Escolar Documentos

Profissional Documentos

Cultura Documentos

Ti 85.250 Ua

Enviado por

nazar750Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Ti 85.250 Ua

Enviado por

nazar750Direitos autorais:

Formatos disponíveis

TECHNICAL INFORMA TION INFORMATION

SERIES 85-250 CHL ORINE DIO XIDE SYSTEM CHLORINE DIOXIDE

FEA TURES FEATURES

Highest efficiency available, converts 96 to 98% of sodium chlorite to chlorine dioxide. Simple automatic-batch control. Automatic monitoring and control of input variables maintains proper chlorine, sodium chlorite, and water mixing ratios. Chlorine Dioxide will not form THMs nor react with ammonia. Choice of capacities: 80 or 240 lb of chlorine dioxide per day. Shipped assembled and wired, easy to install. Less sensitive to pH changes than other oxidants.

CHL ORINE DIO XIDE HLORINE IOXIDE

rine dioxide are sodium chlorite (NaClO2) and chlorine (Cl2). A commercial solution of 25% sodium chlorite is generally used to react with a 3.9 g/L chlorine solution to form chlorine dioxide solution. The chemical equation of this reaction is:

2 NaClO2 + Cl2 = 2CIO2 + 2 NaCl

within the system capacity. Thus, the system converts a high 96 to 98% of available sodium chlorite over its entire operating range and fully utilizes this expensive chemical. For efficient conversion of sodium chlorite to chlorine dioxide, a high concentration/low pH chlorine solution is required. The Wallace & Tiernan Products system utilizes continuous batching and optimum hydraulic conditions to maintain the pH at a low level and provide the acidity necessary to produce high-concentration chlorine dioxide solution rapidly and efficiently.

AUT OMA TIC-BA TCH CONTROL, SIMPLE UTOMA OMATIC BAT

TO

Chlorine dioxide is a powerful disinfectant and oxidizing agent. It is recognized by the EPA as a primary disinfectant; but it is unstable and must be generated onsite. It does not react with ammonia to form less-active chloramines; it will not form trihalomethanes or other chlorinated organic compounds; nor will it react with many impurities that normally consume chlorine. Chlorine dioxide has proved economical and effective treating waters high in ammonia or organic nitrogen and in the destruction of phenol-based taste-andodor- causing compounds. Unlike chlorine, it is essentially unaffected by pH, thus is cost effective as a means of treatment when high pH is present.

A TWO-CHEMICAL PROCESS

At the appropriate ratio of sodium chlorite to chlorine and at a high reaction concentration, nearly pure chlorine dioxide solution can be produced. For the treatment of drinking water or industrial process water, it is usually desirable to generate chlorine-free chlorine dioxide solutions.

EFFICIENT, CONVERTS 96% CHL ORITE HLORITE

TO

98%

OF

SODIUM

OPERA TE PERATE

The Wallace & Tiernan Products system has a control panel for the operators convenience. It shows the status of each process in the system at a glance. It has

The Wallace & Tiernan Products system is a batching system and generates solution at a fixed rate. This design simplifies the system control and assures the optimum mixing ratio-at any delivery rate

In the Wallace & Tiernan system, the chemicals used in the preparation of chlo-

TECHNICAL INFORMA TION INFORMATION

SERIES 85-250 CHL ORINE DIO XIDE SYSTEM CHLORINE DIOXIDE

only one operator control: an on-off switch. Level probes in the chlorine dioxide holding tank monitor the stored solution level and start and stop the batch cycles. Chemical feed rates are fixed.

EFFICIENCY NOT TIED TO DEMAND OPERA TION OPERATION

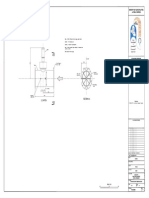

lated by a ball control valve (13) and indicated on a flowmeter (11). The quantity depends on the specific solution strength required (between 2g/L and 4g/L). Chlorine dioxide solution is drawn from the storage tank outlet (15) and passed to the point of application using a metering pump such as the Wallace & Tiernan Chemtube 2000 Tubular Diaphragm Pump or Encore 700 Diaphragm Pump, both described in the section on options. The storage tank for chlorine dioxide solution is fitted with level probes for control of the batch cycle. The high level probe stops the generating cycle by closing the solenoid valve (9) and stopping the metering pump (16), and the low level probe restarts them. The storage tank is open to atmosphere through the vent line (21) to prevent pressurization. An integral overflow relief valve (20) in this line provides for the relief of an overflow condition in the storage tank. Associated with the chlorine dioxide storage tank is an injector (19) connected with the vent line from the tank. Chlorine dioxide vapors resulting from partial degassing of the solution during the generating process are evacuated by the injector. The water passing through this vent injector is injected into the water to be treated or is taken directly to drain. When this injector is turned off, tank fumes are relieved through the vent line (21). The chlorine dioxide generating system is equipped with appropriate monitoring controls to ensure that the mixing ratio is maintained and that no unreacted sodium

