Escolar Documentos

Profissional Documentos

Cultura Documentos

Indian Characterization of Oil Shale

Enviado por

Hossam Mohamed KandilTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Indian Characterization of Oil Shale

Enviado por

Hossam Mohamed KandilDireitos autorais:

Formatos disponíveis

Characterization of Indian origin oil shale using advanced analytical

techniques

Ravindra Kumar

, Veena Bansal, R.M. Badhe, Indu Sekhara Sastry Madhira, Vatsala Sugumaran,

Saeed Ahmed, Jayaraj Christopher, Mitra Bhanu Patel, Biswajit Basu

Indian Oil Corporation Limited, Research & Development Centre, Sector-13, Faridabad 121 007, Haryana, India

h i g h l i g h t s

v The paper highlights the detailed characterization of Indian origin oil shale.

v There is no work reported on detail characterization of Indian origin shale oil.

v The ICAP and XRD identify the metals and minerals in oil shale.

v The IR, NMR and MS give the information regarding hydrocarbons and structural parameters.

v Indian origin shale oil is carbon rich in nature and contains a signicant component of aromatics.

a r t i c l e i n f o

Article history:

Received 5 January 2013

Received in revised form 4 May 2013

Accepted 17 May 2013

Available online 4 June 2013

Keywords:

Oil shale

Metal analysis

Hydrocarbon analysis

Analytical techniques

a b s t r a c t

The paper highlights the detailed characterization of Indian origin oil shale using various analytical tech-

niques viz., Elemental analysis, Induced Coupled Argon Plasma (ICAP), X-ray Diffraction (XRD), Gas Chro-

matography (GC), Infrared spectroscopy (IR), Nuclear Magnetic Resonance (NMR) spectroscopy and High

Resolution Mass Spectrometry (HRMS). The study also focused on the molecular characterization of two

shale oil samples obtained by retorting method from oil shales. A method based on NMR spectroscopy

has been developed for the estimation of total aromatics, types of aromatic substituents and average

alkyl chain length of saturates in shale oil samples. Detailed hydrocarbon type analysis in terms of 22

classes has been carried out by HRMS. The results of aromatics obtained by the

1

H NMR method, corre-

lated with HRMS data. The detailed analyses of Indian origin oil shale provide in depth structural infor-

mation regarding the metals, minerals and hydrocarbons.

2013 Elsevier Ltd. All rights reserved.

1. Introduction

Oil shale is a natural, impermeable, ne-grained, laminated

black or brown combustible material, and it consists of complex

organic material of high molecular weight called kerogen which

is nely distributed in an inorganic matrix [1]. As a kind of fossil

fuel similar to coal, oil shale has a higher mineral content. It is be-

lieved that the minerals in oil shale will affect the reaction of or-

ganic matter physically and chemically [2,3]. In the western

United States, large oil shale deposits exist in Colorado, Utah, and

Wyoming [4] and have been considered for utilization during peri-

ods of high crude oil prices. Patterson [5] did substantial research

on Australian oil shale from different deposits. Their main focus

was on the mineralogy of Australian oil shale and its effect on oil

shale retorting. Jabber et al. [6] described about Jordan oil shale

from different deposits and compared with Colorado oil shale.

According to Jabber et al. Jordan organic matter (shale oil) contains

8.510.3% of sulfur. Oil shales have been divided into three catego-

ries based on mineral composition carbonate-rich shale, siliceous

shale and cannel shale. Carbonate-rich shales derive their name

from the large amount of carbonate minerals such as calcite and

dolomite. Siliceous oil shales are usually dark brown or black

shales. Siliceous oil shales are not rich in carbonates but rather in

siliceous minerals such as quartz, feldspar, clay, chert and opal.

Cannel shales are usually dark brown or black shales, which consist

of organic matter that completely encloses other mineral grains

[7]. Wang et al. [8] identify the mineral composition of oil shale

from different locations and relate it to their interval of occurrence.

The physical and chemical compositions of shale oil, a complex

mixture of hydrocarbons, depend on the source of the raw shale

and the type of processes used to obtain the oil. It is well-known

that liquid products from petroleum, oil shale and coal are difcult

to characterize in terms of chemical structure, as they consist of

large numbers of structurally diverse compounds. Basically, shale

oils differ from petroleum primarily in that they have higher

0016-2361/$ - see front matter 2013 Elsevier Ltd. All rights reserved.

http://dx.doi.org/10.1016/j.fuel.2013.05.055

Corresponding author. Tel.: +91 1292294235.

E-mail address: kumarr88@indianoil.in (R. Kumar).

Fuel 113 (2013) 610616

Contents lists available at SciVerse ScienceDirect

Fuel

j our nal homepage: www. el sevi er . com/ l ocat e/ f uel

nitrogen content and as shale oils are produced by pyrolysis, they

also contain some concentrations of olens, which are generally

found in natural crude oils in low concentrations. Shale oil rich

in alkanes, cyclanes, arenes, as well as nitrogen-, sulfur-, and oxy-

gen-containing non-hydrocarbons; Hence, it is hard to analyze

oxygen compounds in question without pretreatment of oils. Ear-

lier traditional methods such as column chromatography and also

distillation were used for the component analysis of oils. With the

development of chromatographic separation methods, the molecu-

lar constitutions of shale oil and coal tar were gradually

established. Zhu [9] separated two kinds of shale oils from moun-

tainous area (land) and coastal shelf rock (sea), both China, into

four fractions using silica gel column chromatography. The compo-

nents of each fraction were identied by GCMS. The results show

that shale oil from land contains 269 compounds, with abundant

hydrocarbon compounds (79%), and some sulfur, oxygen and nitro-

gen compounds. Shale oil from sea rocks contains 284 compounds

with a high amount of hydrocarbon and oxygen compounds (60%

and 29%, respectively), and some sulfur and nitrogen compounds.

