Escolar Documentos

Profissional Documentos

Cultura Documentos

LS-DYNA Tie-Break Contacts Modeling Guide

Enviado por

mr.aikidoTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

LS-DYNA Tie-Break Contacts Modeling Guide

Enviado por

mr.aikidoDireitos autorais:

Formatos disponíveis

Tie-Break Contacts in LS-DYNA

Suri Bala

Livermore Software

Outline

Introduction

Need for TIEBREAK

Basics of Contact Treatment

Understanding TIEBREAK

Failure and Damage in TIEBREAK contacts

Examples

Introduction

TIEBREAK allows the modeling of connections which transmits both

compressive and tensile forces with optional failure criteria

TIEBREAK contacts are penalty based while TIED contacts are

constraint based

Slave and Master Nodes can belong to other constraint type

definitions such as NODAL_RIGID_BODY, SPOTWELD, etc

There is no sliding allowed between the elements used in the

tiebreak definitions

Need for TIEBREAK Contacts

Traditional contacts transmit only compressive forces. Parts in

contact that experience tensile forces undergo separation with no

resistance

Connections such as Glued surfaces transmit both tensile and

compressive forces until a failure of the glue. Such connections

require the use of TIEBREAK contacts

Mating Parts

Glue

Solid Representation

Physical

Shell Representation

Basics of Contact Treatment

In any contact treatment, understanding steps involved, once the

slave and master information is provided, is important

Besides segment-to-segment contact, all other contact types at the

root level is always working with a node-segment pair in which the

node is just a point (with mass) and the segment is either a 3-noded

or 4-noded connectivity information referencing a shell element or

one of the faces of a solid element

The node is usually called as slave node and the segment is

usually called as master segment as shown below

slave node

master segment

Contact Point

Before a node-segment pair is assembled, the following must occur

The contact (projection) point of the node onto the master segment,

along the master segment normal, must lie within the area enclosed

by the 3 or 4 nodes of the segment.

LS-DYNA uses a small increase in the area of the segment in which

it scales the master segment area by an additional 2% in an attempt

to collect nodes that may lie near the edges

The contact point is calculated just once (at time zero) for all TIED

and TIEBREAK contacts while it is computed at every cycle for all

other contacts

Contact point is computed in the isoparametric coordinates of the

master segment

Contact Point

slave node

master segment

segment normal

contact point

projection distance, d

scaled segment

Projection Distance, d

The projection distance is simply the orthogonal distance of the slave

node from the master segment along the master segment normal

The projection distance is computed in a local coordinate system

embedded in the master segment

If the projection distance, d, is negative it is often called as penetration

If the project distance, d, is positive it is often termed as zero penetration or

positive offet

If the projection distance,d, is zero the slave is said to be ON the master segment

surface

negative (penetration)

positive (offset)

zero (on surface)

Master segment surface

Force Calculation

In standard contact treatment if the penetration depth is found to be

negative, the absolute value will indicate the depth of the penetration

A slave nodal force is then calculated proportional to the penetration

depth and a internally computed contact stiffness

o

c s

K f =

Contact force Contact stiffness Penetration

Force Distribution to the Master Segment Nodes

After the slave force evaluation, the same force needs to be

distributed to the master segment nodes

The magnitude of the force that each master segment node receives

is dependent on its relative location to the contact point

To achieve this, the iso-parametric shape functions are used

q

1

2

3

4

1 (1, 1)

2 (-1, 1)

3 (-1, -1) 4 (1, -1)

Master Nodal Force

Each master node gets a fraction of the slave force that is based on

contact point location

( )( ) q + + = 1 1

4

1

1

N

( )( ) q + = 1 1

4

1

2

N

( )( ) q = 1 1

4

1

3

N

( )( ) q + = 1 1

4

1

4

N

( )

s i

i

m

f N f * ,q =

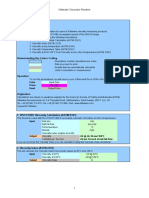

Quick Summary Of TIEBREAK

Allows the transmission of both tensile and compressive forces

resulting in a TIE. The separation of the slave node from the master

is resisted by a linear contact spring for both tensile and compressive

forces until failure after which the tensile coupling is removed

BREAK part of the contact allows the modeling of failure where the

spring decouples the tensile forces allowing independent motion of

the slave node under tension

Post failure in all TIEBREAK contacts allows the node to interact with

the segment as in traditional compression only contacts

Failure can be based on

Force (One-Way Only)

Stress (Two-Way Only)

What contacts model TIE-BREAK type connections ?

