Escolar Documentos

Profissional Documentos

Cultura Documentos

3 SG Strength

Enviado por

Anonymous 59kjvq4OLBDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

3 SG Strength

Enviado por

Anonymous 59kjvq4OLBDireitos autorais:

Formatos disponíveis

Material Strength

Subgrade Strength/Stiffness

California Bearing Ratio (CBR)

Resistance Value (R-Value)

Resilient Modulus (M

R

)

Modulus of Subgrade Reaction (K)

California Bearing Ratio (CBR)

CBR: California Bearing Ratio Test.

Developed by The California State Highways

Department in 1930.

Resistance of the material to uniaxial

penetration.

Measure of soil shear strength relative to

standard crushed stone material.

Field and laboratory test.

California Bearing Ratio (CBR)

Used in Pavement Design

Performed on unbound layers:

Subgrade layer,

Subbase layer

base layer.

California Bearing Ratio (CBR)

Load a piston (area = 3 in

2

) at

a constant rate (0.05 in/min)

Record Load every 0.1 in

penetration

Total penetration not to

exceed 0.5 in.

Draw Load-Penetration

Curve.

CBR Test Equipment

Soaking Samples for 4 days

measure swelling and CBR

Typical Testing Machine

Surcharge

Weights

Surcharge weights are added

during testing and soaking to:

Simulate the weight of

pavement.

Prevent heaving up

around the piston.

Piston

CBR Calculation

|

.

|

\

|

=

Rocks Standard of Stress or Load

Soil of Stress or Load

100 CBR

Calculate CBR at 0.1 in (25 mm) and 0.2 in (50 mm) deformation

then use the Maximum value as the design CBR.

Penetration 0.1 (2.5 mm) 0.2 (5.0 mm)

Load of Standard Rocks (Ib) 3000 4500

Load of Standard Rocks (kN) 13.24 19.96

Stress of Standard Rocks (KPa) 6895 10342

Stress of Standard Rocks (psi) 1000 1500

Loads and Stresses Corresponding to 0.1 and 0.2 inches

Penetration for the Standard Rocks

CBR Curves

0

100

200

300

400

500

600

700

800

0 0.1 0.2 0.3 0.4 0.5 0.6

Penetration (in)

L

o

a

d

(

I

b

)

Wrong Curve

Standard Curve

Need correction

CBR Curve Correction

0

100

200

300

400

500

600

700

0 0.1 0.2 0.3 0.4 0.5 0.6

Penetration (in)

L

o

a

d

(

I

b

)

0.0 0.1

0.2

Influence of Moisture upon CBR

0

100

200

300

400

500

600

700

0 0.1 0.2 0.3 0.4 0.5 0.6

Moisture Content

C

B

R

Use relevant value of moisture content when assessing soils

under laboratory conditions.

Resistance Value (R-Value)

Developed by California Division of Highways:

1940s

Measures frictional resistance of granular

material to deformation

Uses the Hveem Stabilometer

Tests material in a saturated condition (worst

case scenario

Resistance Value (R-Value)

Stabilometer

P

h

P

v

R-value Test (ASTM D2844)

1 ) 1 )(

5 . 2

(

100

100

2

+

=

h

v

P

P

D

R

P

v

= applied

vertical pressure

(typically 160 psi)

P

h

= transmitted

horizontal pressure

D2 = displacement

of stabilometer

fluid necessary to

increase horizontal

pressure from 5 to

100 psi.

Typical R-Value Ranges

General Soil Type USCS Soil Type R-Value Range

Clean gravels

GW

30 80

GP

Gravels with fines

GM

30 80

GC

Clean sands

SW

10 50

SP

Sands with fines

SM

20 60

SC

Silts and clays

ML 5 20

CL 5 20

OL < 7

MH 5 20

CH 5 20

OH < 7

Resilient Modulus (M

R

)

Measures stiffness of the material under repeated load.

Determines the load carrying capacity of the material.

Used for HMA as well as unbound materials

Uses a repeated load triaxial test.

