Escolar Documentos

Profissional Documentos

Cultura Documentos

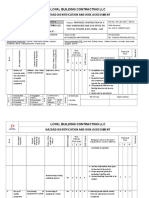

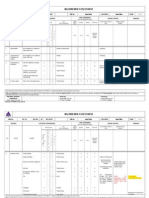

HEALTH & SAFETY RISK ASSESSMENT

Enviado por

mujahid1137Descrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

HEALTH & SAFETY RISK ASSESSMENT

Enviado por

mujahid1137Direitos autorais:

Formatos disponíveis

HEALTH & SAFETY RISK ASSESSMENT

Transportat

ion of

Employees

(Bus /

pickup /

truck)

R

/

N

Noncompliance to

or violation of

Qatar Traffic

Law.

Damaged

or

slippery stairs

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

Penalty

Physical

injuries

Legal requirements are

being complied.

Drivers

are

licensed,

trained and have the

functional capability to

operate the vehicle.

Maintenance

and

inspection is being done

regularly.

Significance

(Likely hood x severity x spread)Risk level

Spread (1 to 5)

Gaps, if

any

Existing Control

Additional controls required

Ensure continuous

compliance

High

Page

1 of

52

Risk Assessment

(See Risk management matrix)

Severity (1 to 5)

Loss

(Risk Consequence)

Personnel at risk

Others

Adequacy of existing control measures

Likely hood of harm (1 to 3)

PROJECT

DESCRIPTION

Visitors

ME- 4894

Sub-Contractors

Job

No.

24-11-2013

All Employees - 2Some Employees 1/

Hazards

Rev

Date

00

(Refer table 3 of procedure)Concern (L/I/B)

Activity

Rev No.

(Refer table 2 of procedure)Hazard Category (D/I)

PSL-ME-4894HRA-01

(Refer table 1 of procedure)Operating Condition (R/N/E)

Sl No

HRA No.

Remarks

Please

Refer

Procedure

No. PSL0000-OCPOHS-25

Low

First aid kit is provided in

the vehicle.

Condition of

Vehicle (Noise,

Vibration, Dust

and Heat)

Crowd during

embarking

and

disembarking

Health issues

Physical

injuries

Maintenance

and

inspection is being done

regularly.

Queue

is

maintained

embarking

disembarking.

being

during

&

Low

Please

Refer

Procedure

No. PSL0000-OCPOHS-26

Risk Assessment shall be done in accordance with the IMS Procedure No. PSL-IMSP-10 (Health and Safety Hazard Identification, Risk Assesment and Control.) ,Loss (Risk consequences)= Physical injury, Health issues, Environmental Issues, Property damage etc

Risk Level Significance: 1 to 6 (Low) are not significant and no further action is required. 8 to 20 (Medium) are Significant Risk and shall be reduced so that they are tolerable / acceptable. 24 -75 (High) are Unacceptable and work activity shall be halted until risk

controls are implemented that reduce the risk so that it is no longer very high.

Project Engineer

(Name, Signature & Date)

Review By:

Review By:

As per IMSP Proc. No.

As per IMSP Proc. No.

Supervisor

PSL-IMSP-10 & Date

PSL-IMSP-10 & Date

HSE Representative

Format No: PSL-IMSP-10-F-01, Rev 00

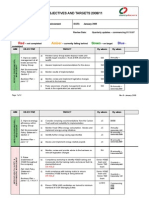

HEALTH & SAFETY RISK ASSESSMENT

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

Significance

(Likely hood x severity x spread)Risk level

Spread (1 to 5)

Gaps, if

any

Existing Control

Page

2 of

52

Risk Assessment

(See Risk management matrix)

Severity (1 to 5)

Loss

(Risk Consequence)

Personnel at risk

Others

Adequacy of existing control measures

Likely hood of harm (1 to 3)

PROJECT

DESCRIPTION

Visitors

ME- 4894

Sub-Contractors

Job

No.

24-11-2013

All Employees - 2Some Employees 1/

Hazards

Rev

Date

00

(Refer table 3 of procedure)Concern (L/I/B)

Activity

Rev No.

(Refer table 2 of procedure)Hazard Category (D/I)

PSL-ME-4894HRA-01

(Refer table 1 of procedure)Operating Condition (R/N/E)

Sl No

HRA No.

Additional controls required

Remarks

First aid kit is provided in

the vehicle.

Unsafe driving

Transportat

ion of

material

R

/

N

Noncompliance to

or violation of

Qatar Traffic

Law.

Condition

of

Vehicle (Noise,

Vibration, Dust

and Heat)

Fatalities,

Physical

injuries,

Property

damage

Penalty

Health issues

Competent driver

been assigned.

has

18

Mediu

m

Traffic rules & regulations

are being complied

Legal requirements are

being complied.

Drivers

are

licensed,

trained and have the

functional capability to

operate the vehicle.

Maintenance

and

inspection of vehicles are

being done regularly

Provide defensive driving

training

Ensure continuous

compliance

High

Low

Please

Refer

Procedure

No. PSL0000-OCPOHS-13

Please

Refer

Procedure

No. PSL0000-OCPOHS-26

Risk Assessment shall be done in accordance with the IMS Procedure No. PSL-IMSP-10 (Health and Safety Hazard Identification, Risk Assesment and Control.) ,Loss (Risk consequences)= Physical injury, Health issues, Environmental Issues, Property damage etc

Risk Level Significance: 1 to 6 (Low) are not significant and no further action is required. 8 to 20 (Medium) are Significant Risk and shall be reduced so that they are tolerable / acceptable. 24 -75 (High) are Unacceptable and work activity shall be halted until risk

controls are implemented that reduce the risk so that it is no longer very high.

Project Engineer

(Name, Signature & Date)

Review By:

Review By:

As per IMSP Proc. No.

As per IMSP Proc. No.

Supervisor

PSL-IMSP-10 & Date

PSL-IMSP-10 & Date

HSE Representative

Format No: PSL-IMSP-10-F-01, Rev 00

HEALTH & SAFETY RISK ASSESSMENT

Material

handling

(Manual)

by workers

R

/

N

Loading /

unloading

material

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

Property

damage,

Physical

injuries,

Fatalities

Physical

injuries,

property

damage

Competent driver

been assigned.

has

Significance

18

Mediu

m

Traffic rules & regulations

are being complied

If possible Trolleys or

wheelbarrows are being

used.

For heavy loads lifting

equipment is being used

to

load

/

unload

materials from vehicle.

When lifting a load along

with another person(s),

communication with the

other

person(s)

is

maintained

before

lowering the load.

Page

3 of

52

Risk Assessment

(See Risk management matrix)

(Likely hood x severity x spread)Risk level

Gaps, if

any

Existing Control

Others

Loss

(Risk Consequence)

Personnel at risk

Visitors

Adequacy of existing control measures

Spread (1 to 5)

PROJECT

DESCRIPTION

Sub-Contractors

ME- 4894

Severity (1 to 5)

Job

No.

Likely hood of harm (1 to 3)

Unsafe driving

24-11-2013

All Employees - 2Some Employees 1/

Hazards

Rev

Date

00

(Refer table 3 of procedure)Concern (L/I/B)

Activity

Rev No.

(Refer table 2 of procedure)Hazard Category (D/I)

PSL-ME-4894HRA-01

(Refer table 1 of procedure)Operating Condition (R/N/E)

Sl No

HRA No.

Low

Additional controls required

Remarks

Provide defensive driving

training

Please

Refer

Procedure

No. PSL0000-OCPOHS-02

For lifting heavy loads

assistance is taken.

Do not twist your body

while carrying a heavy

Risk Assessment shall be done in accordance with the IMS Procedure No. PSL-IMSP-10 (Health and Safety Hazard Identification, Risk Assesment and Control.) ,Loss (Risk consequences)= Physical injury, Health issues, Environmental Issues, Property damage etc

Risk Level Significance: 1 to 6 (Low) are not significant and no further action is required. 8 to 20 (Medium) are Significant Risk and shall be reduced so that they are tolerable / acceptable. 24 -75 (High) are Unacceptable and work activity shall be halted until risk

controls are implemented that reduce the risk so that it is no longer very high.

Project Engineer

(Name, Signature & Date)

Review By:

Review By:

As per IMSP Proc. No.

As per IMSP Proc. No.

