Escolar Documentos

Profissional Documentos

Cultura Documentos

Coeficientes Friccion Varios Materiales PDF

Enviado por

Ant HlszDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Coeficientes Friccion Varios Materiales PDF

Enviado por

Ant HlszDireitos autorais:

Formatos disponíveis

Coefficients Of Friction

Page 1 of 7

Disclaimer: The information on this page has not been checked by an independent person. Use this information at your own risk. ROYMECH

Portable Friction Meter Get CoF in seconds! For friction and slide measurements www.sanyocorpusa.com Terra LOC Abate dust with easy to clean, eco-friendly Terra LOC www.terraloc.com Corrosion Resistance Coatings, Technology, Solutions Request A Quote Today! www.CTS-Inc.net

Structural Engineer's Pocket Book Fiona Cobb Buy New 17.08

Click arrows to page adverts

Privacy Information

Home Tribology_Index Friction Factors Note: I have tried to include a wide range of relevant information on this topic. It will be noted that friction values in one section do not necessarily agree with values in another section...Please use the linked references at the bottom of the page for more detailed information. Factors Affecting friction..... Static Friction..... Sliding/dynamic/kinetic friction..... Coefficients of Friction..... Rolling Friction..... Plain Bearings Friction..... Rolling Bearing Friction..... Clutch Brake Friction..... Bolted Joints..... Power Screws..... Press Fits.... Test Methods.... Linked Reference Info

Factors affecting the friction between surfaces Dry surfaces 1. For low surface pressures the friction is directly proportional to the pressure between the surfaces. As the pressure rises the friction factor rises slightly. At very high pressure the friction factor then quickly increases to seizing 2. For low surface pressures the coefficient of friction is independent of surface area. 3. At low velocities the friction is independent of the relative surface velocity. At higher velocities the coefficent of friction decreases. Well lubricated surfaces 1. The friction resistance is almost independent of the specific pressure between the surfaces. 2. At low pressures the friction varies directly as the relative surface speed 3. At high pressures the friction is high at low velocities falling as the velocity increases to a minimum at about 0,6m/s. The friction then rises in proportion the velocity 2. 4. The friction is not so dependent of the surface materials 5. The friction is related to the temperature which affects the viscosity of the lubricant Please refer to... Surface Friction Notes

Static Coefficient of Friction The static friction coefficient () between two solid surfaces is defined as the ratio of the tangential force (F) required to produce sliding divided by the normal force between the surfaces (N)

= F /N

For a horizontal surface the horizontal force (F) to move a solid resting on a flat surface F= x mass of solid x g. If a body rests on an incline plane the body is prevented from sliding down because of the frictional resistance. If the angle of the plane is increased there will be an angle at which the body begins to slide down the plane. This is the angle of repose and the tangent of this angle is the same as the coefficient of friction. . Sliding Coefficient of Friction When the tangential force F overcomes the frictional force between two surfaces then the surfaces begins to slide relative to each other. In the case of a body resting on a flat surface the body starts to move. The sliding frictional resistance is normally different to the static frictional resistance. The coefficient of sliding friction is expressed using the same formula as the static coefficient and is generally lower than the static coefficient of friction..

http://www.roymech.co.uk/Useful_Tables/Tribology/co_of_frict.htm

24/10/2011

Coefficients Of Friction

Page 2 of 7

Friction Coefficients A table below shows approximate friction coefficients for various materials. All values are approximate and are only suitable for guidance only. The sliding/lubricated values must be used with extreme care. The only way to determine the accurate coefficient of friction between two materials is to conduct experiments. Coefficients of friction are sensitive to atmospheric dust and humidity, oxide films, surface finish, velocity of sliding, temperature, vibration, and extent of contamination. In many cases the degree of contamination is perhaps the most important single variable.. Link Table of Coefficients of Friction The friction values provided are obtained by different test methods under different ambient conditions. This factor can also affect the results. Link Test Methods Rolling Friction When a cylinder rolls on a surface the force resisting motion is termed rolling friction. Rolling friction is generally considerably less than sliding friction. If W is the weight of the cylinder converted to force, or the force between the cylinder and the flat surface, and R is radius of the cylinder and F is the force required to overcome the rolling friction then. center>F = f x W/R f is the coefficient of rolling friction and has the same unit of length as the radius R -in the example below m (metres) Typical values for f are listed below Note: Values for rolling friction from various sources are not consistent and the following values should only be used for approximate calculations. Steel on Steel f = 0,0005m Wood on Steel f = 0,0012m Wood on Wood f = 0,0015m Iron on iron f = 0,00051m Iron on granite f = 0,0021m Iron on Wood f = 0,0056m Polymer on steel f = 0,002m Hardrubber on Steel f = 0,0077m Hardrubber on Concrete f = 0,01 -0,02m Rubber on Concrete f = 0,015 -0,035m

