Escolar Documentos

Profissional Documentos

Cultura Documentos

(A) Production of Cumene: Zeolite Fixed Bed Reactor

Enviado por

Surjendu MaityDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

(A) Production of Cumene: Zeolite Fixed Bed Reactor

Enviado por

Surjendu MaityDireitos autorais:

Formatos disponíveis

(a) Production of cumene

Cumene is the name often given to (1-methylethyl)benzene (isopropylbenzene). It is produced by the reaction of benzene and propene, using an acid catalyst; this is an e ample of a !riedel-Crafts reaction"

In one process, benzene and propene (#"1) are passed over an acid catalyst, usually a zeolite such as $%&-' at ca ()) * and under pressure (ca 1) atm) in a fi ed bed reactor. +he zeolite is more environmentally friendly than traditional acid catalysts such as aluminium chloride. +he effluent is much cleaner and lo,er temperatures and pressures can be used. -lternatively, propene gas is li.uefied under pressure (ca #) atm) and mi ed ,ith benzene before being passed, still under pressure, through a reactor containing the solid zeolite at ca /#' *. +his process is becoming more popular as it uses even lo,er temperatures and thus saves energy. In some plants, solid phosphoric acid is used as the catalyst, in place of zeolites.

Production of Phenol !irst ,rite the production of Cumene. -fter that add"

(b) Conversion of cumene to cumene hydroperoxide

Cumene is then o idized ,ith air to give the hydropero ide. +he reaction is autocatalyzed by cumene hydropero ide. +he overall reaction can be represented as"

+he reaction ta0es place at temperatures bet,een #')-#1) * and 1-2 atm pressure, the latter to retain the system in the li.uid phase. -t higher temperatures, the hydropero ide is unstable and could decompose violently. +he o idizers are generally built some distance from the rest of the plant. (c) Decomposition of cumene hydroperoxide !inally, the hydropero ide is mi ed ,ith sulfuric acid at #1#-#2# * to give, after neutralisation, phenol and propanone. +his reaction ,hen carried out ,ith small amounts of sulfuric acid (')) ppm by mass) is termed homogeneous cleavage"

+he products are separated by distillation, in up to si columns. 3roduct yield is 4'425, based on benzene.

Phthalic Anhydride

C(6/(C6#)7 8 # 97 : C(6/(C9)79 8 # 679

+he basic process consists of mi ing a stream of vaporized ortho- ylene ,ith compressed air and then feeding this stream into a fired heater and then into a catalytic reactor. +he air"o- ylene ratio is maintained at 7)"1. +he reactor operates in the temperature range of #)) to /));C and in the pressure range of 1 to # bar. +he reaction is highly e othermic and the reacting gas stream must be cooled in the reactor to avoid e cessive temperatures and a run a,ay reaction. +his cooling can be achieved by placing the catalyst in tubes and passing a cooling medium (molten salt) on the outside of the tubes ,ith the reacting gases passing on the inside of the tubes over the catalyst. +his configuration is similar to a shell and tube heat e changer. -n alternative scheme is to operate the reactor as a fluidized bed ,here the bed comprises the catalyst and heat transfer tubes, ,ith coolant flo,ing inside the tubes, pass through the bed to remove the heat of reaction. +he process stream containing the ylene and air pass up,ard through the bed and cause the solids to fluidize. <ue to the potential for an e plosion it is common to ad=ust the inlet concentration in the reactor to be outside the e plosive limits. +he stream leaving the reactor is cooled .uic0ly in one or more heat e changers prior to being sent to the s,itch condensers. +hese condensers use a cyclic process to separate the condenseable organics (115 recovery) from the non-condenseable gases. +he organic material, containing phthalic and maleic anhydrides and any unreacted ylene are fed to t,o vacuum distillation columns to recover the products, ,hich are then sent to storage. -ny unreacted ylene may be recycled to the front end of the process. Separations Section <ue to the high boiling points of the products, the separation section is often run under vacuum. +his is necessary to avoid the use of a fired heater to reboil the to,ers (and to avoid possible crac0ing reactions at the higher temperatures).

