Escolar Documentos

Profissional Documentos

Cultura Documentos

High Rise Basement - Superstructure

Enviado por

Siddique AhmedTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

High Rise Basement - Superstructure

Enviado por

Siddique AhmedDireitos autorais:

Formatos disponíveis

Project Land & Rajuk rules on utilization factor:

The project land is 205.46Lx121.13W, measuring 24886.10 sft. (34.564 Katta)

Orientation

NW-NE SW-SE

206'3" NW-SW 204'8" NE-SE

121' 121'3"

A digital Map of the land has been attached is given below:

3 7 C it St y C or e ied nte Bu r ild Fo ing otp ath

121

'-9

"

16 Utt St ara or B ied an Bu k ild ing

Fo

Ja Sto nota rie B d B ank uild ing otp ath

57

otp

'-6 "

ath

58

'-4

"

M Fo oti d otp Isl jh ee lR

Sh a 5 S dhin tor ot ied a B Bu hab ild an ing

-9"

24

Fo

ad

Pu

cca

90

'

5 6'

ath

Ro

an

oa

-9"

Fo

121

nd

Isla

te

57

B tor ank A ied Bu sia ildi n g

'-8

"

25'

ath

237'-6"

91

Ga

Fo otp

29

'-1

0"

Fo otp ath

116

'-9

3"

5 7' -7"

29'

"

59 '-1 "

20

otp

6 '-

ath

239 '-6"

'-3

ath

121

otp

Bu

ildi

Pu

8"

Fo

c ca

ng

20

"

4'-

Dr

ain

Fo cca R otp o ath ad

90

Pu

Client

Bangladesh Jute Mill Corporation (BJMC)

4S

Fo

an

Bo kC

Pu cca

es 6 S h Bi m tor an ied O Bu ffic ild e B ing ha b

30'

-4"

lad

Foo

3S

10

7'

Ba

ng

ath

to r

otp

tpa th

ied

89

Advisory Consultant

Associate Engineers & Consultants Limited

SS Bhaban (4th Floor) 70/D, Panthapath, Dhaka-1205, Bangladesh. Tel: 88-02-9612379, 88-02-9612460 E-mail: aec5050@yahoo.com , hallstone_in@yahoo.com

AECL

Ro

ad

P ar

c ca

tij Mo

Dr

hee

i Gul l To

stan

ha

tte r

ain

SITE LOCATION

99, Karim Chamber Motijheel, Dhaka 1000, Bangladesh

NORTH

Gulist an To

Motijh

eel Ro ad

Pu

Statistics

1. Total Project Area:-

= 24785.48 (in Sq. Feets) = 56.899 (in Decimal) = 34.424 (in Katha)

The constructed floor space has been taken as 20000 sft leaving the set back area as required by RAJUK rules. Podium height is limited to 12m maximum height which at 4 meter can accommodate only 3 floors. Podium floors can utilize only 75% of the plot area. Each floor in tower block is allowed to use only 50% of the plot area. Hence the 46 tower blocks have each been allotted a space of 14800 sft. The constructed floor space has been taken as 19000 sft leaving the set back area as required by RAJUK rules. Podium height is limited to 12m maximum height which at 4 meter can accommodate only 3 floors. Podium floors can utilize only 75% of the plot area. Each floor in tower block is allowed to use only 50% of the plot area. Hence the 46 tower blocks have each been allotted a space of 12800 sft.

Structural Design

Major load factors for design basis shall be wind velocity and earthquake. Bangladesh National Design Code (BNBC) previously classified Dhaka under seismic Zone 2 (moderate) which has presently been upgraded to Zone 3 (major) which falls under SDC category D. The design maximum wind load is specified as Wind load 210 KM/hr Impact & limits of drift due to wind on top most floors and lateral forces on structure shall be considered with reference to high rise buildings in various other countries. 1. Live loads for office buildings are assumed at: Live load in office area : 4 kN/sq m Live load in passage area : 4 kN/sq m Live load in urinals : 2 kN/sq m Floor finish load : 1.5 kN/ sq m Wall thickness : 150 mm thick wall Stair case loading : 4 kN/sq m 2. Codes used for analysis are R.C.C. design: IS 456: 2000 [5] Steel design: IS 800: 1984 [8] Composite design: AISC LRFD 99 [9] 3. Conceptual structural design has been based on Geophysical & soil test data as follows: The strata from EGL-33.3meter upward to 3.75m comprises of Gray spotted brown to gray very stiff to stiff clay. The strata from EGL-45.4m upward to 12m comprises of non plastic, SILT with sand, trace mica.

