Escolar Documentos

Profissional Documentos

Cultura Documentos

LDIP-IPM IM14400-E: Description

Enviado por

mehmeteee0 notas0% acharam este documento útil (0 voto)

94 visualizações0 páginaLDIP-IPM IM14400-E Description Cyntec IPM is integrated Drive, protection and system control functions that is designed for high performance 3-phase motor driver application. Features UL Certified No.E204652. Lower switching loss and higher short-circuit withstanding capability. Under-voltage lockout protection. 2500Vrms isolation rating. Lead-Free packaging and RoHS compatible.

Descrição original:

Título original

IM14400-E

Direitos autorais

© Attribution Non-Commercial (BY-NC)

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoLDIP-IPM IM14400-E Description Cyntec IPM is integrated Drive, protection and system control functions that is designed for high performance 3-phase motor driver application. Features UL Certified No.E204652. Lower switching loss and higher short-circuit withstanding capability. Under-voltage lockout protection. 2500Vrms isolation rating. Lead-Free packaging and RoHS compatible.

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

94 visualizações0 páginaLDIP-IPM IM14400-E: Description

Enviado por

mehmeteeeLDIP-IPM IM14400-E Description Cyntec IPM is integrated Drive, protection and system control functions that is designed for high performance 3-phase motor driver application. Features UL Certified No.E204652. Lower switching loss and higher short-circuit withstanding capability. Under-voltage lockout protection. 2500Vrms isolation rating. Lead-Free packaging and RoHS compatible.

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 0

PAGE 1 OF 14

TITLE: ENGINEERING SPEC. OF LDIP IPM 600V 30A

DOCUMENT

NO.

MM14400E09

PAGE

REV.

A1

UNLESS OTHERWISE SPECIFIED

TOLERQNCES ON

X =

X.X =

X.XX =

ANGLES HOLE DIA.

SCALE X UNIT X

APPROVED BY

DRAWN BY

DESIGNED BY

CHECKED BY

THIS DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF CYNTEC CO., LTD.

AND SHALL NOT BE REPRODUCED OR USED AS THE BASIS FOR THE

MANUFACTURE OR SALE OF APPARATUS OR DEVICES WITHOUT PERMISSION

CYNTEC CO., LTD.

LDIP-IPM IM14400-E

Description

Cyntec IPM is integrated Drive, protection and system

control functions that is designed for high performance 3-phase

motor driver application like:

Home appliances applications.

Inverter drive parts for AC/DC motor driving.

Features

UL Certified No.E204652.

Lower switching loss and higher short-circuit withstanding capability.

Under-voltage lockout protection.

Using copper as the heat-sink to withstand the power semiconductor to get the lower thermal

resistance.

Matched propagation delay for three arms to get balance switching performance.

Provided a fault signal (FO pin) and shut-off internal IGBT, when over current(OC)/short circuit(SC)

and under-voltage(UV) situation are occurred.

2500Vrms isolation rating.

Lead-Free packaging and RoHS compatible.

Figure 1. Package Outlines

PAGE 2 OF 14

TITLE: ENGINEERING SPEC. OF LDIP IPM 600V 30A

DOCUMENT

NO.

MM14400E09

PAGE

REV.

A1

UNLESS OTHERWISE SPECIFIED

TOLERQNCES ON

X =

X.X =

X.XX =

ANGLES HOLE DIA.

SCALE X UNIT X

APPROVED BY

DRAWN BY

DESIGNED BY

CHECKED BY

THIS DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF CYNTEC CO., LTD.

AND SHALL NOT BE REPRODUCED OR USED AS THE BASIS FOR THE

MANUFACTURE OR SALE OF APPARATUS OR DEVICES WITHOUT PERMISSION

CYNTEC CO., LTD.

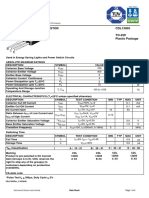

Table1: Pin Descriptions

No. Symbol Pin Description

1 HIN1 Signal Input Terminal for High-side U Phase

2 V

CC

Supply Voltage Terminal for Driver IC

3 V

B1

High -side Bias Voltage for U Phase IGBT Driving

4 V

S1

High -side Bias Voltage Ground for U Phase IGBT Driving

5 HIN2 Signal Input Terminal for High-side V Phase

6 V

CC

Supply Voltage Terminal for Driver IC

7 V

B2

High -side Bias Voltage for V Phase IGBT Driving

8 V

S2

High -side Bias Voltage Ground for V Phase IGBT Driving

9 HIN3 Signal Input Terminal for High-side W Phase

10 V

CC

Supply Voltage Terminal for Driver IC

11 GND

Signal Ground

12 V

B3

High -side Bias Voltage for W Phase IGBT Driving

13 V

S3

High -side Bias Voltage Ground for W Phase IGBT Driving

14 V

CC

Supply Voltage Terminal for Driver IC

15 GND Signal Ground

16 CIN Comparator Input

17 CFO Capacitor for Fault Output Duration Time Selection

18 FO Fault Output Terminal

19 LIN1 Signal Input Terminal for Low-side U Phase

20 LIN2 Signal Input Terminal for Low-side V Phase

21 LIN3 Signal Input Terminal for Low-side W Phase

22 P Positive DC-Bus Input Terminal

23 U Output Terminal for U Phase

24 V Output Terminal for V Phase

25 W Output Terminal for W Phase

26 N Negative DC-Bus Input Terminal

PAGE 3 OF 14

TITLE: ENGINEERING SPEC. OF LDIP IPM 600V 30A

DOCUMENT

NO.

MM14400E09

PAGE

REV.