The low solution level switch in the chlorine dioxide solution holding tank initiates system operation by opening the operating water solenoid valves. The chlorine gas is metered by the chlorinator (5), mixed with water in the chlorinator injector (4) to produce a high concentration chlorine solution for the reaction tower (18). The chlorine gas feedrate is manually set at the chlorinator (5) and indicated on a flowmeter. Another flowmeter (10) indicates the quantity of operating water going to the injector (4). Operating water pressure is set at the pressure reducing valve/strainer assembly (8). In cases where the water supply pressure is lower than required, a booster pump (7) must be installed. At the same time, sodium chlorite solution is taken from the customer storage tank by means of a metering pump (16) and injected into the reaction tower (18). The sodium chlorite feed rate is set at the metering pump and indicated on a flowmeter (17). Chlorine dioxide solution is produced in the reaction tower, which contains ceramic mixing rings. The rings cause turbulence and thorough mixing as the solution rises to the top. A solution containing either pure chlorine dioxide or chlorine and chlorine dioxide, depending on the specific requirements, is obtained. After the reagents have fully reacted, dilution water is added to the chlorine dioxide solution at the outlet of the reaction tower before it is passed into the storage tank (14). The quantity of dilution water is regu-

By design, most chlorine dioxide systems have their chemcial feed rates tied to demand. Due to varying reactant concentrations, their efficiency drops when demand drops. But in the Wallace & Tiernan batch method, hydraulic and chemical-addition systems are fixed. Efficiency is maintained over the full range of operation.

SHIPPED ASSEMBLED, EASY TO INST ALL NSTALL

The Wallace & Tiernan Chlorine Dioxide System is delivered assembled, wired, and pre-tested for easy start-up. It is mounted in a sturdy metal framework designed for convenient maintenance. Installation requires only placing the system on-site, making simple plumbingtype and electrical connections, and installing a metering pump to discharge chlorine dioxide solution to the point of application.

Close-up of control panel showing mimic diagram

TECHNICAL INFORMA TION INFORMATION

SERIES 85-250 CHL ORINE DIO XIDE SYSTEM CHLORINE DIOXIDE

chlorite is passed into the water being treated. Adjustable alarm switches installed on the flowmeters for injector operating water (10), dilution water (11) and sodium chlorite (17), monitor the pre-set flow rates. A vacuum switch (6) situated in the chlorinator vacuum line monitors the chlorine gas supply. All electrical function and controls are grouped at the control panel (22) in such a way that any electrical or hydraulic malfunction will actuate an alarm and shut the system off. The monitoring components and alarm interlocks make incorrect operation of the generating system due to malfunction virtually impossible.

DESIGN AND CONSTRUCTION

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. Chlorine cylinder Vacuum regulator Pressure-relief valve Injector Chlorinator Vacuum switch Booster pump (optional) Pressure-reducing valve Solenoid valve Injector-water flowmeter Dilution-water flowmeter 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. Backpressure-check valve Ball valve Chlorine dioxide storage tank Storage tank outlet Sodium chlorite metering pump Sodium chlorite flowmeter Reaction tower Fume-evacuation injector Overflow relief valve Vent line Control panel

Chlorine-gas supply is monitored by a vacuum switch at the chlorinator. The vacuum switch shuts down the system and activates an alarm on high or low chlorine supply vacuum. The chlorinator meters gas flow. Flow rate is manually set and indicated on a rotameter. The chlorine supply to and from the chlorinator is always under vacuum. In the reaction tower, the sodium chlorite and chlorine solutions produce chlorine dioxide at a concentration of about 7g/L. Dilution water, added at the reaction tower outlet, brings the concentration down to between 2g/L and 4g/L. High-and lowlevel probes in the holding tank start and stop operation to maintain solution level. An alarm switch warns of a high level. There is a fume-evacuation injector in the vent line from the holding tank to con-

trol off-gassing during generation. Chlorine dioxide solution can be delivered from the holding tank to the point of application by a manual or automatic metering pump. The control panel enclosure is rated NEMA 12. The automatic control and monitoring functions are accomplished by a relay-diode control system arranged on a printed circuit board. A remote, normally closed switch can be used to start and stop system operation. Included on the panel are: the system on-off switch; a reset button which restarts the system after an alarm condition; a horn-off button which cancels local and remote alarms without restarting the system. A mimic diagram shows the main system components and monitors each ones operation by means of a lighted alarm LED.

