Escolar Documentos

Profissional Documentos

Cultura Documentos

Member - Light Gage Structural Institute

Enviado por

Ramees Mohamed ODescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Member - Light Gage Structural Institute

Enviado por

Ramees Mohamed ODireitos autorais:

Formatos disponíveis

y

SHEAR CENTER

STEEL FRAMING COMPONENTS

B d GAUGE

EAVE STRUT

Xo y

_ X

R=0.1875

ST

R UCT U R

AL

HT G AG E

IN S

T IT U T

LIG

E

#

ES

T . 19 9

MEMBER - LIGHT GAGE STRUCTURAL INSTITUTE

HATS

Pattern A

B1 50

Pattern D and E

SHEAR CENTER

GAUGE X X R=0.1875 D

d Y

B2

STEEL FRAMING COMPONENTS

Welcome to the World of PROLAMSA!

Thank you for your interest in PROLAMSA, Mexicos largest producer of as welded mechanical tubing, secondary building components and shapes. PROLAMSA, a leader throughout Latin America, is expanding its secondary building components lines, and we are pleased to provide this catalog for your use. The following pages contain technical specifications. At the back youll find sales literature about our products. Because we refine our product offerings to make certain you can get what you need, some of this information may change. To insure you have the latest information available, please visit our Web site at www.prolamsa.com. For pricing and product information, you may also: email us: sales@prolamsausa.com call us: 281-494-0900 fax us: 281-494-0990 We look forward to serving you.

STEEL FRAMING COMPONENTS

TABLE OF CONTENTS

Commercial / Industrial

General Notes...... 4 Manufacturing & Product Information.. 5 Definitions of Loads & Lap Conditions.... 6 Punching Patterns for Cees & Zees............. 9 Lap Patterns for Cees & Zees....... 11 Punching Patterns for Eave Struts...... 15 C-Section Specifications & Properties........... 19 Z-Section Specifications & Properties........ 20 Eave Struts, Angles & Channels....... 21 Hats & Girts.....22 Light Gage Structural Institute........................ 23 LGSI Framing System Design Handbook. Please Inquire

In a continuing effort to refine and improve products, PROLAMSA reserves the right to discontinue products at any time or change specifications and/or designs without incurring obligation. To insure you have the latest information available, please inquire or visit our Web site at http://www.prolamsa.com. Application details are for illustration purposes only and may not be appropriate for all environmental conditions or building designs. Projects should be engineered to conform to applicable building codes, regulations, and accepted industry practices.

STEEL FRAMING COMPONENTS

GENERAL NOTES

PROLAMSA offers a complete line of structural shapes, formed using high strength steel, ASTM A-570 (55,000 psi min. yield point), finished with a baked-on red oxide primer finish or G-90 galvanized finish. Substructural components from PROLAMSA are manufactured in Light Gage Structural Institute (LGSI) sections. LGSI sections have been found to have numerous advantages, including greater ease of installation. Consult the LGSI technical manual for proper product application. All standard structural shapes (except eave struts, hats and girts) are roll-formed to ensure a maximum quality finished product. Standard web and flange punching are available upon request. Custom punching is another feature that PROLAMSA provides. Please contact our office for pricing and availability. PROLAMSA produces many open shapes and sizes that can be manufactured to your design specifications.

STEEL FRAMING COMPONENTS

MANUFACTURING & PRODUCT INFORMATION

1. Standard Z-Sections (Zees) are manufactured with unsymmetrical and symmetrical flange. 2. All C-Sections (Cees) are manufactured with symmetrical flanges only. 3. Cee and Zee purlins are supplied in either of two finishes: Red Oxide Primer and Galvanized. 4. Cee purlins web sizes range from 4 to 14 in half-inch steps. 5. Cee purlins flange are the same size, and range from 2 to 4. 6. Zee purlins web sizes range from 3-1/2 to 14 in one-inch steps. 7. Zee purlins nominal flange standard sizes come with different actual flange widths. 8. Web punching is available on 6 to 12 Zees and 6 to 10 Cees. Punching is not available on 4 or smaller Cees and Zees. 9. Flange punching is available on 8 to 10 Cees and Zees. 10. Perforation sizes are 5/8 x 3/4 slots. 11. Three web punching patterns are available. Pattern A is standard; patterns C and B are optional. 12. Minimum Lengths: Non-punched purlins: 7- 0 Punched purlins: Patterns A and D 9-1 Patterns B and E 12-6 Patterns C and F 8-0 Pattern G 7-0

NOTES: Red oxide components are painted with primers designed for short-term field protection during the erection process. Handling scratches and abrasions are common and will rust if not touched up promptly.

Consult the Light Gage Structural Institute (LGSI) Manual for engineering information.