A1

UNLESS OTHERWISE SPECIFIED

TOLERQNCES ON

X =

X.X =

X.XX =

ANGLES HOLE DIA.

SCALE X UNIT X

APPROVED BY

DRAWN BY

DESIGNED BY

CHECKED BY

THIS DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF CYNTEC CO., LTD.

AND SHALL NOT BE REPRODUCED OR USED AS THE BASIS FOR THE

MANUFACTURE OR SALE OF APPARATUS OR DEVICES WITHOUT PERMISSION

CYNTEC CO., LTD.

LDIP-IPM Internal Block Diagram

Figure. 2 LDIP-IPM Internal Block Diagram

PAGE 4 OF 14

TITLE: ENGINEERING SPEC. OF LDIP IPM 600V 30A

DOCUMENT

NO.

MM14400E09

PAGE

REV.

A1

UNLESS OTHERWISE SPECIFIED

TOLERQNCES ON

X =

X.X =

X.XX =

ANGLES HOLE DIA.

SCALE X UNIT X

APPROVED BY

DRAWN BY

DESIGNED BY

CHECKED BY

THIS DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF CYNTEC CO., LTD.

AND SHALL NOT BE REPRODUCED OR USED AS THE BASIS FOR THE

MANUFACTURE OR SALE OF APPARATUS OR DEVICES WITHOUT PERMISSION

CYNTEC CO., LTD.

MAXIMUM RATINGS (T

j

= 25)

INVERTER PART

Item Symbol Min. Max. Unit

Between collector to emitter voltage V

CES

- 600 V

Supply voltage P-N V

PN

- 450 V

Supply voltage (surge) P-N V

PN (surge)

- 500 V

Each IGBT collector current I

C

( Tc = 25 ) - 30 A

Each IGBT collector current (peak) I

CP

( Tc = 25 , pulse ) - 60 A

Collector dissipation P

C

(Tc = 25, per one chip) - 80 W

Junction temperature Tj (Note 1) -20 +125

Note 1 The maximum junction temperature rating of the power chip integrated within the IPM is 150C (@ Tc 100C). However, It

would be recommended that the average junction temperature should be limited to Tj 125C (@ Tc 100C) in order to

guarantee safe operation.

CONTROL PART

Item Symbol Min. Max. Unit

Driver IC supply voltage V

CC

-0.3 20 V

P- side floating supply voltage V

B1S1,B2S2,B3S3

-0.3 20 V

Current sensing input voltage V

CIN

-0.3 Vcc+0.3 V

Logic input voltage

HIN1,HIN2,HIN3,

LIN1,LIN2,LIN3

-0.3 5.5 V

Fault output voltage V

FO

-0.3 Vcc+0.3 V

Fault output current I

FO

- 10 mA

TOTAL SYSTEM

Item Symbol Min. Max. Unit

Module case operating temperature T

C

(Note 2) -20 +100

Storage temperature T

stg

-40 +125

Isolation voltage (60Hz Sinusoidal, AC 1 min.,

pins to heat-sink plate)

V

iso

- 2500 Vrms

Note 2 : Tc Measurement Point.

Figure.3 Tc measurement point

Heat sink

Tc

Control Terminals

Power Terminals

Tc

Heat sink boundary

PAGE 5 OF 14

TITLE: ENGINEERING SPEC. OF LDIP IPM 600V 30A

DOCUMENT

NO.

MM14400E09

PAGE

REV.

A1

UNLESS OTHERWISE SPECIFIED

TOLERQNCES ON

X =

X.X =

X.XX =

ANGLES HOLE DIA.

SCALE X UNIT X

APPROVED BY

DRAWN BY

DESIGNED BY

CHECKED BY

THIS DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF CYNTEC CO., LTD.

AND SHALL NOT BE REPRODUCED OR USED AS THE BASIS FOR THE

MANUFACTURE OR SALE OF APPARATUS OR DEVICES WITHOUT PERMISSION

CYNTEC CO., LTD.

ELECTRICAL CHARACTERISTICS (T

j

= 25)

INVERTER PART

Item Symbol Condition Min. Typ. Max. Unit

Collector-emitter saturation

voltage

V

CE (sat)

V

CC

=V

B1S1,B2S2,B3S3

=15V,

I

C

=30A, V

CIN

= 0V, T

j

=25

- 2.00 2.60 V

FWD forward voltage drop V

F

T

j

=25, - I

C

= 30A,V

CIN

=5V - 1.90 2.50 V

T

on

- 0.75 1.10

T

r

- 0.20 0.22

T

off

- 1.10 1.40

Switching times

T

f

V

D

=300V,

V

CC

=V

B1S1,B2S2,B3S3

=15V,

I

C

=30A,T

j

=25,

V

HIN

=5V<> 0V,

V

CIN

= 0V, inductive Load - 0.07 0.30

s

Collector-emitter cut-off current I

CES

V

CE

=V

CES

- - 0.09 mA

Figure.4 Switching time define

Ic X

HIN X ( LIN X)

10% 10% 10%

90%

90%

90%

Ton Toff

Td(on) Td(off)

Tr Tf

X:1~3

PAGE 6 OF 14

TITLE: ENGINEERING SPEC. OF LDIP IPM 600V 30A

DOCUMENT

NO.

MM14400E09

PAGE

REV.

A1

UNLESS OTHERWISE SPECIFIED

TOLERQNCES ON

X =

X.X =

X.XX =

ANGLES HOLE DIA.

SCALE X UNIT X

APPROVED BY

DRAWN BY

DESIGNED BY

CHECKED BY

THIS DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF CYNTEC CO., LTD.