Guo and Ruan [10] analyzed by GCMS shale oils from Fushun

oil shale of Liaoning province and Maoming oil shale of Guangdong

province, both China. The main oxygen-containing compounds

identied are phenols, diphenols, 2-, 3- and 4-alkanones, furans

and benzofurans. Among the oxygen compounds, phenols consti-

tute 78 wt% of oil (<350 C), the next most abundant being ke-

tones. Bae et al. [11] compared the molecular compositions of

two shale oils of oil shales from US Western and Russian mines,

using 15 T FT-ICR MS coupled with ESI, and atmospheric pressure

photoionization (APPI). Geng et al. [12] was performed, a compre-

hensive compositional analysis of the oxygen containing com-

pounds present in shale oil and low temperature coal tar using

FT-ICR MS and GCMS. Due to the presence of these components,

shale oils are relatively thermally unstable [13], have poor long-

term storage stability and require modications of the analytical

methods used for petroleum characterization.

Estimation of oil shale reserves in India is greater than 15 billion

tons. North-East India is endowed with rich deposits of coal, found

in the Barail formation of tertiary age. Carbonaceous shale occurs

interblended with the coal. The presence of coal and shale has been

recorded in wells drilled for hydrocarbons by Indian companies.

These formations outcrop on the surface towards the south of

the oil elds in a region called the Belt of Schuppen. Studies have

indicated that this oil shale constitute the principal source rocks

that have generated the hydrocarbons produced from the region.

There is no work reported on detailed characterization of Indian

origin oil shale.

The present work discusses in-depth characterization of Indian

origin oil shale using analytical techniques such as CHNS analyzer,

Induced Coupled Argon Plasma (ICAP), Gas Chromatography (GC),

Infrared spectroscopy (IR), Nuclear Magnetic Resonance (NMR)

spectroscopy and High Resolution Mass Spectrometry (HRMS).

The study also focused on the molecular characterization of two

shale oil samples obtained by retorting method from Indian origin

oil shale.

2. Experimental

2.1. Samples

Oil shale samples S1S7 were obtained from Upper Assam Oil

shale deposits and S8S10 from neighboring area in Arunachal Pra-

desh shale deposits. Indian origin oil shales were dark brown or

black in color. Shale oil samples are obtained by retorting method

from oil shale S-7 and S-10. Retorting of oil shale has been carried

out at -500550 C in Retorter pilot plant using CO

2

as sweep gas.

Shale oil samples were obtained by condensing the oil vapors

downstream of the retorter.

2.2. CHNS Analysis

Oil shale and shale oil samples were analyzed by CHNS analyzer

Vario EL-III from M/s Elementar, Germany as per ASTM D 5291

method.

2.3. ICAP Analysis

The ICAP spectrometer used in this study was radial viewing

Optima 5300V from Perkin Elmer, USA. Deionized water of Milli-

pore quality and Suprapure grades of hydrochloric acid, hydrou-

oric acid, AR grade of perchloric acid and multi-element

standards in water matrix from E. Merck (Germany) were used

throughout this analytical work.

2.3.1. Sample and blank preparation

Sample (-0.5 g) was taken in platinum dish and ashed at 650 C

in mufe furnace to remove carbonaceous matter prior to the acid

digestion. To this, 10 ml each of hydrouoric acid and perchloric

acid were added and the contents were heated on hot plate till dry-

ness to remove silica. To the residue obtained, 20 ml of hydrochlo-

ric acid was used to get it dissolved. The solution was transferred

to 100 ml volumetric ask and made up to 100 ml with water.

Blank solution was also prepared by following exactly the same

procedure as for the sample.

In order to maintain the same acid concentration, stock solution

of multi-element standard (100 ppm) was diluted with blank to

prepare 1, 5 and 10 ppm standard solutions. The peaking of ICAP

spectrometer was performed with Mn line (257.61 nm) to cover

all the elements.

2.3.2. Calibration and analysis

After spectral lines alignment using 10 ppm standard to cover

all the elements, ICAP was calibrated using blank and 1, 5 and

10 ppm standard solutions. Blank subtraction mode was used for

the sample analysis for all analytes.

2.4. X-ray diffraction (XRD)

XRD studies were carried out in an 18 KW X-ray diffractometer

(Rigaku, Japan). XRD patterns were recorded at 50 kV and 250 mA,

at a scan rate of 1/min with a step size of 0.01 in the temperature

range of 275 2-Theta. XRD patterns were processed for smooth-

en, determination of inter-planner distance (d) of observed peaks

and search match was conducted by using search match softwares

to nd out different compounds present in the sample.

2.5. IR Analysis

IR spectra of the oil shale samples are recorded on PerkinElmer

BX-II FT-IR instrument. Known weight (-2 mg) of the sample is

mixed with 100 mg KBr and KBr pellet is prepared using the entire

sample under 58 kg pressure employing a Hydraulic Press. The IR

Spectrumof the KBr pellet is recorded at 4 cm

1

resolution and 100

scans were collected. The IR spectra were corrected for baseline

correction and smoothed to remove the noise and then analyzed

for the presence of organic and inorganic moieties.

2.6. Open-column chromatography

The shale oil samples were fractionated into saturate and aro-

matic fractions as per the ASTM-2549/91 (reapproved 1995)

method.