3

The Wallace & Tiernan Products Chlorine Dioxide System is an automatic-batching system. Its main components are a chlorinator, vacuum switch, sodium chlorite pump and supply tank (user furnished), reaction tower, control panel, water-pressure regulator, solenoid valve, flowmeters and a holding tank. Also included are piping, hardware and the sensors and controls which monitor system operation. Alarm interlocks monitor the water, chlorine gas, and sodium chlorite inputs as well as the holding tank. Water is used to operate the chlorinators injector and to dilute the chlorine dioxide solution generated. A waterpressure regulator and a solenoid valve maintain the proper flow. Rotameters indicate flow; float-level alarms assure proper operation.

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- String: "String".title "String".upper : "String".lower F" Sring (String) (String) String"Documento16 páginasString: "String".title "String".upper : "String".lower F" Sring (String) (String) String"nazar750Ainda não há avaliações

- Conversion Gate01Documento1 páginaConversion Gate01nazar750Ainda não há avaliações

- Python Tutorial PDFDocumento155 páginasPython Tutorial PDFDiana RusuAinda não há avaliações

- Static Mixer Designing QuestionnairesDocumento1 páginaStatic Mixer Designing Questionnairesnazar750Ainda não há avaliações

- LPG Storage VesselsDocumento14 páginasLPG Storage Vesselsthanhphucbr87Ainda não há avaliações

- BoooDocumento1 páginaBooonazar750Ainda não há avaliações

- Helical Static Mixer Data SheetDocumento5 páginasHelical Static Mixer Data Sheetnazar750Ainda não há avaliações

- Static Mixer User ManualDocumento9 páginasStatic Mixer User Manualnazar750Ainda não há avaliações

- Bump Case FPC58-2745-01 RBDocumento8 páginasBump Case FPC58-2745-01 RBnazar750Ainda não há avaliações

- English Grammar in English EnglizecomDocumento102 páginasEnglish Grammar in English Englizecomnazar750100% (1)

- SolidWorks Motion Tutorial 2013Documento32 páginasSolidWorks Motion Tutorial 2013bhumijayaAinda não há avaliações

- The Mathematics of Pumping Water PDFDocumento9 páginasThe Mathematics of Pumping Water PDFOualid LamraouiAinda não há avaliações

- Tank Api650Documento11 páginasTank Api650nazar750Ainda não há avaliações

- Tank Api650Documento6 páginasTank Api650nazar750Ainda não há avaliações

- 1279 Gauge ManualDocumento2 páginas1279 Gauge Manualmasood1369Ainda não há avaliações

- Horizontal ScrubberDocumento8 páginasHorizontal Scrubbernazar750Ainda não há avaliações

- Sewer AppDocumento27 páginasSewer AppEr Harsh MahajanAinda não há avaliações

- Tank Api650Documento11 páginasTank Api650nazar750Ainda não há avaliações

- ElectricalDocumento46 páginasElectricalRobert Columbine100% (2)

- Jonshon ScreenDocumento25 páginasJonshon Screennazar750Ainda não há avaliações

- 01-217 CLB Mechanical DrawingsDocumento5 páginas01-217 CLB Mechanical Drawingsnazar750Ainda não há avaliações

- 01-212 FB Mechanical DrawingsDocumento7 páginas01-212 FB Mechanical Drawingsnazar750Ainda não há avaliações

- 01-203 RW Mechanical DrawingsDocumento6 páginas01-203 RW Mechanical Drawingsnazar750Ainda não há avaliações

- 01-207 CLAR Mechanical DrawingsDocumento5 páginas01-207 CLAR Mechanical Drawingsnazar750Ainda não há avaliações

- 01-203 RW Mechanical DrawingsDocumento6 páginas01-203 RW Mechanical Drawingsnazar750Ainda não há avaliações

- 01-243 TW Mechanical DrawingsDocumento4 páginas01-243 TW Mechanical Drawingsnazar750Ainda não há avaliações

- 01-203 RW Mechanical DrawingsDocumento6 páginas01-203 RW Mechanical Drawingsnazar750Ainda não há avaliações

- 01-206 CD Mechanical DrawingDocumento1 página01-206 CD Mechanical Drawingnazar750Ainda não há avaliações

- Sluice Gate DenizDocumento1 páginaSluice Gate Deniznazar750Ainda não há avaliações

- Dosing PumpDocumento6 páginasDosing Pumpnazar750Ainda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Using MonteCarlo Simulation To Mitigate The Risk of Project Cost OverrunsDocumento8 páginasUsing MonteCarlo Simulation To Mitigate The Risk of Project Cost OverrunsJancarlo Mendoza MartínezAinda não há avaliações

- Top Survival Tips - Kevin Reeve - OnPoint Tactical PDFDocumento8 páginasTop Survival Tips - Kevin Reeve - OnPoint Tactical PDFBillLudley5100% (1)