AND SHALL NOT BE REPRODUCED OR USED AS THE BASIS FOR THE

MANUFACTURE OR SALE OF APPARATUS OR DEVICES WITHOUT PERMISSION

CYNTEC CO., LTD.

CONTROL PART (T

j

= 25)

Note 3 : FO output is open collector type, so this signal line should be pulled up to the +5V power supply with approximately 5.1K.

Note 4 : C

FO

need to adjust if output can not fit 1.8 ms demand.

Note 5 : For high side PWM, HIN pulse width must be 1sec. See fig.5.

Figure.5 Input filter function

THERMAL RESISTANCE

Item Symbol Condition Min. Typ. Max. Unit

HIN1,2,3 , LIN1,2,3 ON

threshold voltage

V

th(on)

1.4 1.7 2.0 V

HIN1,2,3 , LIN1,2,3 OFF

threshold voltage

V

th(off)

2.2 2.5 2.8 V

I

HIN(HI)

V

HIN1,2,3

= 5V - - 220

HIN1,2,3 input current

I

HIN(LO)

V

HIN1,2,3

= 0V - - 300

A

I

LIN(HI)

V

LIN1,2,3

= 5V - - 220

LIN1,2,3 input current

I

LIN(LO)

V

LIN1,2,3

= 0V - - 300

A

Driver IC supply voltage V

CC

13.5 15.0 16.5 V

P- side floating supply voltage V

B1S1,B2S2,B3S3

13.5 15.0 16.5 V

V

CC

terminal input current I

C

- - 2.3 mA

V

FOH

V

CIN

=0V (Note 3) 4.9 - - V

Fault output voltage

V

FOL

V

CIN

=1V (Note 3) - - 200 mV

Short circuit trip level

V

SC(ref)

V

CC

=15V, T

j

= 25 0.37 0.46 0.55 V

Fault output pulse width t

FO

C

F O

=22nF ~ 33nF (Note 4) 1.0 1.8 - ms

UVT

VCC

Trip level 10.4 10.9 11.4 V

UVR

VCC

Reset level 10.6 11.1 11.6 V

Supply circuit under voltage

protection

UVH Hysteresis - 0.2 - V

HIN,LIN Input filter time t

IN,FIL

VIN = 0 & 5 V (Note 5) 100 200 - ns

Item Symbol Condition Min. Typ. Max. Unit

R

th(j-c)Q

IGBT part (1/6) - - 1.24 Junction to case thermal

resistance R

th(j-c)F

FWD part (1/6) - - 1.47

Case to fin thermal

resistance

R

th(c-f) Case to W pin - - 0.03

/W

HIN HIN HIN HIN/ // /LIN LIN LIN LIN

HO HO HO HO/ // /LO LO LO LO

High High High High

ON ON ON ON OFF OFF OFF OFF ON ON ON ON ON ON ON ON OFF OFF OFF OFF OFF OFF OFF OFF

Low Low Low Low

t tt tIN IN IN IN, ,, ,FIL FIL FIL FIL t tt tIN IN IN IN, ,, ,FIL FIL FIL FIL

PAGE 7 OF 14

TITLE: ENGINEERING SPEC. OF LDIP IPM 600V 30A

DOCUMENT

NO.

MM14400E09

PAGE

REV.

A1

UNLESS OTHERWISE SPECIFIED

TOLERQNCES ON

X =

X.X =

X.XX =

ANGLES HOLE DIA.

SCALE X UNIT X

APPROVED BY

DRAWN BY

DESIGNED BY

CHECKED BY

THIS DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF CYNTEC CO., LTD.

AND SHALL NOT BE REPRODUCED OR USED AS THE BASIS FOR THE

MANUFACTURE OR SALE OF APPARATUS OR DEVICES WITHOUT PERMISSION

CYNTEC CO., LTD.

RECOMMENDED OPERATION CONDITIONS

Note 6 : To prevent high and low side IGBT occurred shoot-through

MECHANICAL CHARACTERISTICS AND RATINGS

Item Condition Min. Typ. Max. Unit

Mounting torque Mounting screw : M4 0.98 1.18 1.37 N-m

Weight -- - 75 - g

Heat-sink flatness (Note 7) -100 - 50 m

Note 7 : Measurement location of copper heat-sink flatness

Figure.6 Measurement location of heat-sink flatness

Item Symbol Condition Min. Typ. Max. Unit

DC

_

Link Supply voltage V

D

Applied between P-N 0 300 400 V

Control supply voltage V

CC

Applied between V

CC

- GND

13.5 15.0 16.5 V

Control supply voltage V

B1S1,B2S2,B3S3

Applied between V

B1,2,3

V

S1,2,3

13.5 15.0 16.5 V

Input ON threshold voltage V

CIN(ON)

0 ~ 0.65 V

Input OFF threshold voltage V

CIN(OFF)

Applied between HIN1,2,3 - GND

and LIN1,2,3 - GND

4.0 ~ 5.5 V

Supply voltage ripple V

D

, V

DB

-1 - 1 V/s

Arm shoot-through blocking

time

t

dead

(Note 6) 3 - - s

PWM Input frequency f

PWM

T

C

100, T

j

125 15 - kHz

Place to contact a heat sink

Heat sink

Heat sink

DIP-IPM

Measurement Location

PAGE 8 OF 14

TITLE: ENGINEERING SPEC. OF LDIP IPM 600V 30A

DOCUMENT

NO.

MM14400E09

PAGE

REV.

A1

UNLESS OTHERWISE SPECIFIED

TOLERQNCES ON

X =

X.X =

X.XX =

ANGLES HOLE DIA.