Supervisor

PSL-IMSP-10 & Date

PSL-IMSP-10 & Date

HSE Representative

Format No: PSL-IMSP-10-F-01, Rev 00

HEALTH & SAFETY RISK ASSESSMENT

PROJECT

DESCRIPTION

ME- 4894

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

Adequacy of existing control measures

Personnel at risk

Likely hood of harm (1 to 3)

Severity (1 to 5)

Spread (1 to 5)

Required PPE is utilized.

Slips & falls

due

to

imbalance

Physical

injuries.

Based on requirement

additional personnel are

utilized

for

manual

handling.

Walkways

and

Passageways are kept

clear.

Gaps, if

any

Others

Physical

injuries.

Existing Control

Visitors

Loss

(Risk Consequence)

Sub-Contractors

Sharp edges of

material.

Hazards

Page

4 of

52

Risk Assessment

(See Risk management matrix)

Significance

Job

No.

(Likely hood x severity x spread)Risk level

24-11-2013

All Employees - 2Some Employees 1/

Rev

Date

00

(Refer table 3 of procedure)Concern (L/I/B)

Activity

Rev No.

(Refer table 2 of procedure)Hazard Category (D/I)

PSL-ME-4894HRA-01

(Refer table 1 of procedure)Operating Condition (R/N/E)

Sl No

HRA No.

Additional controls required

Remarks

load

Appropriate PPE is being

used

Lifting

(Material

Handling Mechanical

)

R

/

N

Incorrect

information on

permit/clearan

ce

D

/I

Physical

injuries,

Property

damage

Ground

conditions

D

/I

Property

damage,

Low

Low

18

Mediu

m

18

Mediu

m

Work Permit system shall

be followed.

Please

Refer

Procedure

No. PSL0000-OCPOHS-10

Attention shall be paid on

Risk Assessment shall be done in accordance with the IMS Procedure No. PSL-IMSP-10 (Health and Safety Hazard Identification, Risk Assesment and Control.) ,Loss (Risk consequences)= Physical injury, Health issues, Environmental Issues, Property damage etc

Risk Level Significance: 1 to 6 (Low) are not significant and no further action is required. 8 to 20 (Medium) are Significant Risk and shall be reduced so that they are tolerable / acceptable. 24 -75 (High) are Unacceptable and work activity shall be halted until risk

controls are implemented that reduce the risk so that it is no longer very high.

Project Engineer

(Name, Signature & Date)

Review By:

Review By:

As per IMSP Proc. No.

As per IMSP Proc. No.

Supervisor

PSL-IMSP-10 & Date

PSL-IMSP-10 & Date

HSE Representative

Format No: PSL-IMSP-10-F-01, Rev 00

HEALTH & SAFETY RISK ASSESSMENT

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

Significance

(Likely hood x severity x spread)Risk level

Gaps, if

any

Spread (1 to 5)

Existing Control

Page

5 of

52

Risk Assessment

(See Risk management matrix)

Severity (1 to 5)

Loss

(Risk Consequence)

Personnel at risk

Others

Adequacy of existing control measures

Likely hood of harm (1 to 3)

PROJECT

DESCRIPTION

ME- 4894

Visitors

Job

No.

Sub-Contractors

24-11-2013

All Employees - 2Some Employees 1/

Hazards

Rev

Date

00

(Refer table 3 of procedure)Concern (L/I/B)

Activity

Rev No.

(Refer table 2 of procedure)Hazard Category (D/I)

PSL-ME-4894HRA-01

(Refer table 1 of procedure)Operating Condition (R/N/E)

Sl No

HRA No.

Physical

injuries.

Remarks

Additional controls required

uneven terrain structure.

Hold

pre-job

meeting

safety

Work Permit system shall

be followed..

Site safety

followed

Defective

lifting

equipment

D

/I

Property

damage,

Physical

injuries.

18

Mediu

m

rules

are

Work Permit system shall

be followed.

Ensure lifting equipment

(appliances

and

accessories) has valid

certification.

Ensure

that

lifting

accessories are correctly

colour coded

Inspect equipment prior

to use

Ensure

equipment

regularly maintained

is

Risk Assessment shall be done in accordance with the IMS Procedure No. PSL-IMSP-10 (Health and Safety Hazard Identification, Risk Assesment and Control.) ,Loss (Risk consequences)= Physical injury, Health issues, Environmental Issues, Property damage etc

Risk Level Significance: 1 to 6 (Low) are not significant and no further action is required. 8 to 20 (Medium) are Significant Risk and shall be reduced so that they are tolerable / acceptable. 24 -75 (High) are Unacceptable and work activity shall be halted until risk

controls are implemented that reduce the risk so that it is no longer very high.

Project Engineer

(Name, Signature & Date)

Review By:

Review By:

As per IMSP Proc. No.

As per IMSP Proc. No.

Supervisor

PSL-IMSP-10 & Date

PSL-IMSP-10 & Date

HSE Representative

Format No: PSL-IMSP-10-F-01, Rev 00

HEALTH & SAFETY RISK ASSESSMENT

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

Significance

(Likely hood x severity x spread)Risk level

Spread (1 to 5)

Gaps, if

any

Existing Control

Page

6 of

52

Risk Assessment

(See Risk management matrix)

Severity (1 to 5)

Loss

(Risk Consequence)

Personnel at risk

Others

Adequacy of existing control measures

Likely hood of harm (1 to 3)

PROJECT

DESCRIPTION

ME- 4894

Visitors

Job

No.

Sub-Contractors

24-11-2013

All Employees - 2Some Employees 1/

Hazards

Rev

Date

00

(Refer table 3 of procedure)Concern (L/I/B)

Activity

Rev No.

(Refer table 2 of procedure)Hazard Category (D/I)

PSL-ME-4894HRA-01

(Refer table 1 of procedure)Operating Condition (R/N/E)

Sl No

HRA No.

Additional controls required

Remarks

Only

approved

lifting

equipment is being used.

Improper

lifting

D

/I

Physical

injuries,

property

damage

Certified operators are

operating equipment

Banks man

provided.

is

18

Work Permit system shall

be followed.

being

Lifting plan is prepared

and followed prior to

lifting of equipment /

objects.

Surrounding area is being

barricaded

wherever

lifting activity is going to

be done.

Mediu

m

Supervisor shall ensure

that

maintenance

of

lifting equipment / lifting

gears is being done

regularly.

Check

for

the

environmental conditions

prior to lift.

Keep

all

emergency

sources ready

Follow

manufacturers

instruction.

Risk Assessment shall be done in accordance with the IMS Procedure No. PSL-IMSP-10 (Health and Safety Hazard Identification, Risk Assesment and Control.) ,Loss (Risk consequences)= Physical injury, Health issues, Environmental Issues, Property damage etc

Risk Level Significance: 1 to 6 (Low) are not significant and no further action is required. 8 to 20 (Medium) are Significant Risk and shall be reduced so that they are tolerable / acceptable. 24 -75 (High) are Unacceptable and work activity shall be halted until risk

controls are implemented that reduce the risk so that it is no longer very high.

Project Engineer

(Name, Signature & Date)

Review By:

Review By:

As per IMSP Proc. No.

As per IMSP Proc. No.

Supervisor

PSL-IMSP-10 & Date

PSL-IMSP-10 & Date

HSE Representative

Format No: PSL-IMSP-10-F-01, Rev 00

HEALTH & SAFETY RISK ASSESSMENT

Incorrect

information on

permit/clearan

ce

D

/I

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

Physical

injuries,

Property

damage

Page

7 of

52

Risk Assessment

(See Risk management matrix)

Significance

Others

Gaps, if

any

Visitors

Existing Control

Personnel at risk

Sub-Contractors

Loss

(Risk Consequence)

(Refer table 3 of procedure)Concern (L/I/B)

Adequacy of existing control measures

(Likely hood x severity x spread)Risk level

PROJECT

DESCRIPTION

ME- 4894

All Employees - 2Some Employees 1/

Job

No.

Spread (1 to 5)

24-11-2013

Severity (1 to 5)

Working in

Confined

space

Hazards

Rev

Date

00

(Refer table 2 of procedure)Hazard Category (D/I)

Activity

Rev No.

Likely hood of harm (1 to 3)

PSL-ME-4894HRA-01

(Refer table 1 of procedure)Operating Condition (R/N/E)

Sl No

HRA No.

12

Additional controls required

Work

permit

system

shall be followed.