R. Kumar et al. / Fuel 113 (2013) 610616 611

2.7. NMR Spectroscopic analysis

The

1

H/

13

C NMR spectra were recorded on a Bruker ACP-

300 MHz NMR spectrometer.

1

H,

13

C, Distortion Enhancement

Polarization Transfer (DEPT-135) and Heteronuclear Single Quan-

tum Coherence (HSQC) experiments were carried out using the

pulse sequence of as per the experimental conditions described

in our previous work [14].

2.8. MS Analysis

Samples of shale oil were subjected to high resolution mass

spectrometry using Auto Spec Ultima HRGCMS instrument. Ioni-

zation was carried out at 70 eV electron ionization (EI). The mass

spectrometer was set at 6000 resolution for detailed analysis of

22 classes of hydrocarbon.

3. Results and discussion

3.1. Oil shale analysis

3.1.1. Elemental and metal analysis

The elemental and metal analysis data of all oil shale samples

studied are given in Tables 1 and 2 respectively. The elemental

analysis shows the presence of carbon (625%), hydrogen (0.6

2.5%), nitrogen (0.081.5% and sulfur (211%). The elemental com-

position of an oil shale can be correlated with oil yields [15].

The organic carbon content is a good indicator of the quality of

organic matter in the oil shale. Indian origin oil shale contains low

concentration of carbonates and bicarbonates which are conrmed

by ICAP, calcium (0.070.2%) and XRD. The comparison of XRD pat-

tern of oil shale samples with XRD pattern of standard CaCO

3

con-

rmed the low concentration of carbonate minerals in all the

samples. Indian origin oil shale is siliceous in nature and found

to contain siliceous minerals such as quartz and clay. Other major

deposits of world oil shale viz., Kukersite (Estonia), Jurf ed Dara-

wish and the Sultani deposits (Jordan) [6] and Colorado, Utah,

and Wyoming (United States of America) [4] are carbonaceous in

nature. Due to the presence of very low concentration of carbon-

ates, it is conrmed that carbon (625%) in Indian origin shale is

organic in nature. The samples are found to contain aluminum

(27% range), ferrous (1.89% range), calcium (0.070.2%), sodium

(0.11.05%) and potassium (0.41.23%) as major metals. A correla-

tion among the iron content of the samples with sulfur content is

observed, indicating the presence of iron sulde type component

in all the samples.

3.1.2. X-ray diffraction (XRD)

XRD is one of the techniques normally used for characteriza-

tion of shale [1618]. A labeled XRD pattern of representative

Indian origin oil shale sample is shown in Fig. 1. The XRD spec-

tra are recorded using high power 12.5 kW, because at high

power even though the crystalline compounds present at low

concentration level can give visible diffraction peaks in XRD pat-

tern and there will no doubt to distinguish between peak and

noise. From the XRD spectrum the most probable crystalline

compounds present in the samples are obtained by the search

match programme, which is based on inter-planner distances

(D) and intensity of peak (I) value. There are many compounds

having the same D value and search match programme will

not able to pin point the compound and give number com-

pounds with matching index. XRD analysis showed the presence

of both crystalline and amorphous phase in all the samples.

Based on the search match analysis, the crystalline components

were identied as quartz (SiO

2

) along with kaolin clay (Al

2

SiO

5

(-

OH)

4

), Illite and pyrite (FeS

2

). The XRD pattern shown in this pa-

per are smoothened one which clearly distinguishes noise from

peaks of kaolin and pyrite as evidenced from clear peaks of at

(2h) degree, 12.3, 20.3, 24.8 for kaolin and 33.1, 37.1, 40.8,

47.4 for pyrite. The intensity of these components was found

to be different in all these samples indicating that % weight of

these components varies from sample to sample. However, in

all these samples Quartz was found to be the major component.

XRD analysis also indicated presence of small amounts of oxides

of Iron in all these samples. XRD analysis indicated that SiO

2

was high in S-3 while low in sample S-9. Clay was high in sam-

ple S-2 and low in S-7. Hydrotalcite (magnesium aluminum hy-

droxy carbonate) was found in few of the samples (S-2, 4, 9 and

10) while this phase was absent in S-1, 3 and 8. XRD spectrum

showed a broad weak hump in the two theta range 2030,

which indicates the presence amorphous material in oil shale.

Generally, in XRD even for 100% material amorphous material

it gives broad weak diffraction peak, in two theta range 20

30. Therefore, the weak diffraction observed in the present

samples may be due to shale oil present in the oil shale, which

is amorphous in nature.

3.1.3. IR Spectral analysis

The IR spectrum of Indian origin shale is shown in Fig. 2, which

comprises aliphatic and aromatic stretching and bending vibra-

tions from kerogen overlapped with contributions from the miner-

als present, in particular silica and clay materials. IR spectra of all

the samples indicate the presence of various sharp hydroxyl bands

in 37003600 cm

1

region (3693, 3676.1, 3651.2, 3620,

3398 cm

1

) along with hydrocarbon bands in 30002700 cm

1

re-

gion. A sharp band at 3697 cm

1

has been attributed to OH of

kaolinite, the sharp band at 3625 cm

1

arises from illite in the oil

shale [19]. The broad OH band at 3380 cm

1

is also attributed

to kaolinite, with possible contribution from moisture in the oil

shale, absorbed during sample preparation. The broad OH band

obscures aromatic CH vibrations, expected around 3030 cm

1

.

