Escolar Documentos

Profissional Documentos

Cultura Documentos

CItroen Sphere Recharge DIY

Enviado por

sipeTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

CItroen Sphere Recharge DIY

Enviado por

sipeDireitos autorais:

Formatos disponíveis

Home made Sphere Recharging Jig In this day and age the cost of a new sphere has reduced

dramatically from the sort of prices we paid 10 years ago. As such, on cost grounds, it is debatable whether its worth recharging spheres at all. From an environmental point of view, however, theres usually still plenty of life left in a sphere even after most of the gas has gone. I made this jig 15 years ago when a new sphere was 35-40 and therefore well worth it.

Recharger Body The frame of the jig is made from 10mm thick black steel plate. It has 5 sides welded at all corners. The photo shows a sphere in position ready to be refilled with Nitrogen Gas. The large threaded bolt at the left hand side is what keeps the sphere in position whilst being recharged. To recharge the sphere the first thing you have to do is slacken the plug on the top of the sphere. If you havent tested the sphere for residual pressure you must assume it is fully charged to be safe. Ive found that the best way to slacken the plug is to turn the sphere upside down and grip the plug in the vice. Then, using a sphere removing tool, grip the sphere and turn through 1 revolution. Remove the sphere from the vice and turn up the right way. Grip the sphere in the vice again. Using a pair of molegrips slowly undo the plug. The residual gas pressure will begin to leak past the plug threads but most will still be retained by the o-ring on the underside of the plug.

Photo1 You can either let it bleed away slowly like this for an hour or two or you can speed up the process. Keep turning the plug anticlockwise. When the o-ring can no longer keep contact with the sphere and the plug at the same time it

Sphere Recharger Page 1 of 3 2005 Norrie

releases the residual gas suddenly. This will take you by surprise the first time you do it. Theres no danger since the plug still has most of its threads screwed into the top of the sphere and therefore it cant go anywhere. It will be obvious when all the gas pressure has been released. The plug will go slack and youll be able to turn it with your fingers. The top of the plug is then machined with a 6mm diameter end mill set in a pillar drill to cut two small recessed dogs in the surface. These recesses are used to grip the plug under pressure and screw it back into the sphere.

Photo2

Photo3

Sphere Recharger

Page 2 of 3

2005 Norrie

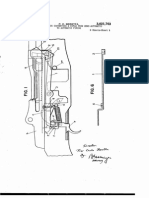

Heres a drawing of the clever bit. It has been inserted at a reasonably high resolution so it should be expandable.

Sphere Recharger

Page 3 of 3

2005 Norrie

Você também pode gostar

- AWCY? Apple PieDocumento8 páginasAWCY? Apple PieCWOAinda não há avaliações

- Dragon Days: The story of Miss Bardahl and the 1960s kids who loved hydros (2020 edition)No EverandDragon Days: The story of Miss Bardahl and the 1960s kids who loved hydros (2020 edition)Ainda não há avaliações

- Corvette Option Codes 1984 - 1996Documento43 páginasCorvette Option Codes 1984 - 1996ChristopherAinda não há avaliações

- How To Build A Potato CannonDocumento16 páginasHow To Build A Potato CannonFknw bdAinda não há avaliações

- The Citroen XM Internet ReferenceDocumento206 páginasThe Citroen XM Internet Referencejosip0% (1)

- Carbine Receiver ExtensionsDocumento2 páginasCarbine Receiver Extensionsjordanbowles2579Ainda não há avaliações

- 1.4 Golf Fluctuating Idle and Poor StartingDocumento23 páginas1.4 Golf Fluctuating Idle and Poor StartingEngine Tuning UPAinda não há avaliações

- How To Build A Fuel LineDocumento15 páginasHow To Build A Fuel LineMech EngrAinda não há avaliações

- A. Ghuohu.: (No Model.)Documento3 páginasA. Ghuohu.: (No Model.)dgfsduuwio100% (1)

- Mike Kojima SE-RDocumento33 páginasMike Kojima SE-Rpinoypride172001Ainda não há avaliações

- Sorrca RulesDocumento6 páginasSorrca RulesDeeds VillapandoAinda não há avaliações

- WAPU Overhaul BZBDocumento8 páginasWAPU Overhaul BZBNedim ErkocevicAinda não há avaliações

- Dual Xtreme Air PistolDocumento84 páginasDual Xtreme Air PistolSamuel Vonlanthen100% (1)

- Patented May 28, 1912.: Air 4. - GentsDocumento12 páginasPatented May 28, 1912.: Air 4. - GentsСлэйтер Строительная компанияAinda não há avaliações