The strata from EGL-51.3m upward 6m comp[rises of Brown and very dense sand, trace mica. up to 6m (from EGL- 51.3m) The strata from EGL-39m upward comprises of very light brown to dark gray. 4. Design code BNBC for earthquake and wind: Major load factors for design basis shall be wind velocity and earthquake. Bangladesh National Design Code (BNBC) previously classified Dhaka under seismic Zone 2 (moderate) which has presently been upgraded to Zone 3 (major) which falls under SDC category D. The design maximum wind load is specified as Wind load 210 KM/hr Impact & limits of drift due to wind on top most floors and lateral forces on structure shall be considered with reference to high rise buildings in various other countries. Design code BNBC for earthquake and wind:

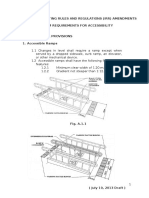

Pile foundation

7'-11"

6'-8"

6'-7"

180'-6"

8'-0"

7'-10"

5'-10"

5'-10"

Pile Foundation Layout Plan

5'-10"

5'-10"

93'-10"

Basement Design By top down method

1. 2. 3. 4. 5. 6. 7. 8. High rise superstructure & Sub basement are to be built simultaneously The height of sub basement floors shall not be more than 10% of the total height above GFL Perimeter foundation walls are constructed using the diaphragm or secant wall method Building columns are installed on load bearing element or drilled shafts and brought upto grade level Ground floor slab is cast and a hole is left to excavate down to 1st basement floor 1st basement floor slab is cast from perimeter wall to all spans through network of load bearing walls and access holes to excavate upto next basement floor Then 1st floor slab is cast and subsequently 2nd basement slab is cast. Each sub-basement floor once completed act as lateral bracing for the perimeter wall system

9. Above grade construction can proceed while the sub-base construction is on going since the buildings structural support is already in place. 10. Equipment used for excavation is Casagrande C90/HT55 with high torque

Core

12-GFL 13-1st basement 12-2nd basement 11-3rd basement 10-4th basement 9-5th

Basement 9-6th Basement

Top down construction 1. Formation of permanent retaining walls to the perimeter of basement area 2. Form internal foundation and column support by using plunge method 3. Create the uppermost floor slab with temporary base 4. Excavate downwards tru openings on slab or service shafts 5. Remove temp. base, excavate until the depth of next floor level. 6. Cast the next floor level, repeat the process. 7. Can use non-suspended slab for the basement slab

Typical sequence of construction 1. Install perimeter secant piles 2. Install bearing piles and plunge columns 3. Cast ground floor slab 4. Excavate and cast upper basement floor slab 5. Extend column and cast 1st floor slab 6. Excavate and cast middle basement slab 7. Extend columns and cast second floor slab 8. Excavate and cast lower basement slab 9. Extend columns and cast upper floor slabs 10.

Questions:

1. 2. 3. 4. 5. 6. 7. Construction procedure of RAMP in the basement floors Can perimeter wall be done on steel sheet piles Shall all the piles (30 diax450 nos) for foundation should be done together with perimeter piles Basement Columns shall be RCC or Steel or composite How the RCC slabs and beams shall be connected with the Basement columns How the basement column loads shall be transferred to the Raft foundation at lowest basement What will be per square meter cost for 4th, 5th and 6th basement floors and a proportionate comparison in top down method. 8. How to remove excavated Earth to disposal area 9. How to remove ground water to disposal area 10. How to handle ground water percolation.