SCALE X UNIT X

APPROVED BY

DRAWN BY

DESIGNED BY

CHECKED BY

THIS DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF CYNTEC CO., LTD.

AND SHALL NOT BE REPRODUCED OR USED AS THE BASIS FOR THE

MANUFACTURE OR SALE OF APPARATUS OR DEVICES WITHOUT PERMISSION

CYNTEC CO., LTD.

Input/Output Timing Diagram

Figure.7 Input/Output Timing Diagram

Note 8The shaded area indicates that both high-side and low-side switches are off and therefore the half-bridge

output voltage would be determined by the direction of current flow in the load.

CIN Hin1,2,3 Lin1,2,3 U,V,W

0 0 1 DC Bus

0 1 0 0

0 1 1 0

Figure.8 Input/Output signal circuit

HIN 1,2,3

LIN 1,2,3

CIN

Fo

Ho 1,2,3

Lo 1,2,3

PAGE 9 OF 14

TITLE: ENGINEERING SPEC. OF LDIP IPM 600V 30A

DOCUMENT

NO.

MM14400E09

PAGE

REV.

A1

UNLESS OTHERWISE SPECIFIED

TOLERQNCES ON

X =

X.X =

X.XX =

ANGLES HOLE DIA.

SCALE X UNIT X

APPROVED BY

DRAWN BY

DESIGNED BY

CHECKED BY

THIS DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF CYNTEC CO., LTD.

AND SHALL NOT BE REPRODUCED OR USED AS THE BASIS FOR THE

MANUFACTURE OR SALE OF APPARATUS OR DEVICES WITHOUT PERMISSION

CYNTEC CO., LTD.

LDIP-IPM Short-Circuit Protection Function

S1. Normal operation : IGBT ON and carrying current.

S2. Short circuit current detection (SC trigger).

S3. IGBT gate interrupt and FO signal starts.

S4. IGBT turns OFF.

S5. IGBT OFF state.

S6. FO signal reset.

S7. Normal operation.

Figure.9 Timing Chart of SC Operation

Input Signal

Shunt R Voltage

Fault output FO

S1

S2

S3

S6

S5

S7

S3

IGBT Gate Signal

Output current Ic

S4

RC Time Constant Delay

SC Trigger Level

PAGE 10 OF 14

TITLE: ENGINEERING SPEC. OF LDIP IPM 600V 30A

DOCUMENT

NO.

MM14400E09

PAGE

REV.

A1

UNLESS OTHERWISE SPECIFIED

TOLERQNCES ON

X =

X.X =

X.XX =

ANGLES HOLE DIA.

SCALE X UNIT X

APPROVED BY

DRAWN BY

DESIGNED BY

CHECKED BY

THIS DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF CYNTEC CO., LTD.

AND SHALL NOT BE REPRODUCED OR USED AS THE BASIS FOR THE

MANUFACTURE OR SALE OF APPARATUS OR DEVICES WITHOUT PERMISSION

CYNTEC CO., LTD.

LDIP-IPM Under-Voltage Protection Function

S1. Normal operation : IGBT ON and carrying current.

S2. Under-Voltage detection.

S3. IGBT gate interrupt.

S4. IGBT OFF state.

S5. Under-Voltage reset.

S6. Normal operation.

Figure.10 Timing Chart of Under-Voltage Operation

Recommended CPU I/O interface Circuit

Figure.11 I/O interface Circuit

Note 9Depending on the wiring impedances and the PWM control circuit of the applications PCB,

the RC coupling at each input may be changed.

Protection circuit state

Input Signal

Driver IC supply V

Output current Ic(A)

Fault output FO

SET

RESET

UVRV

S1

S2

S3

S4

S5

S6

UVTV

CC

CC

CC

IGBT Gate Signal

CPU

LDIP-IPM

HIN1,HIN2,HIN3

LIN1,LIN2,LIN3

FO

GND

5V

5.1k

680~

4.7K

PAGE 11 OF 14

TITLE: ENGINEERING SPEC. OF LDIP IPM 600V 30A

DOCUMENT

NO.

MM14400E09

PAGE

REV.

A1

UNLESS OTHERWISE SPECIFIED

TOLERQNCES ON

X =

X.X =

X.XX =

ANGLES HOLE DIA.

SCALE X UNIT X

APPROVED BY

DRAWN BY

DESIGNED BY

CHECKED BY

THIS DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF CYNTEC CO., LTD.

AND SHALL NOT BE REPRODUCED OR USED AS THE BASIS FOR THE

MANUFACTURE OR SALE OF APPARATUS OR DEVICES WITHOUT PERMISSION

CYNTEC CO., LTD.

Recommended circuit example when using a photo coupler

Vcc

GND

HIN/ LIN

N

P

IPM

15V

5V

Vmcu

MCU

(a) IPM input pin (high-side 3-phase and low-side 3-phase)

(b) Fault output pin

Figure.12 I/O interface Circuit when using photo coupler

PAGE 12 OF 14

TITLE: ENGINEERING SPEC. OF LDIP IPM 600V 30A

DOCUMENT

NO.

MM14400E09

PAGE

REV.

A1

UNLESS OTHERWISE SPECIFIED

TOLERQNCES ON

X =

X.X =

X.XX =

ANGLES HOLE DIA.

SCALE X UNIT X

APPROVED BY

DRAWN BY

DESIGNED BY

CHECKED BY

THIS DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF CYNTEC CO., LTD.

AND SHALL NOT BE REPRODUCED OR USED AS THE BASIS FOR THE

MANUFACTURE OR SALE OF APPARATUS OR DEVICES WITHOUT PERMISSION

CYNTEC CO., LTD.