Non-Automatic

*CONTACT_TIEBREAK_NODES_TO_SURFACE

*CONTACT_TIEBREAK_SURFACE_TO_SURFACE

*CONTACT_TIEBREAK_NODES_ONLY

Automatic

*CONTACT_AUTOMATIC_SURFACE_TO_SURFACE_TIEBREAK

*CONTACT_AUTOMATIC_ONE_WAY_SURFACE_TO_SURFACE_TIEBREAK

There are some subtle differences between the two basic types but

for most purposes their functionality is identical in all the contact

types

Automatic and Non-Automatic Comparison

Yes No

Shell Thickness Offsets

Considered in Post

Failure Interaction

Depends on the parameter OPTION. When

OPTION = 1,3 all nodes that are initially in

contact and that come later into contact will

be tied. All other values will only treat nodes

that are initially in contact. Initially in

contact means that node has a projection

distance that is either zero, positive offset

less than 1% of master diagonal or negative

All slave nodes, irrespective of their

distance from the closest master segment

are tied to it at time zero. Care must be

taken to ensure that the slave node is

roughly 10% of master segment diagonal

for stable solutions

Scope of Slave Nodes

that are Tied

Yes. Many options available based on

OPTION parameter

No Damage Modeling

Yes Yes (Except TIEBREAK_NODES_ONLY)

Post Failure Interaction

Considered

Yes

No. Shell Normals Must Face Each Other.

However, THKOFF can be set to 1(default

0) to invoke this feature only for two-way

contacts

Automatic Shell Normal

Orientation

Yes Yes (Two-Way Type Only) Stress Based Failure

No Yes (One-Way Type Only) Force Based Failure

AUTOMATIC TIEBREAK NON-AUTOMATIC TIEBREAK Features

Why So Many ?

Simply because they have evolved over time

Old ones are retained to support backward compatibility

The basic functionality remains the same in all contacts

How does tying work ?

Tying is always defined between a node-segment pair

For every slave node, we first locate a unique master segment based

on the smallest projected normal distance

Once a unique master segment is found, a contact spring is internally

created between the slave node and the contact point on the master

segment

For any subsequent incremental change in the projected distance, a

force that is proportional to the incremental change in the projected

distance is applied to the slave node and is distributed to the master

nodes based on the contact point

The force applied is irrespective of the sign of the incremental

projected distance in TIEBREAK contacts while the force is applied

only if the projected distance is negative (indicating penetration) in

traditional (non-TIEBREAK) contacts

Understanding TIEBREAK

Following topics are extremely important to understand before using

TIEBREAK contacts

Criteria for Tying

Pre-Tying Behavior

Tied Behavior

Post-Break Behavior

Criteria for Tying

Unlike TIED based contacts, no tolerance is used to determine if a

slave node is to be tied or not

ALL slave nodes are tied to a master segment if a contact point on it

can be found

This can cause difficulties if the projected distance between a slave

node and a master segment is extremely large

In AUTOMATIC TIEBRAK, depending on the value of OPTION, all

nodes or nodes that are initially in contact are tied. Values 1,3 will tie

all nodes that are initially in contact and that may come in contact.

A good guideline is to ensure that the projected distance is within a

small fraction of the master segment thickness

Pre-Tying Behavior

Depending on the type of contact, how the surfaces (slave and

master) interact before tying conditions are established is important

to understand

All non-AUTOMATIC TIEBREAK contacts establish the contact

spring from the start of the simulation (Note: BIRTH is not supported

in TIEBREAK contacts as of version 971 R2. Future versions may

include them)