Você também pode gostar

- Phenol ProductionDocumento9 páginasPhenol ProductionPlant Design100% (1)

- Styrene Methods 2520of ProductionDocumento9 páginasStyrene Methods 2520of ProductionMohd Zulazreen50% (2)

- Phenol From Cuemen and TolueneDocumento9 páginasPhenol From Cuemen and TolueneAnonymous RJkpep7D0rAinda não há avaliações

- Project 1 - Isopropanol and Acetone From Propylene PDFDocumento8 páginasProject 1 - Isopropanol and Acetone From Propylene PDFAnonymous RJkpep7D0rAinda não há avaliações

- Ethylene UnitsDocumento20 páginasEthylene UnitsLindah Turson100% (3)

- TOURTON-páginas-37-124-73-88 PDFDocumento16 páginasTOURTON-páginas-37-124-73-88 PDFJesús David González CañasAinda não há avaliações

- Although This Process Is No Longer in Common UseDocumento15 páginasAlthough This Process Is No Longer in Common Usedia_aldy100% (1)

- Hydrodealkylation SimulationDocumento8 páginasHydrodealkylation SimulationLívia Lopes100% (2)

- Hydration of PropyleneDocumento3 páginasHydration of PropyleneAlfredArulapanAlexanderAinda não há avaliações

- MelamineDocumento18 páginasMelamineSurjendu MaityAinda não há avaliações

- Unit 5 Sulphur Recovery UnitDocumento32 páginasUnit 5 Sulphur Recovery Unitkhalimn100% (1)

- Distillation Column Lab ReportDocumento14 páginasDistillation Column Lab ReportWahida Shukori67% (3)

- UOP Oleflex ProcessDocumento2 páginasUOP Oleflex ProcessssslayerAinda não há avaliações

- 2.1 Manufacturing Processes and Selection:: 2.1.1 Oxidation ProcessDocumento4 páginas2.1 Manufacturing Processes and Selection:: 2.1.1 Oxidation ProcessLucky9922100% (1)

- Simulacion de Procesos Unidad 3Documento8 páginasSimulacion de Procesos Unidad 3ChecoCastilloAinda não há avaliações

- Unit 3Documento11 páginasUnit 3Shreyash UtekarAinda não há avaliações

- Petrochemical Technology: Boä Moân CNCB Daàu Khí, Khoa CNHH, ÑH Baùch Khoa Tp. HCMDocumento21 páginasPetrochemical Technology: Boä Moân CNCB Daàu Khí, Khoa CNHH, ÑH Baùch Khoa Tp. HCMviettiennguyenAinda não há avaliações

- Petrochemical Technology: Boä Moân CNCB Daàu Khí, Khoa CNHH, ÑH Baùch Khoa Tp. HCMDocumento25 páginasPetrochemical Technology: Boä Moân CNCB Daàu Khí, Khoa CNHH, ÑH Baùch Khoa Tp. HCMhatucdao2712Ainda não há avaliações

- Lecture 18 - Isopropanol and Acetone From PropyleneDocumento6 páginasLecture 18 - Isopropanol and Acetone From PropyleneRichardN55Ainda não há avaliações

- LECTURE - 7: Propylene Derivatives Isopropanol and Acetone From PropyleneDocumento8 páginasLECTURE - 7: Propylene Derivatives Isopropanol and Acetone From Propyleneمحمود محمدAinda não há avaliações

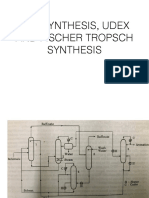

- Oxosynthesis, Udex and Fischer Tropsch SynthesisDocumento21 páginasOxosynthesis, Udex and Fischer Tropsch SynthesisNisha SubashAinda não há avaliações

- OXIDATIONDocumento36 páginasOXIDATIONMansab AliAinda não há avaliações

- Hydrogen ProductionDocumento26 páginasHydrogen Productionsorincarmen88Ainda não há avaliações