Direct Input (without Photo-Coupler) Interface Example

Figure.13 Typical Application Circuit Interface Example with Direct Input

Component selection :

1. R1 : 5.1K ( FO output is open collector type. It is necessary to apply a resistor. )

2. R2 : 680

3. R3 : 2.4~20 ( It could be adjusted depending on the PWM frequency and negative voltage level on phase node. )

4. R4 : 100 ( Recommended the time constant R4xC4 is 2S. )

5. C1 : 100 ~ 1000pF ( Ceramic )

6. C2 : 10 ~ 100F ( Electrolytic, low impendence )

7. C3 : 22nF ( Ceramic )

8. C4 : 0.02F ( Ceramic )

9. C5 : 0.22 ~ 2F ( Ceramic )

10. D1 : 600V/1A ( Ultra-Fast recovery diode )

11. ZD : 24V/1W Zener diode ( It is recommended to insert a Zener diode to prevent surge destruction)

MOTOR

M

C

U

IPM

+5V

+15V

U

V

W

C2

C2

C2 C5

C5

C5

ZD

ZD

ZD

ZD

Shunt

Resistor

C3

C4

R4

R3

R3

R3

D1

D1

D1

VS1

VB1

VS2

VB2

VS3

VB3

HIN1

HIN2

HIN3

LIN1

LIN2

LIN3

VCC

GND

CFO CIN

N

FO

4

3

8

7

13

12

1

5

9

18

19

20

21

11

17 16

26

25

24

23

22 P

15 GND

VCC

VCC

VCC

2

10

6

14

R2 R2 R2 R2 R2 R2

R1

C1 C1 C1 C1 C1 C1

PAGE 13 OF 14

TITLE: ENGINEERING SPEC. OF LDIP IPM 600V 30A

DOCUMENT

NO.

MM14400E09

PAGE

REV.

A1

UNLESS OTHERWISE SPECIFIED

TOLERQNCES ON

X =

X.X =

X.XX =

ANGLES HOLE DIA.

SCALE X UNIT X

APPROVED BY

DRAWN BY

DESIGNED BY

CHECKED BY

THIS DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF CYNTEC CO., LTD.

AND SHALL NOT BE REPRODUCED OR USED AS THE BASIS FOR THE

MANUFACTURE OR SALE OF APPARATUS OR DEVICES WITHOUT PERMISSION

CYNTEC CO., LTD.

Interface Example when a Photo-Coupler is used

Figure.14 Typical Application Circuit Interface Example with Opto-Coupler

Component selection :

1. R1 : 4.7K

2. R2 : 150

3. R3 : 2.4~20 ( It could be adjusted depending on the PWM frequency and negative voltage level on phase node. )

4. R4 : 100 ( Recommended the time constant R4xC4 is 2S. )

5. R5 : 1K

6. R6 : 1K

7. R7 : 1K

8. C1 : 0.1F

9. C2 : 10 ~ 100F ( Electrolytic, low impendence )

10. C3 : 22nF ( Ceramic )

11. C4 : 0.02F ( Ceramic )

12. C5 : 0.22 ~ 2F ( Ceramic )

13. C6 : 0.1F

14. D1 : 600V/1A ( Ultra-Fast recovery diode )

15. Q1 : NPN transistor 2N3904

16. U1 : Photo coupler TLP521

17.ZD : 24V/1W Zener diode ( It is recommended to insert a Zener diode to prevent surge destruction)

MOTOR

M

C

U

IPM

+5V

+15V

U

V

W

C2

C2

C2 C5

C5

C5

C1

C1

C6

C1

C1

C1

C1

ZD

ZD

ZD

ZD

Shunt

Resistor

C3

C4

R4

R3

R3

R3

D1

D1

D1

R1

R1

R1

R1

R1

R1

R2

R2

R2

R2

R2

R2

R5

R5

R5

R5

R5

R5

Q1

Q1

Q1

Q1

Q1

Q1

U1

U1

U1

U1

U1

U1

U1

VS1

VB1

VS2

VB2

VS3

VB3

HIN1

HIN2

HIN3

LIN1

LIN2

LIN3

VCC

GND

CFO CIN

N

FO

4

3

8

7

13

12

1

5

9

18

19

20

21

11

17 16

26

25

24

23

22 P

15 NO

R6

VCC

VCC

2

10

6

14

VCC

PAGE 14 OF 14

TITLE: ENGINEERING SPEC. OF LDIP IPM 600V 30A

DOCUMENT

NO.

MM14400E09

PAGE

REV.

A1

UNLESS OTHERWISE SPECIFIED

TOLERQNCES ON

X =

X.X =

X.XX =

ANGLES HOLE DIA.

SCALE X UNIT X

APPROVED BY

DRAWN BY

DESIGNED BY

CHECKED BY

THIS DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF CYNTEC CO., LTD.

AND SHALL NOT BE REPRODUCED OR USED AS THE BASIS FOR THE

MANUFACTURE OR SALE OF APPARATUS OR DEVICES WITHOUT PERMISSION

CYNTEC CO., LTD.

Precautions on Electrostatic Electricity

(1) Operators must wear anti-static clothing and conductive shoes (or a leg or heel strap).

(2) Operators must wear a wrist strap grounded to earth via a resistor of about 1 M.

(3) Soldering irons must be grounded from iron tip to earth, and must be used only at low voltages.

(4) If the tweezers you use are likely to touch the device terminals, use anti-static tweezers and in particular avoid metallic tweezers. If a

charged device touches a low-resistance tool, rapid discharge can occur. When using vacuum tweezers, attach a conductive chucking

pat to the tip, and connect it to a dedicated ground used especially for anti-static purposes (suggested resistance value: 10

4

to 10

8

).

