Escolar Documentos

Profissional Documentos

Cultura Documentos

PLC Sequence Programming

Enviado por

spate77Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

PLC Sequence Programming

Enviado por

spate77Direitos autorais:

Formatos disponíveis

ROBO242 PLC/Pneumatic Interfacing Week 2: PLC Sequence Programming Richard Day August 2011

PLC SEQUENCE PROGRAMMING

ROBO242 PLC/Pneumatics Interfacing

August 2011

ROBO-242 - PLC/Pneumatic Interfacing Week 2

If there are no signal conflicts, programming a sequence is very easy. easy

�

i.e. A+, B+, A-, B� Use the Start, b0 (and a0) to extend A � Use a1 (and b0) to extend B � Use b1 (and a1) to retract A � Use b0 (and a0)to retract B

There is no practical limit on the number of times a contact can be addressed.

August 2010

ROBO242 - PLC/Pneumatic Interfacing

Week 2: PLC Sequence Programming

ROBO242 PLC/Pneumatics Interfacing

August 2011

August 2010

ROBO242 - PLC/Pneumatic Interfacing

It is often advantageous to check that a hi i R t or Home H position iti machine is i in th the Rest before allowing motion to start. Check that all rest position limits are ON.

ROBO242 - PLC/Pneumatic Interfacing 4

August 2010

Week 2: PLC Sequence Programming

ROBO242 PLC/Pneumatics Interfacing

August 2011

� �

Continuous operation from momentary input. End-of-cycle d f l end d from f momentary input.

�

Normally Closed Stop button.

Check for Home position to ensure safety.

ROBO242 - PLC/Pneumatic Interfacing 5

August 2010

A conflict occurs when two opposing control signals are ON at the same time. time

�

i.e. A+ & A-

Logic solutions can be designed to eliminate conflicts, using signal conversion circuitry:

� �

One-shot [timed pulse] Latching circuit

August 2010

ROBO242 - PLC/Pneumatic Interfacing

Week 2: PLC Sequence Programming

ROBO242 PLC/Pneumatics Interfacing

August 2011

� �

The fastest way to solve conflicts is to design an additive sequencer. sequencer Very similar to Relay Logic design. One rung for each step, and a Reset rung at end of sequence. Use memory bits for steps, and use steps to control t l output t t bit bits

August 2010

ROBO242 - PLC/Pneumatic Interfacing

� �

� � �

August 2010

RUN bit for start Ready to start condition (HOME) (HOME). Not DONE Latch bit on Use a memory bit for output

ROBO242 - PLC/Pneumatic Interfacing 8

Week 2: PLC Sequence Programming

ROBO242 PLC/Pneumatics Interfacing

August 2011

� � �

Actions are completed Latch current step Previous step is ON Use consecutive memory bits for steps. t

�

Easier to reset

August 2010

ROBO242 - PLC/Pneumatic Interfacing

Final actions completed DONE bit will turn off first step. All others will turn off is sequence until DONE DONE bit is cleared. Ready to restart.

10

August 2010

ROBO242 - PLC/Pneumatic Interfacing

Week 2: PLC Sequence Programming

ROBO242 PLC/Pneumatics Interfacing

August 2011

Use N.O. Step bit to p on when turn output required Use N.C. Step bit to turn output off when no longer needed. U parallel Use ll l network t k for multiple actuations.

August 2010

ROBO242 - PLC/Pneumatic Interfacing

11

S 1

S 1

S 2

S 1

S 3

S 1

S4

S 1

Instead of creating a latch in the step. step rungs, use a Set coil Instead of DONE bit, use Reset coil to reset all steps steps.

� This is easy on the

S 1

R 4

Siemens PLC, but not quite so easy on others.

August 2010

ROBO242 - PLC/Pneumatic Interfacing

12

Week 2: PLC Sequence Programming

ROBO242 PLC/Pneumatics Interfacing

August 2011

Easiest way to handle sequence programming with multiple conflicts. conflicts Sequence modifications are easily accommodated. Debugging and trouble-shooting can be quick and easy.