Typical illustrations

1) Architectural details To study the behavior of high rise building under high seismic forces as here taken Zone IV as per IS 1893 : 2002 where building is situated, a typical office building plan is selected with area covering 24 m x 42 m.X30 storey

Design of the building in ETABS version 9.7.1.[2] The basic parameters considered for the design Slab depth : 125 mm thick; Wall thickness : 150 mm thick wall; Lift shaft : 300 mm thick shear wall Live load in office area : 4 kN/sq m; Live load in passage area : 4 kN/sq m; Live load in urinals : 2 kN/sq m Floor finish load : 1.5 kN/ sq m; Stair case loading : 4 kN/sq m; Earthquake parameters considered is Zone : IV Soil type : Hard soil Importance factor : 1 Time period : Program Calculated Seismic zone factor : 0.24 for zone IV Earthquake load in X and Z direction. Rigid frame diaphragm Codes used for analysis R.C.C. design: IS 456: 2000 [5] Steel design: IS 800: 1984 [8] Composite design: AISC LRFD 99 [9]

Você também pode gostar

- Basement ProvisionsDocumento193 páginasBasement ProvisionsAlexi ALfred H. TagoAinda não há avaliações

- JNTU Lecture Notes on Rehabilitation & Retrofitting StructuresDocumento51 páginasJNTU Lecture Notes on Rehabilitation & Retrofitting StructuresKalyan ShadaAinda não há avaliações

- Reinforced Cement ConcreteDocumento280 páginasReinforced Cement ConcreteRisla Abdul SaleemAinda não há avaliações

- TFR1 Precast RCDocumento19 páginasTFR1 Precast RCvaibhavsensesAinda não há avaliações

- Grillage 1Documento9 páginasGrillage 1VINAYANAinda não há avaliações

- PRAGATI TOWERS CASE STUDY: PRECAST CONSTRUCTION OF HIGH-RISE RESIDENTIAL PROJECT IN MUMBAIDocumento11 páginasPRAGATI TOWERS CASE STUDY: PRECAST CONSTRUCTION OF HIGH-RISE RESIDENTIAL PROJECT IN MUMBAIraja vijjayAinda não há avaliações

- Buildings - 1 - High-RiseDocumento20 páginasBuildings - 1 - High-RiseqsultanAinda não há avaliações

- Shear WallsDocumento10 páginasShear WallskiranAinda não há avaliações

- Slab DesignDocumento53 páginasSlab DesignRhyckayen AEAinda não há avaliações

- Chapter 8 Foundation DesignDocumento14 páginasChapter 8 Foundation DesignYau Wen JaeAinda não há avaliações

- L3 Lateral ForceDocumento75 páginasL3 Lateral Forceapirakq100% (1)

- Earthquake Resistant Building Design GuideDocumento44 páginasEarthquake Resistant Building Design Guidesameer100% (1)

- Folded PlatesDocumento8 páginasFolded PlatesAsanka Bandaranayake100% (1)

- Determine Wall Load-Bearing CapacityDocumento2 páginasDetermine Wall Load-Bearing Capacitysalman arafatAinda não há avaliações

- Large span structure loads and formsDocumento20 páginasLarge span structure loads and formsASHFAQAinda não há avaliações

- Prestressed Concrete StructuresDocumento32 páginasPrestressed Concrete StructuresMâjñù MâjñúAinda não há avaliações

- A Review On Base Isolation of Multi-Storied Steel StructureDocumento5 páginasA Review On Base Isolation of Multi-Storied Steel StructureIJRASETPublicationsAinda não há avaliações

- STAAD Pro CE - Seismic Analysis Using Is 1893 Part 1 2016 Das BentleyDocumento302 páginasSTAAD Pro CE - Seismic Analysis Using Is 1893 Part 1 2016 Das BentleyParamjit SinghAinda não há avaliações

- Structural Design of RCC Building ComponentsDocumento9 páginasStructural Design of RCC Building ComponentsAHSANAinda não há avaliações

- Deadload LiveloadDocumento37 páginasDeadload LiveloadVincent Nebria100% (1)

- Seismic Analysis and Design of R.C.C Tall Building With Shear WallDocumento9 páginasSeismic Analysis and Design of R.C.C Tall Building With Shear WallNaveen JatavAinda não há avaliações