(5) Do not place devices or their containers near sources of strong electrical fields (such as above a CRT).

(6) When storing printed circuit boards which have devices mounted on them, use a board container or bag thats protected against static

charge. To avoid the occurrence of static charge or discharge due to friction, keep the boards separate from one other and do not stack

them directly on top of one another.

(7) Ensure, if possible, that any articles (such as clipboards) which are brought to any location where the level of static electricity must be

closely controlled are constructed of anti-static materials.

(8) In cases where the human body comes into direct contact with a device, be sure to wear anti-static finger covers or gloves (suggested

resistance value: 10

8

or less).

(9) Equipment safety covers installed near devices should have resistance ratings of 10

9

or less.

(10) If a wrist strap cannot be used for some reason, and there is a possibility of imparting friction to devices, use an ionizer.

Você também pode gostar

- 4 V Current Transducer HAT 200 ... 1500-SDocumento3 páginas4 V Current Transducer HAT 200 ... 1500-SBharaneeAinda não há avaliações

- Datasheet A1941 Y C5198Documento3 páginasDatasheet A1941 Y C5198Samuel RivasAinda não há avaliações

- Red670 AcceptanceDocumento12 páginasRed670 AcceptancewazakifyAinda não há avaliações

- Isc 2SC1969: Silicon NPN RF Power TransistorDocumento2 páginasIsc 2SC1969: Silicon NPN RF Power TransistorAlessandroAinda não há avaliações

- PS21245 eDocumento9 páginasPS21245 eTol SirtAinda não há avaliações

- VHF Band Power Amplifier Applications: Maximum RatingsDocumento4 páginasVHF Band Power Amplifier Applications: Maximum RatingsWiro WirawanAinda não há avaliações

- Hax 500 2500-sDocumento3 páginasHax 500 2500-sMohammad AsadiAinda não há avaliações

- La 42205Documento7 páginasLa 42205ban4444Ainda não há avaliações

- Auips 7111 SDocumento15 páginasAuips 7111 SPham LongAinda não há avaliações

- Multi Demul 4053Documento7 páginasMulti Demul 4053Edward RinconAinda não há avaliações

- Allegro ACS 709Documento17 páginasAllegro ACS 709David ZammitAinda não há avaliações

- 78RXXDocumento12 páginas78RXXMuhammad MiftachurrohmanAinda não há avaliações

- ACS 140 User GuideDocumento85 páginasACS 140 User GuidefathazamAinda não há avaliações

- 2N3055A (NPN), MJ15015 (NPN), MJ15016 (PNP) Complementary Silicon High Power TransistorsDocumento6 páginas2N3055A (NPN), MJ15015 (NPN), MJ15016 (PNP) Complementary Silicon High Power Transistorsklaus allowsAinda não há avaliações

- sc7001q Ay 961Documento18 páginassc7001q Ay 961r2c1Ainda não há avaliações

- 500 Ma Output LDO Regulator With Voltage Detector: DatasheetDocumento24 páginas500 Ma Output LDO Regulator With Voltage Detector: Datasheetsamsularief03Ainda não há avaliações

- Tda 7379 Data SheetDocumento7 páginasTda 7379 Data SheetJCMAinda não há avaliações

- ADP3338 Data SheetsDocumento16 páginasADP3338 Data SheetstarpinoAinda não há avaliações

- T A7272pDocumento12 páginasT A7272paaaxxxcccsssAinda não há avaliações

- Combivert ManualDocumento20 páginasCombivert Manualfabianespinozag100% (2)

- Everlight Electronics Co., LTD.: 5mm PhototransistorDocumento7 páginasEverlight Electronics Co., LTD.: 5mm PhototransistorFrancisco Javier González HernándezAinda não há avaliações

- Smart High-Side Power Switch Four Channels: 4 X 90m Status FeedbackDocumento14 páginasSmart High-Side Power Switch Four Channels: 4 X 90m Status FeedbackSeyed Amir Ali MousavianAinda não há avaliações

- 2SC3357Documento3 páginas2SC3357Anonymous oyUAtpKAinda não há avaliações

- AN17850A - Silicon Monolithic Bipolar IC - List of Unclassifed ManufacturersDocumento17 páginasAN17850A - Silicon Monolithic Bipolar IC - List of Unclassifed Manufacturersfernandog251186Ainda não há avaliações

- TDA2003 BridgeDocumento10 páginasTDA2003 BridgeMartinaxMgmAinda não há avaliações

- Data SheetDocumento9 páginasData Sheetmauri_melcerAinda não há avaliações

- Igbt - 2sp0115t2a0-Cm600dx-24t-1093489Documento9 páginasIgbt - 2sp0115t2a0-Cm600dx-24t-1093489Hector Zenteno RodriguezAinda não há avaliações

- IRAMX16UP60ADocumento18 páginasIRAMX16UP60Atheylor1990Ainda não há avaliações

- Mitsubishi Semiconductor Mitsubishi SemiconductorDocumento8 páginasMitsubishi Semiconductor Mitsubishi Semiconductoramired2Ainda não há avaliações

- Datasheet l9930Documento12 páginasDatasheet l9930ramisesnery9185Ainda não há avaliações

- Semikron Datasheet Board 1 Skyper 32 R l6100131Documento7 páginasSemikron Datasheet Board 1 Skyper 32 R l6100131machadofelipe88Ainda não há avaliações

- AZ324Documento10 páginasAZ324Franklim Miranda Dos SantosAinda não há avaliações