August 2010

ROBO242 - PLC/Pneumatic Interfacing

13

Week 2: PLC Sequence Programming

Você também pode gostar

- PLC Programming Using SIMATIC MANAGER for Beginners: With Basic Concepts of Ladder Logic ProgrammingNo EverandPLC Programming Using SIMATIC MANAGER for Beginners: With Basic Concepts of Ladder Logic ProgrammingNota: 4 de 5 estrelas4/5 (1)

- PLC Programming Using RSLogix 500 & Industrial Applications: Learn ladder logic step by step with real-world applicationsNo EverandPLC Programming Using RSLogix 500 & Industrial Applications: Learn ladder logic step by step with real-world applicationsNota: 5 de 5 estrelas5/5 (1)

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosNo EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosNota: 5 de 5 estrelas5/5 (1)

- Hacks To Crush Plc Program Fast & Efficiently Everytime... : Coding, Simulating & Testing Programmable Logic Controller With ExamplesNo EverandHacks To Crush Plc Program Fast & Efficiently Everytime... : Coding, Simulating & Testing Programmable Logic Controller With ExamplesNota: 5 de 5 estrelas5/5 (1)

- PLC Analog I/O KL SeriesDocumento12 páginasPLC Analog I/O KL SeriesJoseph Zeaiter100% (1)

- PLCDocumento13 páginasPLCNamitha JayadevAinda não há avaliações

- RSLOGIX5000 Programming A Clear and Concise ReferenceNo EverandRSLOGIX5000 Programming A Clear and Concise ReferenceAinda não há avaliações

- PLC programmable logic controller A Clear and Concise ReferenceNo EverandPLC programmable logic controller A Clear and Concise ReferenceAinda não há avaliações

- Programmable Logic Controllers A Complete Guide - 2020 EditionNo EverandProgrammable Logic Controllers A Complete Guide - 2020 EditionAinda não há avaliações

- Learn To Program, Simulate Plc & Hmi In Minutes with Real-World Examples from Scratch. A No Bs, No Fluff Practical Hands-On Project for Beginner to Intermediate: BoxsetNo EverandLearn To Program, Simulate Plc & Hmi In Minutes with Real-World Examples from Scratch. A No Bs, No Fluff Practical Hands-On Project for Beginner to Intermediate: BoxsetAinda não há avaliações

- Distributed Process Control ReportNo EverandDistributed Process Control ReportAinda não há avaliações

- PLC Exercises: Ladder Diagram ProgrammingDocumento27 páginasPLC Exercises: Ladder Diagram Programmingganeshrudra100% (4)

- 01-Overview of PLC SystemDocumento42 páginas01-Overview of PLC SystemMehtab AhmedAinda não há avaliações

- Fieldbus Systems and Their Applications 2005: A Proceedings volume from the 6th IFAC International Conference, Puebla, Mexico 14-25 November 2005No EverandFieldbus Systems and Their Applications 2005: A Proceedings volume from the 6th IFAC International Conference, Puebla, Mexico 14-25 November 2005Miguel Leon ChavezAinda não há avaliações

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979No EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonAinda não há avaliações

- PLC Programming With RSLogix 5000Documento168 páginasPLC Programming With RSLogix 5000HuangRuanJin100% (19)

- Logic Design Seminar - Programmable Logic ControllersDocumento35 páginasLogic Design Seminar - Programmable Logic Controllersabhisingh28Ainda não há avaliações

- PLC FundamentalsDocumento42 páginasPLC Fundamentalsshivang patelAinda não há avaliações

- PLC Based ExamplesDocumento2 páginasPLC Based ExamplesMangala VidyanandAinda não há avaliações

- Conveyor Control Using Programmable Logic ControllerDocumento7 páginasConveyor Control Using Programmable Logic ControllerdanwAinda não há avaliações

- PLC Programming With RSLogix 5000 ExcerptDocumento33 páginasPLC Programming With RSLogix 5000 Excerptvantiencdtk750% (2)

- 2 Basic Ladder Instructions R1.1Documento19 páginas2 Basic Ladder Instructions R1.1Ahmed SamiAinda não há avaliações

- Start Programming, Simulating HMI and PLC in Your Laptop: A No Bs, No Fluff, HMI and PLC Programming & Simulating Volume 2: Volume, #2No EverandStart Programming, Simulating HMI and PLC in Your Laptop: A No Bs, No Fluff, HMI and PLC Programming & Simulating Volume 2: Volume, #2Nota: 3 de 5 estrelas3/5 (1)

- Introduction to PLC Components, Logic Concepts & ApplicationsDocumento108 páginasIntroduction to PLC Components, Logic Concepts & ApplicationsQais Alsafasfeh100% (2)