STEEL FRAMING COMPONENTS

DEFINITIONS OF LOADS & LAP CONDITIONS

LIVE LOAD (ROOF) Live loads are loads that are produced both during and after construction by movable objects other than wind, snow, seismic and dead loads. Frequently used values for live loads are shown in this table.

ROOF LIVE LOADS

Loaded Area for Any Structural Member (FT2) Roof Slope 0-200 200-600 Over 600 .25:12 to 4:12 20 16 12 4:12 to 12:12 16 14 12 Over 12:12 12 12 12

SNOW LOAD The value used for snow load will be specified by your local building codes. Special conditions that will encourage heavier than normal accumulations should be considered, such as multiple gables, abrupt changes in roof elevation, etc. WIND LOAD Wind load is the amount of load that is imposed on a structure as a result of wind in any horizontal direction. The value you use for wind load is determined by local building codes. Wind action on a structure causes forces to be applied on all exposed surfaces. Determining the wind load value for a roof or wall requires the use of coefficients. The sample calculations refer to the coefficients in this table.

SURFACE ROOF WALLS MEMBER TYPE PURLINS GIRTS SYMBOL RCOEF WCOEF

Consult the Light Gage Structural Institute (LGSI) Manual for engineering information.

STEEL FRAMING COMPONENTS

To obtain the values for these coefficients, refer to local building codes. Typical values for RCOEF and WCOEF are 1.2 and 1.1 respectively. These apply only to enclosed buildings with a roof slope of less than 10 degrees.

DEAD LOAD Dead load is the weight of the building components that are being supported by the section. COLLATERAL LOAD Collateral load is the weight of additional permanent materials, such as sprinklers, mechanical and electrical systems, partitions and ceiling. Collateral loads do not include dead loads.

Consult the Light Gage Structural Institute (LGSI) Manual for engineering information.

STEEL FRAMING COMPONENTS

LOAD COMBINATIONS The value for live load in the sample calculations is the larger of live load and snow load, as defined above. This value is combined with dead load and collateral load in the sample calculations under the heading DEAD + LIVE load. STRUCTURAL MATERIAL SPECIFICATIONS For all Cee, Zee and Eave Strut sections: Fu = 64.7 ksi Fy = 55.0 ksi LAP CONDITIONS

Consult the Light Gage Structural Institute (LGSI) Manual for engineering information.

STEEL FRAMING COMPONENTS

WEB PUNCHING PATTERNS FOR CEES & ZEES

Pattern A

Web punching is available on all 6 10 Zees and Cees and 12 Zees.

Pattern B

Pattern C

NOTES: 1. Common flange punching Pattern D has Pattern A in the web. Common flange punching Pattern E has Pattern B in the web. 2. Punching is not available on 4 or smaller Cees and Zees. 3. All slots are 5/8 x 3/4.

Pattern G

Common End

Consult the Light Gage Structural Institute (LGSI) Manual for engineering information.

STEEL FRAMING COMPONENTS

FLANGE PUNCHING PATTERNS FOR CEES & ZEES

Flange punching is available on 8 and 10 Zees and Cees.

Patterns D and E

Pattern F

NOTES: 1. Common flange punching Pattern D has Pattern A in the web. Common flange punching Pattern E has Pattern B in the web. 2. Punching is not available on 4 or smaller Cees and Zees. 3. All slots are 5/8 x 3/4.

10

Consult the Light Gage Structural Institute (LGSI) Manual for engineering information.

STEEL FRAMING COMPONENTS

LAP PATTERNS FOR CEES & ZEES

Pattern A

TYPICAL

TYPICAL FLANGE BRACE

SIMPLE SPAN

TOTAL LAP

SHORT LAP

TOTAL LAP

LONG LAP

Consult the Light Gage Structural Institute (LGSI) Manual for engineering information.

11

STEEL FRAMING COMPONENTS

LAP PATTERNS FOR CEES & ZEES

Pattern A (continued)

TOTAL LAP

THREE FOOT OFFSET LAP

TOTAL LAP

MAX LAP

12

Consult the Light Gage Structural Institute (LGSI) Manual for engineering information.

STEEL FRAMING COMPONENTS

LAP PATTERNS FOR CEES & ZEES

Pattern B

(includes all laps available in Pattern A)

TOTAL LAP

FLANGE BRACE

FIVE FOOT OFFSET LAP

TOTAL LAP

SUPER LAP

Consult the Light Gage Structural Institute(LGSI) Manual for engineering information.

13

STEEL FRAMING COMPONENTS

LAP PATTERNS FOR CEES & ZEES

Pattern C

TYPICAL

SIMPLE SPAN

TOTAL LAP

SHORT LAP

TOTAL LAP

LONG LAP

14

Consult the Light Gage Structural Institute (LGSI) Manual for engineering information.