- Analysis & Design of Innovative Industrial Roof: Arpita Nikam, Priyanka JoshilkarDocumento9 páginasAnalysis & Design of Innovative Industrial Roof: Arpita Nikam, Priyanka Joshilkardino mohammedAinda não há avaliações

- Secant Piles: What Are Secant Pile Walls?Documento3 páginasSecant Piles: What Are Secant Pile Walls?ulhas_nakashe100% (2)

- CasestudyDocumento21 páginasCasestudyGunjan PataitAinda não há avaliações

- Long Span Beams Design and ApplicationsDocumento14 páginasLong Span Beams Design and ApplicationsashAinda não há avaliações

- Structural AnalysisDocumento27 páginasStructural AnalysisKhalid NadeemAinda não há avaliações

- Space Frames and Geodesic Domes ExplainedDocumento31 páginasSpace Frames and Geodesic Domes ExplainedVishnuVardhan100% (1)

- Ecg Question BankDocumento2 páginasEcg Question BankSohail ShaikhAinda não há avaliações

- Understanding Shear WallsDocumento70 páginasUnderstanding Shear WallsAboalmaaliAinda não há avaliações

- Group1 FinalDocumento63 páginasGroup1 FinalArnav SinghAinda não há avaliações

- Seismic Analysis of G 10 Storey Building With Various Locations of Shear Walls Using EtabsDocumento8 páginasSeismic Analysis of G 10 Storey Building With Various Locations of Shear Walls Using EtabsEditor IJTSRDAinda não há avaliações

- Prefabrication, Systems Building and Mixed/Composite: Presented byDocumento15 páginasPrefabrication, Systems Building and Mixed/Composite: Presented byPrasanna ChaurasiaAinda não há avaliações

- Earth Quake Resistant Design Codal - ProvisionsIS 1893Documento30 páginasEarth Quake Resistant Design Codal - ProvisionsIS 1893SudharsananPRSAinda não há avaliações

- Long Span StructuresDocumento13 páginasLong Span StructuresVinay KatariyaAinda não há avaliações

- Analysis of Elevated Square Water Tank With Different Staging SystemDocumento4 páginasAnalysis of Elevated Square Water Tank With Different Staging SystemInternational Journal of Innovative Science and Research TechnologyAinda não há avaliações

- Foundation: Module - IIDocumento41 páginasFoundation: Module - IISoe ThihaAinda não há avaliações

- High RiseDocumento58 páginasHigh Risekevin100% (1)

- Time-History Seismic Analysis With SAP2000Documento35 páginasTime-History Seismic Analysis With SAP2000pescanova3Ainda não há avaliações

- Structural Framing SystemDocumento20 páginasStructural Framing SystemOdee EbitaAinda não há avaliações

- Building Design PDFDocumento7 páginasBuilding Design PDFkbkwebsAinda não há avaliações

- Rural Development Construction.Documento41 páginasRural Development Construction.Anuj SubbaAinda não há avaliações

- Curtain WallsDocumento34 páginasCurtain WallsKotesh ReddyAinda não há avaliações

- Design and Analysis of Intez Type Water Tank Using SAP 2000 SoftwareDocumento7 páginasDesign and Analysis of Intez Type Water Tank Using SAP 2000 SoftwareIJRASETPublicationsAinda não há avaliações

- LCA Oftallbuildings:stillalongwaytogoDocumento3 páginasLCA Oftallbuildings:stillalongwaytogoNicolas Pardo AlvarezAinda não há avaliações

- Along Wind Load On Tall Buildings - Indian Codal ProvisionsDocumento8 páginasAlong Wind Load On Tall Buildings - Indian Codal ProvisionsKeshav VaityAinda não há avaliações

- 21 Folded Plates ExamplDocumento11 páginas21 Folded Plates ExamplJames CjAinda não há avaliações

- Cable Roofs HistoryDocumento3 páginasCable Roofs HistorySparrow JackAinda não há avaliações

- Skyscrapers v2Documento5 páginasSkyscrapers v2nato_kmqAinda não há avaliações

- Building Materials for Civil EngineeringDocumento17 páginasBuilding Materials for Civil EngineeringJukirman SAinda não há avaliações