Plain Bearing Friction factors For values of rolling bearing friction Plain Bearing Friction Values Rolling Bearing Friction For values of rolling bearing friction Rolling Bearing Friction Values Clutch - Brake Friction Values The coefficient of friction value is important in the design and brakes and clutches. Various values are provided on the following linked page Clutch/Brake Materials Friction coefficient Bolted Joints The coefficient of friction is required in calculating tightening torques and resulting bolt tensile forces and stress and in calculating the resulting friction between the connected surfaces. Below are provided a small number of values showing approximate values of friction coefficients to be used for steel screw fastened connections. The values are only representative values and should be confirmed against other sources of information and preferably testing. Coefficient of Friction for screw threads Female Thread -Nut or Tapped Hole in steel(untreated) Male screw Friction Coefficient (Dry) Friction Coefficient (lub) Untreated Steel 0,12 - 0,18 0,10 - 0,17 Phosphated Steel 0,12 - 0,18 0,10 - 0,17 Cadmium Plated Steel 0,09 - 0,14 0,08 -0,23

http://www.roymech.co.uk/Useful_Tables/Tribology/co_of_frict.htm

24/10/2011

Coefficients Of Friction

Page 3 of 7

Galvanised steel 0,14 - 0,23 0,12 - 0,2 Degreased steel 0,19 - 0,25 Female Thread -Nut or Tapped Hole in steel(Galvanised) Male screw Friction Coeffient (Dry) Friction Coefficient(Lub.) Untreated Steel 0,14 - 0,2 0,12 - 0,18 Phosphated Steel 0,14 - 0,2 0,12 - 0,18 Cadmium Plated Steel 0,1 - 0,16 0,09 - 0,15 Galvanised steel 0,14 - 0,25 0,12 - 0,2 Degreased steel 0,19 - 0,25

Coefficient of Friction Nut/Bolt Face against Clamped surface Clamped Surface = Steel Friction Coeffient (Dry) Friction Coefficient(Lub.) 0,10 - 0,18 0,08 - 0.15 0,10 - 0,18 0,08 - 0,15 0,10 - 0,2 0,09 - 0,18 Clamped Surface -Galvanised Steel Friction Coefficient (Dry) Friction Coefficient (lub) 0,10 - 0,18 0,08 - 0,15 0,10 - 0,18 0,08 - 0,15 0,16 - 0,22 0,09 - 0,18

Bolt/Nut Mat'l Untreated Steel Phosphated Steel Galvanised steel Bolt/Nut Mat'l Untreated Steel Phosphated Steel Galvanised steel

Coefficient of friction between surfaces clamped by bolts /screws. These values allow calculation of the shear force necessary to cause slip between surfaces when clamped by bolts. Contact Surfaces Steel On Steel- No treatment Steel On Cast Iron- No treatment Steel On Steel- Machined (Degreased) Steel On Cast Iron- Machined (Degreased) Grit -Sandblasted surfaces Friction Factors for Power Screws The following factors are typical friction factors for power screw torque and efficiency calculations.. 1) Screw Thread Friction values (s) (Friction factors apply mainly for screw thread friction (s) - can be applied to collar friction(c) Screw Material Steel(Dry) Steel (Lubricated) Bronze (Lubricated) 2) Thrust collar Friction values (c) Surface Combinations Soft Steel on Cast Iron Hard Steel on Cast Iron Soft Steel on Bronze Hard Steel on Bronze Press Fit Mechanical Joints In mechanical engineering rotary motion can be transferred by mechanical connections between a shaft and hub using only a tight fit. Methods of achieving this type of connection include the engineered interference fit, the taper lock bush and hydraulic fit bush. These keyless shaft/hub connections all transfer torque by friction. The coefficient of friction used for designing these types of connections is dependent on the interface pressure, materials, surface condition, surface coatings etc. The coefficient of friction is also dependent on the method of installation. A different value result if the shaft is forced into the hub (force fit) compared to the value if the assemble is completed by heating the hub or freezing the shaft prior to assembly (shrink fit)... Various values of relevant coefficients of friction are provided below; Steel Hub , Steel Shaft unlubricated - force fit ...C. of Friction = 0,07 to 0,16 Steel Hub , Steel Shaft greased - force fit ...C. of Friction = 0,05 to 0,12 Steel Hub , Steel Shaft unlubricated - Shrink fit ...C. of Friction = 0,15 to 0,25 Steel Hub , Steel Shaft greased - Shrink fit ...C. of Friction = 0,08 to 0,16 Moving 0,12 0,09 0,08 0,06 Starting 0,17 0,15 0,10 0,08 Nut Material Brass Bronze 0,15-0,23 0,15-0,19 0,10-0,16 0,10-0,15 0,04-0,06 slip coefficient 0,15- 0,25 0,18 - 0,3 0,12- 0,18 0,15 - 0,25 0,48 - 0,55

