Escolar Documentos

Profissional Documentos

Cultura Documentos

SAES-A-403 - Offshore Platform Drainage Systems

Enviado por

Reda AL-mesbahDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

SAES-A-403 - Offshore Platform Drainage Systems

Enviado por

Reda AL-mesbahDireitos autorais:

Formatos disponíveis

Engineering Standard

SAES-A-403 Offshore Platform Drainage Systems Document Responsibility: Industrial Drainage Standards Committee 30 June 2010

Saudi Aramco DeskTop Standards

Table of Contents 1 2 3 4 5 6 7 8 9 Scope............................................................. 2 Conflicts and Deviations................................. 3 References..................................................... 3 Definitions...................................................... 5 General Requirements................................... 7 Requirements for Manned Platforms........... 11 Requirements for Unmanned Platforms....... 11 Installation Materials..................................... 12 Testing and Inspection................................. 12

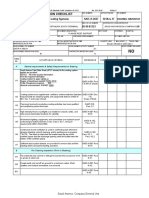

Figure 1 Illustrative CDS Connection to Process Equipment.......................... 14 Figure 2 Illustrative CDS Schematic................ 15 Figure 3 Illustrative OWDS (Slops System) Schematic................... 16

Previous Issue: New Next Planned Update: 30 June 2015 Page 1 of 16 Primary contact: Mehra, Yuv Raj on 966-3-8747953

CopyrightSaudi Aramco 2010. All rights reserved.

Document Responsibility: Industrial Drainage Standards Committee Issue Date: 30 June 2010 Next Planned Update: 30 June 2015

SAES-A-403 Offshore Platform Drainage Systems

Scope 1.1 This standard provides minimum mandatory requirements for the proper design of drainage systems for all offshore platforms to ensure that all industrial liquids can be drained safely with minimum hazard of fire or injury and in compliance with environmental requirements. This standard applies to all fixed offshore facilities and equipment that are in operation or when they are taken out of service for maintenance, and testing and inspections (T&I). Specifically, this standard provides requirements for design and safe handling of: 1.1.1 1.1.2 1.1.3 1.1.4 1.1.5 1.1.6 liquid hydrocarbons, toxic liquids, dissolved chemicals, corrosive liquids, aqueous materials, and other liquid effluents

that are drained in Saudi Aramcos offshore facilities. 1.2 This standard covers all types of industrial liquid drains including, but not limited to, the following: 1.2.1 1.2.2 1.2.3 1.2.4 1.2.5 1.2.6 1.2.7 1.2.8 1.2.9 instrument bridles and sight glasses, thermal relief valves on liquid piping, pump and compressor casings, knockout drums, process vessels and separators, heat exchangers, filters, scraper launchers/receivers, sample points, and

1.2.10 low point drains from control valves and piping systems.

Page 2 of 16

Document Responsibility: Industrial Drainage Standards Committee Issue Date: 30 June 2010 Next Planned Update: 30 June 2015

SAES-A-403 Offshore Platform Drainage Systems

1.3

This standard does not cover: 1.3.1 The environmental design aspects for treating and disposal of liquids from industrial drainage and oily water drainage systems (refer to SAES-A-103 & SAES-A-104). The drain systems of laboratories or dedicated battery rooms (SAES-P-103) governed by SAES-S-060. Drainage systems for marine vessels. Sanitary wastewater systems (refer to SAES-S-010). Drainage for Sea Island facilities.

1.3.2 1.3.3 1.3.4 1.3.5 2

Conflicts and Deviations 2.1 Any conflicts between this Standard and other applicable Saudi Aramco Engineering Standards (SAESs), Saudi Aramco Materials System Specifications (SAMSSs), Saudi Aramco Standard Drawings (SASDs), or industry standards, codes, and forms shall be resolved in writing by the Company or Buyer Representative through the Manager, Process & Control Systems Department of Saudi Aramco, Dhahran. Direct all requests to deviate from the Standard in writing to the Company or Buyer Representative, who shall follow internal company procedure SAEP-302 and forward such requests to the Manager, Process & Control Systems Department of Saudi Aramco, Dhahran.

2.2

References All referenced Specifications, Standards, Codes, Forms, Drawings, and similar material shall be considered part of this Standard to the extent specified herein and shall be the latest issue (including all revisions, addenda, and supplements) unless stated otherwise. 3.1 Saudi Aramco References General Instructions GI-0150.100 Hazardous Materials Communication (HAZCOM) Program

Saudi Aramco Engineering Procedures SAEP-125 Preparation of Saudi Aramco Engineering Standards

Page 3 of 16

Document Responsibility: Industrial Drainage Standards Committee Issue Date: 30 June 2010 Next Planned Update: 30 June 2015