All AUTOMATIC TIEBREAK contacts allow option to determine what

nodes are tied initially. This is controlled using the parameter

OPTION

In both types of contact, it is extremely important to understand what

nodes are tied initially and later in the simulation

Pre-Tying in AUTOMATIC based TIEBREAK - OPTION

OPTION must be specified

Acceptable values for OPTION are the following

-3 -2 -1 1 2 3 4 5 6 7 8 9

POSITIVE NEGATIVE

Moments are

transferred

Moments are not

transferred

Pre-Tying in AUTOMATIC based TIEBREAK - OPTION

One-Way and Two-Way

1 2 3 4 5 6 7 8 9

ONE_WAY_SURFACE_TO_SURFACE_TIEBREAK

AUTOMATIC_SURFACE_TO_SURFACE_TIEBREAK

Pre-Tying in AUTOMATIC based TIEBREAK - OPTION

Scope of nodes that will be tied

1 2 3 4 5 6 7 8 9

Nodes in Contact and All Nodes That Come In Contact Will Be Tied

Only Nodes Initially (t=0) in Contact Will Be Tied

Pre-Tying in AUTOMATIC based TIEBREAK - OPTION

Elements types that can be tied

1 2 3 4 5 6 7 8 9

Solids Only

Failure

All TIEBREAK contacts allow the modeling of failure

One-Way failure is based on Forces Only

Two-Way failure is based on Stresses Only

Except for TIEBREAK_NODES_ONLY, post-failure, the interface

acts as traditional contacts which resist compressive forces only

Force Based Failure

This option applies for one-way contact types only

CONTACT_TIEBREAK_NODES_TO_SURFACE

CONTACT_TIEBREAK_NODES_ONLY

The failure force can be based on normal or shear or both

When the squared normalized radius of the circle is greater than 1,

then failure is assumed and the tensile spring is immediately

deactivated

Normal Force Ratio Squared, Rn

Shear Force Ratio Sqared, Rs

1

2 2

>

|

|

.

|

\

|

+

|

|

.

|

\

|

SFLF

f

NFLF

f

S n

failure

No failure

NFLF, Normal FaiLure Force

SFLF, Shear FaiLure Force

Stress Based Failure

This option applies for two-way contact types only

CONTACT_TIEBREAK_SURFACE_TO_SURFACE

CONTACT_AUTOMATIC_SURFACE_TO_SURFACE_TIEBRAK (OPTION=2,3,6)

CONTACT_AUTOMATIC_ONE_WAY_SURFACE_TO_SURFACE_TIEBREAK

(OPTION=2,3,6)

When the squared normalized radius of the circle is equal to or

greater than 1, then failure is assumed and the tensile spring is

deactivated

Normal Force Ratio Squared, Rn

Shear Force Ratio Squared, Rs

2 2

|

|

.

|

\

|

+

|

|

.

|

\

|

SFLS NFLS

S n

o o

failure

NFLS, Normal FaiLure Stress

SFLS, Shear FaiLure Stress

No failure

Damage Modeling

OPTION = 7

allows crack initiation using Dycos Discrete Crack Model as shown below

Yield

Time

Stress

Stress Profile

1

)) , 0 min( ) sin( 1 (

) 0 , max(

2

=

|

|

.

|

\

|

+

|

.

|

\

|

n

s n

PARAM SFLS NFLS o

o o

Some notes on Failure

Each node-segment pair is independently evaluated allowing the

modeling of peeling

The stress due to contact forces, contact stresses, is computed

based on the spring force and the area of the segment

The components are then decomposed into normal and shear

components in the local coordinate system of the master segment

Significant noise can be present in the forces so some percentage of

viscous damping should be used to avoid pre-mature failure

Damage Modeling

OPTION = 5 (shells and solids)

allows damage by scaling the stress components after the failure is met

Stress is limited by a perfectly plastic yield condition

In tension the yield condition is

In compression, the yield condition is

In addition, the stress is scaled by a factor that is user-defined as a function of the

crack width opening using SFLS which becomes the load curve id

1

3

2

2

s

+

NLFS

s n

o o

1

3

2

s

NLFS

s

o

Crack width opening

Damage

Scale Factor

Removal of tensile spring

1.0

Yield

Time

Stress

Stress Profile

Damage Profile

Damage Modeling

OPTION = 6 (Solids Only)

allows damage by scaling the stress components after the failure is met

Damage is initiated when the stress reaches the failure criteria specified by

After the damage is initiated, a the stress is linearly scaled down until the crack

depth reaches PARAM which is CCRIT

Crack width opening

Damage

Scale Factor

Removal of tensile spring at CCRIT

1.0

Yield

Time

Stress

Stress Profile

Damage Profile

2 2

|

|

.

|

\

|

+

|

|

.

|

\

|

SFLS NFLS

S n

o o

Damage Modeling

OPTION = 8 (Offset Shells Only)