Mediu

m

Have

a

clear

understanding of work to

be

performed

and

location

Remarks

Please

Refer

Procedure

No. PSL0000-OCPOHS-08

Use all the emergency

equipments mentioned

in the work permit.

Maintain entry / exit log.

Lack

of

Communicatio

n

D

/I

Physical

injuries,

Property

damage

12

Mediu

m

Work

permit

system

shall be followed.

Plan the work involving

personnel responsible for

preparation

(isolation,

depressurization,

draining,

venting,

flushing, purging, gas

testing etc.) of confined

space.

Place a Standby Person

Risk Assessment shall be done in accordance with the IMS Procedure No. PSL-IMSP-10 (Health and Safety Hazard Identification, Risk Assesment and Control.) ,Loss (Risk consequences)= Physical injury, Health issues, Environmental Issues, Property damage etc

Risk Level Significance: 1 to 6 (Low) are not significant and no further action is required. 8 to 20 (Medium) are Significant Risk and shall be reduced so that they are tolerable / acceptable. 24 -75 (High) are Unacceptable and work activity shall be halted until risk

controls are implemented that reduce the risk so that it is no longer very high.

Project Engineer

(Name, Signature & Date)

Review By:

Review By:

As per IMSP Proc. No.

As per IMSP Proc. No.

Supervisor

PSL-IMSP-10 & Date

PSL-IMSP-10 & Date

HSE Representative

Format No: PSL-IMSP-10-F-01, Rev 00

HEALTH & SAFETY RISK ASSESSMENT

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

Significance

Gaps, if

any

(Likely hood x severity x spread)Risk level

Existing Control

Page

8 of

52

Risk Assessment

(See Risk management matrix)

Spread (1 to 5)

Loss

(Risk Consequence)

Personnel at risk

Severity (1 to 5)

Adequacy of existing control measures

Likely hood of harm (1 to 3)

PROJECT

DESCRIPTION

Others

ME- 4894

Visitors

Job

No.

Sub-Contractors

24-11-2013

All Employees - 2Some Employees 1/

Hazards

Rev

Date

00

(Refer table 3 of procedure)Concern (L/I/B)

Activity

Rev No.

(Refer table 2 of procedure)Hazard Category (D/I)

PSL-ME-4894HRA-01

(Refer table 1 of procedure)Operating Condition (R/N/E)

Sl No

HRA No.

Additional controls required

Remarks

near to confined space

to maintain contact with

the entrant and record

entry / exit.

Effective

means

of

communication shall be

established

and

maintained

between

personnel in the confined

space and the standby

man.

Communication shall be

visual, voice or a signal

line.

Keep emergency sources

ready

Train all the personnel

involved

in

confined

Space.

Flammable &

or Toxic

Atmosphere

D

/I

Health

issues, burns,

Fatalities

It is being ensured that

the confined space is

16

Mediu

m

Maintain

awareness

gas

leak

by location

Risk Assessment shall be done in accordance with the IMS Procedure No. PSL-IMSP-10 (Health and Safety Hazard Identification, Risk Assesment and Control.) ,Loss (Risk consequences)= Physical injury, Health issues, Environmental Issues, Property damage etc

Risk Level Significance: 1 to 6 (Low) are not significant and no further action is required. 8 to 20 (Medium) are Significant Risk and shall be reduced so that they are tolerable / acceptable. 24 -75 (High) are Unacceptable and work activity shall be halted until risk

controls are implemented that reduce the risk so that it is no longer very high.

Project Engineer

(Name, Signature & Date)

Review By:

Review By:

As per IMSP Proc. No.

As per IMSP Proc. No.

Supervisor

PSL-IMSP-10 & Date

PSL-IMSP-10 & Date

HSE Representative

Format No: PSL-IMSP-10-F-01, Rev 00

HEALTH & SAFETY RISK ASSESSMENT

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

Significance

(Likely hood x severity x spread)Risk level

Spread (1 to 5)

Gaps, if

any

Existing Control

flushed,

purged

and

thoroughly ventilated as

required

Work permit

taken.

is

being

Ensure

the

space

has

oxygen

for

breathing.

Appropriate PPE is being

used.

D

/I

Property

damage,

Physical

injuries

Suitable lights are being

used

for

additional

illumination working in

confined space or as

appropriate.

Additional controls required

Remarks

and wind direction.

H2S monitor is provided.

9 of

52

If

monitor

warning

actuates leave area and

use

a

predetermined

escape

route

across

wind.

Gas test is being carried

out regularly.

Dark

Insufficient

Illumination

Page

Risk Assessment

(See Risk management matrix)

Severity (1 to 5)

Loss

(Risk Consequence)

Personnel at risk

Others

Adequacy of existing control measures

Likely hood of harm (1 to 3)

PROJECT

DESCRIPTION

ME- 4894

Visitors

Job

No.

Sub-Contractors

Hazards

24-11-2013

All Employees - 2Some Employees 1/

Rev

Date

00

(Refer table 3 of procedure)Concern (L/I/B)

Activity

Rev No.

(Refer table 2 of procedure)Hazard Category (D/I)

PSL-ME-4894HRA-01

(Refer table 1 of procedure)Operating Condition (R/N/E)

Sl No

HRA No.

confined

sufficient

normal

Use Breathing Apparatus

(BA) if needed.

-

12

Mediu

m

Ensure safe illumination

suitable to hazardous

area classification.

Have adequate lighting

to ensure the area is

sufficiently illuminated at

all time.

Natural light is preferred

because

of

access

Risk Assessment shall be done in accordance with the IMS Procedure No. PSL-IMSP-10 (Health and Safety Hazard Identification, Risk Assesment and Control.) ,Loss (Risk consequences)= Physical injury, Health issues, Environmental Issues, Property damage etc

Risk Level Significance: 1 to 6 (Low) are not significant and no further action is required. 8 to 20 (Medium) are Significant Risk and shall be reduced so that they are tolerable / acceptable. 24 -75 (High) are Unacceptable and work activity shall be halted until risk

controls are implemented that reduce the risk so that it is no longer very high.

Project Engineer

(Name, Signature & Date)

Review By:

Review By:

As per IMSP Proc. No.

As per IMSP Proc. No.

Supervisor

PSL-IMSP-10 & Date

PSL-IMSP-10 & Date

HSE Representative

Format No: PSL-IMSP-10-F-01, Rev 00

HEALTH & SAFETY RISK ASSESSMENT

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

Significance

Gaps, if

any

(Likely hood x severity x spread)Risk level

Existing Control

Page

10 of

52

Risk Assessment

(See Risk management matrix)

Spread (1 to 5)

Loss

(Risk Consequence)

Personnel at risk

Severity (1 to 5)

Adequacy of existing control measures

Likely hood of harm (1 to 3)

PROJECT

DESCRIPTION

Others

ME- 4894

Visitors

Job

No.

Sub-Contractors

Hazards

24-11-2013

All Employees - 2Some Employees 1/

Rev

Date

00

(Refer table 3 of procedure)Concern (L/I/B)

Activity

Rev No.

(Refer table 2 of procedure)Hazard Category (D/I)

PSL-ME-4894HRA-01

(Refer table 1 of procedure)Operating Condition (R/N/E)

Sl No

HRA No.

Additional controls required

Remarks

restrictions, fouling of air

hoses etc.

Heat

Humidity

&

Improper

emergency

Equipment

/

Rescue team

D

/I

D

/I

Health issues

Health issues

Sufficient ventilation and

air

circulation

inside

confined

space

is

provided

whenever

required.

Provision

of

periodic

break / rest to the

entrant is being done.

Low

12

Mediu

m

Trained Standby man and

Rescue Team shall be

assigned.

An emergency response

plan shall be drawn up

and well understood by

all role players of the

Risk Assessment shall be done in accordance with the IMS Procedure No. PSL-IMSP-10 (Health and Safety Hazard Identification, Risk Assesment and Control.) ,Loss (Risk consequences)= Physical injury, Health issues, Environmental Issues, Property damage etc

Risk Level Significance: 1 to 6 (Low) are not significant and no further action is required. 8 to 20 (Medium) are Significant Risk and shall be reduced so that they are tolerable / acceptable. 24 -75 (High) are Unacceptable and work activity shall be halted until risk

controls are implemented that reduce the risk so that it is no longer very high.