SAES-A-403 Offshore Platform Drainage Systems

SAEP-302 SAEP-327

Instruction for Obtaining a Waiver of a Mandatory Saudi Aramco Engineering Requirement Disposal of Wastewater from Cleaning, Flushing and Dewatering Pipelines and Vessels

Saudi Aramco Engineering Standards SAES-A-103 SAES-A-104 SAES-A-401 SAES-B-009 SAES-B-017 SAES-B-054 SAES-B-055 SAES-B-068 SAES-G-005 SAES-G-006 SAES-J-300 SAES-L-132 SAES-P-103 SAES-S-010 SAES-S-020 SAES-S-030 SAES-S-060 SAES-S-070 Discharges to the Marine Environment Wastewater Treatment, Reuse and Disposal Closed Drain Systems Fire protection and Safety Requirements for Offshore Production Facilities Fire Water System Design Access, Egress, and Materials Handling for Plant Facilities Plant layout Electrical Area Classification Centrifugal Pumps Positive Displacement Pumps - Controlled Volume Level Material Selection for Piping Systems UPS and DC Systems Sanitary Sewers Oily Water Drainage Systems Storm Water Drainage Systems Saudi Aramco Plumbing Code Installation of Utility Piping Systems

Saudi Aramco Engineering Report SAER-5437 3.2 Industry Codes and Standards National Fire Protection Association NFPA 704 Identification of the Hazards of Materials for Emergency Response

Page 4 of 16

Guidelines for Conducting HAZOP Studies

Document Responsibility: Industrial Drainage Standards Committee Issue Date: 30 June 2010 Next Planned Update: 30 June 2015

SAES-A-403 Offshore Platform Drainage Systems

3.3

Chemical Hazard Bulletins (CHBS) CHB# 14 CHB# 47 CHB# 71 CHB# 155 CHB# 400 CHB# 518 CHB# 666 Sodium Hydroxide (Caustic Soda) Benzene Phenol (Carbolic Acid) Hydrogen Sulfide (H2S) Sulfuric Acid STADIS 450 (Anti-Static Additive) Hot Pot 922 (Corrosion Inhibitor)

Definitions Catch Basin (Catch Pot): A device with an integral sediment trap and outlet liquid seal for the collection of surface runoff and effluent (grate at top). Chemical Hazard Bulletin (CHB): An internal company document (Available in both English & Arabic) developed by Environmental Protection Department to provide standardized one-page summary of a materials hazard ratings that will specify health hazard, fire & reactivity, handling, storage & disposal and first aid information for use in the handling of hazardous materials. Use of CHBs shall be consistent with the requirements contained within GI-0150.100 Hazardous Materials Communication Program (HAZCOM) to ensure employees are knowledgeable of the hazards associated with the specific chemicals. Cleanout: A reseal-able port that allows for the cleaning of piping within oily water drainage systems. Closed Drain System (CDS): For the purpose of this standard, a closed drain system is a collection system consisting of piping and vessels connected to selected hydrocarbon drains for the containment, recovery or safe disposal of collected liquids, which would otherwise cause hazardous releases of hydrocarbon or H2S to the atmosphere or to Slops System. A CDS is isolated from air or oxygen sources. A CDS includes a closed drain header (CDS Header), lateral sub-headers, a pressure vessel (CDS Drum), and a liquids transfer piping connected to the Slops Tank. Combustible Liquid: A liquid that has a flash point greater than 54C (130F). Examples of such fluids are diesel, bunker fuel, and sulfur. Corrosive: For the purpose of this standard, materials with a pH level 1-3 (acidic) or pH level 12-14 (basic) are considered corrosive. Flammable Liquid: A liquid that has a flash point equal to or less than 54C (130F). Examples of such fluids are: stabilized crude, gasoline, Jet A-1, Jet JP-4, Jet JP-8, C6

Page 5 of 16

Document Responsibility: Industrial Drainage Standards Committee Issue Date: 30 June 2010 Next Planned Update: 30 June 2015

SAES-A-403 Offshore Platform Drainage Systems

and lighter feed and blending stocks, C7+ feed stocks, and methanol. For purposes of this standard, a combustible liquid stored or processed at a temperature equal to or higher than 8C (15F) below its flashpoint shall be considered a flammable liquid. Flash Point: The flash point of a flammable liquid is the lowest temperature at which it can form an ignitable mixture in air. At this temperature, the vapor may cease to burn when the source of ignition is removed. High Health Hazard Materials: High Health Hazard Materials, as defined herein, include: a) Materials with a Health Hazard rating of 3 or 4 per the Saudi Aramco Chemical Hazards Bulletins (CHBs), or per NFPA 704. Examples of such materials include but are not limited to: b) sodium hydroxide (caustic soda) CHB# 14 benzene CHB# 47 phenol (carbolic acid) CHB# 71 hydrogen sulfide (H2S) CHB# 155 sulfuric acid CHB# 400 STADIS 450 (anti-static additive) CHB# 518 hot pot -922 (corrosion inhibitor) CHB# 666.