- Award Presentation Speech PDFDocumento3 páginasAward Presentation Speech PDFNehal RaiAinda não há avaliações

- Mystakidis2022 MetaverseDocumento13 páginasMystakidis2022 MetaverseVennela NandikondaAinda não há avaliações

- C7.5 Lecture 18: The Schwarzschild Solution 5: Black Holes, White Holes, WormholesDocumento13 páginasC7.5 Lecture 18: The Schwarzschild Solution 5: Black Holes, White Holes, WormholesBhat SaqibAinda não há avaliações

- Solitax SCDocumento8 páginasSolitax SCprannoyAinda não há avaliações

- Product 97 File1Documento2 páginasProduct 97 File1Stefan StefanAinda não há avaliações

- Integrated Management System 2016Documento16 páginasIntegrated Management System 2016Mohamed HamedAinda não há avaliações

- Promoting Services and Educating CustomersDocumento28 páginasPromoting Services and Educating Customershassan mehmoodAinda não há avaliações

- Technology in Society: SciencedirectDocumento10 páginasTechnology in Society: SciencedirectVARGAS MEDINA ALEJANDRAAinda não há avaliações

- Prosocial Behaviour: Hans W. BierhoffDocumento20 páginasProsocial Behaviour: Hans W. BierhoffSahil Mushaf100% (1)

- Submitted By: S.M. Tajuddin Group:245Documento18 páginasSubmitted By: S.M. Tajuddin Group:245KhurshidbuyamayumAinda não há avaliações

- ZyLAB EDiscovery 3.11 What's New ManualDocumento32 páginasZyLAB EDiscovery 3.11 What's New ManualyawahabAinda não há avaliações

- F. Moyra Allen: A Life in Nursing, 1921-1996: Meryn Stuart, R.N., PH.DDocumento9 páginasF. Moyra Allen: A Life in Nursing, 1921-1996: Meryn Stuart, R.N., PH.DRose Nirwana HandayaniAinda não há avaliações

- Machine Tools PDFDocumento57 páginasMachine Tools PDFnikhil tiwariAinda não há avaliações

- Enzymatic Hydrolysis, Analysis of Mucic Acid Crystals and Osazones, and Thin - Layer Chromatography of Carbohydrates From CassavaDocumento8 páginasEnzymatic Hydrolysis, Analysis of Mucic Acid Crystals and Osazones, and Thin - Layer Chromatography of Carbohydrates From CassavaKimberly Mae MesinaAinda não há avaliações

- Suggestions On How To Prepare The PortfolioDocumento2 páginasSuggestions On How To Prepare The PortfolioPeter Pitas DalocdocAinda não há avaliações

- Pepsi Mix Max Mox ExperimentDocumento2 páginasPepsi Mix Max Mox Experimentanon_192325873Ainda não há avaliações

- Quality Assurance Plan - CivilDocumento11 páginasQuality Assurance Plan - CivilDeviPrasadNathAinda não há avaliações

- COACHING TOOLS Mod4 TGOROWDocumento6 páginasCOACHING TOOLS Mod4 TGOROWZoltan GZoltanAinda não há avaliações

- Standalone Financial Results, Limited Review Report For December 31, 2016 (Result)Documento4 páginasStandalone Financial Results, Limited Review Report For December 31, 2016 (Result)Shyam SunderAinda não há avaliações

- Management of StutteringDocumento182 páginasManagement of Stutteringpappu713100% (2)

- Lenovo S340-15iwl Compal LA-H101P SchematicDocumento53 páginasLenovo S340-15iwl Compal LA-H101P SchematicYetawa Guaviare100% (4)

- Annotated Bibliography 2Documento3 páginasAnnotated Bibliography 2api-458997989Ainda não há avaliações

- EIL 6-51-0051-Rev 06 - 1.1kv-Xlpe - Dimension Cat - B Armour-BbpDocumento2 páginasEIL 6-51-0051-Rev 06 - 1.1kv-Xlpe - Dimension Cat - B Armour-BbpShubham BaderiyaAinda não há avaliações

- AJ IntroductionDocumento31 páginasAJ IntroductiontrollergamehuydkAinda não há avaliações

- Excel Lesson 5 QuizDocumento5 páginasExcel Lesson 5 Quizdeep72Ainda não há avaliações

- "Prayagraj ": Destination Visit ReportDocumento5 páginas"Prayagraj ": Destination Visit ReportswetaAinda não há avaliações

- Invenio Flyer enDocumento2 páginasInvenio Flyer enErcx Hijo de AlgoAinda não há avaliações

- Sample Paper Book StandardDocumento24 páginasSample Paper Book StandardArpana GuptaAinda não há avaliações