Project Engineer

(Name, Signature & Date)

Review By:

Review By:

As per IMSP Proc. No.

As per IMSP Proc. No.

Supervisor

PSL-IMSP-10 & Date

PSL-IMSP-10 & Date

HSE Representative

Format No: PSL-IMSP-10-F-01, Rev 00

HEALTH & SAFETY RISK ASSESSMENT

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

Significance

Gaps, if

any

(Likely hood x severity x spread)Risk level

Existing Control

Page

11 of

52

Risk Assessment

(See Risk management matrix)

Spread (1 to 5)

Loss

(Risk Consequence)

Personnel at risk

Severity (1 to 5)

Adequacy of existing control measures

Likely hood of harm (1 to 3)

PROJECT

DESCRIPTION

Others

ME- 4894

Visitors

Job

No.

Sub-Contractors

24-11-2013

All Employees - 2Some Employees 1/

Hazards

Rev

Date

00

(Refer table 3 of procedure)Concern (L/I/B)

Activity

Rev No.

(Refer table 2 of procedure)Hazard Category (D/I)

PSL-ME-4894HRA-01

(Refer table 1 of procedure)Operating Condition (R/N/E)

Sl No

HRA No.

Additional controls required

Remarks

rescue team. Standby

man

shall

call

immediately

to

the

rescue team in case of

confined

space

emergencies.

Instruct the employees

not

to

attempt

any

rescue operation if they

see any person collapsed

in the confined space or

no communication from

the employees working in

the

confined

space

unless they know the real

situation

(Risks

and

Hazards) and properly

protected against the

hazards. Call immediately

the

assigned

rescue

team.

Instruct the employees

that they should not take

Risk Assessment shall be done in accordance with the IMS Procedure No. PSL-IMSP-10 (Health and Safety Hazard Identification, Risk Assesment and Control.) ,Loss (Risk consequences)= Physical injury, Health issues, Environmental Issues, Property damage etc

Risk Level Significance: 1 to 6 (Low) are not significant and no further action is required. 8 to 20 (Medium) are Significant Risk and shall be reduced so that they are tolerable / acceptable. 24 -75 (High) are Unacceptable and work activity shall be halted until risk

controls are implemented that reduce the risk so that it is no longer very high.

Project Engineer

(Name, Signature & Date)

Review By:

Review By:

As per IMSP Proc. No.

As per IMSP Proc. No.

Supervisor

PSL-IMSP-10 & Date

PSL-IMSP-10 & Date

HSE Representative

Format No: PSL-IMSP-10-F-01, Rev 00

HEALTH & SAFETY RISK ASSESSMENT

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

Significance

Gaps, if

any

(Likely hood x severity x spread)Risk level

Existing Control

Page

12 of

52

Risk Assessment

(See Risk management matrix)

Spread (1 to 5)

Loss

(Risk Consequence)

Personnel at risk

Severity (1 to 5)

Adequacy of existing control measures

Likely hood of harm (1 to 3)

PROJECT

DESCRIPTION

Others

ME- 4894

Visitors

Job

No.

Sub-Contractors

Hazards

24-11-2013

All Employees - 2Some Employees 1/

Rev

Date

00

(Refer table 3 of procedure)Concern (L/I/B)

Rev No.

(Refer table 2 of procedure)Hazard Category (D/I)

Sl No

Activity

(Refer table 1 of procedure)Operating Condition (R/N/E)

PSL-ME-4894HRA-01

HRA No.

Additional controls required

Remarks

any step in emotions to

save

their

friends

/

colleagues

during

confined

space

emergencies. Ask them

to call immediately to the

emergency rescue team.

Instruct the employees to

remember

emergency

contact numbers of the

rescue team

6

Gas

Cutting

Defective

Tools

Equipment

Physical

injuries,

burns,

property

damage

Prior to work it is ensured

that the cutting torch,

hoses & gas cylinders are

free from defect.

The equipment and tools

are adequately grounded

to prevent accumulation

of electrostatic charges.

Maintenance

of

equipment

is

done

regularly.

Low

Please

Refer

Procedure

No. PSL0000-OCPOHS-17

Risk Assessment shall be done in accordance with the IMS Procedure No. PSL-IMSP-10 (Health and Safety Hazard Identification, Risk Assesment and Control.) ,Loss (Risk consequences)= Physical injury, Health issues, Environmental Issues, Property damage etc

Risk Level Significance: 1 to 6 (Low) are not significant and no further action is required. 8 to 20 (Medium) are Significant Risk and shall be reduced so that they are tolerable / acceptable. 24 -75 (High) are Unacceptable and work activity shall be halted until risk

controls are implemented that reduce the risk so that it is no longer very high.

Project Engineer

(Name, Signature & Date)

Review By:

Review By:

As per IMSP Proc. No.

As per IMSP Proc. No.

Supervisor

PSL-IMSP-10 & Date

PSL-IMSP-10 & Date

HSE Representative

Format No: PSL-IMSP-10-F-01, Rev 00

HEALTH & SAFETY RISK ASSESSMENT

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

Significance

Gaps, if

any

(Likely hood x severity x spread)Risk level

Existing Control

Page

13 of

52

Risk Assessment

(See Risk management matrix)

Spread (1 to 5)

Loss

(Risk Consequence)

Personnel at risk

Severity (1 to 5)

Adequacy of existing control measures

Likely hood of harm (1 to 3)

PROJECT

DESCRIPTION

Others

ME- 4894

Visitors

Job

No.

Sub-Contractors

Hazards

24-11-2013

All Employees - 2Some Employees 1/

Rev

Date

00

(Refer table 3 of procedure)Concern (L/I/B)

Activity

Rev No.

(Refer table 2 of procedure)Hazard Category (D/I)

PSL-ME-4894HRA-01

(Refer table 1 of procedure)Operating Condition (R/N/E)

Sl No

HRA No.

Additional controls required

Remarks

Required PPE is used.

Fire

Explosion

&

Heat Radiation

Property

damage,

Physical

injuries,

environment

al issues

Health issues

Isolation of equipment is

being done from all

source of energy when

not in use.

Work location is shielded

prior to work.

Working areas are kept

clean

with

no

combustible

material

exists at work site.

Fire extinguishers & fire

hoses at work areas are

kept ready.

Firefighting & first aid

training is provided.

Required PPE is provided.

Periodic Rest is being

provided.

Please

Refer

Procedure

No. PSL0000-ERPOHS-10

Low

Please

Refer

Procedure

No. PSL0000-ERPOHS-11

Low

Risk Assessment shall be done in accordance with the IMS Procedure No. PSL-IMSP-10 (Health and Safety Hazard Identification, Risk Assesment and Control.) ,Loss (Risk consequences)= Physical injury, Health issues, Environmental Issues, Property damage etc

Risk Level Significance: 1 to 6 (Low) are not significant and no further action is required. 8 to 20 (Medium) are Significant Risk and shall be reduced so that they are tolerable / acceptable. 24 -75 (High) are Unacceptable and work activity shall be halted until risk

controls are implemented that reduce the risk so that it is no longer very high.

Project Engineer

(Name, Signature & Date)

Review By:

Review By:

As per IMSP Proc. No.

As per IMSP Proc. No.

Supervisor

PSL-IMSP-10 & Date

PSL-IMSP-10 & Date

HSE Representative

Format No: PSL-IMSP-10-F-01, Rev 00

HEALTH & SAFETY RISK ASSESSMENT

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

Burns,

Property

damage.

Work location is shielded

prior to work.

Significance

Gaps, if

any

Page

14 of

52

Risk Assessment

(See Risk management matrix)

(Likely hood x severity x spread)Risk level

Existing Control

Others

Loss

(Risk Consequence)

Personnel at risk

Visitors

Adequacy of existing control measures

Spread (1 to 5)

PROJECT

DESCRIPTION

Sub-Contractors

ME- 4894

Severity (1 to 5)

Job

No.

Likely hood of harm (1 to 3)

Falling Sparks

24-11-2013

All Employees - 2Some Employees 1/

Hazards

Rev

Date

00

(Refer table 3 of procedure)Concern (L/I/B)

Activity

Rev No.

(Refer table 2 of procedure)Hazard Category (D/I)

PSL-ME-4894HRA-01

(Refer table 1 of procedure)Operating Condition (R/N/E)

Sl No

HRA No.

Additional controls required

Remarks

Fire extinguishers are

available at work place.