Highly corrosive materials such as acid, caustic and other materials injurious to personnel.

Manned Platform: A manned platform shall mean a platform where operating or maintenance personnel are normally found for at least one full shift each working day. Wellhead platforms are not considered to be manned platforms. Tie-in platforms, not bridge-connected to other manned platforms, are not considered to be manned platforms. Oily Water: Mixtures of hydrocarbon residues and water. Oily water is considered to be contaminated water released during normal operation.

Note: Due to unforeseen conditions and during uncontrollable accidental situations such as during fire or spill-containment, the oily water drainage system may receive oilcontaminated wastewater with flammable hydrocarbons as well (refer to SAES-S-020).

Oily Water Drainage System (OWDS): For the purpose of this standard, an OWDS is also a Slop System. A slop system is an oily water collection and conveyance system consisting of catch basins, a network of drainage piping, slops tank for collection, and pumps to transfer collected liquids to a production trap or trunk line, or for gravity draining to a marine vessel.

Page 6 of 16

Document Responsibility: Industrial Drainage Standards Committee Issue Date: 30 June 2010 Next Planned Update: 30 June 2015

SAES-A-403 Offshore Platform Drainage Systems

Slop System: See definition for Oily Water Drainage System (OWDS). Sub lateral: For the purpose of this standard, a sub lateral is a branch of the drainage network, which conveys effluent from source to the lateral branch of the drainage piping system, or serves several drains. Toe Wall: A raised curb that controls and directs effluent to a catch basin. Toxic: See definition for High Health Hazard Materials. Unmanned Platform: An unmanned platform is either a single or a continuous complex of offshore platforms, upon which operators are present for less than one full shift. 5 General Requirements 5.1 5.2 For layout, spacing and access related to drainage facilities follow SAES-B-009, SAES-B-054, and SAES-B-055. All offshore facilities shall be equipped with an OWDS in accordance with SAES-S-020. The slops tank shall be located on the lowest deck of the platform. No liquids drainage piping of any kind shall be directly connected into the gas flare system. All process drain piping shall be isolated by double isolation (e.g., two block valves with plug or blind flange). See Figure 1. All liquid drain systems shall be designed and conformed to the formal Hazard and Operability (HAZOP) methodology following the guidelines in HAZOP Engineering Report SAER-5437. For environmental compliance, the disposal of wastewater from cleaning, flushing and dewatering pipelines, tanks, and vessels at offshore facilities shall be in accordance with SAEP-327. For retroactive application of this standard to existing facilities, refer to SAEP-125, Paragraph 3.1. No building sewer (sanitary) or building drains (sanitary) as defined in SAES-S-010 shall be connected to any part of OWDS or CDS. All OWDS piping networks shall be designed to be free-flowing and selfdraining to ensure that no effluents remain in the piping during no-flow conditions.

Page 7 of 16

5.3 5.4 5.5

5.6

5.7 5.8 5.9

Document Responsibility: Industrial Drainage Standards Committee Issue Date: 30 June 2010 Next Planned Update: 30 June 2015 Exception:

SAES-A-403 Offshore Platform Drainage Systems

Effluent standing in a water seal and in a seal inlet is permissible, provided that the overall intent of having all parts of the OWDS to be free-draining is preserved.

5.10 5.11

Catch basins must be installed for all OWDS. Catch basins and cleanouts shall be designed and located for ease of personnel, equipment access, and cleanout. All effluents entering an OWDS shall enter the drainage piping network through a sealed catch pot. All catch basins shall be equipped with a water seal that is a minimum of 150 mm (6 inch). Electrical area classification shall meet requirements of SAES-B-068. For additional clarifications and exceptions see SAES-B-009. All requirements of referenced paragraphs of SAES-S-020 shall be applicable for: 5.13.1 5.13.2 5.13.3 5.13.4 5.13.5 5.13.6 5.13.7 Flow rate design requirements (see Paragraph 4.4) except that the firewater demand shall be in accordance with SAES-B-009. Line sizing requirements (see Paragraph 4.5) Drainage collection area requirements (see Paragraph 4.6) except that the maximum surface travel shall be in accordance with SAES-B-009. Drain pipe and funnels requirements (see Paragraph 4.8) Catch basin requirements (see Paragraph 4.9) Cleanout requirements (see Paragraph 4.11) Venting requirements (see Paragraph 4.12)

5.12 5.13

5.14 5.15

A helideck with fueling facilities is a hydrocarbon-handling deck. Drains from helideck fueling facilities shall be connected to the OWDS. A deck-edge drainage trough shall be installed on (a) at least two edges of plate decks with hydrocarbon equipment or hydrocarbon storage having a capacity of 4 m (1,057 gal) or greater, and (b) on all edges of helidecks having refueling capabilities. If troughs are installed on only two edges of a deck, the trough edges shall be opposite one another, with trough toe walls provided per SAES-S-020, and a minimum 150 mm high toe wall on any trough-less edge. Handrails along the inboard side of the deck edge trough shall not have kick plates. Each deck penetration shall be surrounded by sleeve that shall extend a