Aliphatic hydrocarbon stretching bands are observed at

2930 cm

1

(m

as

CH

2

) and (m

s

CH

2

) [20]. A small peak observed at

1865 cm

1

is most likely an overtone or combination band of the

silicate mineral fundamental. A shoulder observed at 1710 cm

1

,

due to carboxylic acids in kerogen, is not completely resolved as

a strong band at 1640 cm

1

(aromatic and olenic carboncarbon

double bond) overlaps. The broad band at 1460 cm

1

arises from

methyl and methylene deformation modes, with overlap from car-

bonate minerals, if present. The three unresolved bands at 1190,

1160 and 1105 cm

1

are characteristic of pyrite. The bands in the

region 1000450 cm

1

are due to clay and minerals in the oil shale

and silica, with characteristic silicate vibrations occurring at 537

and 470 cm

1

. The band at 2930 cm

1

is associated with aliphatic

hydrocarbons present in the sample and is assumed to be corre-

lated with the samples kerogen content [21]. IR Spectral analysis

of the sample as such indicates the presence of inorganic materials

such as silica, and clay (Kaolin Clay Al

2

O

3

2SiO

2

2H

2

O) as major

constituents.

Table 1

CHNS data of oil shale samples (wt%).

Sample Carbon (%) Hydrogen (%) Nitrogen (%) Sulfur (%)

S-1 6.1 1.2 0.08 2.3

S-2 14.0 1.9 0.4 2.2

S-3 8.6 1.4 0.4 2.2

S-6 15.4 2.0 1.5 3.6

S-7 11.5 1.7 0.6 4.9

S-8 16.7 2.1 0.6 10.3

S-9 22.9 2.7 1.0 2.4

S-10 17.2 2.1 0.8 4.6

612 R. Kumar et al. / Fuel 113 (2013) 610616

3.2. Molecular characterization of shale oil

3.2.1. Elemental analysis of shale oil

Two shale oil samples were obtained by retorting method from

oil shale S-7 and S-10. The elemental composition of shale oil 7

and 10, given in Table 3 showing H/C ratio as 0.123 and 0.124

respectively, indicating that the Indian origin shale oil is carbon

rich in nature and contains a signicant amount of aromatics.

The main characteristics of the organic matter of oil shale are high

hydrogen and a low nitrogen percentage. Oil shale organic matter

contains on average 2.1% of organic sulfur (Table 3). The sulfur con-

tent of the Indian origin shale oil is low (1.92.3 wt%), whereas

deposits of Jordanian oil shale ranges from 0.3% to 4.3%. The sulfur

content of shale oil from the Jurf ed Darawish and the Sultani

deposits (Jordanian) is high (810%) [6] compared to Indian origin

shale oils. One of the combustible components of oil shale is pyrite

with the general chemical formula FeS

2

. The sum of organic and

pyretic sulfur is called combustible or volatile sulfur: The elemen-

tal composition and chemical nature (H/C ratio and hydrocarbon),

of Indian origin shale oil is similar to Estonian (Kukersite) shale oil

[22].

3.2.2. Estimation of total aromatic content by

1

H NMR method

Estimation of the total aromatic content in the Indian origin

shale oil sample using a

1

H NMR spectrum is based on the group

molecular weight method and the determination of the relative

number of carbon atoms. The philosophy of the group molecular

weight method is to rst assign the

1

H NMR spectrum in terms

of CH

n

groups (n = 1, 2, and 3) in order to calculate the relative

number of carbon atoms. The latter part requires estimation of

the quaternary carbons and the average chain length of the substit-

uents attached to aromatic rings.

1

H NMR spectrum of a represen-

tative Indian origin shale oil sample is shown in Fig. 3. Various

resonance signals assigned to different groups have been marked

in the spectrum. The complete assignment of the

1

H NMR spec-

trumin terms of various hydrocarbon groups is included in Table 4.

The assignments with regard to a-CH

n

(n = 13) have been

made by the application of 2D HSQC and 13C-DEPT-135 NMR

experiments.

Shale oil samples are rich in aromatics; especially, the di-ring

plus aromatics are present in an appreciable amount. The degree

of substituents (r) and the chain length of the alkyl substituents

on the aromatics depend on the boiling range of the sample. The

total aromatic content, therefore, will be the contribution of the

ring and the substituents. Knowledge about the average chain

length attached to aromatics (other than a-methyl groups) de-

noted as n is a must for estimation of the total aromatics using

Table 2

Metal analysis data of oil shale samples (in%).

Sample Al Ca Cr

a

Fe Mg Na Ni

a

V

a

K Zn

a

Ti

a

S-1 4.57 0.10 53 2.24 0.14 0.27 97 <50 0.81 112 55

S-2 3.67 0.14 57 3.19 0.48 0.14 81 56 0.91 60 154

S-3 3.68 0.04 53 2.85 0.14 0.18 <50 <50 0.69 <50 108

S-6 4.21 0.19 79 2.68 0.13 0.11 99 56 0.92 84 183

S-7 4.67 0.11 63 5.32 0.23 0.16 120 52 0.93 82 137

S-8 2.02 0.07 <50 9.06 0.27 0.18 115 72 0.47 83 109

S-9 5.07 0.10 103 1.76 0.25 0.13 186 106 0.67 82 283

S-10 3.78 0.10 74 4.35 0.12 0.13 86 75 0.63 64 155

a

Values in ppm.

Table 3

Hydrocarbon type analysis and CHNS data of Indian origin shale oils.

% w/w wt%

Sample Aromatics by NMR Saturates by NMR Aromatics by MS Saturates by MS C H N S O

Oil-1 85.1 14.9 77.8 22.0 82.0 10.1 0.54 1.9 5.46

Oil-2 72.0 28.0 73.0 27.0 81.4 10.1 0.42 2.33 5.75

Fig. 1. Representative XRD pattern of Indian origin oil shale sample.