- Unisonic Technologies Co., LTD: Medium Power Low Voltage TransistorDocumento5 páginasUnisonic Technologies Co., LTD: Medium Power Low Voltage Transistormj15015Ainda não há avaliações

- 4-Channel Secondary Monitoring IC with OCP and OTPDocumento11 páginas4-Channel Secondary Monitoring IC with OCP and OTPseyyedali2006Ainda não há avaliações

- H209 01 PolaroidDocumento7 páginasH209 01 PolaroidmaurilioctbaAinda não há avaliações

- m28sDocumento2 páginasm28sCarlos J. Suárez P.Ainda não há avaliações

- LV47002PDocumento9 páginasLV47002PchichedemorenoAinda não há avaliações

- TA7262PDocumento10 páginasTA7262Phalcon2Ainda não há avaliações

- Data Sheet: 2 X 6 W Stereo Car Radio Power AmplifierDocumento10 páginasData Sheet: 2 X 6 W Stereo Car Radio Power Amplifierazzeddine_a7601Ainda não há avaliações

- Isc N-Channel Mosfet Transistor Irf540Npbf: FeaturesDocumento2 páginasIsc N-Channel Mosfet Transistor Irf540Npbf: FeaturesCarlos Manuel PeraltaAinda não há avaliações

- Operational Amplifier OP470Documento17 páginasOperational Amplifier OP470gotcha75100% (1)

- WCS1800 PDFDocumento5 páginasWCS1800 PDFAbhii BharadwajAinda não há avaliações

- 20 W 2-Channel BTL AF Power Amplifier For Car Stereos: SANYO Electric Co.,Ltd. Semiconductor Bussiness HeadquartersDocumento9 páginas20 W 2-Channel BTL AF Power Amplifier For Car Stereos: SANYO Electric Co.,Ltd. Semiconductor Bussiness Headquartersfernandes66Ainda não há avaliações

- Datasheet PDFDocumento7 páginasDatasheet PDFpurwadiAinda não há avaliações

- Ad52060 EsmtDocumento23 páginasAd52060 EsmtRoel GloriosoAinda não há avaliações

- Data Sheet TDA 7377Documento8 páginasData Sheet TDA 7377Carlos MorenoAinda não há avaliações

- Unisonic Technologies Co., LTD: Audio Power AmplifierDocumento3 páginasUnisonic Technologies Co., LTD: Audio Power Amplifiermelect60Ainda não há avaliações

- Mje 3055 TDocumento4 páginasMje 3055 Trodrigo dias martinsAinda não há avaliações

- UH277Documento5 páginasUH277Saul D'MishAinda não há avaliações

- 5W 2-Channel AF Power Amplifier With DC Volume ControlDocumento9 páginas5W 2-Channel AF Power Amplifier With DC Volume ControlMiloud ChouguiAinda não há avaliações

- Ps 21 A 79Documento10 páginasPs 21 A 79Omar LeonAinda não há avaliações

- Dual Output Voltage Regulator With Power Saving: BA44W12SATDocumento10 páginasDual Output Voltage Regulator With Power Saving: BA44W12SATBeatris Medellin MendozaAinda não há avaliações

- STK621-033N-E: Inverter Hybrid ICDocumento8 páginasSTK621-033N-E: Inverter Hybrid ICCézar AngelitonAinda não há avaliações

- CYT3000B SpecificationDocumento10 páginasCYT3000B SpecificationTechnical sidhuAinda não há avaliações

- ITR8307-S17-TR8Documento10 páginasITR8307-S17-TR8cointoinAinda não há avaliações

- CDL13005 NPN Plastic Power Transistor Data SheetDocumento4 páginasCDL13005 NPN Plastic Power Transistor Data SheetoscarAinda não há avaliações

- Audio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsNo EverandAudio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsAinda não há avaliações

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsAinda não há avaliações

- Vibration of Oil-Immersed ReactorsDocumento8 páginasVibration of Oil-Immersed ReactorsmehmeteeeAinda não há avaliações

- Description of The Product: SAP P/N: NTCS0805E3103GMTDocumento6 páginasDescription of The Product: SAP P/N: NTCS0805E3103GMTmehmeteeeAinda não há avaliações

- Problem Set 1Documento3 páginasProblem Set 1mehmeteeeAinda não há avaliações

- Dynamic Response of DFIG Wind TurbinesDocumento7 páginasDynamic Response of DFIG Wind TurbinesmehmeteeeAinda não há avaliações

- Acs800 Pump CTRL Appl PRG Fwmanual Rev D Commenting EnabledDocumento244 páginasAcs800 Pump CTRL Appl PRG Fwmanual Rev D Commenting Enabledmehmeteee100% (1)

- En Fsca-01-Hw A ScreenDocumento24 páginasEn Fsca-01-Hw A ScreenmehmeteeeAinda não há avaliações

- New Design For Sensorless BLDC MotorDocumento4 páginasNew Design For Sensorless BLDC MotormehmeteeeAinda não há avaliações

- A Novel Traction Control Without Chassis Velocity ForDocumento7 páginasA Novel Traction Control Without Chassis Velocity FormehmeteeeAinda não há avaliações

- Design and Control of The Induction MotorDocumento6 páginasDesign and Control of The Induction MotormehmeteeeAinda não há avaliações

- Selection of Electric Motor For EVDocumento6 páginasSelection of Electric Motor For EVaerobeetleAinda não há avaliações

- Wevj3 6680712Documento7 páginasWevj3 6680712Pratik SarkarAinda não há avaliações

