Escolar Documentos

Profissional Documentos

Cultura Documentos

AT02

Enviado por

rashidkingDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

AT02

Enviado por

rashidkingDireitos autorais:

Formatos disponíveis

45th IEP Convention 12

IDENTIFYING MAINTENANCE MANAGEMENT CHALLENGES FACED BY CHARTER OPERATORS

SUHAIL NASIR GENERAL MANAGER QUALITY ASSURANCE PRINCELY JET (PVT) LTD

1. INTRODUCTION

Aviation maintenance can be rightly termed as one of the most demanding profession. Besides fulfilling stringent technical and quality requirements, the regulatory compliance has to be accorded highest priority. In the prevailing economic environment, maintenance managers are called upon to ensure safety and reliability at optimal cost. Supporting a charter operation poses still greater challenges. Based on my experience, I shall identify practical challenges that are to be surmounted for survival.

2. CHALLENGES

Unlike regular maintenance charter maintenance is un-predictable. By itself this intrinsic factor generates serious challenges if operations are spread over regions lacking in support facilities. Providing repair support at a location far away from base if aircraft goes technical can wipe out any expected revenue. It is of paramount importance to given due weight-age to this aspect, when selling a charter.

3. TRENDS

Charter trends in the Middle East have a profound effect in the region. For most part, Middle East has been experiencing slow, inconsistent growth in last three years. The fluctuations in demand can be attributed to certain events, like domestic uprisings and disturbances in the region as well as the Hajj season. Charter requests in Middle East by aircraft category, is as shown in this slide. The ratio, between heavy to midsize Jets stand at 60 to 30. Light Jet representation is very small. UAE is the dominant market in this region. Currently market is seeing long haul traffic with clients coming from China to UAE and moving on to Africa or Europe. The aim of highlighting these trends is that small charter operators like my company, are operating in a competitive environment. Our maintenance management challenges are further compounded due to existing regulations applicable to Aviation Industry

4. SPECIFIC TO PAKISTAN

I shall present some case studies which will illustrate following challenges that are specific to Pakistan. a. Managing maintenance support from base. b. Regulatory requirements c. Balancing the safety, regulatory compliance and cost equation.

5. MAINTENANCE MANAGEMENT FROM PAKISTAN

The area of operation of Princely Jets, my company, includes South East Asia, Middle East, Europe and Africa. We are based in Karachi, Pakistan. Most of our charter originates from UAE. In their effort to get charter, the marketing team requirements keep changing. During charter, it is demanded from us to keep maintenance ferry flight to minimum and carry out the line

45th IEP Convention 12

maintenance on location as far as possible. From the next three case studies of aircraft going technical in faraway locations, the challenges posed to maintenance manager will stand out. Any Charter management may face such like situations.

6. STUDY-I, CHALLENGER 604- TOKYO

On 13 Aug 2008, a flight of Challenger originating from Dubai was to return after three days stay in Tokyo. After landing, the Pilot reported right thrust reverser unlock light on. Through the good offices of the manufacturers regional representative, a qualified engineer was flown from Metro Jet (Hong Kong), after obtaining Pakistan Civil Aviation Authority (PCAA) approval. Aircraft was made available to client for return flight at scheduled time.

7. STUDY-II, CHALLENGER 601- ROME

On 27 August 2008 in Rome, while landing the Challenger 60s Landing gear down and locked light did not come on. The Crew executed emergency procedure. Due to non-availability of approved facility, aircraft was flown to Basel; with gears down under OEMs specified limitations. Since move of own engineer to Rome was not possible due to administrative problems, we went for an expensive option to ensure quick recovery of aircraft.

8. STUDY-III, CHALLENGER 604- CAPE TOWN

Challenger 604 while on charter flight to Cape Town, South Africa reported a crack in front left windshield and generator fail light on. Whereas Minimum Equipment list permits flights with limitations for cracked windshield, but the Generator had to be replaced. Efforts were made for quick recovery. Required parts costing 134,000 USD covered under smart parts program were moved to location. Qualified engineer for windshield replacement was flown from Johannesburg and PCAA approvals were obtained on fact track. This time aircraft could not be made available to the VVIP client. According to my marketing team beside financial loss we lost a very high profit customer.

9. REGULATORY REQUIREMENTS

For an aircraft registered in Pakistan, its repair/ maintenance can only be performed at PCAA approved center. Only PCAA licensed or approved engineers can work on the aircraft. There is a provision for one time approval for maintenance organization for specific tasks and limited duration. Following are three challenges of conforming to regulatory requirement even when all other aspects were catered for.