STEEL FRAMING COMPONENTS

PUNCHING PATTERNS FOR 8 x 5 x 5 EAVE STRUTS

Standard

UNIVERSAL SINGLE SLOPE DOUBLE SLOPE

FLANGE PUNCHING SIDE VIEW

NOTES 1. All slots are 5/8 x 3/4. 2. Eave strut is 14 gauge. 3. Universal eave strut is designed for all roof slopes 1:12 through 4:12.

Consult the Light Gage Structural Institute (LGSI) Manual for engineering information.

15

STEEL FRAMING COMPONENTS

PUNCHING PATTERNS FOR 8 x 5 x 5 EAVE STRUTS

Optional

UNIVERSAL SINGLE SLOPE DOUBLE SLOPE

FLANGE PUNCHING SIDE VIEW

NOTES: 1. All slots are 5/8 x 3/4. 2. Eave strut is 14 gauge.

16

Consult the Light Gage Structural Institute (LGSI) Manual for engineering information.

STEEL FRAMING COMPONENTS

PUNCHING PATTERNS FOR 8 x 5 x 2-3/4 EAVE STRUTS

Standard

LOW EAVE DOUBLE SLOPE HIGH EAVE DOUBLE SLOPE LOW EAVE SINGLE SLOPE HIGH EAVE SINGLE SLOPE

FLANGE PUNCHING SIDE VIEW

NOTES: 1. All slots are 5/8 x 3/4. 2. Eave strut is 14 gauge.

Consult the Light Gage Structural Institute (LGSI) Manual for engineering information.

17

STEEL FRAMING COMPONENTS

PUNCHING PATTERNS FOR 8 x 5 x 2-3/4 EAVE STRUTS

Optional

LOW EAVE DOUBLE SLOPE HIGH EAVE DOUBLE SLOPE LOW EAVE SINGLE SLOPE HIGH EAVE SINGLE SLOPE

FLANGE PUNCHING SIDE VIEW

NOTES: 1. All slots are 5/8 x 3/4. 2. Eave strut is 14 gauge.

18

Consult the Light Gage Structural Institute (LGSI) Manual for engineering information.

STEEL FRAMING COMPONENTS

C-SECTION SPECIFICATIONS & PROPERTIES

Gross Section Properties

C-SECTIONS

DIMENSIONS

Section

12 X 3.5 C 12 X 3.5 C 10 X 3.5 C 10 X 3.5 C 10 X 2.5 C 10 X 2.5 C 8 X 3.5 C 8 X 3.5 C 8 X 3.5 C 8 X 2.5 C 8 X 2.5 C 8 X 2.5 C 6 X 2.5 C 6 X 2.5 C 4 X 2.5 C 4 X 2.5 C

PROPERTIES OF FULL SECTION Axis x-x Axis y-y Gauge M inim um

12 (0.096") 14 (0.069") 12 (0.096") 14 (0.069") 12 (0.096") 14 (0.069") 12 (0.096") 14 (0.069") 16 (0.056") 12 (0.096") 14 (0.069") 16 (0.056") 14 (0.069") 16 (0.056") 14 (0.069") 16 (0.056")

D in.

12 12 10 10 10 10 8 8 8 8 8 8 6 6 4 4

B in.

3.5 3.5 3.5 3.5 2.5 2.5 3.5 3.5 3.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5

d in.

0.885 0.800 0.885 0.800 0.885 0.800 0.885 0.800 0.773 0.885 0.800 0.773 0.800 0.773 0.800 0.773

R in.

0.1875 0.1875 0.1875 0.1875 0.1875 0.1875 0.1875 0.1875 0.1875 0.1875 0.1875 0.1875 0.1875 0.1875 0.1875 0.1875

Area in.

2

wt/ft lb

7.271 5.195 6.542 4.673 5.812 4.152 5.812 4.152 3.321 5.083 3.631 2.905 3.110 2.488 2.589 2.071

Ix 4 in.

43.753 29.370 28.452 19.134 23.311 15.683 16.918 11.410 9.651 13.645 9.209 7.791 4.686 3.971 1.834 1.559

Sx 3 in.

7.292 4.895 5.690 3.827 4.662 3.137 4.229 2.852 2.413 3.411 2.302 1.948 1.562 1.324 0.917 0.780

rx in.

4.572 4.587 3.887 3.904 3.732 3.749 3.180 3.198 3.204 3.054 3.072 3.078 2.368 2.374 1.624 1.631

Iy 4 in.

3.069 2.043 2.909 1.938 1.275 0.852 2.710 1.807 1.523 1.194 0.799 0.674 0.729 0.615 0.630 0.532

Sy 3 in.

1.171 0.773 1.150 0.759 0.682 0.451 1.123 0.741 0.623 0.669 0.442 0.372 0.429 0.361 0.408 0.343

ry in.