Used in most modern methods of pavement design.

r

R M

c

o o

3 1

strain e Recoverabl

stress Deviator

= =

o

1

o

3

o

2

o

3

o

1

Triaxial Test Equipment

Inside Rods

Load Cell

Chamber

Soil Specimen

Bottom Platen

Top Platen

Frame

External LVDT

Loading Piston

Cell Pressure Inlet

LVDT Clamp

LVDT

Typical Stress Strain Response During one

Loading Cycle

0.0

5.0

10.0

15.0

20.0

25.0

30.0

0.0 0.5 1.0 1.5

Ti me (sec)

S

t

r

e

s

s

(

p

s

i

)

0.000

0.004

0.008

0.012

0.016

0.0 0.5 1.0 1.5

Ti me (sec)

S

t

r

a

i

n

(

i

n

/

i

n

)

Stress vs. Time

Strain vs. Time

c

p

c

r

Dwell

Loading

Unloading

Resilient Modulus

Animation from University of Tokyo Geotechnical Engineering Lab

2 14 16 2 14 16

load rest

Time

Load

c

r

= AL/L

ASU Advanced Pavement Laboratory

Nonlinear Material Behavior:

Coarse-Grained Soils

Bulk stress: u = o

1

+ o

2

+ o

3

K

1

, K

2

are material constants

K

1

> 0

K

2

0 (stress-stiffening)

log M

R

log u

log M

R

log t

oct

K

1

K

2

2

1

K

R K M u =

Nonlinear Material Behavior:

Fine-Grained Soils

Octahedral shear stress:

K

3

, K

4

are material constants

K

3

> 0

K

4

0 (stress-softening)

K

3

K

4

log M

R

log

t

oct

4

3

K

oct

R K M t =

Combined Stress Dependence of M

R

(NCHRP 1-37A)

Bulk (Confining) Stress

Stiffening term (k

2

> 0)

Dominates for coarse granular

soils (base, subbase)

Shear (Deviatoric) Stress

Softening Term (k

3

< 0)

Dominates for fine-grained

soils (subgrade)

3 2

1

1

k

a

oct

k

a

a R

P P

p k M

|

|

.

|

\

|

+

|

|

.

|

\

|

=

t u

Effect of Stress on M

R

log M

R

log u

log M

R

log t

oct

Bulk Stress| Stiffening Shear Stress| Softening

u = o

1

+ o

2

+ o

3

t

oct

= Octahedral shear stress

u = I = Bulk stress = First

stress invariant

Coarse Materials

Fine Materials

Effect of Moisture/Density on M

R

log M

R

S

dry

log M

R

Moisture| Softening Density| Stiffening

Correlations

Conversions between CBR, R-value, M

R

Important points:

No direct correlation

Each test measures a fundamentally different property

Developed correlations are only for limited data sets

Correlations (CBR M

R

)

( ) CBR M

R

1500 =

Origin: Heukelom and Klomp (1962)

Limitation: Fine-grained non-expansive soils with soaked CBR s 10

( )

64 . 0

2555 CBR M

R

=

Origin: NCHRP 1-37A Mechanistic Design Guide

Limitation: not stated

Units: CBR %

M

R,

psi

Correlations

( )

555

1155 1500

Value R

=

CBR

Origin: HDOT

Limitation: Fine-grained non-expansive soils with soaked CBR s 8

( ) Value R 555 1000 + =

R

M

Origin: 1993 AASHTO Guide

Limitation: Fine-grained non-expansive soils with R s 20

Correlation Example

M

R

vs. R-value for some Washington State soils

M

R

R-Value

50 60 40 30 20 15 10 8 6 5 4 3 2 1.5

1 2 3 4 5 10 15 20 40 60 80 100

100 80 60 40 30 20 15 10 5 4 3 2 1

Poor Medium Good Excellent Subgrade Soil

Category

Unified Soil

Classification

AASHTO Soil

Classification

Mr (ksi)

CBR (%)

R- Value

A-1-b

A-2-7

A-3

A-4

A-5

A-6

A-7-6

CH

MH

CL

ML

SW

GM

GC

GP - GM

GP - GC

GW - GM

GW - GC

GP

GW

SM

SC

SP - SM

SP - SC

SW - SM

SW - SC

SP

A-1-a

A-7-5

A-2-5

A-2-4

A-2-6

M

R

Correlations

w/ I ndex

Properties and

Soil Classification

(NCHRP 1-37A)

Plate Loading Test

Measure supporting power of subgrades,

subases, bases and a complete pavement.