Steel 0,15-0,25 0,11-0,17 0,08-0,12

Cast Iron 0,15-0,25 0,11-0,17 0,06-0,09

The manufacturers of the proprietary keyless hub/shaft systems indicate that their products are based on a coefficient of friction of 0,12 for lightly oiled connections and 0,15 for dry assemblies. These companies can provide surface coating fluids containing particles to increase the coefficient of friction i.e. coefficient of friction to 0,25 to 0,3. (ref links 1 below) The American Gear Manufactures Association (AGMA) recommends a value of between 0,12-0,15 for hydraulically expanded hubs and 0,15-0,20 for shrink or press fit hubs. When calculated the torque to be transmitted it is generally sufficient to use the simple equation T= ..d2.L.Pc/2 d= the shaft diameter L is the length of the interference joint. The surface pressure Pc is calculated typically using lame's equation.

http://www.roymech.co.uk/Useful_Tables/Tribology/co_of_frict.htm

24/10/2011

Coefficients Of Friction

Page 4 of 7

Calculators are available for obtaining the transmitted toque very conveniently. Tribology -abc Engineers edge - press fit calculatgor Testing Methods There are a number of test methods for coefficient of frictions as some of which are listed below Flat block pressed against a OD of rotating ring (FOR) Flat block against another flat block (FOF) Flat block sliding down an inclined runway(IS) Pin pressed against a OD of rotating ring (POR Reciprocating loaded spherical end pin pressed on a flat surface(RSOF)

It is clear that the different test methods provide different friction results..

Coefficient of Friction Extreme care is needed in using friction coefficients and additional independent references should be used. For any specific application the ideal method of determining the coefficient of friction is by trials. A short table is included above the main table to illustrate how the coefficient of friction is affected by surface films. When a metal surface is perfectly clean in a vacuum , the friction is much higher than the normal accepted value and seizure can easily occur. ......The links below the tables provide further information. Effect of oxide film etc on coefficient of static friction Material Steel-Steel Copper-Copper Clean Dry 0,78 1,21 Thick Oxide Film 0,27 0,76 Sulfide Film 0,39 0,74

The level of uncertainty of the information below is indicated by using steel on steel as an example. Various reference sources provide values similar to the values below.(0,74 Static- 0,42 sliding) Gieck( 7th ed) provides values of (0,15...0,30 Static - 0,10...0,30 sliding). Concise Metals Data Handbook by J.R. Davis (table 14,1) includes values (0,31 static -0,23 sliding - for steel 1032? on steel 1032?).. The same table includes a value for mild steel on mild steel of 0,62 sliding.

Coefficient Of Friction Material 1 Material 2 Static Aluminum Aluminum Brake Material Brake Material Brass Brick Bronze Bronze Cadmium Cadmium Cast Iron Cast Iron Chromium Copper Copper Copper Copper Copper Copper-Lead Alloy Diamond Diamond Glass Glass Glass Graphite Graphite Graphite (In vacuum) Hard Carbon Hard Carbon Iron Aluminum Mild Steel Cast Iron Cast Iron (Wet) Cast Iron Wood Cast Iron Steel Cadmium Mild Steel Cast Iron Oak Chromium Cast Iron Copper Mild Steel Steel Steel (304 stainless) Steel Diamond Metal Glass Metal Nickel Graphite Steel Graphite (In vacuum) Hard Carbon Steel Iron 0,23 0,22 0,1 0,1 -0,15 0,9 - 1,0 0,5 - 0,7 0,78 0,1 0,1 0,5 - 0,8 0,16 0,14 1,0 0,12 - 0,14 0,11 - 0,14 0,15 - 0,2 0,56 0,1 0,1 0,4 0,41 1,05 1,0 0,53 0,36 0,8 0,21 0,05 - 0,1 0,1 0,1 - 0,6 0,2 - 0,3 0,09-0,12 0,29 0,08 0,18 SPOF FOF 1,1 0,5 0,46 0,15 0,49 0,34 0,07 0,075 0,6 0,22 0,16 0,05 1,05-1,35 0,61 0,4 0,2 0,3 1,4 0,47 DRY Sliding 0,3 Static Greasy Sliding Test method