Low

Firefighting & first aid

training is provided.

Gas Cylinder

Property

damage,

Physical

injuries

Isolation

valve

of

cylinder is kept closed

when not in use.

Fire extinguishers are

available at work place.

Mediu

m

Keep Cylinders safely at

least 5 meters away from

the work location.

Firefighting & first aid

training is provided.

Appropriate PPE is used.

Risk Assessment shall be done in accordance with the IMS Procedure No. PSL-IMSP-10 (Health and Safety Hazard Identification, Risk Assesment and Control.) ,Loss (Risk consequences)= Physical injury, Health issues, Environmental Issues, Property damage etc

Risk Level Significance: 1 to 6 (Low) are not significant and no further action is required. 8 to 20 (Medium) are Significant Risk and shall be reduced so that they are tolerable / acceptable. 24 -75 (High) are Unacceptable and work activity shall be halted until risk

controls are implemented that reduce the risk so that it is no longer very high.

Project Engineer

(Name, Signature & Date)

Review By:

Review By:

As per IMSP Proc. No.

As per IMSP Proc. No.

Supervisor

PSL-IMSP-10 & Date

PSL-IMSP-10 & Date

HSE Representative

Format No: PSL-IMSP-10-F-01, Rev 00

HEALTH & SAFETY RISK ASSESSMENT

Grinding /

Metal

cutting by

cutter

grinder

Falling Sparks.

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

Physical

injuries

Eye injury

Proper

wind

up

&

housekeeping is being

done at worksite.

The accessories (torch,

hoses & cylinders) not in

use are disconnected and

stored separately.

Face shield, goggles are

used

Page

15 of

52

Significance

Risk Assessment

(See Risk management matrix)

(Likely hood x severity x spread)Risk level

Gaps, if

any

Others

Existing Control

Visitors

Loss

(Risk Consequence)

Personnel at risk

Sub-Contractors

Adequacy of existing control measures

Spread (1 to 5)

PROJECT

DESCRIPTION

Severity (1 to 5)

ME- 4894

Likely hood of harm (1 to 3)

Scattered

Material

Job

No.

24-11-2013

All Employees - 2Some Employees 1/

Hazards

Rev

Date

00

(Refer table 3 of procedure)Concern (L/I/B)

Activity

Rev No.

(Refer table 2 of procedure)Hazard Category (D/I)

PSL-ME-4894HRA-01

(Refer table 1 of procedure)Operating Condition (R/N/E)

Sl No

HRA No.

Additional controls required

Remarks

6

Low

6

Low

Hot material

Burn injuries.

Required PPE is Provided.

Low

Slip of grinding

machine

Physical

injury

Required PPE is provided.

Low

Please

Refer

Procedure

No. PSL0000-OCPOHS-17

Grinding machine has

appropriate

guarding

system.

Risk Assessment shall be done in accordance with the IMS Procedure No. PSL-IMSP-10 (Health and Safety Hazard Identification, Risk Assesment and Control.) ,Loss (Risk consequences)= Physical injury, Health issues, Environmental Issues, Property damage etc

Risk Level Significance: 1 to 6 (Low) are not significant and no further action is required. 8 to 20 (Medium) are Significant Risk and shall be reduced so that they are tolerable / acceptable. 24 -75 (High) are Unacceptable and work activity shall be halted until risk

controls are implemented that reduce the risk so that it is no longer very high.

Project Engineer

(Name, Signature & Date)

Review By:

Review By:

As per IMSP Proc. No.

As per IMSP Proc. No.

Supervisor

PSL-IMSP-10 & Date

PSL-IMSP-10 & Date

HSE Representative

Format No: PSL-IMSP-10-F-01, Rev 00

HEALTH & SAFETY RISK ASSESSMENT

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

Physical

Injury.

Grinding

wheels

are

inspected and wheels are

removed if expired or

damaged.

Page

16 of

52

Significance

Risk Assessment

(See Risk management matrix)

(Likely hood x severity x spread)Risk level

Others

Gaps, if

any

Existing Control

Visitors

Loss

(Risk Consequence)

Personnel at risk

Sub-Contractors

Adequacy of existing control measures

Spread (1 to 5)

PROJECT

DESCRIPTION

Severity (1 to 5)

ME- 4894

Likely hood of harm (1 to 3)

Breakage of

grinding wheel

Job

No.

24-11-2013

All Employees - 2Some Employees 1/

Hazards

Rev

Date

00

(Refer table 3 of procedure)Concern (L/I/B)

Activity

Rev No.

(Refer table 2 of procedure)Hazard Category (D/I)

PSL-ME-4894HRA-01

(Refer table 1 of procedure)Operating Condition (R/N/E)

Sl No

HRA No.

Additional controls required

Remarks

Low

Grinding machine has

appropriate

guarding

system.

Required PPE is provided.

Electricity

Noise

Electrocution,

burns,

electric

shock.

Hearing

impairment,

deafness

M/C & wire condition is

monitored.

6

Low

Maintenance

of

equipment is being done

regularly.

Please

Refer

Procedure

No. PSL0000-OCPOHS-03

Low

Duration and intensity of

exposure to noise is

monitored.

Appropriate

work

Risk Assessment shall be done in accordance with the IMS Procedure No. PSL-IMSP-10 (Health and Safety Hazard Identification, Risk Assesment and Control.) ,Loss (Risk consequences)= Physical injury, Health issues, Environmental Issues, Property damage etc

Risk Level Significance: 1 to 6 (Low) are not significant and no further action is required. 8 to 20 (Medium) are Significant Risk and shall be reduced so that they are tolerable / acceptable. 24 -75 (High) are Unacceptable and work activity shall be halted until risk

controls are implemented that reduce the risk so that it is no longer very high.

Project Engineer

(Name, Signature & Date)

Review By:

Review By:

As per IMSP Proc. No.

As per IMSP Proc. No.

Supervisor

PSL-IMSP-10 & Date

PSL-IMSP-10 & Date

HSE Representative

Format No: PSL-IMSP-10-F-01, Rev 00

HEALTH & SAFETY RISK ASSESSMENT

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

Page

17 of

52

Significance

(Likely hood x severity x spread)Risk level

Spread (1 to 5)

Risk Assessment

(See Risk management matrix)

Severity (1 to 5)

Gaps, if

any

Existing Control

Others

Loss

(Risk Consequence)

Personnel at risk

Visitors

Adequacy of existing control measures

Likely hood of harm (1 to 3)

PROJECT

DESCRIPTION

ME- 4894

Sub-Contractors

Hazards

Job

No.

24-11-2013

All Employees - 2Some Employees 1/

Rev

Date

00

(Refer table 3 of procedure)Concern (L/I/B)

Activity

Rev No.

(Refer table 2 of procedure)Hazard Category (D/I)

PSL-ME-4894HRA-01

(Refer table 1 of procedure)Operating Condition (R/N/E)

Sl No

HRA No.

Additional controls required

Remarks

schedules with adequate

rest

period

are

maintained.

Proper PPEs (Ear Plugs or

Ear Muffs) are used.

8

Welding

Defective

Tools

Equipment

Physical

injuries,

Property

damage

Required

used

PPE

is

being

18

Mediu

m

Ensure the gas Welding

equipment

(blowpipe,

hoses,

oxy-acetylene

cylinders,

pressure

gauge) are free from

defect.

Please

Refer

Procedure

No. PSL0000-OCPOHS-17

Supervisor shall ensure

that

maintenance

is

being done regularly.

Welding fumes

Health Issues

Required PPE is provided.

Low

Proper ventilation and

fume

extraction

equipment in case of

welding

inside

an

enclosure is provided.

Risk Assessment shall be done in accordance with the IMS Procedure No. PSL-IMSP-10 (Health and Safety Hazard Identification, Risk Assesment and Control.) ,Loss (Risk consequences)= Physical injury, Health issues, Environmental Issues, Property damage etc

Risk Level Significance: 1 to 6 (Low) are not significant and no further action is required. 8 to 20 (Medium) are Significant Risk and shall be reduced so that they are tolerable / acceptable. 24 -75 (High) are Unacceptable and work activity shall be halted until risk

controls are implemented that reduce the risk so that it is no longer very high.

Project Engineer

(Name, Signature & Date)

Review By:

Review By:

As per IMSP Proc. No.

As per IMSP Proc. No.