- BasementsDocumento15 páginasBasementsMeshari FahimAinda não há avaliações

- Shear WallDocumento10 páginasShear WallZeus GhoshAinda não há avaliações

- Tube Structure Concept for Tall BuildingsDocumento3 páginasTube Structure Concept for Tall BuildingsMohibullah BappiAinda não há avaliações

- Shear WallDocumento22 páginasShear Wallrenganathank1987100% (1)

- Earthquake Resistent Building ConstructionDocumento14 páginasEarthquake Resistent Building ConstructionAbdullah MohamedAinda não há avaliações

- Housing PoliciesDocumento24 páginasHousing PoliciesS M Khalid HossainAinda não há avaliações

- 06 Earth - Quake - Tips PDFDocumento55 páginas06 Earth - Quake - Tips PDFMaheshbabu CheetakoruAinda não há avaliações

- 1.0 Behaviour of Tall BuildingDocumento22 páginas1.0 Behaviour of Tall BuildingOne The100% (1)

- DRCS Important Questions For Gtu ExamsDocumento5 páginasDRCS Important Questions For Gtu ExamsNAKUM ManishAinda não há avaliações

- School Building Structural ReportDocumento51 páginasSchool Building Structural ReportNabin Acharya100% (1)

- A Reinforced Soil Mix Wall Cofferdam Supported by High Capacity Removable Soil AnchorsDocumento9 páginasA Reinforced Soil Mix Wall Cofferdam Supported by High Capacity Removable Soil AnchorsHüseyin EkiciAinda não há avaliações

- GDP Growth-Fiscal Policy & InflationDocumento2 páginasGDP Growth-Fiscal Policy & InflationSiddique AhmedAinda não há avaliações

- Draft Renewable Energy Policy of BangladeshDocumento12 páginasDraft Renewable Energy Policy of BangladeshMakame Mahmud DiptaAinda não há avaliações

- Bangladesh: Rooppur Nuclear Plant Unsafe, Not Viable by Concerned CitizensDocumento4 páginasBangladesh: Rooppur Nuclear Plant Unsafe, Not Viable by Concerned CitizensSiddique AhmedAinda não há avaliações

- Bangladesh: Rooppur Nuclear Plant Unsafe, Not Viable by Concerned CitizensDocumento4 páginasBangladesh: Rooppur Nuclear Plant Unsafe, Not Viable by Concerned CitizensSiddique AhmedAinda não há avaliações

- Life Cycle of CivilizationDocumento20 páginasLife Cycle of CivilizationSiddique AhmedAinda não há avaliações

- Affortdable Housing in MauritiousDocumento61 páginasAffortdable Housing in MauritiousSiddique AhmedAinda não há avaliações

- Sustainable Hydropower Toward Community DevelopmentDocumento6 páginasSustainable Hydropower Toward Community DevelopmentSiddique AhmedAinda não há avaliações

- No Ambiguity This Time Bangladesh FailedDocumento10 páginasNo Ambiguity This Time Bangladesh FailedSiddique AhmedAinda não há avaliações

- Report On Urban HouisngDocumento54 páginasReport On Urban HouisngSaleha NhAinda não há avaliações

- Political Violence Looking Like Organised CrimeDocumento4 páginasPolitical Violence Looking Like Organised CrimeSiddique AhmedAinda não há avaliações

- Air Pollution Killed 7 Million People in 2012Documento6 páginasAir Pollution Killed 7 Million People in 2012Siddique AhmedAinda não há avaliações

- Life Cycle of CivilizationDocumento20 páginasLife Cycle of CivilizationSiddique AhmedAinda não há avaliações

- Report On Urban HouisngDocumento54 páginasReport On Urban HouisngSaleha NhAinda não há avaliações

- A Quiet Change-IndonesiaDocumento3 páginasA Quiet Change-IndonesiaSiddique AhmedAinda não há avaliações

- Rethink Your RevolutionsDocumento3 páginasRethink Your RevolutionsSiddique AhmedAinda não há avaliações

- Small Hydro PowerDocumento8 páginasSmall Hydro PowerSiddique AhmedAinda não há avaliações