- 420a Edz SwapDocumento12 páginas420a Edz SwapAll StaffAinda não há avaliações

- Vacuum From Toyota Corolla 4aDocumento6 páginasVacuum From Toyota Corolla 4azulAinda não há avaliações

- Aprilia-2003 - SXV - RXV - 450 - 550 - Technical PDFDocumento82 páginasAprilia-2003 - SXV - RXV - 450 - 550 - Technical PDFrosario100% (1)

- 9mm Bolt RampingDocumento6 páginas9mm Bolt RampingMatthew Nelson100% (1)

- Homemade Paintball GunDocumento8 páginasHomemade Paintball GunAinis Štelemėkas0% (1)

- Homemade Mini Coaxial AirgunDocumento9 páginasHomemade Mini Coaxial Airgunnfk100% (1)

- C4 Corvette AlignmentDocumento7 páginasC4 Corvette AlignmentGeorge finkleAinda não há avaliações

- Lancia Scorpion Tecnhnical TipsDocumento11 páginasLancia Scorpion Tecnhnical Tipsphantom fiatAinda não há avaliações

- VL Commodore Vol 1 0a-0bDocumento10 páginasVL Commodore Vol 1 0a-0bmattAinda não há avaliações

- Two Shot Pistol (US Patent D686685)Documento7 páginasTwo Shot Pistol (US Patent D686685)PriorSmartAinda não há avaliações

- 1977 Jeep-1977 TSBDocumento126 páginas1977 Jeep-1977 TSBperzaklieAinda não há avaliações

- Rb30 Dohc: R32 & R33 Skyline Specific Last Update - This Guide Has Originated From The Following HUGE Thread On SAUDocumento10 páginasRb30 Dohc: R32 & R33 Skyline Specific Last Update - This Guide Has Originated From The Following HUGE Thread On SAUChris Mi-e Dor RomâniaAinda não há avaliações

- Glock Generation PDFDocumento18 páginasGlock Generation PDFสุรา ไทประดิษฐ์100% (2)

- Mini UziDocumento7 páginasMini UzideweywolfAinda não há avaliações

- 7 3LInjectorDiagnosticDocumento6 páginas7 3LInjectorDiagnosticimamfadili0% (1)

- Low Range HD 2 Inch Body Lift Kit (Sidekick, GV, Vitara, Tracker, X90)Documento45 páginasLow Range HD 2 Inch Body Lift Kit (Sidekick, GV, Vitara, Tracker, X90)Cesar Jesus Castellanos TrejoAinda não há avaliações

- 2000 F150 Heater Core ReplacementDocumento29 páginas2000 F150 Heater Core ReplacementJeff ComfortAinda não há avaliações

- VW Bettle 2013Documento209 páginasVW Bettle 2013Enrique GomezAinda não há avaliações

- W245 Fuse Assignment of Fuse Box in Interior CompartmentDocumento3 páginasW245 Fuse Assignment of Fuse Box in Interior Compartmentnicolas antonio pallero fernandezAinda não há avaliações

- Intro25MM Pneumatic Sniper RifleDocumento63 páginasIntro25MM Pneumatic Sniper Riflezaion08100% (1)

- 2012 Ford F150 Owners ManualDocumento472 páginas2012 Ford F150 Owners Manualghentch100% (1)

- Modifying .223 Magazines For The SAR-3Documento13 páginasModifying .223 Magazines For The SAR-3Arkane1988100% (1)

- Stirling Walking Beam EngineDocumento13 páginasStirling Walking Beam EngineTomescu PaulAinda não há avaliações

- A o BrochureDocumento20 páginasA o Brochuremax69442Ainda não há avaliações

- CrossFire150R Owners ManualDocumento65 páginasCrossFire150R Owners Manual2005bajaAinda não há avaliações

- Alt PresDocumento32 páginasAlt PresmdgtallAinda não há avaliações

- PALM SQUEEZERS and Other Unique HandgunsDocumento10 páginasPALM SQUEEZERS and Other Unique Handgunsblowmeasshole1911Ainda não há avaliações

- mk2 Mirror - 90-92Documento5 páginasmk2 Mirror - 90-92pitoAinda não há avaliações

- Caddi PartsDocumento46 páginasCaddi PartsehteshamahmedAinda não há avaliações

- Armalite Technical Note 29 Rifle Cleaning InstructionsDocumento4 páginasArmalite Technical Note 29 Rifle Cleaning InstructionsJohn M Buol Jr.Ainda não há avaliações