1.211 1.210 1.243 1.242 0.873 0.874 1.273 1.273 1.273 0.903 0.905 0.906 0.934 0.935 0.952 0.953

x bar in.

0.879 0.855 0.971 0.947 0.632 0.610 1.086 1.061 1.053 0.715 0.692 0.685 0.802 0.795 0.957 0.949

Ixy 4 in.

1.493 0.941 1.238 0.781 0.854 0.542 0.984 0.621 0.514 0.678 0.431 0.357 0.320 0.265 0.209 0.173

2.093 1.396 1.883 1.256 1.673 1.116 1.673 1.116 0.94 1.463 0.976 0.822 0.836 0.704 0.696 0.586

GAUGE x x

R=0.1875

Xo y

NOTES: Consult the LGSI technical manual for proper product application, design details, and other product information All Cees available in Red Oxide Primer and Galvanized finish. Properties are based on ASTM A570/A607 Grade 55 or 60 having a minimum yield strength of 55 ksi.

Consult the Light Gage Structural Institute (LGSI) Manual for engineering information.

19

STEEL FRAMING COMPONENTS

Z-SECTION SPECIFICATIONS & PROPERTIES

Gross Section Properties

Z-SECTIONS

DIMENSIONS

Section 12 X 3.5 Z 12 X 3.5 Z 10 X 3.5 Z 10 X 3.5 Z 10 X 2.5 Z 10 X 2.5 Z 8 X 3.5 Z 8 X 3.5 Z 8 X 3.5 Z 8 X 2.5 Z 8 X 2.5 Z 8 X 2.5 Z 6 X 2.5 Z 6 X 2.5 Z 4 X 2.5 Z 4 X 2.5 Z 3.5 X 1.5 Z 3.5 X 1.5 Z D in. 12 12 10 10 10 10 8 8 8 8 8 8 6 6 4 4 3.5 3.5 B1 in. 3.125 3.125 3.125 3.125 2.125 2.125 3.125 3.125 3.125 2.125 2.125 2.125 2.125 2.125 2.125 2.125 1.500 1.500 B2 in. 3.375 3.375 3.375 3.375 2.375 2.375 3.375 3.375 3.375 2.375 2.375 2.375 2.375 2.375 2.375 2.375 1.500 1.500 d in. 0.990 0.930 0.990 0.930 0.990 0.930 0.990 0.930 0.911 0.990 0.930 0.911 0.930 0.911 0.930 0.911 0.680 0.661 g deg 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 R in. 0.1875 0.1875 0.1875 0.1875 0.1875 0.1875 0.1875 0.1875 0.1875 0.1875 0.1875 0.1875 0.1875 0.1875 0.1875 0.1875 0.1875 0.1875 Area in.2 2.093 1.396 1.883 1.256 1.673 1.116 1.673 1.116 0.940 1.463 0.976 0.822 0.836 0.704 0.696 0.586 0.534 0.450 Gauge Minimum 12 (0.096") 14 (0.069") 12 (0.096") 14 (0.069") 12 (0.096") 14 (0.069") 12 (0.096") 14 (0.069") 16 (0.056") 12 (0.096") 14 (0.069") 16 (0.056") 14 (0.069") 16 (0.056") 14 (0.069") 16 (0.056") 14 (0.069") 16 (0.056") wt/ft lb 7.118 4.745 6.404 4.269 5.690 3.793 5.690 3.793 3.197 4.976 3.317 2.796 2.841 2.395 2.365 1.993 1.815 1.529 Ix in.4 43.717 29.32 28.423 19.093 23.281 15.641 16.895 11.377 9.62 13.621 9.176 7.759 4.662 3.947 1.819 1.544 1.003 0.853

PROPERTIES OF FULL SECTION

Axis x-x Sx in.3 7.197 4.827 5.607 3.767 4.585 3.08 4.159 2.801 2.368 3.346 2.254 1.906 1.522 1.289 0.887 0.754 0.573 0.488 rx in. 4.57 4.584 3.885 3.9 3.73 3.744 3.177 3.194 3.199 3.051 3.067 3.072 2.362 2.367 1.617 1.623 1.371 1.377 Iy in.4 4.68 3.077 4.679 3.077 1.967 1.289 4.679 3.076 2.582 1.966 1.289 1.081 1.288 1.08 1.288 1.08 0.444 0.371 Axis y-y Sy in.3 1.194 0.79 1.196 0.791 0.673 0.445 1.198 0.793 0.666 0.675 0.446 0.375 0.447 0.376 0.449 0.377 0.225 0.189 ry in. 1.495 1.485 1.576 1.565 1.084 1.075 1.672 1.661 1.657 1.159 1.149 1.146 1.242 1.238 1.361 1.357 0.912 0.908 y bar in. 5.873 5.89 4.879 4.896 4.87 4.887 3.886 3.903 3.908 3.877 3.894 3.899 2.903 2.908 1.916 1.921 1.715 1.721 Ixy in.4 10.177 6.75 8.422 5.592 4.733 3.136 6.666 4.434 3.734 3.738 2.481 2.088 1.827 1.539 1.173 0.99 0.504 0.425

B2 50

SHEAR CENTER

x R=0.1875 d B1 y

GAUGE

NOTES: Consult the LGSI technical manual for proper product application, design details, and other product information. All Zees available in Red Oxide Primer and Galvanized finish. Properties are based on ASTM A57/A607 Grade 55 or 60 having a minimum yield strength of 55 ksi.