Field test.

Data from the test are applicable for design of

both flexible and rigid pavements.

Results might need some corrections.

Plate Loading Test

Plate Loading Test

Plate Loading Test Schematic

Reaction

Pressure

Gauge

3 Deflection

Dials

Reaction

for Dial

Hydraulic

Jack

30 | Plate

24 | Plate

18 | Plate

Tested Layer

12 | Plate

Reaction

Effect of Plate Size

p = n + m (P/A)

p = Unit load (stress)

n, m =Empirical values obtained by test

P/A = Perimeter over area

n

m

P/A

p

Modulus of Subgrade Reaction (k)

K = modulus of subgrade reaction

P = unit load on the plate (stress) (psi)

A = deflection of the plate (in)

For design use stress P = 10 psi (68.95 kN/m

2

)

P

K =

Required for rigid pavement design.

S

t

r

e

s

s

,

p

s

i

10 psi

A

Deformation, in

Corrections for K

Correction due to saturation (worst case

scenario).

Correction due to bending of the plates.

Correction Due to saturation

u

s

u

s

K K

A

A

=

K

s

= modulus of subgrade reaction corrected for saturation

K

u

= field modulus of subgrade reaction

A

u

/A

s

= ratio of the deflection in the unsaturated and saturated tests

Deformation

S

t

r

e

s

s

10 psi

A

u

A

s

10 psi

S

t

r

e

s

s

Deformation

Saturated

Condition

Field

Condition

Correction due to Bending of the Plates

Some bending of the plates might occur When

materials of high modulus are tested.

Use chart for correction of k for plate bending.

K (pci)

K

corrected

(pci)

Basic Plate Loading Test Types

Deformation

S

t

r

e

s

s

Time

D

e

f

o

r

m

a

t

i

o

n

R

a

t

e

Static Load

Basic Plate Loading Test Types

Deformation

S

t

r

e

s

s

Deformation

S

t

r

e

s

s

Accumulated Plastic

Deformation

Elastic

Rebound

Repeated Load

To do a good job you need to

study Hard, dont you?!

Você também pode gostar

- InfoDocumento1 páginaInfoAnonymous 59kjvq4OLBAinda não há avaliações

- Simple Delivery Order Template DownloadDocumento1 páginaSimple Delivery Order Template DownloadAnonymous 59kjvq4OLBAinda não há avaliações

- Designing for Construction SafetyDocumento52 páginasDesigning for Construction SafetyAnonymous 59kjvq4OLBAinda não há avaliações

- Contoh Delivery OrderDocumento2 páginasContoh Delivery OrderAnonymous 59kjvq4OLB100% (3)

- Bullet LicenseDocumento1 páginaBullet LicensekaliamahsksiAinda não há avaliações

- Water Quality Index BrochureDocumento2 páginasWater Quality Index BrochureHolo ZoroAinda não há avaliações

- UnconfinedDocumento4 páginasUnconfinedRen SalazarAinda não há avaliações

- ReadmeDocumento1 páginaReadmeAnonymous 59kjvq4OLBAinda não há avaliações

- A Review of Geotechnical Behavior of Stabilized SoilsDocumento62 páginasA Review of Geotechnical Behavior of Stabilized SoilsAnonymous 59kjvq4OLBAinda não há avaliações

- Impact of Wastewater To EnvironmentDocumento1 páginaImpact of Wastewater To EnvironmentAnonymous 59kjvq4OLBAinda não há avaliações