4000 3500 3000 2500 2000 1500 1000 500

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3698

3620

2924

1638

1031

912

796

694

537

476

A

b

s

o

r

b

a

n

c

e

Wavenumber (cm

-1

)

Fig. 2. Representative IR Spectrum of oil shale sample.

R. Kumar et al. / Fuel 113 (2013) 610616 613

the present methodology. The nature and average length of the al-

kyl substituents greater than CH

3

groups cannot be estimated di-

rectly, as their signals are merged with the signals of parafns

(0.52.0 ppm) in

1

H NMR spectra. Besides this, knowledge about

the contribution of substituted aromatic ring (ARs) and bridge-

head aromatic carbons (ARb) is also required. However, these car-

bons cannot be estimated directly from a

1

H NMR spectrum be-

cause they are non-protonated and not appear in

1

H NMR

spectrum.

In the present method, an indirect approach has been adopted

to obtain information about the parameters: ARs, ARb, and n.

The relative ARs carbons have been realized from the signals in

the region 2.04.0 ppm assigned to a-CH

3

and a-CH

2

groups. ARb

carbons have been realized by the developed equations. An average

value of n has been estimated from the

1

H NMR spectral analysis

of the pure aromatic fractions collected from open-column chro-

matographic separation of a shale oil sample. After the complete

assignment of the

1

H NMR spectrum has been made and the rela-

tive contribution of ARs and ARb has been realized, the total aro-

matic content of a sample can be estimated by the following

equations.

Tc = A=1 B=2 C=3 D=1:25 E=2 F=3 ARs=1

ARb=1 (1)

Tw = 13(A B) 9C 13:25D=1:25 7E 5F 12 0:7Id (2)

Aw = 13A n 7B 5C 12ARs 12Arb (3)

where Tc, Tw, Aw, and n are the relative total carbons, total group

molecular weight of the sample, total group molecular weight of

aromatics, and average alkyl chain length of the alkyl substituents

(other than methyl groups) on the aromatic rings.

The total aromatic content (A) of the sample (weight %) can then

be estimated as

A = 100[Aw=Tw[ (4)

The total aromatic content for the shale oil samples have been

estimated from the developed equation and the data are given in

Table 3.

3.2.2.1. 2D HSQC. Protoncarbon chemical shift correlation exper-

iments (HSQC) provide both carbon and proton chemical shifts at

the same time and establish a one-to-one correspondence for each

pair of directly bonded carbon and hydrogen atoms. Fig. 4 shows

the HSQC contour spectrum of the shale oil sample. The 2D HSQC

heteronuclear correlation NMR spectra analysis has resolved the

complexity of the region 2.04.0 ppm of the

1

H NMR spectra and

provided useful and reliable information regarding the identity of

the a-CH

n

(n = 13) group. Thus, the regions of 2.052.65 and

2.654.0 ppm in the

1

H NMR spectra are used for the estimation

of a-CH

3

and a-CH

2

groups, respectively.

3.2.2.2. Estimation of substituted aromatic ring carbons (ARs). On the

basis of the above discussion, the substituted carbons can be esti-

mated by the following equation:

ARs = B=2 C=3 (5)

where B and C are integral areas as shown in Fig. 3.

Fig. 3. 300 MHz

1

H NMR spectrum of shale oil 1.

Table 4

Divisions of

1

H NMR spectrum of Indian origin shale oil (for measuring integral

intensity as per Fig. 1).

Region

(ppm)

Assignment Integral

intensity

9.06.5 CH of aromatics rings A

4.02.65 a-CH

2

to aromatic rings B

2.652.00 a-CH

3

to aromatic rings C

2.001.40 CH, CH

2

of naphthenes, and iso-parafns

(average CH

1.25

groups)

D

1.01.4 CH

2

E

0.51.0 CH

3

F

4.56.5 CH of olens

7.49.0 di-plus aromatic rings Id

614 R. Kumar et al. / Fuel 113 (2013) 610616

3.2.2.3. Contribution of bridge-head carbons (ARb). The contribution

of bridge-head carbons is required to be known, in samples where

polyaromatics are also present (7.49.0 ppm region). The following

equation will be applicable for feed samples also, where apprecia-

ble amounts of di-plus aromatics are present as discussed in our

earlier work [14].

ARb = 0:7Id (6)

where Id is the integral intensity of the signals in the region 7.4

9.0 ppm.

3.2.3. Determination of average alkyl chain length (n)

The value of n is required to be known in order to realize the

contribution of longer alkyl chains (b, c, and d carbons) attached to

aromatic rings whose signals overlap with those of parafn chains

in the region 0.52.0 ppm. The average alkyl chain length (n) of

aromatic ring substituents (other than a-CH

3

) has been estimated

from the

1

H NMR spectral analysis of pure aromatic fractions of

two samples separated by silica gel column chromatography. The

value of n has been calculated using the following equation:

n = [(I

4:02:65

=2) (I

2:01:0

=2) (I

1:00:5

=3)[=(I

4:02:65

=2) (7)

The a-CH

3

groups have been excluded as their contribution can

be directly realized from the integral intensity of the region 2.05

2.65 ppm. The average value of n has been estimated to be 3.0 in

both shale oil samples. The value of n has also been estimated

according Cantor [23], which is also found to be same.

3.2.4. Structural characterization of aromatics by NMR

The total aromatic carbon (Ca) has been estimated from

13

C

NMR spectral analysis as per the equation given below:

Ca = 100(I

120:0160:0

=I

T

) (8)

where I

120.0160.0

and I

T

correspond to the integral intensities of the

aromatic region and the total integral intensity in the region 5

160 ppm.