10. REGULATORY STUDY I - TIRE CHANGE

A worn out nose wheel tire required replacement on Challenger 604, in Abuja Nigeria. Spare wheel was on-board. B1 & B2 engineer was also available in Lagos. Flying own licensed engineer required 4-5 days. To meet this challenge a special onetime approval for an engineer in Lagos was obtained from PCAA, after completing all formalities within one day. We not only saved on cost and time but regulatory compliance was ensured. Such like approvals within hours are not routine. May I admit that we were lucky.

11. REGULATORY STUDY-II - CITATION BRAVO

The Phase-V of Cessna Bravo was due on 31 Jan 2011. Two months before the due date the quotations was obtained from PCAA approved organization (in Riyadh & Zurich). These were extremely high. Quotation from Cessna Certified and EASA approved MRO were obtained.

45th IEP Convention 12

ATLAS Aviation Germany was finally selected. Special PCAA approval was obtained with condition to send an inspector to ATLAS Aviation during the inspection at our expense. This unusual effort by maintenance management saved the company over 100,000 USD.

12. COST SAVINGS BY SPECIAL ARRANGEMENT

100 hours of challenger 604 was due at 5544 hours. Part of an airworthiness directive (AD-CF200-39) was due at 5539 hours. Aircraft reached Riyadh on 30 Nov 2009. Marketing had received advance payment for another 4 flying hours. To save cost and ensure compliance (Technical and Regulatory): under guidance of Execu- Jet engineer in Dubai (PCAA approved), an Arabsco engineer carried out required visual check of hydraulic accumulator. The Aircraft was cleared for flight after endorsement by ExecuJet engineer. Here also please appreciate an unusual arrangement enabled us to ensure compliance and save cost.

13. COST SAVING- BRAVO PHASE-21, DUBAI

Phase 21 was due on 31 Dec 2011. A PCAA approved facility in Riyadh regretted a slot due non availability of qualified engineer just two weeks before the due date. Taking aircraft to PCAA approved facility in Zurich was an expensive option. Jet Aviation Dubai had PCAA approval till Feb 2011. Special approval of PCAA was obtained for own licensed engineers to use facility and equipment of Jet Aviation Dubai that resulted in substantial saving of maintenance cost.

14. COST FERRY FOR MINOR INSPECTION

Maintenance Managers of charter operators are not always successful in saving cost. At times for minor inspection, aircraft has to be ferried to nearest MRO as moving an engineer is not possible due to visa problems. As can be seen in this slide, for the monthly inspection of Challengers 604 there are only three simple tasks. On one instance we had no option but to ferry aircraft from Riyadh to Dubai for carrying out the inspection. In this case despite every effort, loss of revenue had to be absorbed, to ensure regulatory compliance.

15. MISCELLANEOUS

Maintenance manager cannot lower his guards to some of the other challenges (threats), faced by all operators, more so the charter operators. One of these is SAFA (Safety Assessment of Foreign Aircraft). Last year one of our aircraft on charter in France was checked. A Cat G finding, MEL items not fully customized was noted. The response could not reach the co rrect address. After seven days same observation was made at another location in France. For this a detailed explanation was given to PCAA, before we were let off the hook. The audits by regulatory authorities and also by firms hired by some of the multinational companies cannot be taken lightly. Maintenance managers are tasked to keep this front also fully covered.

16. MUST HAVE.

My dear colleagues, for those who dare to venture into maintenance management of charter operations, you must have the following minimum tools or aids: a) Computerized Aircraft maintenance programs subscription. b) Also be supported by spare programs. c) System in place for round the clock monitoring of flying. d) Work hand in glove with marketing, a daunting task at times.

45th IEP Convention 12

e) Arrangement with MROs in areas of operations.

17. CONCLUSION

Charter air Operators have to weather the existing adverse market conditions. A lean organization is of immense help in cutting cost. This can make signification contribution. The key however is cost effective, safe and compliant maintenance handled by engineering professionals having deep understanding of operations and marketing. Pakistan CAA is all set to adopt the EASA standards by December 2013. Whereas this may be a tall order, but once our system switches over to EASA regulations, it will be of great help for Charter Operations.