20

Consult the Light Gage Structural Institute (LGSI) Manual for engineering information.

STEEL FRAMING COMPONENTS

EAVE STRUTS, ANGLES & CHANNELS

Eave Struts

NORMAL Size (in) 8" x 5" x 2 3/4" 8" x 5" x 5"

GAUGE Min. Thickness

14 ( 0.069") 16 ( 0.056") 14 (0.069") 16 ( 0.056")

WEIGHT Lb/Ft

4.348 3.478 4.932 3.945

All finishes 5 to 30. Properties are based on ASTM A570/A607 Grade 55 or 60 having a minimum yield strength of 55 ksi.

Angles

NORMAL Size (in) 2 1/2" x 2" 3" x 2" 3" x 3" 4" x 2" 6" x 4"

GAUGE Min. Thickness

14 16 14 16 14 16 14 16 14 16 ( ( ( ( ( ( ( ( ( ( 0.069") 0.056") 0.069") 0.056") 0.069") 0.056") 0.069") 0.056") 0.069") 0.056")

WEIGHT Lb/Ft

1.172 0.938 1.303 1.042 1.563 1.250 1.563 1.250 2.605 2.084

All finishes 5 to 25. Properties are based on ASTM A570/A607 Grade 55 or 60 having a minimum yield strength of 55 ksi.

Channels

NORMAL Size (in) 4 3/16" x 2" 6 3/16" x 2" GAUGE Min. Thickness

14 ( 0.069" 16 ( 0.056") 12 (0.096") 14 (0.069") 16 ( 0.056") 12 (0.096") 14 (0.069") 16 ( 0.056") 12 (0.096") 14 (0.069") 16 ( 0.056")

WEIGHT Lb/Ft

2.040 1.632 3.585 2.561 2.048 4.314 3.082 2.465 5.044 3.603 2.882

8 3/16" x 2"

10 3/16"" x 2"

All finishes 5 to 25. Properties are based on ASTM A570/A607 Grade 55 or 60 having a minimum yield strength of 55 ksi.

Consult the Light Gage Structural Institute (LGSI) Manual for engineering information.

21

STEEL FRAMING COMPONENTS

HATS & GIRTS

NORMAL Size (in) Hat Section # H1 Sub-Girt 1" # SG1 Sub-Girt 1/2" # SG2 GAUGE Min. Thickness

16 ( 0.056") 16 (0.056") 18 (0.045") 16 (0.056") 18 (0.045")

WEIGHT Lb/Ft

1.278 1.123 0.899 0.705 0.564

LENGTH

20 20 20 20 20

HAT #H1

1 SUB-GIRT #SG1

1/2 SUB-GIRT # SG2

22

Consult the Light Gage Structural Institute (LGSI) Manual for engineering information.

STEEL FRAMING COMPONENTS

LIGHT GAGE STRUCTURAL INSTITUTE

In an effort to promote efficient, safe use of member companies products, several manufacturers formed the Light Gage Structural Institute (LGSI) in 1989. The LGSI is a nonprofit organization composed of member companies who manufacture light gage coldformed sections. Those members, while cooperating to advance the state of the art in the metal component and metal building industries, continue to participate in a robust and highly competitive market for their products. LGSI members have adopted, and follow, an Antitrust Policy that requires all members to avoid any type of conduct that is anti-competitive or violates any federal or state antitrust laws. Companies that are members of LGSI conform to a set of bylaws and standards that ensure their compliance with the various policies set forth by the Institute. Specification advances incorporated in the 1986 and 1996 American Iron and Steel Institute Specification provide a framework for reaching the goals of LGSI member companies. The expanded LGSI manual, "Light Gage Structural Steel Framing System Design Handbook," is the result of LGSIs ongoing efforts. It builds on the success of the previous edition, which was widely used throughout the metal component and metal building industries.

Light Gage Structural Institute P.O. Box 560746 The Colony, TX 75056 (972) 625-4560 Fax: (972) 370-0968

23

Escobedo Plant and Headquarters

Professional. Pro-Active. Pro-Customer.