- Bangladesh Enviromental DisasterDocumento4 páginasBangladesh Enviromental DisasterSiddique AhmedAinda não há avaliações

- The Daily Star All Survey ReportsDocumento249 páginasThe Daily Star All Survey ReportsSiddique AhmedAinda não há avaliações

- Cheese Manufacturing ProcessDocumento13 páginasCheese Manufacturing ProcessSiddique AhmedAinda não há avaliações

- Piled Up Reserve & Fall On Credit Haunts Bangladesh EconomyDocumento5 páginasPiled Up Reserve & Fall On Credit Haunts Bangladesh EconomySiddique AhmedAinda não há avaliações

- Bangladesh 5th in E-Governance in SAARCDocumento1 páginaBangladesh 5th in E-Governance in SAARCSiddique AhmedAinda não há avaliações

- Safety Program Emergency Procedures For High-Rise Buildings PDFDocumento57 páginasSafety Program Emergency Procedures For High-Rise Buildings PDFSiddique Ahmed0% (1)

- LAND DEGRADATION CAUSES AND IMPACTSDocumento16 páginasLAND DEGRADATION CAUSES AND IMPACTSSiddique AhmedAinda não há avaliações

- Asia's Water WarDocumento9 páginasAsia's Water WarSiddique AhmedAinda não há avaliações

- LAND DEGRADATION CAUSES AND IMPACTSDocumento16 páginasLAND DEGRADATION CAUSES AND IMPACTSSiddique AhmedAinda não há avaliações

- Bay of Bengal During Late QuarternaryDocumento11 páginasBay of Bengal During Late QuarternarySiddique AhmedAinda não há avaliações

- Climate Change and BangladeshDocumento28 páginasClimate Change and BangladeshS. M. Hasan ZidnyAinda não há avaliações

- Let There Be No More BloodshedDocumento6 páginasLet There Be No More BloodshedSiddique AhmedAinda não há avaliações

- Historical DocumentDocumento3 páginasHistorical DocumentSiddique AhmedAinda não há avaliações

- 12 Ways To Repair A Loose Wood Screw Hole For A Hinge - WikiDocumento14 páginas12 Ways To Repair A Loose Wood Screw Hole For A Hinge - Wikisrikrish24Ainda não há avaliações

- Shear WallDocumento1 páginaShear WallAbdullah SimpsonAinda não há avaliações

- Stjepan Planic Katalog Izlozbe 005 015 UvodnikDocumento11 páginasStjepan Planic Katalog Izlozbe 005 015 Uvodnikvedran1980100% (1)

- Module 8 - Electrical LayoutDocumento36 páginasModule 8 - Electrical LayoutMargarette ManaloAinda não há avaliações

- Eton Emerald Ortigas Condominium Paolo FloresDocumento2 páginasEton Emerald Ortigas Condominium Paolo FloresetonpropertiesAinda não há avaliações

- Glass HoleDocumento170 páginasGlass HoleAhsan SattarAinda não há avaliações

- Mechanical Properties of Soil-Cement Interlocking BlocksDocumento17 páginasMechanical Properties of Soil-Cement Interlocking BlocksMahsa ChavoshiAinda não há avaliações

- Esic Hospital ComparisonDocumento25 páginasEsic Hospital ComparisonPrakriti GoelAinda não há avaliações

- Earthbound Canada 2011Documento12 páginasEarthbound Canada 2011Christopher GarciaAinda não há avaliações

- Waterway Woodcress - Maps & PlansDocumento36 páginasWaterway Woodcress - Maps & PlanspinkcoralAinda não há avaliações

- Singapore Property Weekly Issue 322Documento15 páginasSingapore Property Weekly Issue 322Propwise.sgAinda não há avaliações

- Architeam Awards Book 3 WFCRZZCCQBNJDocumento47 páginasArchiteam Awards Book 3 WFCRZZCCQBNJFaith CabuagAinda não há avaliações

- BP 220 BookletDocumento18 páginasBP 220 BookletKenneth CachoAinda não há avaliações

- Pictorial Travelogue - UsaDocumento56 páginasPictorial Travelogue - UsaMaqsood Ahmad KhanAinda não há avaliações