Cs = 100 Ca (9)

The Ca content has been found to be 42.1% w/w and 39.7% w/w

in shale oil S-7 and shale oil S-10 respectively; whereas in column-

separated aromatic fractions of shale oil S-7, Ca has been estimated

56.4% w/w. Other structural parameters estimated by NMR spec-

troscopy are given in Table 5.

3.2.5. MS Analysis of shale oil

Detailed hydrocarbon type analysis in terms of hydrocarbon

(HC 22) classes was carried out by HRMS, The details of HC 22 clas-

ses for both shale oils are given in Table 6. The results conrm the

high aromatic nature of Indian origin shale oils. The analysis

indicate that the nature of aromatics are naphthalenes (16.0

18.8% w/w) and acenaphthylenes (8.112.4% w/w) type in majorly

and sulfur compounds are found to be 13.4% w/w and 16.9% w/w in

shale oil S-7 and S-10 respectively. Saturates are found to contain

parafns and naphthenes approximately in equal amount in both

samples. There is a good correlation between the

1

H NMR and

MS methods (Table 3) for aromatics. The MS data show the differ-

ence in saturates due to presence of olens, which is conrmed by

1

H NMR spectroscopy. IR and

13

C NMR analysis conrmed the pres-

ence of small amounts of carboxylic acids, amides and carbonate

moieties also in both shale oil samples.

4. Conclusions

The detailed analyses of Indian origin oil shale provide in depth

structural information regarding the metals, minerals and hydro-

carbons. The ICAP and XRD identify the metals and minerals in

oil shale. Indian origin oil shale is siliceous in nature and found

Fig. 4. 2D-HSQC contour plot of the shale oil 1.

Table 5

Structural parameters by NMR spectroscopy.

Sample n Deg. of sub. ARs ARb Ca

Oil-1 2.8 63.1 9.3 3.2 42.1

Oil-2 3.2 52.2 9.3 3.6 39.7

n = Average alkyl chain length on aromatics, ARs = Substituted aromatic ring

carbons.

ARb = Contribution of bridge-head carbons, Ca = aromatic carbon.

Table 6

Mass spectrometry analysis HC 22 classes.

Hydrocarbon Classes (% w/w) Oil-1 Oil-2 Hydrocarbon classes (% w/w) Oil-1 Oil-2

Parafns 11.0 8.2 Naphthalenes 16.0 18.8

Monocycloparafns 4.8 4.5 Acenaphenes, biphenyls 8.2 5.0

Dicycloparafns 2.9 4.7 Acenaphthylenes, uorenes 12.4 8.1

Tricycloparafns 3.5 6.1 Phenanthrenes 5.6 4.4

Tetracycloparafns 0.0 2.3 Pyrenes 3.6 2.8

Pentacycloparafns 0.0 1.2 Chrysenes 0.3 0.8

Hexacycloparafns 0.0 0.0 Benzopyrenes 0.0 0.0

Heptacycloparafns 0.0 0.0 Aromatics 64.3 56.0

Saturates 22.2 27.0 Thiophenes 1.0 1.7

Alkylbenzenes 7.6 6.1 Benzothiophenes 9.2 10.5

Benzocycloparafns 4.6 3.0 Dibenzothiophenes 3.2 4.7

Benzodicycloparafns 5.8 7.0 Naphthobenzothiophenes 0.0 0.0

Sulfur compounds 13.4 16.9

R. Kumar et al. / Fuel 113 (2013) 610616 615

to contain siliceous minerals such as quartz and clay. The elemen-

tal composition and chemical nature of Indian origin shale oil is

similar to Estonian (Kukersite) shale oil which is potential shale

oil producers in the world. The main characteristics of the organic

matter of Indian origin oil shales are high hydrogen and a low

nitrogen percentage. Oil shale organic matter contains on average

2.1% of organic sulfur. There is no work reported on detailed

molecular characterization of Indian origin oil shale. The results

obtained in this study suggest that the Indian origin shale oil is car-

bon rich in nature and contains a signicant component of aromat-

ics. Even though the oil yields are lower comparative to other

known oil shales. The IR, NMR and MS spectroscopy give the infor-

mation regarding hydrocarbons and structural parameters. The

structural parameters can be used for the prediction of product

proles and their physico-chemical properties.

Acknowledgments

The authors wish to acknowledge the Management of IOC, R&D

Faridabad, for allowing them to publish the present work.

References

[1] Lisboa ACL. Investigations on oil shale particle reactions. Ph.D.

thesis. Vancouver, BC Canada: The University of British Columbia; 1997. p.

112.

[2] Kyotani T, Kubota K, Cao JQ, Yamashita H, Tomita A. Combustion and CO

2

gasication of coals in a wide temperature range. Fuel Process Technol

1993;36:20917.

[3] Evans RJ, Felbeck GT. High temperature simulation of petroleum formation I.

The pyrolysis of Green River Shale. Org Geochem 1983;4:14552.

[4] Johnson RC, Mercier TJ, Ryder RT, Browneld ME, Self JG. Geological survey

digital data series, DDS-69-DD. U.S. Geological Survey; 2011.

[5] Patterson JH. A review of the effects of minerals in processing of Australian oil

shales. Fuel 1994;73(3):3217.

[6] Jaber JO, Sladek TA, Mernitz S, Tarawneh TM. Future policies and strategies for

oil shale development in Jordan. JJMIE 2008;2(1):3144.

[7] Yen TF, Chilingarian GV, editors. Oil shale. Amsterdam, Netherlands: Elsevier

Science Publishing Company; 1976. p. 1526.