http://www.roymech.co.uk/Useful_Tables/Tribology/co_of_frict.htm

24/10/2011

Coefficients Of Friction

Page 5 of 7

Lead Lead Leather Leather Leather Leather Magnesium Nickel Nickel Nylon Oak Oak Platinum Plexiglas Plexiglas Polystyrene Polystyrene Polythene Rubber Rubber Rubber Rubber Saphire Silver Sintered Bronze Solids Steel Steel Steel(Mild) Steel (Mild) Steel Steel Steel (Hard) Steel Steel (Mild) Steel (Mild) Steel Steel(Hard) Steel(Hard) Steel (Mild) Steel (Mild) Steel(Hard) Steel Teflon Teflon Tin Titanium Alloy Ti-6Al-4V(Grade 5) Titanium Alloy Ti-6Al-4V(Grade 5) Titanium Alloy Ti-6Al-4V(Grade 5) Tungsten Carbide Tungsten Carbide Tungsten Carbide Tungsten Carbide Wood Wood Wood Wood Wood Wood Zinc Zinc

Cast Iron Steel Wood Metal(Clean) Metal(Wet) Oak (Parallel grain) Magnesium Nickel Mild Steel Nylon Oak (parallel grain) Oak (cross grain) Platinum Plexiglas Steel Polystyrene Steel Steel Asphalt (Dry) Asphalt (Wet) Concrete (Dry) Concrete (Wet) Saphire Silver Steel Rubber Aluminium Bros Brass Brass Cast Iron Cast Iron Copper Lead Alloy Graphite Graphite Lead Phos. Bros Phos Bros Polythened Polystyrene Steel (Mild) Steel (Mild) Steel (Hard) Zinc (Plated on steel) Steel Teflon Cast Iron Aluminium Alloy 6061-T6 Titanium Alloy Ti-6Al-4V(Grade 5) Bronze Tungsten Carbide Steel Copper Iron Wood(clean) Wood (Wet) Metals(Clean) Metals (Wet) Brick Concrete Zinc Cast Iron 0,41 0,36 0,36 0,2-0,25 0,4 - 0,6 0,35 0,8 0,25 - 0,5 0,2 0,2-0,6 0,2 0,6 0,62 0,6 0,85 0,35 0,2 0,3-0,35 0,74 0,78 0,5 0,04 0,04 0,4 0,22 0,21 0,1 0,95 0,2 1,4 1,0 - 4,0 0,45 0,35 0,51 0,15 - 0,25 0,62 0,54 1,2 0,8 0,4 - 0,5 0,5 0,3-0,35 0,2 0,3 - 0,4 0,6 0,4 0,61 0,6 0,7-1,1

0,43 1,4 0,2 0,52 0,08 0,53 0,64; 0,48 0,32 0,25 0,8 0,4 - 0,5 0,5 0,3-0,35 0,2 0,5-0,8 0,25-0,75 0,6-0,85 0,45-0,75 0,2 0,55 0,13 -0,19 0,44 0,23 0,183 0,21 0,16 0,09 0,1 0,95 0,34 0,2 0,3-0,35 0,57 0,62 0,42 0,45 0,05 -0,11 0,04 0,04 ,32 0,38 0,30 0,27 0,12 0,08 - 0,2 FOF FOF FOF 0,029-,12 0,04 0,04 0,09-0,19 FOR 0,5 0,3 0,173 0,145 0,133 0,072 0,28 0,12 0,178 SPOF

0,04 0,21 Coefficient Of Friction

Material 1

Material 2 Static

DRY Sliding

LUBRICATED Static Sliding

Test method

http://www.roymech.co.uk/Useful_Tables/Tribology/co_of_frict.htm

24/10/2011

Coefficients Of Friction

Page 6 of 7

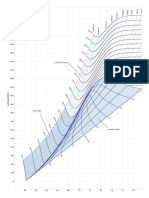

FOR = Flat against rotating Cylinder, FOF = Flat against flat, POF = Pin on flat, IS = inclined surface,SPOF Spherical end pin on flat. Source of above values.... The values are checked against a variety of internet and literature sources including the links below eg Link 6-Page 16. I have referred to books including Machinerys Handbook Eighteenth edition, Kempes Engineers Year Book 1980, Concise Metals Handbook by J.R.Davis ASM - (Good source of referenced data) and Kurt Giecks Engineering Formulas 7th Edition.. 1980, etc etc Table of friction Values for elements I provide the table below as a consistent set of values for simple elements using the simplest of test methods. It can be seen that values are generally different to the values in the table above... Friction tests in air at room temperature. (50% relative humidity)

