Escolar Documentos

Profissional Documentos

Cultura Documentos

As10 Sol

Enviado por

Wahyu WijanarkoDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

As10 Sol

Enviado por

Wahyu WijanarkoDireitos autorais:

Formatos disponíveis

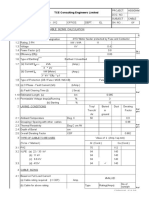

ME 24-221 THERMODYNAMICS I Solutions to Assignment 10 November 27, 2000 J.

Murthy

9.5

Air at 100 kPa, 17C is compressed to 400 kPa after which it is expanded through a nozzle back to the atmosphere. The compressor and the nozzle are both reversible and adiabatic and kinetic energy in/out of the compressor can be neglected. Find the compressor work and its exit temperature and find the nozzle exit velocity. Solution: SSSF separate control volumes around compressor and nozzle. For ideal compressor we have inlet : 1 and exit : 2 Adiabatic : q = 0. Reversible: sgen = 0 s Energy Eq.: h 1 + 0 = w C + h 2; Entropy Eq.: s1 + 0/T + 0 = s2

1

C

T

2

P2 2 P1

- w C = h 2 - h 1 , s 2 = s1 State 1: Air Table A.7: h1 = 290.43 kJ/kg Pr2 = Pr1 P2/P1 = 0.9899 400 / 100 = 3.98 State 2: Pr2 = 3.98 in Table A.7 gives T2 = 430.5 K, h2 = 432.3 kJ/kg

-wC = 432.3 - 290.43 = 141.86 kJ/kg

The ideal nozzle then expands back down to state 1 (constant s) so energy equation gives:

1 2 V = h2 - h1 = -wC =141860 J/kg 2

(remember conversion to J)

V=

2 141860 = 532.7 m/s

9.14

A diffuser is a steady-state, steady-flow device in which a fluid flowing at high velocity is decelerated such that the pressure increases in the process. Air at 120 kPa, 30C enters a diffuser with velocity 200 m/s and exits with a velocity of 20 m/s. Assuming the process is reversible and adiabatic what are the exit pressure and temperature of the air? C.V. Diffuser, SSSF single inlet and exit flow, no work or heat transfer. Energy Eq.: Entropy Eq.: hi + Vi /2 = he + Ve /2,

2 2

=>

he - hi = CPo(Te - Ti)

si + dq/T + sgen = si + 0 + 0 = se (Reversible, adiabatic)

Energy equation then gives: CPo(Te - Ti) = 1.004(Te - 303.2) = (2002 - 202)/(21000) Pe =

k Pi(Te/Ti)k-1

=>

Te = 322.9 K

= 120(322.9/303.2)3.5 = 149.6 kPa

9.20

A certain industrial process requires a steady supply of saturated vapor steam at 200 kPa, at a rate of 0.5 kg/s. Also required is a steady supply of compressed air at 500 kPa, at a rate of 0.1 kg/s. Both are to be supplied by the process shown in Fig. P9.20. Steam is expanded in a turbine to supply the power needed to drive the air compressor, and the exhaust steam exits the turbine at the desired state. Air into the compressor is at the ambient conditions, 100 kPa, 20C. Give the required steam inlet pressure and temperature, assuming that both the turbine and the compressor are reversible and adiabatic. C.V. Each device. SSSF. Both adiabatic (q = 0), reversible (sgen = 0) Compressor: s4 = s3 => T4 = T3(P4/P3

k-1 )k

. . WC = m3(h3 - h4) = 0.1 1.004(293.2 - 464.6) = -17.2 kW . . Turbine: Energy: WT = +17.2 kW = m1(h1 - h2); Entropy: s2 = s1 Table B.1.2: P2 = 200 kPa, x2 = 1 => h2 = 2706.6, s2 = 7.1271 h1 = 2706.6 + 17.2/0.5 = 2741.0 kJ/kg s1 = s2 = 7.1271 kJ/kg K P1 = 242 kPa At h1, s1 T 1 = 138.3C

5000.286 = 293.2 = 464.6 K 100

9.50

A mixing chamber receives 5 kg/min ammonia as saturated liquid at 20C from one line and ammonia at 40C, 250 kPa from another line through a valve. The chamber also receives 325 kJ/min energy as heat transferred from a 40C reservoir. This should produce saturated ammonia vapor at 20C in the exit line. What is the mass flow rate in the second line and what is the total entropy generation in the process?