Supervisor

PSL-IMSP-10 & Date

PSL-IMSP-10 & Date

HSE Representative

Format No: PSL-IMSP-10-F-01, Rev 00

HEALTH & SAFETY RISK ASSESSMENT

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

Fire extinguishers & fire

hoses are kept ready

prior to work.

Significance

(Likely hood x severity x spread)Risk level

Others

Low

Work location is being

shielded.

Areas are kept clean with

no combustible material

exists at work site.

Radiation from

Welding Flame

/

Rays

(Flash

Eye)

D

/I

Eye injuries

has

been

Wear the required PPE

(Long Sleeve Coverall,

apron,

safety

Goggle

etc.)

18 of

52

Additional controls required

Remarks

Please

Refer

Procedure

No. PSL0000-ERPOHS-10

Isolation of equipment is

done from all source of

energy when not in use.

Fire fighter

provided.

Page

Risk Assessment

(See Risk management matrix)

Spread (1 to 5)

Property

damage,

Physical

injuries,

environment

al issues

Gaps, if

any

Existing Control

Visitors

Loss

(Risk Consequence)

Personnel at risk

Sub-Contractors

Adequacy of existing control measures

Severity (1 to 5)

PROJECT

DESCRIPTION

ME- 4894

Likely hood of harm (1 to 3)

&

Job

No.

24-11-2013

All Employees - 2Some Employees 1/

Hazards

Fire

Explosion

Rev

Date

00

(Refer table 3 of procedure)Concern (L/I/B)

Activity

Rev No.

(Refer table 2 of procedure)Hazard Category (D/I)

PSL-ME-4894HRA-01

(Refer table 1 of procedure)Operating Condition (R/N/E)

Sl No

HRA No.

Please

Refer

Procedure

No. PSL0000-ERPOHS-11

Low

Risk Assessment shall be done in accordance with the IMS Procedure No. PSL-IMSP-10 (Health and Safety Hazard Identification, Risk Assesment and Control.) ,Loss (Risk consequences)= Physical injury, Health issues, Environmental Issues, Property damage etc

Risk Level Significance: 1 to 6 (Low) are not significant and no further action is required. 8 to 20 (Medium) are Significant Risk and shall be reduced so that they are tolerable / acceptable. 24 -75 (High) are Unacceptable and work activity shall be halted until risk

controls are implemented that reduce the risk so that it is no longer very high.

Project Engineer

(Name, Signature & Date)

Review By:

Review By:

As per IMSP Proc. No.

As per IMSP Proc. No.

Supervisor

PSL-IMSP-10 & Date

PSL-IMSP-10 & Date

HSE Representative

Format No: PSL-IMSP-10-F-01, Rev 00

HEALTH & SAFETY RISK ASSESSMENT

Physical

injuries,

property

damage

Flash

Fire

Scattered

Material

Back

D

/I

D

/I

Work location is shielded

while work is in process.

Property

damage,

burns,

environment

al issues

Property

damage,

Physical

19 of

52

Additional controls required

Remarks

6

Low

aid

Equipment

&

wire

condition is monitored.

Welding equipment

grounded.

Significance

Fire extinguishers are

available at work place.

Electrocution,

burns,

electric

shock.

Page

Risk Assessment

(See Risk management matrix)

(Likely hood x severity x spread)Risk level

Others

Gaps, if

any

Existing Control

Visitors

Loss

(Risk Consequence)

Personnel at risk

Sub-Contractors

Adequacy of existing control measures

Firefighting & first

training is provided.

Electricity

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

Spread (1 to 5)

PROJECT

DESCRIPTION

Severity (1 to 5)

D

/I

ME- 4894

Likely hood of harm (1 to 3)

Falling Sparks

Job

No.

24-11-2013

All Employees - 2Some Employees 1/

Hazards

Rev

Date

00

(Refer table 3 of procedure)Concern (L/I/B)

Activity

Rev No.

(Refer table 2 of procedure)Hazard Category (D/I)

PSL-ME-4894HRA-01

(Refer table 1 of procedure)Operating Condition (R/N/E)

Sl No

HRA No.

is

Low

It is ensured that the

flash back arrestor is in

place

between

oxyacetylene hose & gas

regulator.

Ensure proper wind up &

housekeeping

at

worksite.

Please

Refer

Procedure

No. PSL0000-OCPOHS-03

6

Low

6

Low

Risk Assessment shall be done in accordance with the IMS Procedure No. PSL-IMSP-10 (Health and Safety Hazard Identification, Risk Assesment and Control.) ,Loss (Risk consequences)= Physical injury, Health issues, Environmental Issues, Property damage etc

Risk Level Significance: 1 to 6 (Low) are not significant and no further action is required. 8 to 20 (Medium) are Significant Risk and shall be reduced so that they are tolerable / acceptable. 24 -75 (High) are Unacceptable and work activity shall be halted until risk

controls are implemented that reduce the risk so that it is no longer very high.

Project Engineer

(Name, Signature & Date)

Review By:

Review By:

As per IMSP Proc. No.

As per IMSP Proc. No.

Supervisor

PSL-IMSP-10 & Date

PSL-IMSP-10 & Date

HSE Representative

Format No: PSL-IMSP-10-F-01, Rev 00

HEALTH & SAFETY RISK ASSESSMENT

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

Significance

(Likely hood x severity x spread)Risk level

Spread (1 to 5)

Gaps, if

any

Page

20 of

52

Risk Assessment

(See Risk management matrix)

Severity (1 to 5)

injuries,

environment

al issues

Existing Control

Others

Loss

(Risk Consequence)

Personnel at risk

Visitors

Adequacy of existing control measures

Likely hood of harm (1 to 3)

PROJECT

DESCRIPTION

ME- 4894

Sub-Contractors

Job

No.

24-11-2013

All Employees - 2Some Employees 1/

Hazards

Rev

Date

00

(Refer table 3 of procedure)Concern (L/I/B)

Activity

Rev No.

(Refer table 2 of procedure)Hazard Category (D/I)

PSL-ME-4894HRA-01

(Refer table 1 of procedure)Operating Condition (R/N/E)

Sl No

HRA No.

Additional controls required

Remarks

The

accessories

(regulator,

blowpipe,

hose, isolation valve, and

gauge) not in use is

disconnected from gas

cylinder

and

stored

separately.

Walk ways and staircases

are

kept

clear

of

materials,

equipments

and other items.

Scaffolding

(Erection)

Incorrect

information on

permit/clearan

ce

Physical

injuries,

Property

damage

18

Mediu

m

Work permit system shall

be followed.

Have

a

clear

understanding of work to

be

performed

and

location.

Please

Refer

Procedure

No. PSL0000-OCPOHS-14

Risk Assessment shall be done in accordance with the IMS Procedure No. PSL-IMSP-10 (Health and Safety Hazard Identification, Risk Assesment and Control.) ,Loss (Risk consequences)= Physical injury, Health issues, Environmental Issues, Property damage etc

Risk Level Significance: 1 to 6 (Low) are not significant and no further action is required. 8 to 20 (Medium) are Significant Risk and shall be reduced so that they are tolerable / acceptable. 24 -75 (High) are Unacceptable and work activity shall be halted until risk

controls are implemented that reduce the risk so that it is no longer very high.

Project Engineer

(Name, Signature & Date)

Review By:

Review By:

As per IMSP Proc. No.

As per IMSP Proc. No.

Supervisor

PSL-IMSP-10 & Date

PSL-IMSP-10 & Date

HSE Representative

Format No: PSL-IMSP-10-F-01, Rev 00

HEALTH & SAFETY RISK ASSESSMENT

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

Significance

(Likely hood x severity x spread)Risk level

Others

Gaps, if

any

Page

21 of

52

Risk Assessment

(See Risk management matrix)

Spread (1 to 5)

Physical

injuries,

Property

damage

Existing Control

Visitors

Loss

(Risk Consequence)

Personnel at risk

Sub-Contractors

Adequacy of existing control measures

Severity (1 to 5)

PROJECT

DESCRIPTION

ME- 4894

Likely hood of harm (1 to 3)

Ground

conditions

Job

No.

24-11-2013

All Employees - 2Some Employees 1/

Hazards

Rev

Date

00

(Refer table 3 of procedure)Concern (L/I/B)

Activity

Rev No.