[8] Wang DM, Xu YM, He De-Min, Guan J, Zhang QM. Investigation of mineral

composition of oil shale. Asia-Pac J Chem Eng 2009;4:6917.

[9] Zhu ZR. Analysis of composition of shale oils from different places. Acta

Petrolei Sinica (Petroleum Processing Section) 1993;9(3):6671 [in Chinese].

[10] Guo SH, Ruan Z. The composition of Fushun and Maoming shale oils. Fuel

1995;74(11):171921.

[11] Bae EJ, Na JG, Chung SH, Kim HS, Kim S. Identication of about 30,000 chemical

components in shale oils by electrospray ionization (ESI) and atmospheric

pressure photoionization (APPI) coupled with 15 T Fourier transform ion

cyclotron resonance mass spectrometry (FT-ICR MS) and a comparison to

conventional oil. Energy Fuel 2010;24(4):25639.

[12] Geng C, Li S, Yue MA, Yue C, He Z, Shang W. Analysis and identication of

oxygen compounds in longkou shale oil and shenmu coal tar. Oil Shale

2012;29(4):32233.

[13] Stevens RF, Dinneen GU, Ball JS. Analysis of crude shale oil. US Bureau of Mines

Report of Investigations 4898, US BuMines, Washington, DC; 1952.

[14] Bansal V, Krishna GJ, Chopra A, Sarpal AS. Detailed hydrocarbon

characterization of RFCC feed stocks by NMR spectroscopic techniques.

Energy Fuels 2007;21(2):10249.

[15] Cook EW. Green River shale-oil yields: correlation with elemental analysis.

Fuel 1974;53:1620.

[16] Cogo SL, Brinatti AM, Saab SC, Simes ML, Martin Neto L, Rosa JA, et al.

Characterization of oil shale residue and rejects from Irati formation by

electron Paramagnetic resonance. Braz J Phys 2009;39(1):314.

[17] Al-Otoom Awni Y, Reyad A, Adnan Shawabkeh, Al-Harahsheh M, Ahmad T,

Shawaqfeh. The chemistry of minerals obtained from the combustion of

Jordanian oil shale. Energy 2005;30:6119.

[18] Muhamad AF, El Salmawy MS, Abdelaala AM, Sameah S, El-nakheil. Oil shale:

material characterization and effect of acid leaching. Oil Shale 2011;28(4):

52847.

[19] Gadsden JA. Infrared spectra of minerals and related inorganic compounds.

Butterworth MA; 1975.

[20] Bruan V, Halim M, Ziyad M, Largeau M, Ambles A. Characterization of the

Moroccan Timahdit (X-layer) oil shale kerogen using pyrolysis and thermally

assisted hydrolysis and methylation. J Anal Appl Pyrol 2001;61(12):16579.

[21] Dogan OM, Uysal BZ. Pyrolysis of three Turkish oil shales and analysis of shale

oils using FT-IR and NMR spectroscopy. Oil Shale 2002;19(4):399410.

[22] Oat A. Estonian oil shale properties and utilization in power plants. Energetika

2007;53(2):818.

[23] Cantor DM. Nuclear magnetic resonance spectrometric determination of

average molecular structure parameters for coal-derived liquids. Anal Chem

1978;50(8):11857.

616 R. Kumar et al. / Fuel 113 (2013) 610616

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Plant Design 2Documento6 páginasPlant Design 2Hossam Mohamed KandilAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Nebosh IGC Q&ADocumento287 páginasNebosh IGC Q&AHossam Mohamed Kandil92% (24)

- Nebosh Gc-2 Answering Techniques With ExamplesDocumento7 páginasNebosh Gc-2 Answering Techniques With ExamplesHossam Mohamed Kandil100% (1)

- Extraction of Oil From Oil ShaleDocumento7 páginasExtraction of Oil From Oil ShaleHossam Mohamed Kandil100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Is The Common Denominator For: ProfitabilityDocumento3 páginasIs The Common Denominator For: ProfitabilityHossam Mohamed KandilAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Oil Shale EgyptDocumento2 páginasOil Shale EgyptHossam Mohamed KandilAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Saudi Petrochemical Industry Report SummaryDocumento8 páginasSaudi Petrochemical Industry Report SummaryHossam Mohamed KandilAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Roland Berger India Chem 20101109Documento235 páginasRoland Berger India Chem 20101109Naveen KamatAinda não há avaliações

- Lecture 9 NITRIC ACID PRODUCTIONDocumento2 páginasLecture 9 NITRIC ACID PRODUCTIONHossam Mohamed KandilAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- اشهر الكلمات الانجليزيةDocumento79 páginasاشهر الكلمات الانجليزيةlovely sosoAinda não há avaliações

- اشهر الكلمات الانجليزيةDocumento79 páginasاشهر الكلمات الانجليزيةlovely sosoAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- CircuitsDocumento3 páginasCircuitsHossam Mohamed KandilAinda não há avaliações

- Fueltypedescriptions tcm77-187938Documento2 páginasFueltypedescriptions tcm77-187938Hossam Mohamed KandilAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Oil Shale EgyptDocumento2 páginasOil Shale EgyptHossam Mohamed KandilAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Analytical Laboratory Techniques For Oil ShaleDocumento7 páginasAnalytical Laboratory Techniques For Oil ShaleHossam Mohamed KandilAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Broadbent Sugar Centrifugal BrochureDocumento0 páginaBroadbent Sugar Centrifugal BrochureHossam Mohamed KandilAinda não há avaliações

- Shale Gas and Shale Oil Petrology and PetrophysicsDocumento2 páginasShale Gas and Shale Oil Petrology and PetrophysicsHossam Mohamed KandilAinda não há avaliações