- (1.0 Credit) : Structural Analysis and Design Sessional-IDocumento34 páginas(1.0 Credit) : Structural Analysis and Design Sessional-IAnonymous aE0YYlCOKAinda não há avaliações

- PD 1096Documento3 páginasPD 1096DINGLE, Ana Lerizze B.Ainda não há avaliações

- BP 344 Accessibility LawDocumento63 páginasBP 344 Accessibility LawStein Luib Jael100% (1)

- Estimating Costing PDFDocumento9 páginasEstimating Costing PDFPriscilla MurrayAinda não há avaliações

- Southwest Type 7gp Pds-FireproofingDocumento3 páginasSouthwest Type 7gp Pds-FireproofingMarcelo AlvesAinda não há avaliações

- ESD Flooring Installation GuideDocumento4 páginasESD Flooring Installation GuideSyed Fawad Hasan100% (1)

- Tenant Guideline: Vieng Vang Sole Co., LTDDocumento3 páginasTenant Guideline: Vieng Vang Sole Co., LTDVishan SharmaAinda não há avaliações

- Aveyond: Lord of Twilight WalkthroughDocumento45 páginasAveyond: Lord of Twilight WalkthroughYennisa YPAinda não há avaliações

- 7600 ICU Installation ManualDocumento12 páginas7600 ICU Installation ManualAngelo Colombo RauterAinda não há avaliações

- Pro-Forma 1 Design Information ChecklistDocumento38 páginasPro-Forma 1 Design Information ChecklistSanthosh KumarAinda não há avaliações

- Stone LithochromeColorHardener 1110 21Documento5 páginasStone LithochromeColorHardener 1110 21tigre_fielAinda não há avaliações

- Res Load 11Documento18 páginasRes Load 11nguyentienphatAinda não há avaliações

- SSS Housing AssetsDocumento18 páginasSSS Housing AssetsMafe CalunsodAinda não há avaliações

- Medium-Rise Housing For University of The Philippines-DilimanDocumento13 páginasMedium-Rise Housing For University of The Philippines-DilimanArchitect ArchitectAinda não há avaliações

- 2011 CIVITAS Benefit JournalDocumento40 páginas2011 CIVITAS Benefit JournalCIVITASAinda não há avaliações

- Fire DampersDocumento20 páginasFire DampersRommelAinda não há avaliações

- Crochet Impkins: Over a million possible combinations! Yes, really!No EverandCrochet Impkins: Over a million possible combinations! Yes, really!Nota: 4.5 de 5 estrelas4.5/5 (9)

- Coloring Book for Adults & Grown Ups : An Easy & Quick Guide to Mastering Coloring for Stress Relieving Relaxation & Health Today!: The Stress Relieving Adult Coloring PagesNo EverandColoring Book for Adults & Grown Ups : An Easy & Quick Guide to Mastering Coloring for Stress Relieving Relaxation & Health Today!: The Stress Relieving Adult Coloring PagesNota: 2 de 5 estrelas2/5 (12)

- The Martha Manual: How to Do (Almost) EverythingNo EverandThe Martha Manual: How to Do (Almost) EverythingNota: 4 de 5 estrelas4/5 (11)

- A Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionNo EverandA Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionNota: 4.5 de 5 estrelas4.5/5 (23)

- Sharpie Art Workshop: Techniques & Ideas for Transforming Your WorldNo EverandSharpie Art Workshop: Techniques & Ideas for Transforming Your WorldNota: 3 de 5 estrelas3/5 (16)

- Bright & Bold Cozy Modern Quilts: 20 Projects, Easy Piecing, Stash BustingNo EverandBright & Bold Cozy Modern Quilts: 20 Projects, Easy Piecing, Stash BustingAinda não há avaliações

- Too Cute Amigurumi: 30 Crochet Patterns for Adorable Animals, Playful Plants, Sweet Treats and MoreNo EverandToo Cute Amigurumi: 30 Crochet Patterns for Adorable Animals, Playful Plants, Sweet Treats and MoreNota: 5 de 5 estrelas5/5 (2)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiNo Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiNota: 5 de 5 estrelas5/5 (2)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindAinda não há avaliações