To be used only with ONE_WAY AUTOMATIC TIEBREAK

Allows damage by scaling the stress components after the failure is met

Damage is initiated when the stress reaches the failure criteria specified by

After the damage is initiated, a the stress is linearly scaled down until the crack

depth reaches PARAM which is CCRIT

Crack width opening

Damage

Scale Factor

Yield

Time

Stress

Stress Profile

Damage Profile

2 2

|

|

.

|

\

|

+

|

|

.

|

\

|

SFLS NFLS

S n

o o

Removal of tensile spring at CCRIT

1.0

OPTION comparison

See

MAT_COHESIVE_MIX

ED_MOD

NONE

Yes. Linear

Yes. Using a

LoadCurve so

Nonlinearity is allowed.

NONE

NONE

NONE

NONE. Nodes will stick

permanantly

Damage Evolution

Causes SFLS to be a frictional

stress limit

4

See

MAT_COHESIVE_MIXED_MOD

Cohesive Model

9

8

Causes SFLS to become frictional

angle

7

Causes PARAM to become a

CCRIT which is the critical crack

opening for complete failure

6

Causes SFLS to become a

loadcurve id that defines stress

reduction scale factor vs crack

opening

5

NONE

3

When PARAM=1, shell offsets are

ignored after failure

2

NONE NONE. Nodes will stick permanently

1

Significance of PARAM Initiation of Failure Values

2 2

|

|

.

|

\

|

+

|

|

.

|

\

|

SFLS NFLS

S n

o o

2 2

|

|

.

|

\

|

+

|

|

.

|

\

|

SFLS NFLS

S n

o o

2 2

|

|

.

|

\

|

+

|

|

.

|

\

|

SFLS NFLS

S n

o o

1 >

nfls

N

o

1

3

2

2

s

+

NLFS

s n

o o

1

3

2

s

NLFS

s

o

T C

2 2

|

|

.

|

\

|

+

|

|

.

|

\

|

SFLS NFLS

S n

o o

1

)) , 0 min( ) sin( 1 (

) 0 , max(

2

=

|

|

.

|

\

|

+ |

.

|

\

|

n

s n

PARAM SFLS NFLS o

o o

Examples

Initially in contact

Peeling

Post-Failure Interaction

Linear-Damage Modeling

Nonlinear-Damage Modeling

Você também pode gostar

- Contact Modelling in LSDYNADocumento35 páginasContact Modelling in LSDYNASidharth PothalAinda não há avaliações

- Implicit Analysis Intro 02-2011Documento50 páginasImplicit Analysis Intro 02-2011Jhony GolombieskiAinda não há avaliações

- LS-DYNA contact modeling guideDocumento11 páginasLS-DYNA contact modeling guidePunith MlAinda não há avaliações

- 10 Session19and20 LS-DYNA3Documento71 páginas10 Session19and20 LS-DYNA3Chandra ClarkAinda não há avaliações

- Elements in Ls Dyna PDFDocumento70 páginasElements in Ls Dyna PDFEren KalayAinda não há avaliações

- Contatc Definition in LS-DynaDocumento34 páginasContatc Definition in LS-DynaMr PolashAinda não há avaliações

- Lab #1 Introduction To LSDyna: Simple CantileverDocumento22 páginasLab #1 Introduction To LSDyna: Simple CantileverMohammed A. MaherAinda não há avaliações

- Prevent Negative Volume in Foam ModelsDocumento9 páginasPrevent Negative Volume in Foam ModelsGustavo Yippeekayyay GusAinda não há avaliações

- Ls Dyna BeamsDocumento18 páginasLs Dyna BeamsAleem Ullah CheemaAinda não há avaliações

- Implicit NewerDocumento207 páginasImplicit NewerThutchai PhoAinda não há avaliações

- Element Type LS-DYNADocumento7 páginasElement Type LS-DYNAاحمد تسنیمAinda não há avaliações

- LS-DYNA Concrete MaterialDocumento3 páginasLS-DYNA Concrete MaterialaktcAinda não há avaliações

- LS DYNA Basic CardsDocumento30 páginasLS DYNA Basic Cardsmadblaster100% (1)

- Implicit Simulations With Ls Dyna Introduction andDocumento36 páginasImplicit Simulations With Ls Dyna Introduction andVirginija BortkevičienėAinda não há avaliações

- LS-PrePost Intro 073012Documento368 páginasLS-PrePost Intro 073012Saad Al HelyAinda não há avaliações