- 1957 Chevrolet Chevy Manual DespieceDocumento257 páginas1957 Chevrolet Chevy Manual Despiecechamis1Ainda não há avaliações

- Patent eDocumento5 páginasPatent eDaniel OliveiraAinda não há avaliações

- Corvette C4 ABS-ASR Operation and Diagnosis ManualDocumento72 páginasCorvette C4 ABS-ASR Operation and Diagnosis ManualDejvis Pale100% (3)

- HK Flat Bending JigDocumento7 páginasHK Flat Bending JigRon Walsh100% (1)

- @VLNNR:: Beretta 3,021,763Documento8 páginas@VLNNR:: Beretta 3,021,763wererAinda não há avaliações

- VW Passat B5 1.8T Timing Belt Replacement DIYDocumento26 páginasVW Passat B5 1.8T Timing Belt Replacement DIYaweed100% (1)

- Silver Streak and Blue Streak Repair Manual: All Rights Reserved, UJ BackusDocumento20 páginasSilver Streak and Blue Streak Repair Manual: All Rights Reserved, UJ BackusRonAinda não há avaliações

- Poh Sd-1 TG Se-33Documento19 páginasPoh Sd-1 TG Se-33Łukasz50% (2)

- Owner's Manual: Generator EM500 EM600Documento37 páginasOwner's Manual: Generator EM500 EM600mariopilarAinda não há avaliações

- Info Manual 3Documento21 páginasInfo Manual 3dali2Ainda não há avaliações

- A Ball MillDocumento5 páginasA Ball Millgy0rgy0murvaiAinda não há avaliações

- GMC Pad - A New Motorhome Living Concept (2006)Documento9 páginasGMC Pad - A New Motorhome Living Concept (2006)kbreenbo1Ainda não há avaliações

- Eng-Template-1 - C: Scale: Drawing No: Rev: Sheet: OFDocumento4 páginasEng-Template-1 - C: Scale: Drawing No: Rev: Sheet: OFlogostar5Ainda não há avaliações

- Rejetting The CV CarburetorDocumento28 páginasRejetting The CV CarburetorЮрий100% (1)

- Fire PistonDocumento10 páginasFire PistonCiovica Lucian CatalinAinda não há avaliações

- Thermo King CG 2000Documento155 páginasThermo King CG 2000Connie TaibaAinda não há avaliações

- Contingent Liabilities For Philippines, by Tarun DasDocumento62 páginasContingent Liabilities For Philippines, by Tarun DasProfessor Tarun DasAinda não há avaliações

- Urban Issues: Rio Case StudyDocumento4 páginasUrban Issues: Rio Case Studyxbox pro hiAinda não há avaliações

- Add MITx Credentials To Resume and LinkedIn PDFDocumento5 páginasAdd MITx Credentials To Resume and LinkedIn PDFRizwanAinda não há avaliações

- CRM Short QuizDocumento1 páginaCRM Short QuizDaria Par-HughesAinda não há avaliações

- The Price of Peace by A. LAWRENCE LOWELDocumento4 páginasThe Price of Peace by A. LAWRENCE LOWELeden galasAinda não há avaliações

- Maintenance Repair Overhaul: Safely To New Horizons Ensuring Your Aircraft Is Ready Whenever Duty CallsDocumento10 páginasMaintenance Repair Overhaul: Safely To New Horizons Ensuring Your Aircraft Is Ready Whenever Duty CallsSuryaAinda não há avaliações

- Green Tyre TechnologyDocumento4 páginasGreen Tyre TechnologyAnuj SharmaAinda não há avaliações

- Uj 76 HD 5 CdivutDocumento18 páginasUj 76 HD 5 Cdivuttfrcuy76Ainda não há avaliações

- Apples-to-Apples in Cross-Validation Studies: Pitfalls in Classifier Performance MeasurementDocumento9 páginasApples-to-Apples in Cross-Validation Studies: Pitfalls in Classifier Performance MeasurementLuis Martínez RamírezAinda não há avaliações

- Taxicab Operators V BOTDocumento2 páginasTaxicab Operators V BOTHazel P.Ainda não há avaliações

- Tata Steel Ratio AnalysisDocumento41 páginasTata Steel Ratio AnalysisGourav VallakattiAinda não há avaliações

- Chennai CMDA Master Plan 2026 Volume 3 Sectorial BackgroundDocumento270 páginasChennai CMDA Master Plan 2026 Volume 3 Sectorial BackgroundMalathi Kathirvel100% (1)