- PLC Programming According To The IEC 61 131-3Documento108 páginasPLC Programming According To The IEC 61 131-3r-helou100% (1)

- PLC Programming Example - ClockDocumento2 páginasPLC Programming Example - ClockDon - BIN95.com100% (1)

- STL FestoDocumento117 páginasSTL FestoRenzo Delgado100% (2)

- Start Programming & Simulating PLC In Your Laptop from Scratch: A No BS, No Fluff, PLC Programming Volume 1: Volume, #1No EverandStart Programming & Simulating PLC In Your Laptop from Scratch: A No BS, No Fluff, PLC Programming Volume 1: Volume, #1Nota: 4.5 de 5 estrelas4.5/5 (2)

- Process Control and Industrial Automation Complete Self-Assessment GuideNo EverandProcess Control and Industrial Automation Complete Self-Assessment GuideAinda não há avaliações

- PLC Interview QuestionsDocumento2 páginasPLC Interview QuestionsSushant100% (1)

- Certified Automation Professional A Complete Guide - 2020 EditionNo EverandCertified Automation Professional A Complete Guide - 2020 EditionAinda não há avaliações

- Motion Control ReportNo EverandMotion Control ReportNota: 4 de 5 estrelas4/5 (1)

- Advanced Process Control A Complete Guide - 2020 EditionNo EverandAdvanced Process Control A Complete Guide - 2020 EditionAinda não há avaliações

- ABB PLC-2 System 1772Documento170 páginasABB PLC-2 System 1772Mohsin Shaukat100% (1)

- SFC ST Presentation1Documento51 páginasSFC ST Presentation1Jose Alberto Herrera OgazAinda não há avaliações

- Automatic Car Wash PLC ProgramDocumento105 páginasAutomatic Car Wash PLC Programtechknow leader50% (2)

- PLC Programming For Industrial ApplicationsDocumento20 páginasPLC Programming For Industrial Applicationssayyan50% (2)

- AB PLC TrainingDocumento96 páginasAB PLC TrainingTetsusaiga100% (1)

- PLC Solution BookDocumento49 páginasPLC Solution BookJagadeesh Rajamanickam71% (14)

- RSLogix 500 EtherNet-IP Logic Examples PDFDocumento4 páginasRSLogix 500 EtherNet-IP Logic Examples PDFchapsboiAinda não há avaliações

- Example of PLC Program PDFDocumento2 páginasExample of PLC Program PDFMia0% (1)

- PLC Program Development GuideDocumento19 páginasPLC Program Development GuideRadwa EL-MahdyAinda não há avaliações

- Automation FileDocumento56 páginasAutomation FileLoveable ShubhamAinda não há avaliações

- PLC Programming 2Documento117 páginasPLC Programming 2tanmoy ghoshAinda não há avaliações

- Programming Industrial Automation Laboratory Manual 2021-22Documento60 páginasProgramming Industrial Automation Laboratory Manual 2021-22Insane PersonAinda não há avaliações

- RSLogix 5000 and RSLogix 500Documento90 páginasRSLogix 5000 and RSLogix 500sayedmh100% (9)

- Siemens PLC Programming Example1Documento12 páginasSiemens PLC Programming Example1Pantea IonAinda não há avaliações

- RS Logix 5000Documento16 páginasRS Logix 5000Mohammad M HossainAinda não há avaliações

- DcsDocumento187 páginasDcsislamooov100% (1)

- RSLogix 5000Documento36 páginasRSLogix 5000Er. Piush Jindal83% (6)

- ST Programming PDFDocumento446 páginasST Programming PDFJaime LledóAinda não há avaliações

- Beginner - Guide PLC ControllerDocumento255 páginasBeginner - Guide PLC ControllerLuís Ki-llahAinda não há avaliações

- PLC Teaching BookDocumento167 páginasPLC Teaching BookMitchell Daniels100% (2)

- PLC NotesDocumento170 páginasPLC NotesBikasita Talukdar100% (2)

- Introduction To Industrial Automation in PLCDocumento50 páginasIntroduction To Industrial Automation in PLCkaushikei22100% (1)

- Control LOGIX 5000 SystemDocumento42 páginasControl LOGIX 5000 SystemhobergerAinda não há avaliações

- PLC Training Tutor0001 PDFDocumento158 páginasPLC Training Tutor0001 PDFengineeraina100% (1)