1 2 Tres 3 . Q

CV: Mixing chamber out to reservoir . . . m1 + m2 = m3 . . . . m1h1 + m2h2 + Q = m3h3 . . . . . m1s 1 + m2s 2 + Q /T res + S gen = m3s 3

From the energy equation: . . . m2 = [( m1(h1 - h3) + Q ]/(h3 - h2) = [ 5 (89.05 - 1418.05) + 325] /(1418.05 - 1551.7) . = 47.288 kg/min m3 = 52.288 kg/min . . . . . S gen = m3s 3 - m1s 1 - m2s 2 - Q /T res = 52.288 5.6158 - 5 0.3657 47.288 5.9599 325/313.15 = 8.94 kJ/K min

9.80

A certain industrial process requires a steady 0.5 kg/s supply of compressed air at 500 kPa, at a maximum temperature of 30C. This air is to be supplied by installing a compressor and aftercooler. Local ambient conditions are 100 kPa, 20C. Using an isentropic compressor efficiency of 80%, determine the power required to drive the compressor and the rate of heat rejection in the aftercooler. Air: R = 0.287 kJ/kg-K, Cp = 1.004 kJ/kg-K, k = 1.4 . State 1: T 1 = To = 20oC, P1 = Po = 100 kPa, m = 0.5 kg/s State 2: P2 = P3 = 500 kPa State 3: T 3 = 30oC, P3 = 500 kPa Assume s = 80 % (Any value between 70%-90% is OK) Compressor: Assume Isentropic

k-1 T2s = T1 (P 2/P1) k ,

T2s = 464.6 K

1st Law: q c + h1 = h2 + wc; qc = 0, assume constant specific heat w cs = Cp(T1 - T2s) = -172.0 kJ/kg . . s = wcs/wc, wc = wcs/s = -215, WC = mw C = -107.5 kW w c = Cp(T1 - T2), solve for T2 = 507.5 K Aftercooler: 1st Law: q + h2 = h3 + w; w = 0, assume constant specific heat . . q = Cp(T3 - T2) = 205 kJ/kg, Q = mq = -102.5 kW

9.66

A flow of 20 kg/s steam at 10 MPa, 550C enters a two-stage turbine. The exit of the first stage is at 2 MPa where 4 kg/s is taken out for process steam and the rest continues through the second stage, which has an exit at 50 kPa. Assume both stages have an isentropic efficiency of 85% find the total actual turbine work and the entropy generation.

1 . T1 T2 WT 2 3

C.V.: T1 Ideal State 1: Table B.1.2, h1 = 3500.9 kJ/kg, s1 = 6.7561 h1 = h2s + wT1,s ; s1 + 0 / = s2s State 2s:P2, s2s = s1 h2s = 3017.9 kJ/kg wT1,s = 3500.9 - 3017.9 = 483 kJ/kg

C.V. T1 Actual wT1,ac = wT1,sT1 = 410.5 = h1 - h2ac h2ac = 3090.4 kJ/kg State 2ac: P2 h2,ac s2ac = 6.8802 kJ/kg K C.V. T2 Ideal h2ac = h3,s + wT2s ; s2ac + 0 / = s3s State 3s: P3 , s3s = s2ac x3s = (6.8802-1.091)/6.5029 = 0.890 , h3s = 340.5 + 0.89 2305.4 = 2392.9 kJ/kg wT2s = 3090.4 - 2392.9 = 697.5 kJ/kg C.V. T2 Actual wT2,ac = wT2sT2 = 592.9 = h2ac - h3ac => h 3ac = 2497.5 State 3ac: P3 , h3ac x3ac = (2497.5-340.5)/2305.4 = 0.9356 , s3ac = 1.091 + 0.9356 6.5029 = 7.1754 C.V. T1 + T2 Actual . . . . WT = m1wT1ac + (m1 - m2)wT2ac = 20 410.5 + 16 592.9 = 17696 kW . . . . Sgen = m2s2ac + m3s3ac - m1s1 = 4 6.8802 + 16 7.1754 - 20 6.7561 = 7.20 kW/K

P 2s

1 2ac 3ac

T 2s

1 2ac 3s 3ac

3s

Você também pode gostar

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- ElectrolysisDocumento3 páginasElectrolysisRaymond ChanAinda não há avaliações