Prolamsa USA, Inc. (U.S. Headquarters) 770 South Post Oak Lane Suite 200, Houston, TX 77056 Tel (281) 494-0900 Fax (281) 494-0990 sales@prolamsausa.com Prolamsa (Mexico Headquarters) Carretera a Colombia Km. 5.75 Escobedo, N.L., Mexico C.P. 45560 Tel +52 (81) 8154-0200 Fax +52 (81) 8901-1709 www.prolamsa.com

www.prolamsausa.com

ISO 9002 certified QS-9000 certified

Você também pode gostar

- Inertia Base FrameDocumento2 páginasInertia Base FrameLasandu WanniarachchiAinda não há avaliações

- Handbook MogliceDocumento63 páginasHandbook MoglicesolidsverigeAinda não há avaliações

- Isuzu 2008 I290 Owner's ManualDocumento384 páginasIsuzu 2008 I290 Owner's ManualpapagunzAinda não há avaliações

- Alberta Specification For Bridge ConstructionDocumento468 páginasAlberta Specification For Bridge ConstructionkacemAinda não há avaliações

- High Pressure Washer Owner's Manual: Problems? Questions?Documento20 páginasHigh Pressure Washer Owner's Manual: Problems? Questions?Greggo1010Ainda não há avaliações

- Troy Bilt MowerDocumento20 páginasTroy Bilt MowerBob GinelAinda não há avaliações

- Static Analysis of Tractor Trolley AxleDocumento5 páginasStatic Analysis of Tractor Trolley AxleseventhsensegroupAinda não há avaliações

- WWMM Lumber Storage CartDocumento9 páginasWWMM Lumber Storage CartjlpicardAinda não há avaliações

- Split HangerDocumento6 páginasSplit HangerjlolhnpAinda não há avaliações

- DoubleLok ManualDocumento94 páginasDoubleLok Manualhviviani451Ainda não há avaliações

- Dietrich CatalogDocumento248 páginasDietrich CatalogAnonymous PjmE9RJcghAinda não há avaliações

- Software Verification: CSA A23.3-14 Example 002Documento4 páginasSoftware Verification: CSA A23.3-14 Example 002yudhi putraAinda não há avaliações

- Tech Bulletin 95-1060 MCA Oil CanningDocumento2 páginasTech Bulletin 95-1060 MCA Oil Canningm0172Ainda não há avaliações

- Owner Manual Swift 1 2L (Eng)Documento234 páginasOwner Manual Swift 1 2L (Eng)ginoAinda não há avaliações

- Machine Tools (Tk103n)Documento20 páginasMachine Tools (Tk103n)noragarcia76Ainda não há avaliações

- USDA Forest Service Floating Trail Bridges and DocksDocumento31 páginasUSDA Forest Service Floating Trail Bridges and DocksRockWagonAinda não há avaliações

- PIP STF05501 FixedLaddersAndCagesDocumento17 páginasPIP STF05501 FixedLaddersAndCageslopezmedgarAinda não há avaliações

- Craftsman Pressure WasherDocumento54 páginasCraftsman Pressure WasherGeorge LowryAinda não há avaliações

- Steel B.B.S. For Hotel at Sohana: ' (Inch.) (Inch.) (Inch.) (Inch.) (Inch.) Items X Bars A Foundations 1 F-1 Main 8Documento7 páginasSteel B.B.S. For Hotel at Sohana: ' (Inch.) (Inch.) (Inch.) (Inch.) (Inch.) Items X Bars A Foundations 1 F-1 Main 8rajendraAinda não há avaliações

- Agricultural Machinery Mech PDFDocumento263 páginasAgricultural Machinery Mech PDFDenis Yasmin AlineAinda não há avaliações

- An Easy-To-Follow Guide To Achieving A Perfect Result. - Outlines All The Tools You Will Need For The Job. - Includes A Materials ChecklistDocumento12 páginasAn Easy-To-Follow Guide To Achieving A Perfect Result. - Outlines All The Tools You Will Need For The Job. - Includes A Materials ChecklistIrinel DobrisorAinda não há avaliações

- Hubcity Spline&AgDocumento24 páginasHubcity Spline&AgMiiss PoojaAinda não há avaliações

- Steel Joist IntroDocumento11 páginasSteel Joist IntroKrup KolandAinda não há avaliações

- Dimension:: Blind RivetsDocumento1 páginaDimension:: Blind RivetsrimshadtpAinda não há avaliações

- Hougen CatalogDocumento40 páginasHougen CatalogchivetoAinda não há avaliações

- ITW Buildex Catalogue 2010-2011Documento48 páginasITW Buildex Catalogue 2010-2011Nugraha BintangAinda não há avaliações

- CTS Catalog 2019Documento80 páginasCTS Catalog 2019justin ClarkAinda não há avaliações