Fixed Surface

Moving Block

Friction coefficient Static Sliding 0,5 0,53 0,48 0,49 0,57 0,54 0,53 0,49 0,79 0,52 0,56 0,41 0,41 0,46 0,44 0,46 0,55 0,50 0,49 0,56 0,41 0,48 0,51 0,51 0,46 0,49 0,47 0,55 1,46 0,69 0,46 0,44 0,46 0,59 0,50 0,64 0,73 0,61 0,55 0,53 0,54 0,90 0,64 0,55 0,55 0,74 0,54 0,55 0,41 0,47 0,51 0,56

Test Method

Silver (Ag)

Silver (Ag) Gold(Au) Copper(Cu) Iron(Fe)

Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Incline Plane Flat Sliding Incline Plane Incline Plane Incline Plane Incline Plane

Aluminium(Al) Gold(au) Cadmium(Cd) Cobalt(Co) Chromium(Cr) Copper(Cu)

Aluminium(Al) Titanium (Ti) Silver (Ag) Gold(Au) Cadmium(Cd) Iron(Fe) Cobalt(Co) Chromium(Cr) Cobalt(Co) Chromium(Cr) Cobalt(Co) Chromium(Cr) Copper(Cu) Iron(Fe) Nickel(Ni) Zinc(Zn)

Iron(Fe)

Cobalt(Co) Chromium(Cr) Iron(Fe) Maganese(Mg) Molybdenum(Mo) Titanium(Ti) Tungsten(W) Zinc(Zn)

Indium(In) Maganese(Mg) Molybdenum(Mo) Niobium(Nb) Nickel(Ni)

Indium(In) Maganese(Mg) Iron(Fe) Molybdenum(Mo) Niobium(Nb) Chromium(Cr) Nickel(Ni) Platinum(Pt)

Lead(Pb)

Silver (Ag) Gold(Au) Copper(Cu) Chromium(Cr) Iron(Fe) Lead(Pb)

Platinum(Pt) Tin(Sn) Titanium(Ti) Tungsten(W)

Nickel(Ni) Platinum(Pt) Iron(Fe) Tin(Sn) Aluminium(Al) Titanium(Ti) Copper(Cu) Iron(Fe) Tungsten(W)

Zinc(Zn)

Copper(Cu)

http://www.roymech.co.uk/Useful_Tables/Tribology/co_of_frict.htm

24/10/2011

Coefficients Of Friction

Page 7 of 7

Iron(Fe) Zinc(Zn)

0,55 0,75

Incline Plane Incline Plane

Links to Friction Information 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. Carbide Depot.. Friction Coefficients Supercivilcd Com.. Coefficient of Sliding Friction for various civil Materials Fastener Design Manual...NASA GRC RP-1228 (9,6 Mbyte pdf file) Includes comprehensive table with friction values. Physlinks - Coefficient of Friction...A Table of Friction Coefficients Engineers Edge- Coefficient of Friction...A Table of Friction Coefficients School for Champions...Lots of very useful Notes Bolt Council...Guide to Design Criteria for Bolted and Riveted Joints.(6,7 Mbyte pdf ). Info on Slip coefficients (P.82) etc MD Metric...Datasheet for PTFE Friction coefficients in "Rail- Wheel" contacts .......Downloadable paper providing very theoretical information Hypertextbooks _Physics Factbooks.....Physics Factbook .A page inlcuding a number of very good (school) articles on coe-fficents of friction of different materials Fund'ls of Friction and Wear of Automobile Brake Materials .....Paper Download ..Very informative document Classical Friction...A very simple and clear description of what determines the coefficient of friction. 12 Friction...Brown University-Division of Engineering..Very clear document on friction Rolling Friction...Very useful notes on rolling friction