Page 8 of 16

5.16 5.17

Document Responsibility: Industrial Drainage Standards Committee Issue Date: 30 June 2010 Next Planned Update: 30 June 2015

SAES-A-403 Offshore Platform Drainage Systems

minimum of 150 mm (6 inch) above the deck level, and which shall provide the amount of clearance necessary to allow free movement between the sleeve and piping, conduit, cable, or equipment in the penetration. 5.18 5.19 Each plate deck handling hydrocarbons shall constitute at least one surface drainage collection area. The maximum plate deck travel distance of any liquid shall be 30 m. The subdivision of plate deck areas shall be accomplished through the use of ridge lines and deck-edge troughs. Surfaces shall drain free, with no liquid pooling. The plate deck shall have a slope of not less than 1:100 (1%) to a trough. In-deck troughs shall not be more than 300 mm (12 inch) wide and shall be covered with grating. Use of in-deck troughs shall be reviewed and approved by the Chief Fire Prevention Engineer. Sealed in-deck drain points are permissible for local area drainage needs such as at scraper launchers/receivers. All troughs shall have a minimum pitch of 1:65 (1.5%). A baffle plate shall be installed at the high point of each trough section. Area and equipment drainage shall include sub laterals and laterals tying into a sub main. All liquids, such as surface runoff and effluent, that flow into the gravity OWDS shall enter through sealed catch basins, or sealed and vented drain box including entries from drainage troughs. Sub mains from each deck shall be connected via sealed pot a minimum of 150 mm (6 inch) and vented drain box (which has the same function as an onshore manhole) to a common main or riser discharging to the slops tank. 5.26 5.27 5.28 5.29 All lines discharging into a slops tank shall terminate a minimum of 150 mm (6 inch) below the lowest possible slops tank liquid level. Each slops tank shall be vented. Vents of slops tanks shall be routed free of pockets and shall terminate as specified in SAES-B-009. Catch basins for drain troughs shall be incorporated into the drain trough, or bolted directly onto the bottom of the drain trough. Catch basins shall be accessible for cleaning from the deck containing the drain trough.

5.20 5.21

5.22 5.23 5.24 5.25

Page 9 of 16

Document Responsibility: Industrial Drainage Standards Committee Issue Date: 30 June 2010 Next Planned Update: 30 June 2015

SAES-A-403 Offshore Platform Drainage Systems

5.30 5.31

A minimum liquid seal height of 150 mm (6 inch) shall be provided in all individual drains prior to their entering sub-laterals or laterals. Vents protecting liquid seals and drain boxes shall terminate at least 3 meters (10 feet) above the highest process pipe, process equipment, or platform on the uppermost deck within 7.6 meters (25 feet) horizontally.

Commentary Note: For some platforms, vents can be routed to a safe location off the side of the platform as long as the prevailing wind carries the vent gas away from the platform.

5.32

The following are requirements for slops tank: 5.32.1 Each slops tank shall have a minimum of two pumps; one pump functions as the primary while the other pump is the spare. The pumps shall be designed to handle normal operating flow in accordance with SAES-G-005. For some process applications, such as low flow and high-pressure, positive displacement (PD) pumps in accordance with SAES-G-006 may be required. The slops tank shall be provided with two radar level transmitters, in a redundant configuration, for level measurement and control of pumps. The level transmitters can be either: a) b) 5.32.3 5.32.4 Guided wave radar (GWR) as specified in SAES-J-300; or 4-wire non-contact radar transmitters.

5.32.2

A local control panel mounted at least 3 meters (10 feet) away from the closest edge of the slops tank shall be provided. The following slops tank level set points shall be configured for starting and stopping pumps set to handle normal incoming flow:

Low Level First Level Second Level All pumps off Primary normal flow pump on Actuate high level alarm in DCS operator interface/display, and start spare pump.

5.33

There shall be no treatment of drained waste streams on the platforms. All drained hydrocarbons and oily water shall be collected in the slops tanks and returned to the process or pumped onshore through the production header or gravity drained to marine vessels.

Page 10 of 16

Document Responsibility: Industrial Drainage Standards Committee Issue Date: 30 June 2010 Next Planned Update: 30 June 2015

SAES-A-403 Offshore Platform Drainage Systems

5.34

A separate drainage collection system shall be provided for each risk area in accordance with SAES-B-017, which shall independently discharge through a liquid sealed inlet into the required slops tank. The capacity of each drainage system shall be designed to ensure that anticipated spills will not overflow the toe walls. Utility vessels, day-tanks, and equipment handling combustible liquids such as diesel fuel, lube oils, transformer oils, etc., shall be curbed and separately drained through a catch basin having a liquid seal.