- Electric CircuitsDocumento1 páginaElectric CircuitsHossam Mohamed KandilAinda não há avaliações

- Extraction of Oil From Oil ShaleDocumento7 páginasExtraction of Oil From Oil ShaleHossam Mohamed Kandil100% (1)

- Kinetic Studies of Rapid Oil Shale PyrolysisDocumento8 páginasKinetic Studies of Rapid Oil Shale PyrolysisHossam Mohamed KandilAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Chapter 15, Lecture 3, Organic 2Documento13 páginasChapter 15, Lecture 3, Organic 2Hossam Mohamed KandilAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- 4Documento14 páginas4Hossam Mohamed KandilAinda não há avaliações

- Broadbent Sugar Centrifugal BrochureDocumento0 páginaBroadbent Sugar Centrifugal BrochureHossam Mohamed KandilAinda não há avaliações

- Sorbents for Desulfurizing Natural Gas, LPG and Transportation FuelsDocumento29 páginasSorbents for Desulfurizing Natural Gas, LPG and Transportation FuelsHossam Mohamed KandilAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- M T ADocumento1 páginaM T AHossam Mohamed KandilAinda não há avaliações

- Formula Sheet - PCMDocumento7 páginasFormula Sheet - PCMRonit MalhotraAinda não há avaliações

- Physics Class 11 Important QuestionDocumento2 páginasPhysics Class 11 Important QuestionBanna Mohit Singh TanwarAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)

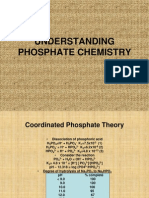

- PhosphateDocumento18 páginasPhosphatejaykotak12345100% (8)

- Map The MaticsDocumento1 páginaMap The Maticsfcc3Ainda não há avaliações

- Index Notation and Its Use PDFDocumento5 páginasIndex Notation and Its Use PDFchetanAinda não há avaliações

- Phy F315 1494Documento4 páginasPhy F315 1494pankazspamAinda não há avaliações

- Hibbeler, Mechanics of Materials-Deflections 1Documento57 páginasHibbeler, Mechanics of Materials-Deflections 1poom2007Ainda não há avaliações

- H2 Math Paper 1 SolutionsDocumento30 páginasH2 Math Paper 1 SolutionsHANSAinda não há avaliações

- Microscopy from Carl ZeissDocumento7 páginasMicroscopy from Carl ZeissYudha Part IIAinda não há avaliações

- Week 2 of Aqs110 Fluid Mechanics PDFDocumento9 páginasWeek 2 of Aqs110 Fluid Mechanics PDFDhayane Redoquerio AquinoAinda não há avaliações

- Einstein Fields EquationsDocumento23 páginasEinstein Fields Equationsdendi231Ainda não há avaliações

- Advanced Solid State Physics Lab ReportDocumento32 páginasAdvanced Solid State Physics Lab ReportLakshay BhardwajAinda não há avaliações

- STD 9 Test On Sound 16 Feb 2024 - StudentDocumento4 páginasSTD 9 Test On Sound 16 Feb 2024 - Studentbavanthbalasubramanian.stuAinda não há avaliações

- 1 - Physical Science The Origin of The ElementsDocumento25 páginas1 - Physical Science The Origin of The ElementsTom FernandoAinda não há avaliações

- Advanced Fluid Mechanics: Lecture Notes Module-IIIDocumento15 páginasAdvanced Fluid Mechanics: Lecture Notes Module-IIInarasimha raoAinda não há avaliações

- Brehm MullinDocumento968 páginasBrehm MullinLUIZ MATHEUS DE SOUZA AGUIAR LEITEAinda não há avaliações

- Nuclear Decay Series ExplainedDocumento9 páginasNuclear Decay Series ExplainedFitri Aulia PermatasariAinda não há avaliações

- Food PropertiesDocumento18 páginasFood PropertiesMayceline CarlosAinda não há avaliações

- Physics Project-2017-18: Topic: To Determine The Wavelength of Sodium LightDocumento19 páginasPhysics Project-2017-18: Topic: To Determine The Wavelength of Sodium Lightvibhav sharmaAinda não há avaliações

- Final Exam in PhysicsDocumento5 páginasFinal Exam in Physicsmvmbapple0% (1)

- Dark MatterDocumento25 páginasDark Mattergaming so MatejAinda não há avaliações

- Chapter Test 2nd Quarter.Documento5 páginasChapter Test 2nd Quarter.Roziel MontalbanAinda não há avaliações

- 40t Rope Drum Hoist220512Documento37 páginas40t Rope Drum Hoist220512Anonymous sfkedkymAinda não há avaliações

- Amit Goswami Quantum Mechanics, Second Edition 2003Documento577 páginasAmit Goswami Quantum Mechanics, Second Edition 2003Solange Ev75% (4)

- Geant4 ExercisesDocumento17 páginasGeant4 Exercisesxzenislevx100% (1)

- Retaining Wall ScopeDocumento5 páginasRetaining Wall ScopeVenkata Mayur100% (1)

- Flooding Velocities in Packed ColumnDocumento5 páginasFlooding Velocities in Packed Columnsireesha.greenAinda não há avaliações

- M3 MIII Unit 4 MCQDocumento9 páginasM3 MIII Unit 4 MCQAbhay mane88% (8)

- ELECTRIC CHARGE, FORCE, AND FIELDDocumento28 páginasELECTRIC CHARGE, FORCE, AND FIELDNelson MeiAinda não há avaliações

- Transformer Testing Purchase OrderDocumento2 páginasTransformer Testing Purchase Orderabdulyunus_amirAinda não há avaliações