- Introduction To Java HomeworkDocumento2 páginasIntroduction To Java Homeworkstefan16394Ainda não há avaliações

- RTC Device DriverDocumento3 páginasRTC Device Driverapi-3802111Ainda não há avaliações

- Release Notes - Materialise Mimics 22.0 RTM PDFDocumento14 páginasRelease Notes - Materialise Mimics 22.0 RTM PDFhello singhAinda não há avaliações

- Nel Pro Fuser GuideDocumento64 páginasNel Pro Fuser GuideChan PhingAinda não há avaliações

- Apply for Allahabad Bank Internet BankingDocumento6 páginasApply for Allahabad Bank Internet Bankingnijju2009Ainda não há avaliações

- Lee Varis Skin 2nd EditionDocumento368 páginasLee Varis Skin 2nd EditionIvanIvanov2013Ainda não há avaliações

- Manual Virex Pro 3.19r2 FR - 19!04!2012Documento73 páginasManual Virex Pro 3.19r2 FR - 19!04!2012Lance Johnpaul SyAinda não há avaliações

- ARMS TSA Brochure Final 4Documento2 páginasARMS TSA Brochure Final 4Hugo AlemanAinda não há avaliações

- 1-Getting To Know The BoardDocumento4 páginas1-Getting To Know The BoardaposhekerAinda não há avaliações

- How To Become An Online Entrepreneur Ebook V2Documento7 páginasHow To Become An Online Entrepreneur Ebook V2Nick BlackAinda não há avaliações

- Tingklik Manual (Kontakt EXS)Documento15 páginasTingklik Manual (Kontakt EXS)David BlanesAinda não há avaliações

- Simatic Net: Step by Step: Ethernet Communication Between OPC Server and S7-200 Incl. CP243-1Documento45 páginasSimatic Net: Step by Step: Ethernet Communication Between OPC Server and S7-200 Incl. CP243-1Franco SotoAinda não há avaliações

- Lexmark Ms310dn UG enDocumento196 páginasLexmark Ms310dn UG enXenopoulosAndreasAinda não há avaliações

- Modul File Server 15. Samba Server: 15.1. InstallasiDocumento3 páginasModul File Server 15. Samba Server: 15.1. Installasieko wahonoAinda não há avaliações

- Computer Notes - Networking and Internet For IBPS Bank ExamDocumento4 páginasComputer Notes - Networking and Internet For IBPS Bank ExamakshitaAinda não há avaliações

- Disha Publication Shortcut On Coding DecodingDocumento5 páginasDisha Publication Shortcut On Coding DecodingJanaki KrishnanAinda não há avaliações

- WordDocumento61 páginasWordapi-3777069Ainda não há avaliações

- Bcs 031Documento25 páginasBcs 031rsadgaAinda não há avaliações

- Burner Logic System PDFDocumento5 páginasBurner Logic System PDFshiviitd02Ainda não há avaliações

- Agfa CR 35-XDocumento82 páginasAgfa CR 35-XPaulo PortelaAinda não há avaliações

- CSTP BrochureDocumento5 páginasCSTP Brochureapi-3738664Ainda não há avaliações

- A New Approach: Data Segregation ModelDocumento3 páginasA New Approach: Data Segregation ModelEditor IJRITCCAinda não há avaliações

- Digital Design Through Verilog HDLDocumento4 páginasDigital Design Through Verilog HDLmukesh_sonuAinda não há avaliações

- Vita Template PDFDocumento2 páginasVita Template PDFMoath AlhajiriAinda não há avaliações

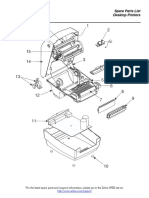

- Zebra GC420tDocumento2 páginasZebra GC420treginaldo2005100% (1)

- Pseudocode Test 2 Cram UpDocumento7 páginasPseudocode Test 2 Cram UpPallavi BhartiAinda não há avaliações

- P442 CortecDocumento6 páginasP442 CortecHari Krishna.MAinda não há avaliações

- Unit 5 Machine Learning With PU SolutionDocumento68 páginasUnit 5 Machine Learning With PU SolutionKavi Raj AwasthiAinda não há avaliações

- MET 205 - Cotter PinDocumento64 páginasMET 205 - Cotter Pintomtom9649Ainda não há avaliações

- BYD DemoScript Product Cycle CountDocumento14 páginasBYD DemoScript Product Cycle CountLakhbir SinghAinda não há avaliações