5.35

Requirements for Manned Platforms 6.1 A CDS shall be provided where flammable and pressurized hydrocarbon liquids, toxic and high health hazard materials are expected. The CDS design, construction and inspection shall be in accordance with SAES-A-401. Separate CDS header connected to CDS Drum (see Figure 2) and OWDS header connected to Slops Tank (see Figure 3) shall be provided. This requirement is applicable to new and existing facilities. Existing facilities may use available systems to meet the intent of CDS and OWDS definitions under Section 4. OWDS from each platform deck shall be vented immediately before the last catch basin, located upstream of the Slops Tank, in a deck drainage system for gravity drainage. Slops tank shall be sized for the controlling case among: (1) hold maximum single area firewater demand in accordance with SAES-B-017 and SAES-B-009 for 5 minutes, but not to exceed 250 barrels, or (2) maximum rainfall as specified by SAES-S-030, and in addition include (3) spillage resulting from normal operation. In other words, the holding volume shall be either [(1) + (3)] or [(2) + (3)].

Commentary Notes: 1. Use of open bottom slop tanks in not allowed by environmental regulations. 2. Only during emergency the water may be drained to the sea.

6.2

6.3

6.4

Requirements for Unmanned Platforms 7.1 7.2 CDS is not required. Any pressure blow down shall be directed to a dedicated flash drum. Vent from the flash drum shall be routed free of pockets and shall terminate as specified in SAES-B-009. The separated liquid from flash drum shall be gravity drained directly into the slops tank.

Page 11 of 16

Document Responsibility: Industrial Drainage Standards Committee Issue Date: 30 June 2010 Next Planned Update: 30 June 2015

SAES-A-403 Offshore Platform Drainage Systems

7.3

At least one pump shall be provided for transferring recovered oil from the slops tank to a safe location downstream of the isolation valve on the main outlet header from the platform. Slops tank shall be sized for maximum rainfall as specified by SAES-S-030 and spillage resulting from normal operation.

Commentary Note: Use of open bottom slop tanks in not allowed by environmental regulations.

7.4

7.5 7.6 7.7

The slops tank pump shall be sized as a normal drainage flow. All lines discharging into a slops tank shall terminate a minimum of 150 mm (6 inch) below the lowest possible liquid level in slops tank. The system shall be equipped with a level device that transmits the data through the SCADA system so that the Control Room operator can review the level.

Installation Materials Drainage fittings shall have a smooth interior waterway of the same diameter as the piping served and all such fittings shall be compatible with the type of pipe used. All fittings shall be DWV (drainage, waste and vent) type, such as 45 Ys, long 90 elbows, sixth, eighth and sixteenth bends, and combinations of such fittings. 8.1 8.2 Plastic or RTR piping shall not be used for offshore hydrocarbon (pressure) or oily-water (gravity) sewer systems. Acceptable materials shall conform to SAES-L-132.

Testing and Inspection 9.1 Unless otherwise stated below, OWDS shall be inspected and tested in accordance with SAES-S-070.

Commentary Note: To assure a clog-free drainage within the OWDS, a monthly inspection is recommended.

9.2

Vents shall be hydrostatically tested by filling the vent pipe from its connection to the OWDS to the top of the pipe. The vent shall be proven watertight for a period of no less than 4 hours.

Exception: If hydrotesting of above ground metallic vent pipe is deemed impractical, then it Page 12 of 16

Document Responsibility: Industrial Drainage Standards Committee Issue Date: 30 June 2010 Next Planned Update: 30 June 2015

SAES-A-403 Offshore Platform Drainage Systems

could be substituted with 10% radiography; and all welds shall be 100% visually inspected.

9.3

Drain lines shall be tested from the funnel or catch basin to the connection with a catch basin or manhole by filling the line with water to the top of the funnel or catch basin. Drains shall be watertight for a period of no less than 4 hours. Gravity OWDSs shall be tested from the catch basin to the first manhole connection and from manhole to manhole, by filling the line to the top of the catch basin, or the upper manhole. Drainages shall be watertight for a period of no less than 4 hours. Force mains shall be hydrostatically tested at a minimum of 1034 kPa (150 psig) or 345 kPa (50 psig) above the pump shut-off head, whichever is greater for a period of no less than 4 hours.

Exception: If hydrotesting of force main piping is deemed impractical, then it could be substituted with 100% radiography.

9.4

9.5

30 June 2010

Revision Summary New Saudi Aramco Engineering Standard.