- Angle Section DimensionsDocumento4 páginasAngle Section DimensionsAnonymous q0irDXlWAmAinda não há avaliações

- Aop Portal Shed Construction ManualDocumento61 páginasAop Portal Shed Construction ManualbAinda não há avaliações

- Elocone NutsDocumento2 páginasElocone NutsThiago PasqualAinda não há avaliações

- Warning: Tow Dolly User InstructionsDocumento26 páginasWarning: Tow Dolly User InstructionsthatbaddogAinda não há avaliações

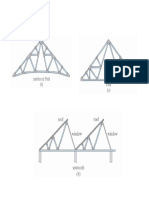

- Tech Brochures Truss Facts AusDocumento28 páginasTech Brochures Truss Facts AusDee Reyes100% (1)

- Msx150 Part DiagDocumento58 páginasMsx150 Part Diagmoi28Ainda não há avaliações

- What Is The Difference Between JASO MA and JASO MBDocumento1 páginaWhat Is The Difference Between JASO MA and JASO MBGuntér Ögies HijackerAinda não há avaliações

- 6th Edition (2017) Florida Building Code - Chapter I (With Amendments Effective Through November 25, 2019)Documento76 páginas6th Edition (2017) Florida Building Code - Chapter I (With Amendments Effective Through November 25, 2019)Myron BrandwineAinda não há avaliações

- Material Submittal - GRP Sectional Panel TanksDocumento204 páginasMaterial Submittal - GRP Sectional Panel Tanksmohamed kamalAinda não há avaliações

- "Weldgrp" - Weld Group Analysis ProgramDocumento1 página"Weldgrp" - Weld Group Analysis Programj_herndzAinda não há avaliações

- CI 4014 PMDocumento63 páginasCI 4014 PMrop703406Ainda não há avaliações

- Rivnut GBDocumento36 páginasRivnut GBJeffry KarundengAinda não há avaliações

- Anchor 101 - Anchoring Principles and DesignDocumento26 páginasAnchor 101 - Anchoring Principles and DesignPerry PintoAinda não há avaliações

- Victa Spare Parts Manual 1990s To Early 2000Documento62 páginasVicta Spare Parts Manual 1990s To Early 2000James HanlonAinda não há avaliações

- Honda HR21 5Documento40 páginasHonda HR21 5Ferenc Norbert100% (1)

- Canam Purlins and Girts Catalogue CanadaDocumento0 páginaCanam Purlins and Girts Catalogue CanadasaivanvalendezAinda não há avaliações

- Roof Structure Guide - Basics For The Design and Construction of Leightweight Sloped Roof Structures (SKAT, 1993, 144 PDocumento77 páginasRoof Structure Guide - Basics For The Design and Construction of Leightweight Sloped Roof Structures (SKAT, 1993, 144 PDauji SahaAinda não há avaliações

- 2007 Nissan Xterra 25Documento36 páginas2007 Nissan Xterra 25Roma Roma100% (1)

- CATALOGO Vulcraft DeckcatDocumento100 páginasCATALOGO Vulcraft DeckcatRicardo Jesus Mallma Cubas100% (1)

- Clearwater Self-Cleaning Suction Screen BrochureDocumento2 páginasClearwater Self-Cleaning Suction Screen BrochureIonut SomneaAinda não há avaliações

- Enerpac CLRG Series CatalogDocumento4 páginasEnerpac CLRG Series CatalogTitanplyAinda não há avaliações

- C CFS08Documento68 páginasC CFS08isaaaAinda não há avaliações

- 5' X 8' Single Axle TrailerDocumento34 páginas5' X 8' Single Axle Trailertony9waldronAinda não há avaliações

- Rubber Stopper DimensionsDocumento4 páginasRubber Stopper DimensionsSandraAinda não há avaliações

- 98 Tips For Designing Structural SteelDocumento5 páginas98 Tips For Designing Structural Steelklynchelle100% (2)

- Air 5065Documento11 páginasAir 5065niky186Ainda não há avaliações

- 98 Tips: For DesigningDocumento6 páginas98 Tips: For DesigningKarthikeyan KrishAinda não há avaliações

- 2010v09 98 TipsDocumento6 páginas2010v09 98 Tipsvenkatesh19701Ainda não há avaliações

- Pile SplicesDocumento27 páginasPile Splicesfree4bruceAinda não há avaliações

- Dayton Superior Bar-Lock Coupler SystemDocumento4 páginasDayton Superior Bar-Lock Coupler SystemJosh ReynoldsAinda não há avaliações

- Presentation On Reinforcing Detailing of R.CDocumento16 páginasPresentation On Reinforcing Detailing of R.CbertazcorpAinda não há avaliações

- Open Web Joist SystemDocumento122 páginasOpen Web Joist Systemaminjoles100% (3)