- Ls DynaDocumento33 páginasLs DynaRajAinda não há avaliações

- LS-DYNA Non-linear Implicit - Overview of Implicit Analysis in LS-DYNADocumento28 páginasLS-DYNA Non-linear Implicit - Overview of Implicit Analysis in LS-DYNAAref AbadelAinda não há avaliações

- LS-DYNA AnalysisDocumento29 páginasLS-DYNA AnalysisJohn TerryAinda não há avaliações

- LS-PrePost Intro 2014Documento143 páginasLS-PrePost Intro 2014mohsenAinda não há avaliações

- Scalar and Vectorized User Defined Material Routines in LS-DYNADocumento52 páginasScalar and Vectorized User Defined Material Routines in LS-DYNATirumala Rao100% (1)

- LS-PrePost Intro 2016Documento138 páginasLS-PrePost Intro 2016Ray FaiersAinda não há avaliações

- LS-DYNA Introductory Oct 30 Nov 1-2012Documento328 páginasLS-DYNA Introductory Oct 30 Nov 1-2012unmeshAinda não há avaliações

- Slam AnalysisDocumento2 páginasSlam AnalysisfrecciaaaAinda não há avaliações

- SPHTitle-NewSPHFeatureinLS-DYNADocumento6 páginasSPHTitle-NewSPHFeatureinLS-DYNABarath SundarAinda não há avaliações

- Predictive Engineering Ls-Dyna BrochureDocumento16 páginasPredictive Engineering Ls-Dyna BrochureSumit SehgalAinda não há avaliações

- Time Step Size - LS-DYNA Support PDFDocumento4 páginasTime Step Size - LS-DYNA Support PDFHemanth SarabuAinda não há avaliações

- LS-DYNA Crash Box Tutorial: Rectangular Impact AnalysisDocumento33 páginasLS-DYNA Crash Box Tutorial: Rectangular Impact AnalysisAgus Wijaya0% (1)

- Manual For LS-DYNA Wood Material Model 143Documento53 páginasManual For LS-DYNA Wood Material Model 143DraganAinda não há avaliações

- LS Dyna Tutorial FEADocumento16 páginasLS Dyna Tutorial FEAsravis69Ainda não há avaliações

- physics on screen - ANSA Model Checks for LS-DYNADocumento5 páginasphysics on screen - ANSA Model Checks for LS-DYNAShailesh SainiAinda não há avaliações

- LS-Dyna Impact Analysis TutorialDocumento29 páginasLS-Dyna Impact Analysis Tutorialsravis69100% (1)

- Dubois BookDocumento506 páginasDubois BookkasreedharAinda não há avaliações

- LS Dyna Ice Load TutorialDocumento23 páginasLS Dyna Ice Load TutorialEren KalayAinda não há avaliações

- 6 Composites Modelling LS-DYNA Galal-Mohamed-InDocumento71 páginas6 Composites Modelling LS-DYNA Galal-Mohamed-InSathi MechAinda não há avaliações

- Nastran in A NutshellDocumento32 páginasNastran in A NutshelljmorlierAinda não há avaliações

- LS Dyna TipsDocumento5 páginasLS Dyna TipsSaravanakumar_IAinda não há avaliações

- 3.0 Material Modeling Guidelines-V11-1 PDFDocumento33 páginas3.0 Material Modeling Guidelines-V11-1 PDFRahul MahajanAinda não há avaliações

- 08 Session15and16 LS-DYNA1Documento32 páginas08 Session15and16 LS-DYNA1vinod reddy mAinda não há avaliações

- Sec2 Solid Composites 021712Documento35 páginasSec2 Solid Composites 021712Jamshid PishdadiAinda não há avaliações

- LS Dyna NotesDocumento61 páginasLS Dyna NotesDeepak C. RajwarAinda não há avaliações

- Introduction To LS-DYNA MPP&RestartDocumento38 páginasIntroduction To LS-DYNA MPP&Restart임종윤Ainda não há avaliações

- A New Generation of Crash Barrier Models For LS-DYNADocumento22 páginasA New Generation of Crash Barrier Models For LS-DYNAKaran AroraAinda não há avaliações

- Finite element procedures for nonlinear analysis: Lagrangian and Eulerian formulations of 1D continuaDocumento40 páginasFinite element procedures for nonlinear analysis: Lagrangian and Eulerian formulations of 1D continuatechAinda não há avaliações