Page 13 of 16

Document Responsibility: Industrial Drainage Standards Committee Issue Date: 30 June 2010 Next Planned Update: 30 June 2015

SAES-A-403 Offshore Platform Drainage Systems

Figure 1 Illustrative CDS Connection to Process Equipment

Page 14 of 16

Document Responsibility: Industrial Drainage Standards Committee Issue Date: 30 June 2010 Next Planned Update: 30 June 2015

SAES-A-403 Offshore Platform Drainage Systems

Figure 2 Illustrative CDS Schematic

Page 15 of 16

Document Responsibility: Industrial Drainage Standards Committee Issue Date: 30 June 2010 Next Planned Update: 30 June 2015

SAES-A-403 Offshore Platform Drainage Systems

Figure 3 Illustrative OWDS (Slops System) Schematic

Page 16 of 16

Você também pode gostar

- 32 Samss 022Documento11 páginas32 Samss 022naruto256Ainda não há avaliações

- SAES-L-133 PDF Download - Corrosion Protection Requirements - PDFYARDocumento6 páginasSAES-L-133 PDF Download - Corrosion Protection Requirements - PDFYARZahidRafique100% (1)

- 76-040 - 2012 Orifice Meter RunsDocumento7 páginas76-040 - 2012 Orifice Meter RunspradeepAinda não há avaliações

- Saes H 204Documento33 páginasSaes H 204Rei Lizardo100% (1)

- 01 Samss 031Documento3 páginas01 Samss 031Awais CheemaAinda não há avaliações

- Saes B 058Documento15 páginasSaes B 058Rashid ArshadAinda não há avaliações

- Mesc Spec 76/222Documento9 páginasMesc Spec 76/222ManoAinda não há avaliações

- Reinforced Thermoplastic Pipe For Oil and Gas: Saudi Aramco Journal of Technology September 2003Documento9 páginasReinforced Thermoplastic Pipe For Oil and Gas: Saudi Aramco Journal of Technology September 2003shizu monAinda não há avaliações

- 76 204 16Documento7 páginas76 204 16finiteinjusticeAinda não há avaliações

- 32 Samss 007Documento84 páginas32 Samss 007Inamullah KhanAinda não há avaliações

- 100 Yer Pe PDB 0113Documento10 páginas100 Yer Pe PDB 0113Janakiraman MalligaAinda não há avaliações

- Saudi-Arabian-Engineering-Standardssaes-J-001 PDFDocumento11 páginasSaudi-Arabian-Engineering-Standardssaes-J-001 PDFsalasineAinda não há avaliações

- Engineering Standard: IPS-E-PR-700Documento17 páginasEngineering Standard: IPS-E-PR-700ssureshkumar85100% (1)

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocumento2 páginasInspection & Testing Requirements Scope:: Test and Inspection PerdheenasweetAinda não há avaliações

- Flow MeasurementDocumento62 páginasFlow MeasurementnwabukingzAinda não há avaliações

- Sabp J 902Documento9 páginasSabp J 902kartik_harwani4387Ainda não há avaliações

- Schedule B - Attachment III SCOPE OF WORKDocumento6 páginasSchedule B - Attachment III SCOPE OF WORKxue jun xiangAinda não há avaliações

- Mesc Spe 74 001 2016Documento7 páginasMesc Spe 74 001 2016Salahuddin FarooquiAinda não há avaliações

- GI-0002.600 (Unit Accpetance After T&I Shut DownDocumento4 páginasGI-0002.600 (Unit Accpetance After T&I Shut DownSanthoshAinda não há avaliações

- Satip - S-050-01Documento4 páginasSatip - S-050-01LIJINAinda não há avaliações

- Sabp D 002Documento16 páginasSabp D 002engforever AdnanAinda não há avaliações

- Satah Al-Razboot (SARB) Offshore Oilfield, Abu Dhabi - Offshore TechnologyDocumento35 páginasSatah Al-Razboot (SARB) Offshore Oilfield, Abu Dhabi - Offshore Technologyandi suntoroAinda não há avaliações

- Saudi Aramco Inspection ChecklistDocumento2 páginasSaudi Aramco Inspection Checklistnadeem shaikhAinda não há avaliações

- Navigational Aids For Offshore StructuresDocumento35 páginasNavigational Aids For Offshore Structuresdebjit2001100% (1)

- Ut in Lieu of RT For Code Construction of Pressure EquipmentDocumento16 páginasUt in Lieu of RT For Code Construction of Pressure EquipmentbmkaleAinda não há avaliações

- SAIC-K-2026 Rev 0Documento2 páginasSAIC-K-2026 Rev 0philipyapAinda não há avaliações

- Explosion FPSO Cidade de Sao Mateus Investigation Report Brasilian NavyDocumento43 páginasExplosion FPSO Cidade de Sao Mateus Investigation Report Brasilian NavyTim HopperAinda não há avaliações

- Saes A 109Documento5 páginasSaes A 109SIVAAinda não há avaliações

- Chevron Regulatory Report Draft For Public CommentDocumento115 páginasChevron Regulatory Report Draft For Public CommentKQED NewsAinda não há avaliações