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Electronic Installations and Service-Parts Manual PDFDocumento745 páginasElectronic Installations and Service-Parts Manual PDFmastrangelo2973100% (3)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Development of Seismic Vulnerability Assessment Methodologies Over The Past 30 YearsDocumento6 páginasDevelopment of Seismic Vulnerability Assessment Methodologies Over The Past 30 YearsrashidkingAinda não há avaliações

- 160901-TC21 Tor R07Documento4 páginas160901-TC21 Tor R07rashidkingAinda não há avaliações

- Karachi To Kotri - The First Railways in PakistanDocumento14 páginasKarachi To Kotri - The First Railways in PakistanrashidkingAinda não há avaliações

- SHSCP 11 ArchDocumento1 páginaSHSCP 11 ArchrashidkingAinda não há avaliações

- Tructural Ealth Onitoring: M. Mayur S.I.E.T.K PutturDocumento37 páginasTructural Ealth Onitoring: M. Mayur S.I.E.T.K PutturrashidkingAinda não há avaliações

- Seismic Analysis - Conc Build - D ValueDocumento18 páginasSeismic Analysis - Conc Build - D ValuerashidkingAinda não há avaliações

- Guidebook On Technologies For Disaster Preparedness and Mitigation ISRO Satyabrata SahuDocumento102 páginasGuidebook On Technologies For Disaster Preparedness and Mitigation ISRO Satyabrata SahuS.Alec KnowleAinda não há avaliações

- Seismo-Tectonic Routes of PakistanDocumento9 páginasSeismo-Tectonic Routes of PakistanrashidkingAinda não há avaliações

- Heavy Monsoon Downpour Lashes KarachiDocumento9 páginasHeavy Monsoon Downpour Lashes KarachirashidkingAinda não há avaliações

- Self Assessment Manual PDFDocumento45 páginasSelf Assessment Manual PDFrashidkingAinda não há avaliações

- 14 S07-013Documento8 páginas14 S07-013rashidkingAinda não há avaliações

- Heidarzadeh Et Al 2008 OE Historical Tsunami in Makran Subduction ZoneDocumento13 páginasHeidarzadeh Et Al 2008 OE Historical Tsunami in Makran Subduction ZonerashidkingAinda não há avaliações

- First General StatutesDocumento6 páginasFirst General StatutesrashidkingAinda não há avaliações

- Brrda: FCGKJ Xzkeh.K Ifk Fodkl, TsalhDocumento2 páginasBrrda: FCGKJ Xzkeh.K Ifk Fodkl, TsalhrashidkingAinda não há avaliações

- May 12th Evening JournalDocumento1 páginaMay 12th Evening JournalrashidkingAinda não há avaliações

- 1.3153330 HAZUS Second ImportantDocumento12 páginas1.3153330 HAZUS Second ImportantrashidkingAinda não há avaliações

- 3rd Eastern SF Bay Earthquake ConferenceDocumento1 página3rd Eastern SF Bay Earthquake ConferencerashidkingAinda não há avaliações

- A1 Example Fire Safety Maintenance ChecklistDocumento30 páginasA1 Example Fire Safety Maintenance ChecklistrashidkingAinda não há avaliações

- Environment and Urbanization 2003 Ahmed 33 42Documento10 páginasEnvironment and Urbanization 2003 Ahmed 33 42rashidkingAinda não há avaliações

- KW&SB Bid Evaluation Report for COD Filter Plant Silt RemovalDocumento6 páginasKW&SB Bid Evaluation Report for COD Filter Plant Silt RemovalrashidkingAinda não há avaliações

- Aashto Pedestrian Bridge CatalogueDocumento5 páginasAashto Pedestrian Bridge CataloguerashidkingAinda não há avaliações

- DPR Historic Structure Assessment FormDocumento6 páginasDPR Historic Structure Assessment FormrashidkingAinda não há avaliações

- BOE Is Structural 3.2Documento28 páginasBOE Is Structural 3.2aomareltayebAinda não há avaliações

- Hydrological and Hydraulic Study of Bridges / Culverts: N K, S A, S A A S, M E S, N ADocumento5 páginasHydrological and Hydraulic Study of Bridges / Culverts: N K, S A, S A A S, M E S, N ArashidkingAinda não há avaliações

- Scanned CardsDocumento1 páginaScanned CardsrashidkingAinda não há avaliações

- HazusicgmanualDocumento22 páginasHazusicgmanualrashidkingAinda não há avaliações

- 1.3153330 HAZUS Second ImportantDocumento12 páginas1.3153330 HAZUS Second ImportantrashidkingAinda não há avaliações

- Addresses 1Documento5 páginasAddresses 1rashidkingAinda não há avaliações

- Collaborative Simulation Interface For Planning Disaster MeasuresDocumento6 páginasCollaborative Simulation Interface For Planning Disaster MeasuresrashidkingAinda não há avaliações