- Control of EvDocumento20 páginasControl of EvmehmeteeeAinda não há avaliações

- LCM 150Documento3 páginasLCM 150mehmeteeeAinda não há avaliações

- Brigham Joffs Electric Vehicle Conversion DesignDocumento21 páginasBrigham Joffs Electric Vehicle Conversion DesignVenkatesh Subramanya0% (1)

- CB15 155 Operating Instruction 76Documento32 páginasCB15 155 Operating Instruction 76mehmeteeeAinda não há avaliações

- A Collaborative Augmented Reality Based Modeling EnvironmentDocumento9 páginasA Collaborative Augmented Reality Based Modeling EnvironmentmehmeteeeAinda não há avaliações

- RC3216F Series52Documento2 páginasRC3216F Series52mehmeteeeAinda não há avaliações

- Ed Pcim01 EconomacDocumento6 páginasEd Pcim01 EconomacmehmeteeeAinda não há avaliações

- M Array Manipulation Tips and Tricks: AtlabDocumento31 páginasM Array Manipulation Tips and Tricks: AtlabberkAinda não há avaliações

- Food Salt: By: Saad, Rehan, Asad, Hasan, Adil, Abdur Rehman, AzharDocumento10 páginasFood Salt: By: Saad, Rehan, Asad, Hasan, Adil, Abdur Rehman, AzharsaadAinda não há avaliações

- Comparative Analysis of Mineral Constituents of Ethanol Leaf and SeedDocumento9 páginasComparative Analysis of Mineral Constituents of Ethanol Leaf and SeedKIU PUBLICATION AND EXTENSIONAinda não há avaliações

- Chapter-14 - Person and CareersDocumento69 páginasChapter-14 - Person and CareersMarlon SagunAinda não há avaliações

- Integrated Management of Childhood IllnessDocumento8 páginasIntegrated Management of Childhood IllnessSehar162Ainda não há avaliações

- NCL ReportDocumento20 páginasNCL ReportSwati Tripathi33% (3)

- Firemac FM Fire Ducts Provide Fire Resistant VentilationDocumento12 páginasFiremac FM Fire Ducts Provide Fire Resistant Ventilationsiva8784Ainda não há avaliações

- Trilead bis(carbonate) dihydroxide identified as SVHC due to reproductive toxicityDocumento7 páginasTrilead bis(carbonate) dihydroxide identified as SVHC due to reproductive toxicityCekinAinda não há avaliações

- Music Genre AnalysisDocumento5 páginasMusic Genre AnalysisPeh Xin YingAinda não há avaliações

- TST-13 Aircraft Manual With 503 Engine LSA Rev.1Documento52 páginasTST-13 Aircraft Manual With 503 Engine LSA Rev.1smeassick100% (1)

- CAPE Biology 2006 U2 P1 PDFDocumento28 páginasCAPE Biology 2006 U2 P1 PDFvedant seerattanAinda não há avaliações

- Inu 2216 Idt - Question PaperDocumento5 páginasInu 2216 Idt - Question PaperVinil JainAinda não há avaliações

- (UNISIM (BEHAS) - Introduction To Aerospace) EAS105 - Lab4Documento33 páginas(UNISIM (BEHAS) - Introduction To Aerospace) EAS105 - Lab4Mohd Ashraf Mohd IsmailAinda não há avaliações

- QCVN 162019BXD National Technical Regulation On Products, Goods of Building Materials (Eng)Documento41 páginasQCVN 162019BXD National Technical Regulation On Products, Goods of Building Materials (Eng)lwin_oo2435Ainda não há avaliações

- Original Instruction Manual: Hypro Series 9303Documento24 páginasOriginal Instruction Manual: Hypro Series 9303vandoAinda não há avaliações

- Environmental Clearance CertificateDocumento4 páginasEnvironmental Clearance CertificateAra Jane T. PiniliAinda não há avaliações

- We Get Results!: Spring FlingDocumento35 páginasWe Get Results!: Spring FlingThe WorldAinda não há avaliações

- HemophiliaDocumento62 páginasHemophiliamuhirwa Samuel100% (1)

- Low Back Pain Anatomy of Thoracolumbar SpineDocumento10 páginasLow Back Pain Anatomy of Thoracolumbar SpineMAinda não há avaliações

- Cape Vincent Area Events January 2019Documento5 páginasCape Vincent Area Events January 2019NewzjunkyAinda não há avaliações

- 02-Plant Morphology (Exercise)Documento5 páginas02-Plant Morphology (Exercise)varshavishuAinda não há avaliações

- DLL - Science 6 - Q2 - W1Documento6 páginasDLL - Science 6 - Q2 - W1AnatasukiAinda não há avaliações

- Basseri TribeDocumento3 páginasBasseri TribeMaddah HussainAinda não há avaliações

- Sara Salon and SpaDocumento4 páginasSara Salon and Spasania zehraAinda não há avaliações

- Quickscan™ Lite Qw2100: Multi-Purpose Uses For Different ApplicationsDocumento2 páginasQuickscan™ Lite Qw2100: Multi-Purpose Uses For Different ApplicationsHaythem BchirAinda não há avaliações

- Duty Resume ReportDocumento1 páginaDuty Resume ReportaleemuddinAinda não há avaliações

- Communicating Across AgesDocumento35 páginasCommunicating Across AgesConrad TarihoranAinda não há avaliações

- ThesisDocumento26 páginasThesiscmomcqueenAinda não há avaliações

- Butterfly Valve ConcentricDocumento6 páginasButterfly Valve ConcentricpramodtryAinda não há avaliações

- Making your own Agar PlateDocumento8 páginasMaking your own Agar PlateCheska EngadaAinda não há avaliações