Ads by Google

Steel Plate Steel Beams Metric Steel

This Page is being developed

Home Tribology_Index Please Send Comments to Roy Beardmore Last Updated 10/09/2010

http://www.roymech.co.uk/Useful_Tables/Tribology/co_of_frict.htm

24/10/2011

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Magnetophoresis and Electromagnetophoresis of Microparticles in LiquidsDocumento7 páginasMagnetophoresis and Electromagnetophoresis of Microparticles in Liquids3issazakaAinda não há avaliações

- The Power of Human Connection Review 2Documento81 páginasThe Power of Human Connection Review 2Tajam SoftAinda não há avaliações

- Pavement Materials - AggregatesDocumento14 páginasPavement Materials - AggregatestombasinghAinda não há avaliações

- Pre Calculus MIdTermsDocumento5 páginasPre Calculus MIdTermsLamette Austria Ayong0% (1)

- App NandDocumento30 páginasApp NandRajesh MedampudiAinda não há avaliações

- BSS - Report - Effect of Heat in A Building DemonstratorDocumento15 páginasBSS - Report - Effect of Heat in A Building DemonstratorAh Mok100% (1)

- 86-Article Text-596-1-10-20211030Documento7 páginas86-Article Text-596-1-10-20211030adel bbAinda não há avaliações

- Hazardous Area ClassificationDocumento36 páginasHazardous Area Classificationvenkeeku100% (1)

- Mollier Enthalpy Entropy Chart For Steam - US UnitsDocumento1 páginaMollier Enthalpy Entropy Chart For Steam - US Unitslin tongAinda não há avaliações

- OVA37066E: Product Data SheetDocumento2 páginasOVA37066E: Product Data SheetFred BionAinda não há avaliações

- OODBMSDocumento19 páginasOODBMSashimsarkar2006Ainda não há avaliações

- Physics Sample Question PaperDocumento9 páginasPhysics Sample Question PaperVarsha SharmaAinda não há avaliações

- Teaching and Learning Plan (TLP) : S. P. Mandali'S Prin L. N. Welingkar Institute of Management Development & ResearchDocumento6 páginasTeaching and Learning Plan (TLP) : S. P. Mandali'S Prin L. N. Welingkar Institute of Management Development & ResearchBhagath VarenyaAinda não há avaliações

- Mackie USB Driver InstructionsDocumento4 páginasMackie USB Driver InstructionsSamuel CotoAinda não há avaliações

- Binary PDFDocumento13 páginasBinary PDFbyprasadAinda não há avaliações

- FlopX NT5.1 Patch V1aDocumento5 páginasFlopX NT5.1 Patch V1aAmilcar AndradeAinda não há avaliações

- Case Study Class 12 Physics ImportantDocumento5 páginasCase Study Class 12 Physics Importantdivanshu2006yadavAinda não há avaliações

- Ap Unit 1 NotesDocumento42 páginasAp Unit 1 NotesDhruv GoyalAinda não há avaliações

- ABAP Training PlanDocumento4 páginasABAP Training PlanAhmed HamadAinda não há avaliações

- Lecture 5Documento35 páginasLecture 5MAHAMA SADIKAinda não há avaliações

- TribunaloLo Ex#6Documento14 páginasTribunaloLo Ex#6Jaylou OpondaAinda não há avaliações

- FP - ES - 28 - Rindu Grahabhakti Intani - PERMEABLE ENTRY CHARACTERIZATION AT DARAJAT FIELD, WEST JAVA PDFDocumento4 páginasFP - ES - 28 - Rindu Grahabhakti Intani - PERMEABLE ENTRY CHARACTERIZATION AT DARAJAT FIELD, WEST JAVA PDFrindu_intaniAinda não há avaliações

- Kids Curriculum BreakdownDocumento6 páginasKids Curriculum BreakdownSuniel ChhetriAinda não há avaliações

- Elecon GearboxDocumento19 páginasElecon GearboxShirley Farrace100% (3)

- MTH 108Documento10 páginasMTH 108GetlozzAwabaAinda não há avaliações

- Brazil (1997) The Communicative Value BW PDFDocumento200 páginasBrazil (1997) The Communicative Value BW PDFJuan LopezAinda não há avaliações

- 09.0 Product Description - MAN EcoTorqueDocumento2 páginas09.0 Product Description - MAN EcoTorquegoginemAinda não há avaliações

- C.KESAVAN - Diploma EEE: Phone No Mail IdDocumento3 páginasC.KESAVAN - Diploma EEE: Phone No Mail IdKesavan ChinaswmiAinda não há avaliações

- 2nd Grading LAA Grade 10Documento54 páginas2nd Grading LAA Grade 10Urduja Kyle OdiacerAinda não há avaliações