- MathDocumento4 páginasMathHermann Dejero LozanoAinda não há avaliações

- 144S... - PCB Series: Signal Conditioned Precision Pressure TransducersDocumento4 páginas144S... - PCB Series: Signal Conditioned Precision Pressure TransducersAnish KumarAinda não há avaliações

- Case StudyDocumento10 páginasCase StudyVintage ArtAinda não há avaliações

- 6100 SQ Lcms Data SheetDocumento4 páginas6100 SQ Lcms Data Sheet王皓Ainda não há avaliações

- ASUS U47A Repair GuideDocumento5 páginasASUS U47A Repair GuideCarlos ZarateAinda não há avaliações

- Case StudyDocumento4 páginasCase Studyadil rangoonAinda não há avaliações

- Calculation Eurocode 2Documento4 páginasCalculation Eurocode 2rammirisAinda não há avaliações

- Graphite PropertiesDocumento42 páginasGraphite PropertiesAnnisa Puspa MustikaAinda não há avaliações

- Bobrick 2021 Class. Quantum Grav. 38 105009Documento23 páginasBobrick 2021 Class. Quantum Grav. 38 105009MaxAinda não há avaliações

- Dbms-Lab Assignment - 1: Name - VIKAS SINGH Roll No - 4257Documento3 páginasDbms-Lab Assignment - 1: Name - VIKAS SINGH Roll No - 4257Vikas SinghAinda não há avaliações

- Binary PDFDocumento13 páginasBinary PDFbyprasadAinda não há avaliações

- NumaticsFRLFlexiblokR072010 EsDocumento40 páginasNumaticsFRLFlexiblokR072010 EsGabriel San Martin RifoAinda não há avaliações

- EXCEL - How To Write Perfect VLOOKUP and INDEX and MATCH FormulasDocumento29 páginasEXCEL - How To Write Perfect VLOOKUP and INDEX and MATCH Formulasgerrydimayuga100% (1)

- Machine Fault Detection Using Vibration Signal Peak DetectorDocumento31 páginasMachine Fault Detection Using Vibration Signal Peak Detectordavison coyAinda não há avaliações

- Bodybuilder Guidelines: Update: 2011-22Documento438 páginasBodybuilder Guidelines: Update: 2011-22thkimzone73100% (12)

- Gantt ChartDocumento4 páginasGantt ChartSyed FaridAinda não há avaliações

- Epson L6170 Wi-Fi Duplex All-in-One Ink Tank Printer With ADFDocumento3 páginasEpson L6170 Wi-Fi Duplex All-in-One Ink Tank Printer With ADFCarl DonaireAinda não há avaliações

- Cable Size Calculations SpreadsheetDocumento4 páginasCable Size Calculations Spreadsheetbhavin24uAinda não há avaliações

- HPC168 Passenger CounterDocumento9 páginasHPC168 Passenger CounterRommel GómezAinda não há avaliações

- Cable Sizing CalculationDocumento72 páginasCable Sizing CalculationHARI my songs100% (1)

- Creative Computing v06 n12 1980 DecemberDocumento232 páginasCreative Computing v06 n12 1980 Decemberdarkstar314Ainda não há avaliações

- Introduction To DatabasesDocumento33 páginasIntroduction To Databases米皮皮Ainda não há avaliações

- A Report On Traffic Volume StudyDocumento33 páginasA Report On Traffic Volume StudyManoj Durairaj100% (1)

- Practical - Magnetic - Design (Fill Factor) PDFDocumento20 páginasPractical - Magnetic - Design (Fill Factor) PDFAhtasham ChaudhryAinda não há avaliações

- Chem Cheat Sheet MasterDocumento6 páginasChem Cheat Sheet MasteradamhamelehAinda não há avaliações

- OODBMSDocumento19 páginasOODBMSashimsarkar2006Ainda não há avaliações

- Ant CabDocumento93 páginasAnt CabZubair MinhasAinda não há avaliações

- Gas Turbine Compressor WashingDocumento8 páginasGas Turbine Compressor Washingwolf_ns100% (1)

- Bruh I Hate File Handling - CPPDocumento3 páginasBruh I Hate File Handling - CPPJayson AmodiaAinda não há avaliações