- 10 1 1 117Documento9 páginas10 1 1 117kasreedharAinda não há avaliações

- Explicit Contents LectureDocumento21 páginasExplicit Contents LectureBrian Egan100% (1)

- LSDYNA Basic NotesDocumento83 páginasLSDYNA Basic NotesJayDeep Khajure100% (1)

- Workbench LS DYNADocumento16 páginasWorkbench LS DYNARoss WaringAinda não há avaliações

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsNo EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsAinda não há avaliações

- Computational Methods in Nonlinear Structural and Solid Mechanics: Papers Presented at the Symposium on Computational Methods in Nonlinear Structural and Solid MechanicsNo EverandComputational Methods in Nonlinear Structural and Solid Mechanics: Papers Presented at the Symposium on Computational Methods in Nonlinear Structural and Solid MechanicsAhmed K. NoorAinda não há avaliações

- Viscoelastic Structures: Mechanics of Growth and AgingNo EverandViscoelastic Structures: Mechanics of Growth and AgingAinda não há avaliações

- Nonlinear Finite Element Analysis of Solids and StructuresNo EverandNonlinear Finite Element Analysis of Solids and StructuresAinda não há avaliações

- Tie BreakDocumento33 páginasTie Breaksuribala100% (3)

- Contact Modeling in LSDynaDocumento25 páginasContact Modeling in LSDynaHasan M RangwalaAinda não há avaliações

- ContactDocumento8 páginasContactN.g. NagarajAinda não há avaliações

- Contact Analysis SettingsDocumento30 páginasContact Analysis Settingsbabak4537Ainda não há avaliações

- Contact CardDocumento4 páginasContact CardJader ClarindoAinda não há avaliações

- ContactDeflts Sum04Documento4 páginasContactDeflts Sum04mahd6Ainda não há avaliações

- HexaplateDocumento24 páginasHexaplatemr.aikidoAinda não há avaliações

- Installation Manual for Midea Air Conditioner Models KFR-26GW/BP2DN1Y-PA402(A3), KFR-32GW/BP2DN1Y-PA402(A3), and KFR-35GW/BP2DN1Y-PA402(A3Documento40 páginasInstallation Manual for Midea Air Conditioner Models KFR-26GW/BP2DN1Y-PA402(A3), KFR-32GW/BP2DN1Y-PA402(A3), and KFR-35GW/BP2DN1Y-PA402(A3mr.aikidoAinda não há avaliações

- HP NS1020Documento8 páginasHP NS1020mr.aikidoAinda não há avaliações

- MFL67568754 EngDocumento44 páginasMFL67568754 Engmr.aikidoAinda não há avaliações

- Asus X99-E PDFDocumento110 páginasAsus X99-E PDFmr.aikidoAinda não há avaliações

- AOC Product Manual 24B2XH 27B2H EnglishDocumento32 páginasAOC Product Manual 24B2XH 27B2H EnglishSikorsky 75Ainda não há avaliações

- Samsung Side-by-Side Refrigerator User ManualDocumento76 páginasSamsung Side-by-Side Refrigerator User Manualmr.aikidoAinda não há avaliações

- ASUS VS229 VS239 UserGuide EnglishDocumento25 páginasASUS VS229 VS239 UserGuide Englishmr.aikidoAinda não há avaliações

- X99 Series DRAM QVL For I7 69xx-68xx ProcessorsDocumento14 páginasX99 Series DRAM QVL For I7 69xx-68xx Processorsmr.aikidoAinda não há avaliações

- MiWand 2 Pro Manual-EnDocumento45 páginasMiWand 2 Pro Manual-Enmr.aikidoAinda não há avaliações

- LS-Dyna 971 R4/R5 New Solid and New ContactDocumento23 páginasLS-Dyna 971 R4/R5 New Solid and New Contactmr.aikidoAinda não há avaliações

- Cal Man El9900 PDFDocumento284 páginasCal Man El9900 PDFAnonymous KEwEj4uAinda não há avaliações

- Autocad Utility Design Product Brochure Us enDocumento4 páginasAutocad Utility Design Product Brochure Us enmr.aikidoAinda não há avaliações

- Prob02 n4w Modal W ReductionDocumento10 páginasProb02 n4w Modal W Reductionglenn11897Ainda não há avaliações