- 1.0 1.1 Overview of TPADocumento8 páginas1.0 1.1 Overview of TPAlilyAinda não há avaliações

- 102 & 103 Hydrotreater ReportDocumento31 páginas102 & 103 Hydrotreater ReportMuhammadAinda não há avaliações

- Distillation Column BasicsDocumento4 páginasDistillation Column BasicsTejas PatelAinda não há avaliações

- Process DescriptionDocumento5 páginasProcess DescriptionGurunath EpiliAinda não há avaliações

- EvaporationDocumento8 páginasEvaporationrajesh kothariAinda não há avaliações

- Production of CumeneDocumento5 páginasProduction of CumeneMohit YaduwanshiAinda não há avaliações

- RefluxDocumento5 páginasRefluxFranco Salerno100% (1)

- Naptha Hydrotreating UnitDocumento7 páginasNaptha Hydrotreating UnitreetiAinda não há avaliações

- Industrial TrainingDocumento25 páginasIndustrial TrainingheroAinda não há avaliações

- Yg Mau DitranslateDocumento13 páginasYg Mau DitranslateTeknik Kimia PLS1 Kelas B 2018Ainda não há avaliações

- Group WorkDocumento4 páginasGroup WorkRuva Oscass JimmyAinda não há avaliações

- Review Proses CumeneDocumento15 páginasReview Proses Cumenerachma tiaAinda não há avaliações

- Ammonia ProductionDocumento28 páginasAmmonia ProductionMuhammad Ali HashmiAinda não há avaliações

- Allyl BDocumento9 páginasAllyl BDemet AcargilAinda não há avaliações

- Major Engineering ProblemsDocumento5 páginasMajor Engineering ProblemsaathiraAinda não há avaliações

- Implant Training: Hindustan Organic Chemicals LTDDocumento7 páginasImplant Training: Hindustan Organic Chemicals LTDajin k bobanAinda não há avaliações

- Evaporation 2Documento18 páginasEvaporation 2Kuma Gloria100% (1)

- Ammonia PlantDocumento10 páginasAmmonia PlantHemal Patel Sam100% (3)

- Evaporator EfficiencyDocumento15 páginasEvaporator EfficiencySanjaySinghAdhikariAinda não há avaliações

- CT-308 Ethylene Oxide Production 2023Documento6 páginasCT-308 Ethylene Oxide Production 2023Divyansh NagarAinda não há avaliações

- New Microsoft Office Word DocumentDocumento5 páginasNew Microsoft Office Word DocumentSangam GuptaAinda não há avaliações

- Modelling of Naphtha Cracking For Olefins Production - Joao MarcosDocumento9 páginasModelling of Naphtha Cracking For Olefins Production - Joao MarcosBahar MeschiAinda não há avaliações

- Petrochemical 2Documento60 páginasPetrochemical 2AnilKumarAinda não há avaliações

- Styrene: Ethyly Benzene and StyreneDocumento7 páginasStyrene: Ethyly Benzene and Styreneم.احمد سالمAinda não há avaliações

- Edz 1Documento14 páginasEdz 1Joshua Peter Evangelista CadoyAinda não há avaliações

- Lecture9 - Hydrogen Generation Unit (HGU)Documento3 páginasLecture9 - Hydrogen Generation Unit (HGU)Bipradeep GhoshAinda não há avaliações

- Report On Multi Effect Evaporators (Part - 2)Documento32 páginasReport On Multi Effect Evaporators (Part - 2)Utkarsh Jain33% (3)

- Production MethodsDocumento44 páginasProduction MethodsNavaganesh KannappenAinda não há avaliações

- NHTDocumento6 páginasNHTPadarthi Venkateswarlu50% (2)

- Lecture - 11 - Gas Processing and PolymerizationDocumento6 páginasLecture - 11 - Gas Processing and Polymerizationrin karinAinda não há avaliações

- Nitric Acid Process AbstractDocumento2 páginasNitric Acid Process AbstractEduardo MagallonAinda não há avaliações