- SSMA Product Technical Guide 2014Documento72 páginasSSMA Product Technical Guide 2014Diego PovedaAinda não há avaliações

- Initial Load Test Pile-Calc (450 MM) Rev0Documento2 páginasInitial Load Test Pile-Calc (450 MM) Rev0sathishAinda não há avaliações

- Thumb RuleDocumento6 páginasThumb RuleShafique AhmedAinda não há avaliações

- 48m BowStringDocumento1 página48m BowStringgoutammand100% (2)

- Space TrussDocumento74 páginasSpace Trussomer1299Ainda não há avaliações

- CALCULATORDocumento6 páginasCALCULATORSrikanth Sikha100% (1)

- Fibre Reinforced ConcreteDocumento288 páginasFibre Reinforced ConcreteDinesh Babu100% (1)

- CWS100 PresentationDocumento34 páginasCWS100 PresentationGuntur SaputroAinda não há avaliações

- CE2404 Pre Stressed Concrete StructuresDocumento149 páginasCE2404 Pre Stressed Concrete StructuresPrantik Adhar Samanta100% (1)

- Brickwork For Structures, Rev.a1, 19.10.00Documento6 páginasBrickwork For Structures, Rev.a1, 19.10.00TAMILAinda não há avaliações

- Important Compatability Superlasticizes Portland CementDocumento23 páginasImportant Compatability Superlasticizes Portland CementAliAliAinda não há avaliações

- CE-411 Structural Analysis and Design II (2010-2016) PDFDocumento28 páginasCE-411 Structural Analysis and Design II (2010-2016) PDFAhmed RolinAinda não há avaliações

- Beam AnalysisDocumento143 páginasBeam AnalysisJheremae DeypalubosAinda não há avaliações

- Design of Column BasesDocumento9 páginasDesign of Column Basesdarshanakp100% (1)

- DS - en 1999-1-2 DK Na - 2007 eDocumento3 páginasDS - en 1999-1-2 DK Na - 2007 ep_meulendijks108Ainda não há avaliações

- Structural Response of Modular Buildings - An OverviewDocumento25 páginasStructural Response of Modular Buildings - An OverviewAngga AriefAinda não há avaliações

- Concept of Camber and Method For Assembly of OwgsDocumento21 páginasConcept of Camber and Method For Assembly of OwgsARUN RAJ100% (3)

- DLB @4.465Documento51 páginasDLB @4.465rvkumar3619690Ainda não há avaliações

- Quick Master 35 DD Engineering 2021 155 Temel Detay 1Documento1 páginaQuick Master 35 DD Engineering 2021 155 Temel Detay 1Zoran PerićAinda não há avaliações

- Behaviour of Fly AshDocumento65 páginasBehaviour of Fly AshTahir HussainAinda não há avaliações

- Section 09100 Metal Framing SystemDocumento5 páginasSection 09100 Metal Framing Systemestimasi100% (1)

- Spun Piles PT. Komponindo BetonjayaDocumento12 páginasSpun Piles PT. Komponindo Betonjayanapis jauhari100% (2)

- B IntroductionDocumento6 páginasB IntroductionRonald PanaliganAinda não há avaliações

- Presentation by Gursharan SinghDocumento46 páginasPresentation by Gursharan SinghNishanth SoansAinda não há avaliações

- DatabankofConcentricPunchingOspinaetal PDFDocumento19 páginasDatabankofConcentricPunchingOspinaetal PDFАлександр БударинAinda não há avaliações

- Theoretical and Applied Fracture Mechanics: SciencedirectDocumento10 páginasTheoretical and Applied Fracture Mechanics: SciencedirectDevan1984Ainda não há avaliações

- Division 04: Brick Works, Patent Stone in Floor and Fancy Screen Block WorkDocumento3 páginasDivision 04: Brick Works, Patent Stone in Floor and Fancy Screen Block Workamit dasguptaAinda não há avaliações

- Fibermesh Sikafiber Guide and ChartDocumento6 páginasFibermesh Sikafiber Guide and ChartajatAinda não há avaliações

- 2017 MEET (Civil) - Case Studies of Steel Bridge Design Using FEM Analysis 1493823183Documento49 páginas2017 MEET (Civil) - Case Studies of Steel Bridge Design Using FEM Analysis 1493823183shish0iitrAinda não há avaliações

- Seismic Performance of Emulative Precast Concrete Beam-Column Connections With Alternative Reinforcing DetailsDocumento14 páginasSeismic Performance of Emulative Precast Concrete Beam-Column Connections With Alternative Reinforcing DetailsMălíķ ĂsfęnđýårAinda não há avaliações

- Bondek Design & Construct ManualDocumento131 páginasBondek Design & Construct ManualAkuma.Gokai7328100% (12)