- Render Mental RayDocumento57 páginasRender Mental RayyiuntisAinda não há avaliações

- Factors Affecting Rates of Reaction Lab ReportDocumento3 páginasFactors Affecting Rates of Reaction Lab Reportjohnson_tranvo100% (1)

- Important changes to SA-1 syllabus for classes VI to XIIDocumento4 páginasImportant changes to SA-1 syllabus for classes VI to XIICornelius WalkerAinda não há avaliações

- University of Craiova Faculty of Electrotechnics: Eng. George Marian PISCDocumento10 páginasUniversity of Craiova Faculty of Electrotechnics: Eng. George Marian PISCcfcshakerAinda não há avaliações

- Ceramic Coated Brake Disc PerformanceDocumento13 páginasCeramic Coated Brake Disc Performancebotan_mihaiAinda não há avaliações

- Rigorous Steady-State Simulation of Acetone Production Using Aspen Hysys®Documento9 páginasRigorous Steady-State Simulation of Acetone Production Using Aspen Hysys®eva apriliaAinda não há avaliações

- Spe 151395 MSDocumento14 páginasSpe 151395 MSOmidAinda não há avaliações

- Emoto Speed Control PresentationDocumento21 páginasEmoto Speed Control PresentationericelijahAinda não há avaliações

- Recovery of Platinum from Brine by ElectrodepositionDocumento27 páginasRecovery of Platinum from Brine by ElectrodepositionGmmmm123Ainda não há avaliações

- Can Crush Lab JavyDocumento3 páginasCan Crush Lab JavyFernanda Gomez ZamoraAinda não há avaliações

- DR AQ KhanDocumento31 páginasDR AQ KhanTasleem100% (5)

- CH5100 Peristaltic FlowDocumento21 páginasCH5100 Peristaltic FlowashuiskeshavAinda não há avaliações

- Sieve Analysis of Given Soil SampleDocumento7 páginasSieve Analysis of Given Soil SampleWaQar SaleemAinda não há avaliações

- The Design and Performance of The Retaining Walls at Newton Station - Nicholson PDFDocumento8 páginasThe Design and Performance of The Retaining Walls at Newton Station - Nicholson PDFsonnykinAinda não há avaliações

- Bra-ket notation explainedDocumento12 páginasBra-ket notation explainedfaisalphyAinda não há avaliações

- 1-5 Practice - ADocumento2 páginas1-5 Practice - AStanleyAinda não há avaliações

- A I0131e PDFDocumento219 páginasA I0131e PDFTëk AñdotAinda não há avaliações

- Understanding The Colour Coding: Kittiwake Viscotube ReadmeDocumento15 páginasUnderstanding The Colour Coding: Kittiwake Viscotube ReadmemusaveerAinda não há avaliações

- 2SC5793 TT2206Documento4 páginas2SC5793 TT2206Anil BpsAinda não há avaliações

- HV XLPE Cables State of the Art Design and Manufacturing IssuesDocumento34 páginasHV XLPE Cables State of the Art Design and Manufacturing IssuesA. HassanAinda não há avaliações

- Chapter - 11: Work and EnergyDocumento10 páginasChapter - 11: Work and Energyuma mishraAinda não há avaliações

- The Divine MatrixDocumento3 páginasThe Divine MatrixDeWayne RobertsAinda não há avaliações

- Setalux D A 760 Ba X - Emea - enDocumento2 páginasSetalux D A 760 Ba X - Emea - enMy SukkaAinda não há avaliações

- Mechanics of Structures (CE130N) Lab 14 1 ObjectiveDocumento10 páginasMechanics of Structures (CE130N) Lab 14 1 Objectiveram_108Ainda não há avaliações

- Theory of Plasticity For Steel StructuresDocumento257 páginasTheory of Plasticity For Steel StructuresMahdi100% (2)

- Conditiong Monitoring Techniques For Electric Cables Used in Nuclear Power PlantsDocumento16 páginasConditiong Monitoring Techniques For Electric Cables Used in Nuclear Power PlantsGualadrakeAinda não há avaliações

- Calculation of Liquid Petroleum QuantitiesDocumento10 páginasCalculation of Liquid Petroleum QuantitiesHenry MaedaAinda não há avaliações

- Introduction To Ozone DepletionDocumento2 páginasIntroduction To Ozone DepletionJudelynElentorioAinda não há avaliações