- HDTB SectorDocumento7 páginasHDTB SectorPartha AichAinda não há avaliações

- EN Study Analysis of Flue Gas Utilization ADocumento6 páginasEN Study Analysis of Flue Gas Utilization AiimcaemdwAinda não há avaliações

- ERT 209 Heat and Mass Transfer For Bioprocess Engineering EvaporatorDocumento50 páginasERT 209 Heat and Mass Transfer For Bioprocess Engineering EvaporatorSreenivasAinda não há avaliações

- CiclohexanoDocumento6 páginasCiclohexanoSebastian BelloAinda não há avaliações

- Process Flow Diagram For Ammonia SynthesisDocumento6 páginasProcess Flow Diagram For Ammonia SynthesisHanan Ahmed Ibrahim100% (1)

- Reflux: The Reflux System in A Typical Industrial Distillation ColumnDocumento4 páginasReflux: The Reflux System in A Typical Industrial Distillation ColumnMohammed AliraqiAinda não há avaliações

- Transition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesNo EverandTransition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesAinda não há avaliações

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsAinda não há avaliações

- 7th Edition - Yunus Cengel, Michael Boles-Thermodynamics - An Engineering Approach With Student Resources DVD-McGraw-Hill Science - Engineering - Math (2010)Documento7 páginas7th Edition - Yunus Cengel, Michael Boles-Thermodynamics - An Engineering Approach With Student Resources DVD-McGraw-Hill Science - Engineering - Math (2010)Surjendu MaityAinda não há avaliações

- Online T Est Dashboard: Explanation (Showexplanation - PHP? Test - Id Test48)Documento6 páginasOnline T Est Dashboard: Explanation (Showexplanation - PHP? Test - Id Test48)Surjendu MaityAinda não há avaliações

- Chemical Engineering - MCQs 2012Documento17 páginasChemical Engineering - MCQs 2012Surjendu Maity100% (5)

- Online T Est Dashboard: Explanation (Showexplanation - PHP? Test - Id Test47)Documento10 páginasOnline T Est Dashboard: Explanation (Showexplanation - PHP? Test - Id Test47)Surjendu MaityAinda não há avaliações

- Online T Est Dashboard: Explanation (Showexplanation - PHP? Test - Id Test46)Documento9 páginasOnline T Est Dashboard: Explanation (Showexplanation - PHP? Test - Id Test46)Surjendu MaityAinda não há avaliações

- Online T Est Dashboard: Explanation (Showexplanation - PHP? Test - Id Test18)Documento9 páginasOnline T Est Dashboard: Explanation (Showexplanation - PHP? Test - Id Test18)Surjendu MaityAinda não há avaliações

- Online T Est Dashboard: Explanation (Showexplanation - PHP? Test - Id Test18)Documento9 páginasOnline T Est Dashboard: Explanation (Showexplanation - PHP? Test - Id Test18)Surjendu MaityAinda não há avaliações

- Training Report of Different Block of Haldia RefineryDocumento63 páginasTraining Report of Different Block of Haldia Refineryneo_86868675% (4)

- Chemical Engineering - MCQs 2012Documento17 páginasChemical Engineering - MCQs 2012Surjendu Maity100% (5)

- CRE ProblemsDocumento13 páginasCRE ProblemsSurjendu MaityAinda não há avaliações

- Co:H 1:1 in Partial Oxidation Produced Syn GasDocumento4 páginasCo:H 1:1 in Partial Oxidation Produced Syn GasSurjendu MaityAinda não há avaliações

- 02 01 05 Formaldehyde Contributions Us Canada EconomyDocumento11 páginas02 01 05 Formaldehyde Contributions Us Canada EconomySurjendu MaityAinda não há avaliações

- Lect-4-Material Balances With Chemical ReactionDocumento23 páginasLect-4-Material Balances With Chemical ReactionBa 4xAinda não há avaliações