- Power of Company Law BoardDocumento21 páginasPower of Company Law Boardraman raghavAinda não há avaliações

- Battlab Report 12 FinalDocumento48 páginasBattlab Report 12 FinalLianAinda não há avaliações

- Epsilon Range Bomba HorizontalDocumento8 páginasEpsilon Range Bomba HorizontalsalazarafaelAinda não há avaliações

- Modern Theory of Interest: IS-LM CurveDocumento36 páginasModern Theory of Interest: IS-LM CurveSouvik DeAinda não há avaliações

- FBL ManualDocumento12 páginasFBL Manualaurumstar2000Ainda não há avaliações

- National Knowledge Commision and Its Implication in Higher EducationDocumento73 páginasNational Knowledge Commision and Its Implication in Higher Educationabhi301280100% (1)

- National School Building Inventory (NSBI) Encoding For SY 2021-2022Documento31 páginasNational School Building Inventory (NSBI) Encoding For SY 2021-2022Renato Rivera100% (1)

- Crime Report Management SystemDocumento49 páginasCrime Report Management SystemAbimbolaÀdésíréAdegbiteAinda não há avaliações

- Assignment On Industrial Relation of BDDocumento12 páginasAssignment On Industrial Relation of BDKh Fahad Koushik50% (6)

- 2011 Hyundai Service FiltersDocumento18 páginas2011 Hyundai Service FiltersTan JaiAinda não há avaliações

- Business and Finance TerminologyDocumento15 páginasBusiness and Finance TerminologyKat KatAinda não há avaliações

- Bonus 6 - Mastering ASP - NET Core SecurityDocumento147 páginasBonus 6 - Mastering ASP - NET Core SecurityDark Shadow100% (1)

- Fashion Law - Trademark ParodyDocumento12 páginasFashion Law - Trademark ParodyArinta PratiwiAinda não há avaliações

- Eligibility To Become IAS Officer: Career As A IAS Officer About IAS OfficerDocumento4 páginasEligibility To Become IAS Officer: Career As A IAS Officer About IAS Officersamiie30Ainda não há avaliações

- Questionnaire On EthnocentrismDocumento14 páginasQuestionnaire On Ethnocentrismkalpa vrikshaAinda não há avaliações

- Ge Washing Machine ManualDocumento52 páginasGe Washing Machine Manuallillith1723Ainda não há avaliações

- Media DRIVEON Vol25 No2Documento21 páginasMedia DRIVEON Vol25 No2Nagenthara PoobathyAinda não há avaliações

- You Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherNo EverandYou Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherAinda não há avaliações

- The House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedNo EverandThe House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedNota: 4.5 de 5 estrelas4.5/5 (5)

- The Importance of Being Earnest: Classic Tales EditionNo EverandThe Importance of Being Earnest: Classic Tales EditionNota: 4.5 de 5 estrelas4.5/5 (44)

- The Book of Bad:: Stuff You Should Know Unless You’re a PussyNo EverandThe Book of Bad:: Stuff You Should Know Unless You’re a PussyNota: 3.5 de 5 estrelas3.5/5 (3)

- The Little Book of Big F*#k Ups: 220 of History's Most-Regrettable MomentsNo EverandThe Little Book of Big F*#k Ups: 220 of History's Most-Regrettable MomentsAinda não há avaliações

- Sex, Drugs, and Cocoa Puffs: A Low Culture ManifestoNo EverandSex, Drugs, and Cocoa Puffs: A Low Culture ManifestoNota: 3.5 de 5 estrelas3.5/5 (1428)

- The Asshole Survival Guide: How to Deal with People Who Treat You Like DirtNo EverandThe Asshole Survival Guide: How to Deal with People Who Treat You Like DirtNota: 4 de 5 estrelas4/5 (60)

- 1,001 Facts that Will Scare the S#*t Out of You: The Ultimate Bathroom ReaderNo Everand1,001 Facts that Will Scare the S#*t Out of You: The Ultimate Bathroom ReaderNota: 3.5 de 5 estrelas3.5/5 (48)

- Welcome to the United States of Anxiety: Observations from a Reforming NeuroticNo EverandWelcome to the United States of Anxiety: Observations from a Reforming NeuroticNota: 3.5 de 5 estrelas3.5/5 (10)

![The Inimitable Jeeves [Classic Tales Edition]](https://imgv2-1-f.scribdassets.com/img/audiobook_square_badge/711420909/198x198/ba98be6b93/1712018618?v=1)