- Hazardous Area Classification of Gas InstallationsDocumento3 páginasHazardous Area Classification of Gas InstallationspomaukAinda não há avaliações

- EPA-600-2-85-106 Evaluation of The Efficiency of Industrial Flares: Flare Head Design and Gas CompositionDocumento140 páginasEPA-600-2-85-106 Evaluation of The Efficiency of Industrial Flares: Flare Head Design and Gas CompositionkrcomeyAinda não há avaliações

- Saic-H-2027Documento3 páginasSaic-H-2027momin0% (1)

- Mesc Spe 76 030 2015Documento6 páginasMesc Spe 76 030 2015Salahuddin FarooquiAinda não há avaliações

- J06 PT PDT 5988 5989 PDFDocumento10 páginasJ06 PT PDT 5988 5989 PDFnashittAinda não há avaliações

- 04 Samss 041Documento6 páginas04 Samss 041Moustafa BayoumiAinda não há avaliações

- Ip 0 0 2Documento4 páginasIp 0 0 2Atan B AtanAinda não há avaliações

- Marjan Development Program: Tanajib Gas Plant (TGP)Documento11 páginasMarjan Development Program: Tanajib Gas Plant (TGP)Maged GalalAinda não há avaliações

- High-Integrity Pressure Protection System: Traditional SystemsDocumento4 páginasHigh-Integrity Pressure Protection System: Traditional SystemsgowtemdmAinda não há avaliações

- CPM 1400 CP of Offshore StructuresDocumento34 páginasCPM 1400 CP of Offshore StructuresEmekaAinda não há avaliações

- Saes H 201Documento9 páginasSaes H 201heartbreakkid132Ainda não há avaliações

- STD 152Documento49 páginasSTD 152Mugesh KannaAinda não há avaliações

- Simops V3 I3 03 PDFDocumento5 páginasSimops V3 I3 03 PDFravikrssAinda não há avaliações

- AGT2012-Vessel Blowdown Systems - Assurance Framework For Operate PhaseDocumento17 páginasAGT2012-Vessel Blowdown Systems - Assurance Framework For Operate Phasearunperth0% (1)

- FPSODocumento29 páginasFPSOLee Teck WeiAinda não há avaliações

- Spe 76-031Documento9 páginasSpe 76-031manuneedhi0% (1)

- Colour Coding and Material Identification-000-GA-E-060090 - 00ADocumento6 páginasColour Coding and Material Identification-000-GA-E-060090 - 00Asalah abddayemAinda não há avaliações

- Saudi Aramco Typical Inspection PlanDocumento3 páginasSaudi Aramco Typical Inspection PlanOmer aliAinda não há avaliações

- Containment and Blasting ProcedureDocumento20 páginasContainment and Blasting ProcedureEzemeh NigeriaAinda não há avaliações

- Sabp A 011Documento27 páginasSabp A 011aamirtec301Ainda não há avaliações

- 32372010Documento32 páginas32372010harshkumar patel0% (1)

- Materials System SpecificationDocumento9 páginasMaterials System SpecificationHandri YantoAinda não há avaliações

- Saes Z 003Documento10 páginasSaes Z 003salic2013Ainda não há avaliações

- Nioec-Sp-00-50 Criteria For Process and MechanicsDocumento37 páginasNioec-Sp-00-50 Criteria For Process and MechanicsCalAinda não há avaliações

- Saep 125Documento9 páginasSaep 125Demac SaudAinda não há avaliações

- Sample Examination Manual (Shell)Documento113 páginasSample Examination Manual (Shell)Erick ArizaAinda não há avaliações

- Hydrocarbon Blanket Gas System: Guide ForDocumento13 páginasHydrocarbon Blanket Gas System: Guide ForhamedAinda não há avaliações

- SAES-A-014 Design of Hydrate Inhibition and Dehydration Systems PDFDocumento21 páginasSAES-A-014 Design of Hydrate Inhibition and Dehydration Systems PDFFlorante NoblezaAinda não há avaliações

- Saes A 010 PDFDocumento32 páginasSaes A 010 PDFcywaha100% (1)

- Saes B 055Documento33 páginasSaes B 055Tarek Mustafa100% (1)

- Saes A 010Documento32 páginasSaes A 010hyderabadAinda não há avaliações

- Sandline Flagging Operation Results in FatalityDocumento2 páginasSandline Flagging Operation Results in FatalityReda AL-mesbahAinda não há avaliações

- Laying Down A Joint of Casing Results in FallDocumento1 páginaLaying Down A Joint of Casing Results in FallReda AL-mesbahAinda não há avaliações

- 2007-10 Safety Alert Crane OperationDocumento1 página2007-10 Safety Alert Crane OperationReda AL-mesbahAinda não há avaliações