- Summary of Immiscible WAG at Tapis FieldDocumento2 páginasSummary of Immiscible WAG at Tapis FieldUmmu Mus'abAinda não há avaliações

- Chemical Kinetics MCQ 2Documento16 páginasChemical Kinetics MCQ 2vijayresup123Ainda não há avaliações

- Petroleum PowerpointDocumento33 páginasPetroleum Powerpointapi-27547259567% (6)

- UTP For LNG PDFDocumento5 páginasUTP For LNG PDFkamals55Ainda não há avaliações

- Reverse Osmosis and Nanofiltration Operating Data NormalizationDocumento74 páginasReverse Osmosis and Nanofiltration Operating Data NormalizationShark1971Ainda não há avaliações

- Aec 444 - Cryogenic Engineering Question BankDocumento18 páginasAec 444 - Cryogenic Engineering Question Bankmeera50% (2)

- CO2 To Methanol-Single StepDocumento2 páginasCO2 To Methanol-Single StepUmesh DeshAinda não há avaliações

- Catalytic Reforming - 2Documento30 páginasCatalytic Reforming - 2Alekhya Bandaru0% (1)

- Apch3.1 Problems-Equilibrium AnsDocumento5 páginasApch3.1 Problems-Equilibrium AnsQueenQiAinda não há avaliações

- Separation and PurificationDocumento4 páginasSeparation and PurificationNarges MalikAinda não há avaliações

- LECTUREDocumento5 páginasLECTUREkarim shahAinda não há avaliações

- LeachingDocumento11 páginasLeachingFakhirah Ahmad BasriAinda não há avaliações

- DOPAK - Closed - LPG - S32-LG Expansion Chamber & Purge Expansion F4Documento2 páginasDOPAK - Closed - LPG - S32-LG Expansion Chamber & Purge Expansion F4Chia Sze KiatAinda não há avaliações

- Computers and Chemical Engineering: Pravin D. Ghuge, Nilesh A. Mali, Sunil S. JoshiDocumento13 páginasComputers and Chemical Engineering: Pravin D. Ghuge, Nilesh A. Mali, Sunil S. JoshiSebastián Castañeda100% (1)

- Experiment 4Documento2 páginasExperiment 4Nour FaizahAinda não há avaliações

- Project Statement S2 2015 (V2)Documento10 páginasProject Statement S2 2015 (V2)Devandra Eko RadityoAinda não há avaliações

- Refrigerant Safety in Hvac SystemsDocumento71 páginasRefrigerant Safety in Hvac SystemsArnob KunduAinda não há avaliações

- ELCAS5 Exergoceonomics Methanol ProductionDocumento26 páginasELCAS5 Exergoceonomics Methanol ProductionAnsinath BarathiAinda não há avaliações

- Natural Gas TreatmentDocumento33 páginasNatural Gas Treatmentmohamed100% (1)

- Mixtures WKST KeyDocumento2 páginasMixtures WKST KeyMelbaAinda não há avaliações

- Diagram Alir Proses Pengolahan Gula Pabrik Gula Cinta Manis: Cane LifterDocumento1 páginaDiagram Alir Proses Pengolahan Gula Pabrik Gula Cinta Manis: Cane LifterTika SeptiaAinda não há avaliações

- 9094S1TKCE50332018 - Operasi Teknik Kimia II - Pertemuan 8 - TugasDocumento1 página9094S1TKCE50332018 - Operasi Teknik Kimia II - Pertemuan 8 - Tugaslintang cahyaniAinda não há avaliações

- Chemical KineticsDocumento49 páginasChemical KineticsS KAinda não há avaliações

- 13lectureppt 101122094708 Phpapp01Documento41 páginas13lectureppt 101122094708 Phpapp01Salim Ahmad Salim AlirajaAinda não há avaliações

- New Text DocumentDocumento17 páginasNew Text DocumentParesh MishraAinda não há avaliações

- Laporan mingguan-LUTHFIDocumento6 páginasLaporan mingguan-LUTHFIluthfiAinda não há avaliações