- Field Moisture and Density Testing With Nuclear GaugeDocumento30 páginasField Moisture and Density Testing With Nuclear GaugeAnonymous 59kjvq4OLB100% (1)

- Soil Stabilization Methods and MaterialsDocumento38 páginasSoil Stabilization Methods and Materialstyas_pramesthi100% (5)

- Lab Experiment #5: Standard Proctor Compaction TestDocumento4 páginasLab Experiment #5: Standard Proctor Compaction TestfadyAinda não há avaliações

- Designing for Construction SafetyDocumento52 páginasDesigning for Construction SafetyAnonymous 59kjvq4OLBAinda não há avaliações

- STAAD Report" STAAD.Pro structural analysis reportDocumento7 páginasSTAAD Report" STAAD.Pro structural analysis reportAnonymous 59kjvq4OLBAinda não há avaliações

- Assignment 2Documento2 páginasAssignment 2Anonymous 59kjvq4OLBAinda não há avaliações

- Hydraulic Apr 09 PDFDocumento15 páginasHydraulic Apr 09 PDFAnonymous 59kjvq4OLBAinda não há avaliações

- Final Report Format for STAAD.Pro Roof Truss AnalysisDocumento1 páginaFinal Report Format for STAAD.Pro Roof Truss AnalysisAnonymous 59kjvq4OLBAinda não há avaliações

- Experiment 3 - Total SolidDocumento13 páginasExperiment 3 - Total SolidAnonymous 59kjvq4OLBAinda não há avaliações

- Experiment 3 - Total SolidDocumento13 páginasExperiment 3 - Total SolidAnonymous 59kjvq4OLBAinda não há avaliações

- Tips For The Muet Reading ExaminationDocumento3 páginasTips For The Muet Reading ExaminationAnonymous 59kjvq4OLB100% (1)

- MSI07 Force in A Statically Determinate Cantilever TrussDocumento6 páginasMSI07 Force in A Statically Determinate Cantilever TrussAnonymous 59kjvq4OLBAinda não há avaliações

- MSI06 Span DeflectionDocumento5 páginasMSI06 Span DeflectionSyamsul IzuanAinda não há avaliações

- Soil Types and Properties GuideDocumento13 páginasSoil Types and Properties GuideAnonymous 59kjvq4OLB100% (1)

- Report Buckling of StructsDocumento7 páginasReport Buckling of StructsAnonymous 59kjvq4OLBAinda não há avaliações

- Chapter 1 Cement Civil Engineering MaterialDocumento12 páginasChapter 1 Cement Civil Engineering MaterialAnonymous 59kjvq4OLB100% (1)

- SMM2Documento139 páginasSMM2Shazwan Taib0% (1)

- SyaitanDocumento2 páginasSyaitanAnonymous 59kjvq4OLBAinda não há avaliações

- Chapter 2 Aggregate PDFDocumento17 páginasChapter 2 Aggregate PDFmoshilizaAinda não há avaliações

- Climate Change AyeipDocumento16 páginasClimate Change AyeipAnonymous 59kjvq4OLBAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Civil Engineering Construction ChecklistDocumento8 páginasCivil Engineering Construction ChecklistAditya ConstructionAinda não há avaliações

- Vertical forces-WPS OfficeDocumento2 páginasVertical forces-WPS OfficeJesusa EstradaAinda não há avaliações

- Service Manual: Central Air ConditioningDocumento151 páginasService Manual: Central Air ConditioningIvan GrechAinda não há avaliações

- CarbonFiberReinforcedPolymer JRMCoDocumento44 páginasCarbonFiberReinforcedPolymer JRMCoAbhishek PawarAinda não há avaliações

- PACTOBond SBR-DatasheetDocumento2 páginasPACTOBond SBR-DatasheethidiAinda não há avaliações

- Tekaflex Pu 40 For Use in ConstructionDocumento2 páginasTekaflex Pu 40 For Use in ConstructionEzeval GráficaAinda não há avaliações

- Hyflo Company Brochure 2010 WebDocumento12 páginasHyflo Company Brochure 2010 WebsafinditAinda não há avaliações