(Refer table 2 of procedure)Hazard Category (D/I)

PSL-ME-4894HRA-01

(Refer table 1 of procedure)Operating Condition (R/N/E)

Sl No

HRA No.

18

Additional controls required

Remarks

Attention to be paid on

uneven terrain structure.

Mediu

m

Do a Pre-job safety

meeting prior to work.

Site safety rules shall be

followed.

Improper

Transportation

Physical

injuries,

Property

damage

Traffic rules & regulations

are followed.

All loads transported in a

pick-up (or utility) truck

or other cargo vehicle is

securely fastened and

not

exceeding

the

manufacturers

specifications and legal

limits for the vehicles.

12

Mediu

m

Shut off the engine and

hand brake shall be

applied when leaving the

vehicle.

The driver must leave his

vehicle and not return to

it until the loading /

unloading

activity

is

complete.

Ensure

that

contractors shall

traffic

Rules

Regulations.

subfollow

&

Risk Assessment shall be done in accordance with the IMS Procedure No. PSL-IMSP-10 (Health and Safety Hazard Identification, Risk Assesment and Control.) ,Loss (Risk consequences)= Physical injury, Health issues, Environmental Issues, Property damage etc

Risk Level Significance: 1 to 6 (Low) are not significant and no further action is required. 8 to 20 (Medium) are Significant Risk and shall be reduced so that they are tolerable / acceptable. 24 -75 (High) are Unacceptable and work activity shall be halted until risk

controls are implemented that reduce the risk so that it is no longer very high.

Project Engineer

(Name, Signature & Date)

Review By:

Review By:

As per IMSP Proc. No.

As per IMSP Proc. No.

Supervisor

PSL-IMSP-10 & Date

PSL-IMSP-10 & Date

HSE Representative

Format No: PSL-IMSP-10-F-01, Rev 00

HEALTH & SAFETY RISK ASSESSMENT

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

Physical

injuries,

Property

damage

If possible Trolleys or

wheelbarrows are used.

When lifting a load along

with another person(s),

communication with the

other

person(s)

is

maintained

before

lowering the load.

Page

22 of

52

Significance

Risk Assessment

(See Risk management matrix)

(Likely hood x severity x spread)Risk level

Gaps, if

any

Others

Existing Control

Visitors

Loss

(Risk Consequence)

Personnel at risk

Sub-Contractors

Adequacy of existing control measures

Spread (1 to 5)

PROJECT

DESCRIPTION

Severity (1 to 5)

ME- 4894

Likely hood of harm (1 to 3)

Material

Handling

(Manual)

Job

No.

24-11-2013

All Employees - 2Some Employees 1/

Hazards

Rev

Date

00

(Refer table 3 of procedure)Concern (L/I/B)

Activity

Rev No.

(Refer table 2 of procedure)Hazard Category (D/I)

PSL-ME-4894HRA-01

(Refer table 1 of procedure)Operating Condition (R/N/E)

Sl No

HRA No.

Additional controls required

Remarks

Low

Appropriate PPE is being

used

Dropping tools

&

scaffold

components,

clips

Scaffold

Collapse

Physical

injuries,

Property

damage

Physical

injuries,

Property

damage

Hoists are used for lifting

and dropping the loads.

It is ensured that tools

belts

are

in

good

condition

and

are

capable of securing tools.

Inspection for all stages

is being done.

Graded wood is used.

Low

6

Low

Required PPE is used.

Risk Assessment shall be done in accordance with the IMS Procedure No. PSL-IMSP-10 (Health and Safety Hazard Identification, Risk Assesment and Control.) ,Loss (Risk consequences)= Physical injury, Health issues, Environmental Issues, Property damage etc

Risk Level Significance: 1 to 6 (Low) are not significant and no further action is required. 8 to 20 (Medium) are Significant Risk and shall be reduced so that they are tolerable / acceptable. 24 -75 (High) are Unacceptable and work activity shall be halted until risk

controls are implemented that reduce the risk so that it is no longer very high.

Project Engineer

(Name, Signature & Date)

Review By:

Review By:

As per IMSP Proc. No.

As per IMSP Proc. No.

Supervisor

PSL-IMSP-10 & Date

PSL-IMSP-10 & Date

HSE Representative

Format No: PSL-IMSP-10-F-01, Rev 00

HEALTH & SAFETY RISK ASSESSMENT

Significance

(Likely hood x severity x spread)Risk level

Gaps, if

any

Page

23 of

52

Risk Assessment

(See Risk management matrix)

Spread (1 to 5)

Physical

injuries,

Property

damage

Existing Control

Others

Loss

(Risk Consequence)

Personnel at risk

Visitors

Adequacy of existing control measures

Severity (1 to 5)

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

Likely hood of harm (1 to 3)

Unstable

scaffold

PROJECT

DESCRIPTION

ME- 4894

Sub-Contractors

Hazards

Job

No.

24-11-2013

All Employees - 2Some Employees 1/

Rev

Date

00

(Refer table 3 of procedure)Concern (L/I/B)

Activity

Rev No.

(Refer table 2 of procedure)Hazard Category (D/I)

PSL-ME-4894HRA-01

(Refer table 1 of procedure)Operating Condition (R/N/E)

Sl No

HRA No.

18

Mediu

m

Additional controls required

Remarks

Inspect Scaffold prior to

Handover

for

secure

access,

boards

are

adequate

and

any

lapboard or plies are

secured.

Scafftag is secured to

scaffold and is dated,

signed off by qualified

person.

Weak

Damaged

Scaffold

Physical

injuries,

Property

damage

18

Mediu

m

The scaffold tag must

indicate the maximum

load that it can bear.

The scaffold shall be

inspected, certified &

tagged by the competent

person

confirming

its

stability & suitability.

The scaffolding shall be

inspected at least weekly

for any damage due to

weather condition (rain,

Risk Assessment shall be done in accordance with the IMS Procedure No. PSL-IMSP-10 (Health and Safety Hazard Identification, Risk Assesment and Control.) ,Loss (Risk consequences)= Physical injury, Health issues, Environmental Issues, Property damage etc

Risk Level Significance: 1 to 6 (Low) are not significant and no further action is required. 8 to 20 (Medium) are Significant Risk and shall be reduced so that they are tolerable / acceptable. 24 -75 (High) are Unacceptable and work activity shall be halted until risk

controls are implemented that reduce the risk so that it is no longer very high.

Project Engineer

(Name, Signature & Date)

Review By:

Review By:

As per IMSP Proc. No.

As per IMSP Proc. No.

Supervisor

PSL-IMSP-10 & Date

PSL-IMSP-10 & Date

HSE Representative

Format No: PSL-IMSP-10-F-01, Rev 00

HEALTH & SAFETY RISK ASSESSMENT

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

Significance

(Likely hood x severity x spread)Risk level

Spread (1 to 5)

Gaps, if

any

Page

24 of

52

Risk Assessment

(See Risk management matrix)

Severity (1 to 5)

Existing Control

Others

Loss

(Risk Consequence)

Personnel at risk

Visitors

Adequacy of existing control measures

Likely hood of harm (1 to 3)

PROJECT

DESCRIPTION

ME- 4894

Sub-Contractors

Job

No.

24-11-2013

All Employees - 2Some Employees 1/

Hazards

Rev

Date

00

(Refer table 3 of procedure)Concern (L/I/B)

Activity

Rev No.

(Refer table 2 of procedure)Hazard Category (D/I)

PSL-ME-4894HRA-01

(Refer table 1 of procedure)Operating Condition (R/N/E)

Sl No

HRA No.

Additional controls required

Remarks

high wind etc) or other

unsafe conditions.

10

Scaffolding

(Dismantlin

g)

Modified

Scaffold

Unauthorized

Removal

of

scaffolding

Incorrect

information on

permit/clearan

ce

Physical

injuries,

Property

damage

Physical

injuries,

Property

damage

Physical

injuries,

Property

damage

18

Mediu

m

18

Mediu

m

18

Mediu

m

In

case

of

any

modification, addition in

the scaffold, it shall be

re-inspected & certified

by competent person.

Work permit system shall

be followed

Please

Refer

Procedure

No. PSL0000-OCPOHS-14

Work

permit

system

shall be followed.

Have

a

clear

understanding of work to

be

performed

and

location.