- SAEP-32 - Environmental Performance Assessment (EPA) ProgramDocumento15 páginasSAEP-32 - Environmental Performance Assessment (EPA) ProgramReda AL-mesbahAinda não há avaliações

- Checklist CEHA Rev01Documento14 páginasChecklist CEHA Rev01Reda AL-mesbahAinda não há avaliações

- API 650 10th Edition ErrataDocumento6 páginasAPI 650 10th Edition ErrataJosé Ramón GutierrezAinda não há avaliações

- Post Traumatic Stress DisorderDocumento2 páginasPost Traumatic Stress Disorderapi-188978784100% (1)

- Unit 9 Organic Law On Provincial and Local-Level Government (OLPLLG) - SlidesDocumento29 páginasUnit 9 Organic Law On Provincial and Local-Level Government (OLPLLG) - SlidesMark DemAinda não há avaliações

- This Unit Group Contains The Following Occupations Included On The 2012 Skilled Occupation List (SOL)Documento4 páginasThis Unit Group Contains The Following Occupations Included On The 2012 Skilled Occupation List (SOL)Abdul Rahim QhurramAinda não há avaliações

- Signage Method of Statement and Risk AssessmentDocumento3 páginasSignage Method of Statement and Risk AssessmentNajmal AmanAinda não há avaliações

- WT Chapter 5Documento34 páginasWT Chapter 5Wariyo GalgaloAinda não há avaliações

- Basic Electrical Engineering Mcqs Unit 1Documento13 páginasBasic Electrical Engineering Mcqs Unit 1shubha christopherAinda não há avaliações

- C 1 WorkbookDocumento101 páginasC 1 WorkbookGeraldineAinda não há avaliações

- E3sconf 2F20187307002Documento4 páginasE3sconf 2F20187307002Nguyễn Thành VinhAinda não há avaliações

- Mbs KatalogDocumento68 páginasMbs KatalogDobroslav SoskicAinda não há avaliações

- MelatoninaDocumento32 páginasMelatoninaCodrut GeorgescuAinda não há avaliações

- MSU-Iligan Institute of TechnologyDocumento5 páginasMSU-Iligan Institute of TechnologyYuvi Rociandel LUARDOAinda não há avaliações

- Revised List of Maharashtra HospitalsDocumento16 páginasRevised List of Maharashtra Hospitalsdummy data100% (1)

- ResearchDocumento13 páginasResearchCHOYSON RIVERALAinda não há avaliações

- Gintex DSDocumento1 páginaGintex DSRaihanulKabirAinda não há avaliações

- Readers Digest November 2021 PDF RD 2021 PDF EnglishDocumento172 páginasReaders Digest November 2021 PDF RD 2021 PDF EnglishIslam Gold100% (1)

- Monitoring AlkesDocumento41 páginasMonitoring AlkesEndangMiryaningAstutiAinda não há avaliações

- NSTP1 MODULE 3 Disaster Awareness Preparedness and ManagementDocumento16 páginasNSTP1 MODULE 3 Disaster Awareness Preparedness and Managementrenz dave100% (2)

- Final Manuscript GROUP2Documento102 páginasFinal Manuscript GROUP222102279Ainda não há avaliações

- Microbial Communities From Arid Environments On A Global Scale. A Systematic ReviewDocumento12 páginasMicrobial Communities From Arid Environments On A Global Scale. A Systematic ReviewAnnaAinda não há avaliações

- VOC & CO - EnglishDocumento50 páginasVOC & CO - EnglishAnandKumarPAinda não há avaliações

- Laws and Regulation Related To FoodDocumento33 páginasLaws and Regulation Related To FoodDr. Satish JangraAinda não há avaliações

- UM-1D User ManualDocumento30 páginasUM-1D User ManualAhmedBalaoutaAinda não há avaliações

- Ammonium Chloride: Product InformationDocumento2 páginasAmmonium Chloride: Product InformationusamaAinda não há avaliações

- Preservation and Collection of Biological EvidenceDocumento4 páginasPreservation and Collection of Biological EvidenceanastasiaAinda não há avaliações

- Ineffective Breastfeeding - NCPDocumento10 páginasIneffective Breastfeeding - NCPJullian PloyaAinda não há avaliações

- Afforestation Powerpoint For NandniDocumento9 páginasAfforestation Powerpoint For NandniFagun Sahni100% (1)

- Poster For Optimisation of The Conversion of Waste Cooking Oil Into BiodieselDocumento1 páginaPoster For Optimisation of The Conversion of Waste Cooking Oil Into BiodieselcxmzswAinda não há avaliações

- Kenwood Report FinalDocumento43 páginasKenwood Report Finaltooba siddiquiAinda não há avaliações

- Ground-Fault Protection - All You Need To KnowDocumento9 páginasGround-Fault Protection - All You Need To KnowCamila RubioAinda não há avaliações