal Applications: A Definitive Practical GuideAinda não há avaliações

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsNo EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsNota: 5 de 5 estrelas5/5 (3)

- The Periodic Table: A Very Short IntroductionNo EverandThe Periodic Table: A Very Short IntroductionNota: 4.5 de 5 estrelas4.5/5 (3)

- Tribology: Friction and Wear of Engineering MaterialsNo EverandTribology: Friction and Wear of Engineering MaterialsNota: 5 de 5 estrelas5/5 (1)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsNo EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsNota: 4 de 5 estrelas4/5 (146)

- AP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeNo EverandAP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeAinda não há avaliações

- The Billion-Dollar Molecule: The Quest for the Perfect DrugNo EverandThe Billion-Dollar Molecule: The Quest for the Perfect DrugNota: 5 de 5 estrelas5/5 (2)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactNo EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactNota: 5 de 5 estrelas5/5 (1)

- Guidelines for Integrating Process Safety into Engineering ProjectsNo EverandGuidelines for Integrating Process Safety into Engineering ProjectsAinda não há avaliações