- Eminent Structural Engineer: Julius Natterer: Brief CVDocumento3 páginasEminent Structural Engineer: Julius Natterer: Brief CVDesign explorer olomizanaAinda não há avaliações

- 1936 Casagrande A. Characteristics of Cohesionless Soils Affecting The Stability of Slopes and Earth FillsDocumento10 páginas1936 Casagrande A. Characteristics of Cohesionless Soils Affecting The Stability of Slopes and Earth FillsErickaAinda não há avaliações

- Factors Affecting PSU CE Graduates' Board Exam PerformanceDocumento14 páginasFactors Affecting PSU CE Graduates' Board Exam PerformanceKennethAinda não há avaliações

- 4239-AA-DC-41U52RN001-IS01 - CheckprintDocumento1 página4239-AA-DC-41U52RN001-IS01 - CheckprintamitAinda não há avaliações

- 74 Toyohashi Tech EngDocumento21 páginas74 Toyohashi Tech EngKip YegoAinda não há avaliações

- Proceedings of The 9th International Conference On Civil EngineeringDocumento627 páginasProceedings of The 9th International Conference On Civil Engineeringtsaniya.mardhiyahAinda não há avaliações

- HILTI Technical Guide Volume 1Documento175 páginasHILTI Technical Guide Volume 1xpertsteelAinda não há avaliações

- Sewers and Types of SewersDocumento3 páginasSewers and Types of SewersMâħêšħ BabuAinda não há avaliações

- Design ManualDocumento138 páginasDesign Manualtags7991% (11)

- NZ Glulam Beam Span TablesDocumento112 páginasNZ Glulam Beam Span Tables형표 김Ainda não há avaliações

- Wireline Pipe Recovery Considerations in Stuck Drill Pipe SituationsDocumento6 páginasWireline Pipe Recovery Considerations in Stuck Drill Pipe Situationsreborn2Ainda não há avaliações

- JBCC Priceindex September 2022Documento7 páginasJBCC Priceindex September 2022kandy saidAinda não há avaliações

- Column Analogy Method PDFDocumento2 páginasColumn Analogy Method PDFHeather0% (1)

- Post Tensioned Design1Documento40 páginasPost Tensioned Design1Magdy BakryAinda não há avaliações

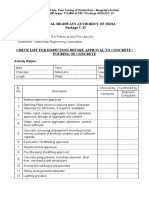

- Check List For Inspection Before Approval To Concrete or Pouring of ConcreteDocumento2 páginasCheck List For Inspection Before Approval To Concrete or Pouring of ConcreteAnil Kumar T BAinda não há avaliações

- Austempered Ductile Iron Offers Superior Strength, Toughness & DurabilityDocumento14 páginasAustempered Ductile Iron Offers Superior Strength, Toughness & DurabilitylucianoAinda não há avaliações

- Method Statement CladdingDocumento2 páginasMethod Statement Claddingasrihamid77% (26)

- Ch5 Retaining Walls (1-37)Documento37 páginasCh5 Retaining Walls (1-37)Rafi Sulaiman100% (1)

- Structural Steel Code Operational Part Analysis and DesignDocumento625 páginasStructural Steel Code Operational Part Analysis and Designsecanet10Ainda não há avaliações

- Fluid Flow Analysis of A Shark-Inspired MicrostructureDocumento25 páginasFluid Flow Analysis of A Shark-Inspired Microstructurehouse zengAinda não há avaliações

- Module 4 - Phase Separation Theory and Separator Design - LectDocumento23 páginasModule 4 - Phase Separation Theory and Separator Design - LectmahmoudAinda não há avaliações

- BRIDGE DESIGN CONSIDERATIONSDocumento32 páginasBRIDGE DESIGN CONSIDERATIONSDammy Taiwo-AbdulAinda não há avaliações

- Renr4113 - TXT Manual de Servicio Hidraulico y DireccionDocumento92 páginasRenr4113 - TXT Manual de Servicio Hidraulico y DireccionEdgar Martinez CarmonaAinda não há avaliações