Risk Assessment shall be done in accordance with the IMS Procedure No. PSL-IMSP-10 (Health and Safety Hazard Identification, Risk Assesment and Control.) ,Loss (Risk consequences)= Physical injury, Health issues, Environmental Issues, Property damage etc

Risk Level Significance: 1 to 6 (Low) are not significant and no further action is required. 8 to 20 (Medium) are Significant Risk and shall be reduced so that they are tolerable / acceptable. 24 -75 (High) are Unacceptable and work activity shall be halted until risk

controls are implemented that reduce the risk so that it is no longer very high.

Project Engineer

(Name, Signature & Date)

Review By:

Review By:

As per IMSP Proc. No.

As per IMSP Proc. No.

Supervisor

PSL-IMSP-10 & Date

PSL-IMSP-10 & Date

HSE Representative

Format No: PSL-IMSP-10-F-01, Rev 00

HEALTH & SAFETY RISK ASSESSMENT

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

Significance

(Likely hood x severity x spread)Risk level

Others

Gaps, if

any

Page

25 of

52

Risk Assessment

(See Risk management matrix)

Spread (1 to 5)

Physical

injuries,

Property

damage

Existing Control

Visitors

Loss

(Risk Consequence)

Personnel at risk

Sub-Contractors

Adequacy of existing control measures

Severity (1 to 5)

PROJECT

DESCRIPTION

ME- 4894

Likely hood of harm (1 to 3)

Fall

of

objects / Tools

Job

No.

24-11-2013

All Employees - 2Some Employees 1/

Hazards

Rev

Date

00

(Refer table 3 of procedure)Concern (L/I/B)

Activity

Rev No.

(Refer table 2 of procedure)Hazard Category (D/I)

PSL-ME-4894HRA-01

(Refer table 1 of procedure)Operating Condition (R/N/E)

Sl No

HRA No.

18

Mediu

m

Remarks

Additional controls required

Take proper care while

dismantling the scaffold

to prevent fall of scaffold

parts.

Use proper PPE during

removal of scaffold.

If required barricade the

area during dismantle

work.

Unstable

Scaffold

Physical

injuries,

Property

damage

18

Mediu

m

Inspect the scaffold for

its stability & support

before

removing

in

sequence.

Required

used.

Loaded

Scaffolding

Physical

injuries,

Property

damage

18

Mediu

m

PPE

shall

be

Remove safely the load /

equipment / tools from

the

scaffold

before

Risk Assessment shall be done in accordance with the IMS Procedure No. PSL-IMSP-10 (Health and Safety Hazard Identification, Risk Assesment and Control.) ,Loss (Risk consequences)= Physical injury, Health issues, Environmental Issues, Property damage etc

Risk Level Significance: 1 to 6 (Low) are not significant and no further action is required. 8 to 20 (Medium) are Significant Risk and shall be reduced so that they are tolerable / acceptable. 24 -75 (High) are Unacceptable and work activity shall be halted until risk

controls are implemented that reduce the risk so that it is no longer very high.

Project Engineer

(Name, Signature & Date)

Review By:

Review By:

As per IMSP Proc. No.

As per IMSP Proc. No.

Supervisor

PSL-IMSP-10 & Date

PSL-IMSP-10 & Date

HSE Representative

Format No: PSL-IMSP-10-F-01, Rev 00

HEALTH & SAFETY RISK ASSESSMENT

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

Significance

(Likely hood x severity x spread)Risk level

Spread (1 to 5)

Gaps, if

any

Page

26 of

52

Risk Assessment

(See Risk management matrix)

Severity (1 to 5)

Existing Control

Others

Loss

(Risk Consequence)

Personnel at risk

Visitors

Adequacy of existing control measures

Likely hood of harm (1 to 3)

PROJECT

DESCRIPTION

ME- 4894

Sub-Contractors

Job

No.

24-11-2013

All Employees - 2Some Employees 1/

Hazards

Rev

Date

00

(Refer table 3 of procedure)Concern (L/I/B)

Activity

Rev No.

(Refer table 2 of procedure)Hazard Category (D/I)

PSL-ME-4894HRA-01

(Refer table 1 of procedure)Operating Condition (R/N/E)

Sl No

HRA No.

Remarks

Additional controls required

dismantling the scaffold.

Required

used

11

Painting

Unauthorized

person

Incorrect

information on

permit/clearan

ce

Physical

injuries,

Property

damage

Physical

injuries,

Property

damage

18

18

PPE

shall

be

Mediu

m

Only authorized person

shall remove the scaffold

under the supervision of

certified supervisor

Mediu

m

Work Permit system shall

be followed.

Have

a

clear

understanding of work to

be

performed

and

location.

Please

Refer

Procedure

No. PSL0000-OCPOHS-12

Risk Assessment shall be done in accordance with the IMS Procedure No. PSL-IMSP-10 (Health and Safety Hazard Identification, Risk Assesment and Control.) ,Loss (Risk consequences)= Physical injury, Health issues, Environmental Issues, Property damage etc

Risk Level Significance: 1 to 6 (Low) are not significant and no further action is required. 8 to 20 (Medium) are Significant Risk and shall be reduced so that they are tolerable / acceptable. 24 -75 (High) are Unacceptable and work activity shall be halted until risk

controls are implemented that reduce the risk so that it is no longer very high.

Project Engineer

(Name, Signature & Date)

Review By:

Review By:

As per IMSP Proc. No.

As per IMSP Proc. No.

Supervisor

PSL-IMSP-10 & Date

PSL-IMSP-10 & Date

HSE Representative

Format No: PSL-IMSP-10-F-01, Rev 00

HEALTH & SAFETY RISK ASSESSMENT

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

If possible Trolleys or

wheelbarrows are used.

When lifting a load along

with another person(s),

communication with the

other

person(s)

is

maintained

before

lowering the load.

Significance

(Likely hood x severity x spread)Risk level

Others

Page

27 of

52

Risk Assessment

(See Risk management matrix)

Spread (1 to 5)

Property

damage,

Physical

injuries

Gaps, if

any

Existing Control

Visitors

Loss

(Risk Consequence)

Personnel at risk

Sub-Contractors

Adequacy of existing control measures

Severity (1 to 5)

PROJECT

DESCRIPTION

ME- 4894

Likely hood of harm (1 to 3)

Material

Handling

(Manual)

Job

No.

24-11-2013

All Employees - 2Some Employees 1/

Hazards

Rev

Date

00

(Refer table 3 of procedure)Concern (L/I/B)

Activity

Rev No.

(Refer table 2 of procedure)Hazard Category (D/I)

PSL-ME-4894HRA-01

(Refer table 1 of procedure)Operating Condition (R/N/E)

Sl No

HRA No.

Low

Additional controls required

Remarks

Please

Refer

Procedure

No. PSL0000-OCPOHS-02

Lifting of heavy load is

avoided.

Appropriate

provided.

Defective

Tools

/

Equipment

(Spray

Paint

Gun,

Hoses,

pump)

Property

damage,

Physical

injuries.

PPE

is

Inspection is done for the

equipment / tool that

shall be used for painting

(such as Spray Paint

Gun, Hoses, pump etc.)

prior to work.

Low

The equipment and tools

are grounded to prevent

electricity hazards.

Risk Assessment shall be done in accordance with the IMS Procedure No. PSL-IMSP-10 (Health and Safety Hazard Identification, Risk Assesment and Control.) ,Loss (Risk consequences)= Physical injury, Health issues, Environmental Issues, Property damage etc

Risk Level Significance: 1 to 6 (Low) are not significant and no further action is required. 8 to 20 (Medium) are Significant Risk and shall be reduced so that they are tolerable / acceptable. 24 -75 (High) are Unacceptable and work activity shall be halted until risk

controls are implemented that reduce the risk so that it is no longer very high.

Project Engineer

(Name, Signature & Date)

Review By:

Review By:

As per IMSP Proc. No.

As per IMSP Proc. No.

Supervisor

PSL-IMSP-10 & Date

PSL-IMSP-10 & Date

HSE Representative

Format No: PSL-IMSP-10-F-01, Rev 00

HEALTH & SAFETY RISK ASSESSMENT

FABRICATION, ERECTION AND COMMISSIONING OF 14 NOS STORAGE

TANKS AND TANK FARM FOUNDATION WORK

is

Significance

(Likely hood x severity x spread)Risk level

Spread (1 to 5)

Maintenance

regularly.

Page

28 of

52

Risk Assessment

(See Risk management matrix)

Severity (1 to 5)

Gaps, if

any