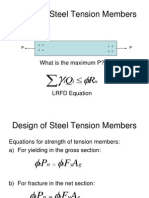

- 02 - Design of Steel Tension MembersDocumento15 páginas02 - Design of Steel Tension MembersMayur PatelAinda não há avaliações

- SP-177 Users ManualDocumento4 páginasSP-177 Users ManualLuis Gustavo FavarettoAinda não há avaliações

- Revision Question Chapter 1-5Documento20 páginasRevision Question Chapter 1-5Sealtiel1020Ainda não há avaliações

- Become an Airline Pilot: A Guide to Earning Your Commercial Pilot CertificateDocumento5 páginasBecome an Airline Pilot: A Guide to Earning Your Commercial Pilot CertificateViorel CrinelAinda não há avaliações

- Flight Warning SystemsDocumento18 páginasFlight Warning Systemsprakasa88Ainda não há avaliações

- Unmanned Aircraft Systems Roadmap 2005-2030Documento21 páginasUnmanned Aircraft Systems Roadmap 2005-2030Roberto OliverioAinda não há avaliações

- Axial Momentum TheoryDocumento10 páginasAxial Momentum Theorymanikandan_murugaiahAinda não há avaliações

- LETO (Torrejon) : General InfoDocumento39 páginasLETO (Torrejon) : General InfoMiguel Angel MartinAinda não há avaliações

- BAe 146Documento6 páginasBAe 146NeethAinda não há avaliações

- Aviation English & Aviation Weather PresentationDocumento12 páginasAviation English & Aviation Weather PresentationAhsan AfzaalAinda não há avaliações

- PPL Lesson 5 OverviewDocumento3 páginasPPL Lesson 5 OverviewShannon-claire McauleyAinda não há avaliações

- Ufo News ReportsDocumento17 páginasUfo News Reportsmweastboston3Ainda não há avaliações

- OJT Guidelines for CAR-66 AME Licence Type Rating EndorsementDocumento152 páginasOJT Guidelines for CAR-66 AME Licence Type Rating EndorsementdeepAinda não há avaliações

- Design Engineer with experience in structural design and flight control systems for light aircraftDocumento12 páginasDesign Engineer with experience in structural design and flight control systems for light aircraftkrpraveenkumar2003Ainda não há avaliações

- Elements of Practical Aerodynamics by B. JonesDocumento403 páginasElements of Practical Aerodynamics by B. JonesJasper SaceAinda não há avaliações

- Toward Space-Based Wireless Sensor NetworksDocumento21 páginasToward Space-Based Wireless Sensor NetworksAhmed El ShafieAinda não há avaliações

- MH370 Search DOC 1 - Investigation - FlaperonDocumento16 páginasMH370 Search DOC 1 - Investigation - FlaperonTeresAinda não há avaliações

- Project Pulse Jet EngineDocumento18 páginasProject Pulse Jet EngineJoel Kevin SaldanhaAinda não há avaliações

- E IM 126 - PW210 TCDS Issue 03 - 0-1 PDFDocumento8 páginasE IM 126 - PW210 TCDS Issue 03 - 0-1 PDFValBMSAinda não há avaliações

- Clay M Lucky MeDocumento178 páginasClay M Lucky MeDWFAinda não há avaliações

- 4E Questionnaire PDFDocumento8 páginas4E Questionnaire PDFAkash AggarwalAinda não há avaliações

- Fundamentals of Propulsion BabuDocumento164 páginasFundamentals of Propulsion BabuSara50% (2)

- Airport Site SelectionDocumento2 páginasAirport Site SelectionJyothi Jyotisha100% (1)

- EPWAEDDB PDF 20jan24Documento43 páginasEPWAEDDB PDF 20jan24Dawid ZborowskiAinda não há avaliações

- UFO Newspaper/Magazine Cuttings From NSW Australia - 1968 To 1973Documento40 páginasUFO Newspaper/Magazine Cuttings From NSW Australia - 1968 To 1973UFO Research (NSW) Incorporated, Australia100% (5)

- ROV Brochure EnglishDocumento8 páginasROV Brochure EnglishMuhammad Hayeri100% (1)

- Afwal TR 81 3109 Guide For Mil F 8785cDocumento255 páginasAfwal TR 81 3109 Guide For Mil F 8785cminyshow23Ainda não há avaliações

- Vintage Airplane - Apr 1985Documento32 páginasVintage Airplane - Apr 1985Aviation/Space History LibraryAinda não há avaliações

- Communicate via satellitesDocumento46 páginasCommunicate via satellitesJason MiralloAinda não há avaliações