- Crafts For Adults Basics - The Ultimate Starting Guide For All Craft Beginners To Master The Knowledge & Basics Of Different CraftsNo EverandCrafts For Adults Basics - The Ultimate Starting Guide For All Craft Beginners To Master The Knowledge & Basics Of Different CraftsNota: 1.5 de 5 estrelas1.5/5 (3)

- Knit a Box of Socks: 24 sock knitting patterns for your dream box of socksNo EverandKnit a Box of Socks: 24 sock knitting patterns for your dream box of socksAinda não há avaliações

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastNo EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastNota: 5 de 5 estrelas5/5 (1)

- 100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesNo Everand100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesAinda não há avaliações

- Handmade: Creative Focus in the Age of DistractionNo EverandHandmade: Creative Focus in the Age of DistractionNota: 4.5 de 5 estrelas4.5/5 (25)

- The Basics of Corset Building: A Handbook for BeginnersNo EverandThe Basics of Corset Building: A Handbook for BeginnersNota: 4.5 de 5 estrelas4.5/5 (17)

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiNo EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiNota: 4 de 5 estrelas4/5 (3)

- Knitting for Anarchists: The What, Why and How of KnittingNo EverandKnitting for Anarchists: The What, Why and How of KnittingNota: 4 de 5 estrelas4/5 (51)

- Playful Petals: Learn Simple, Fusible Appliqué • 18 Quilted Projects Made From PrecutsNo EverandPlayful Petals: Learn Simple, Fusible Appliqué • 18 Quilted Projects Made From PrecutsNota: 3.5 de 5 estrelas3.5/5 (3)

- Creative Stitches for Contemporary Embroidery: Visual Guide to 120 Essential Stitches for Stunning DesignsNo EverandCreative Stitches for Contemporary Embroidery: Visual Guide to 120 Essential Stitches for Stunning DesignsNota: 4.5 de 5 estrelas4.5/5 (2)

- Famous Frocks: The Little Black Dress: Patterns for 20 Garment Inspired by Fashion IconsNo EverandFamous Frocks: The Little Black Dress: Patterns for 20 Garment Inspired by Fashion IconsNota: 4 de 5 estrelas4/5 (4)

- Sri Yantra with Golden Ratio Triangle and InscriptionsNo EverandSri Yantra with Golden Ratio Triangle and InscriptionsNota: 5 de 5 estrelas5/5 (1)

- Crochet Collage Garden: 100 patterns for crochet flowers, plants and petalsNo EverandCrochet Collage Garden: 100 patterns for crochet flowers, plants and petalsNota: 5 de 5 estrelas5/5 (1)

- Modern Patchwork: 12 Quilts to Take You Beyond the BasicsNo EverandModern Patchwork: 12 Quilts to Take You Beyond the BasicsNota: 4 de 5 estrelas4/5 (5)

- Edward's Menagerie: The New Collection: 50 animal patterns to learn to crochetNo EverandEdward's Menagerie: The New Collection: 50 animal patterns to learn to crochetNota: 3.5 de 5 estrelas3.5/5 (4)

- Edward's Menagerie: Dogs: 50 canine crochet patternsNo EverandEdward's Menagerie: Dogs: 50 canine crochet patternsNota: 3 de 5 estrelas3/5 (5)

- Soap Making Guide With Recipes: DIY Homemade Soapmaking Made Easy: DIY Homemade Soapmaking Made EasyNo EverandSoap Making Guide With Recipes: DIY Homemade Soapmaking Made Easy: DIY Homemade Soapmaking Made EasyNota: 4.5 de 5 estrelas4.5/5 (17)

- Sleeves: A Directory of Design Details and TechniquesNo EverandSleeves: A Directory of Design Details and TechniquesNota: 5 de 5 estrelas5/5 (5)

- Irene Strange's Curious Crochet Creatures: Amazing amigurumi patterns for wonderfully weird animalsNo EverandIrene Strange's Curious Crochet Creatures: Amazing amigurumi patterns for wonderfully weird animalsNota: 5 de 5 estrelas5/5 (2)